Cont. current:130A

(Good heat dissipation)

Burst Current:150A

(Good heat dissipation)

Default Trottle Range:1100-1900us

(Fixed,can not be calibrated)

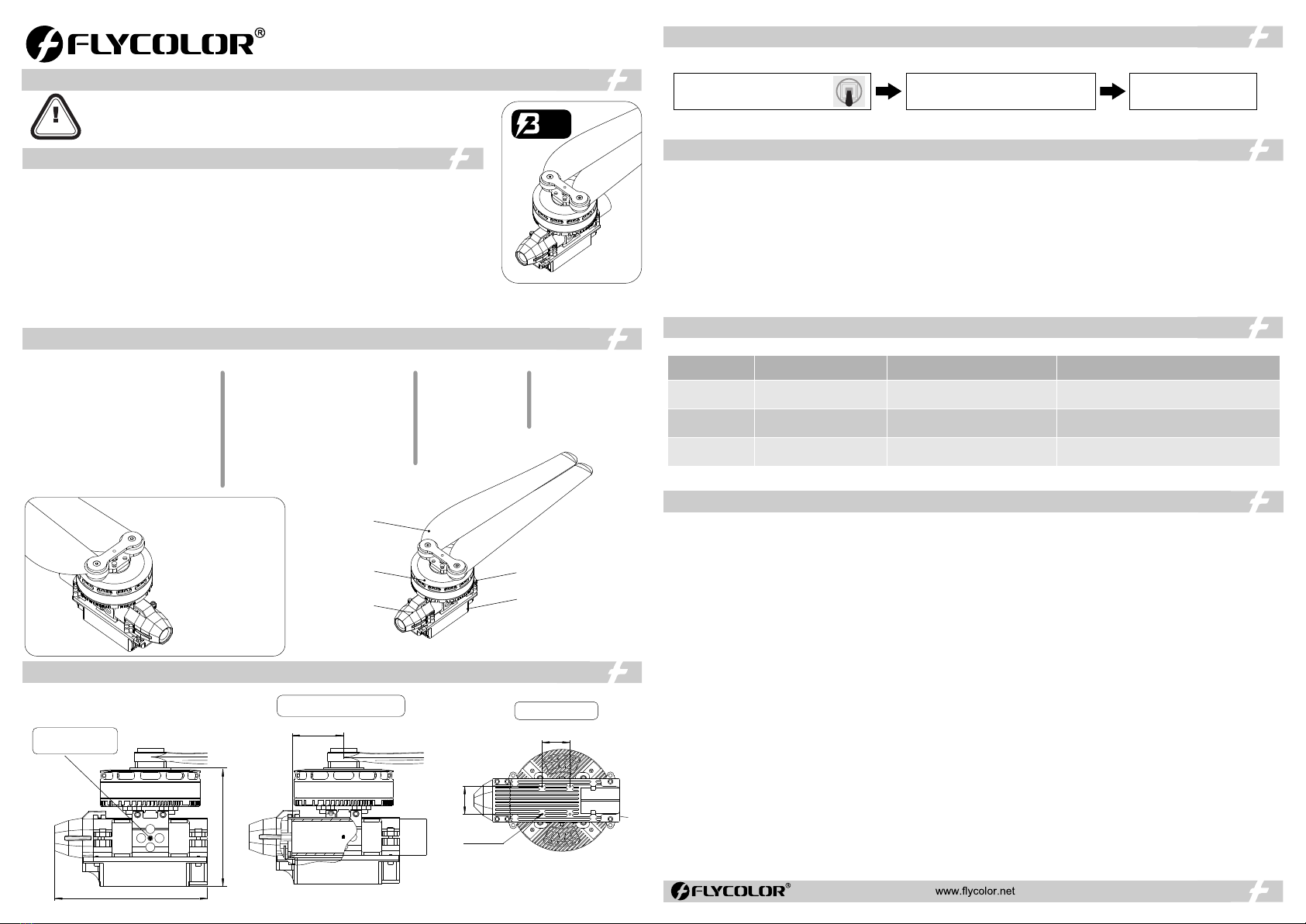

Model:3316

Carbon fiber folding

Weight:0.2kg

Model:10010

KV:105KV

OD:110mm

ESC Motor Propeller

Model: FlyDragon B10

Mfg Model: B-FW130013-40A1

LiPo Cells:5-14S

Recommended load:

7-10kg per axis w/12S

8.5-11kg per axis w/13S

9.5-12kg per axis w/14S

Recommended carbon tube:40mm

Weight:1.25kg (Propeller not included )

Maximum Thrust:21kg

ATTENTION

01 Main features

02 Specification

03 Dimensions

30mm

Bottom mounting

hole size

30mm

4-M3 *5mm

06 Trouble shooting

07 Attention

05 Protections

04 Operation instruction

Turn on the transmitter, move the

throttle stick to the bottom position

Connect ESC & battery packs, wait for 2

seconds, motor emits continuously

1 long and 1 short tone.

● Start-up Protection: ESC will cut off output if it fails to start the motor within 3 seconds by accelerating throttle. you need to move the

throttle stick back to the bottom position and restart the motor.( The possible causes : Bad connection or disconnection between E SC

& motor , propellers are blocked, etc)

● Over-load Protection: E SC will cut off power or output when the load suddenly increases to a very high value, normal operation will

resume after moving the throttle stick to the bottom position. ES C will automatically try to restart when ESC and motor are out-of-step.

● Throttle Signal Loss Protection: When ESC detects the loss of throttle signal for over 0.32 seconds, it will cut off power or output

immediately to avoid an even greater loss caused by the continuous high speed rotation of propellers. ESC will resume the

corresponding output after the normal signal is restored.

Trouble

ESC was unable to

start the motor

ESC was unable to

start the motor

“Beep beep beep…”

Urgent short tone

Warning Tone

“Beep,beep,beep…”

Time interval is 1 second

Possible Cause

The throttle stick is not at the bottom

position or throttle range is too small.

No output signal from the throttle

channel on the receiver.

ESC was unable to

start the motor

“Beep-beep,beep-beep-beep,…

Beep--beep-” Circular tones

The”Normal/Reverse”direction of the

throttle channel on transmitter is incorrect.

Solution

Move the throttle stick to the bottom position or reset

the throttle range.

Check if the communication is normal between

transmitter and receiver; Check throttle channel

connection well.

Refer to the transmitter instruction and adjust the

setting of “Normal/Reverse”direction of the throttle

channel.

251400-1118, V1.0

● ES C can not work under water. Reasonable use of ESC can prolong the service life.Splash-proof and corrosion resistant, please clean

up the water and stains on the ESC after a certain period of time , to avoid electric short circuit.

● ES C and Motor has been assembled in the factory. The user can install the propeller according to the rotation direction of the motor.

● If you need to replace accessories, such as propeller, propeller clips, etc., please contact Flycolor for support. Users are not allowed to

use improper accessories by themselves.

● ESC factory default value is 22.5°,This power system has been matched well, and it is not necessary to change the timing under normal

conditions).

● The color of the LE D can be preset at the factory. If you want to change it again in use, you need to use the Flycolor app and WiFi Trans

(to be purchased separately), please contact Flycolor sales for support.

● Please keep away from the crowd, high voltage line, etc. Please follow the laws and regulations.

● Pay attention to polarity at any time, and check it repeatedly before power on.

● Please turn off the power supply when plugging or making any connection.

● Before flight, check whether all screws are loose and whether the motor is installed horizontally.

● User need to calibrate the throttle range when starting to use a new ES C or change another transmitter.

● Please ensure all solder joints are insulated well .

● Please contact Flycolor sales or technical support for more information.

User Manual

Multi-Rotor Power System

Thank you for using our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

● ES C use STM32F051 MCU, ARM 32-bit Cortex Core with 48 MHz frequency.

● Special international famous brand MOSF E T is used in the E SC, which is combined with low impedance circuit

board to reduce the temperature rise and improve the reliability of the ESC.

● The firmware is specialized for multi-rotor , uses ASCF technology ( ),higher Active Switch Continued Flow

efficiency, significantly reduce the heat when E SC’s working.

● Aluminum cover, significantly improving heat dissipation. Unique low heat conduction design, motor and ES C

isolation, effectively reduce the heat conduction between them.

● Splash proof, - corrosion resistant, especially suitable for agricultural plant protection multi-rotor;

● Supports frequency of throttle signal to 500Hz max , compatible with various kinds of flight control.

( ≥500Hz throttle signal is nonstandard signal )

● according to requirement .The color of the LED can be preset

● Modular design of power system makes maintenance more convenient.

All pictures are for reference only.

FlyDragon B10

10

ESC X1pcs

Motor X1pcs

Propeller X1pcs

Fastener X1set

Built-in ESC

Motor

Propeller

40mm mounting hole

LED

Distance between the terminal

of Arm and motor center

57.5mm

167.5mm

130mm

Rivet or Set screw

installation

location

ESC is ready for working.