www.flycolor.net 251400-1110 V1.0

*Picture for reference only.

04 Operation instruction

05 Programming parameter

*Please ensure all solder joints are insulated with heat shrink where necessary.

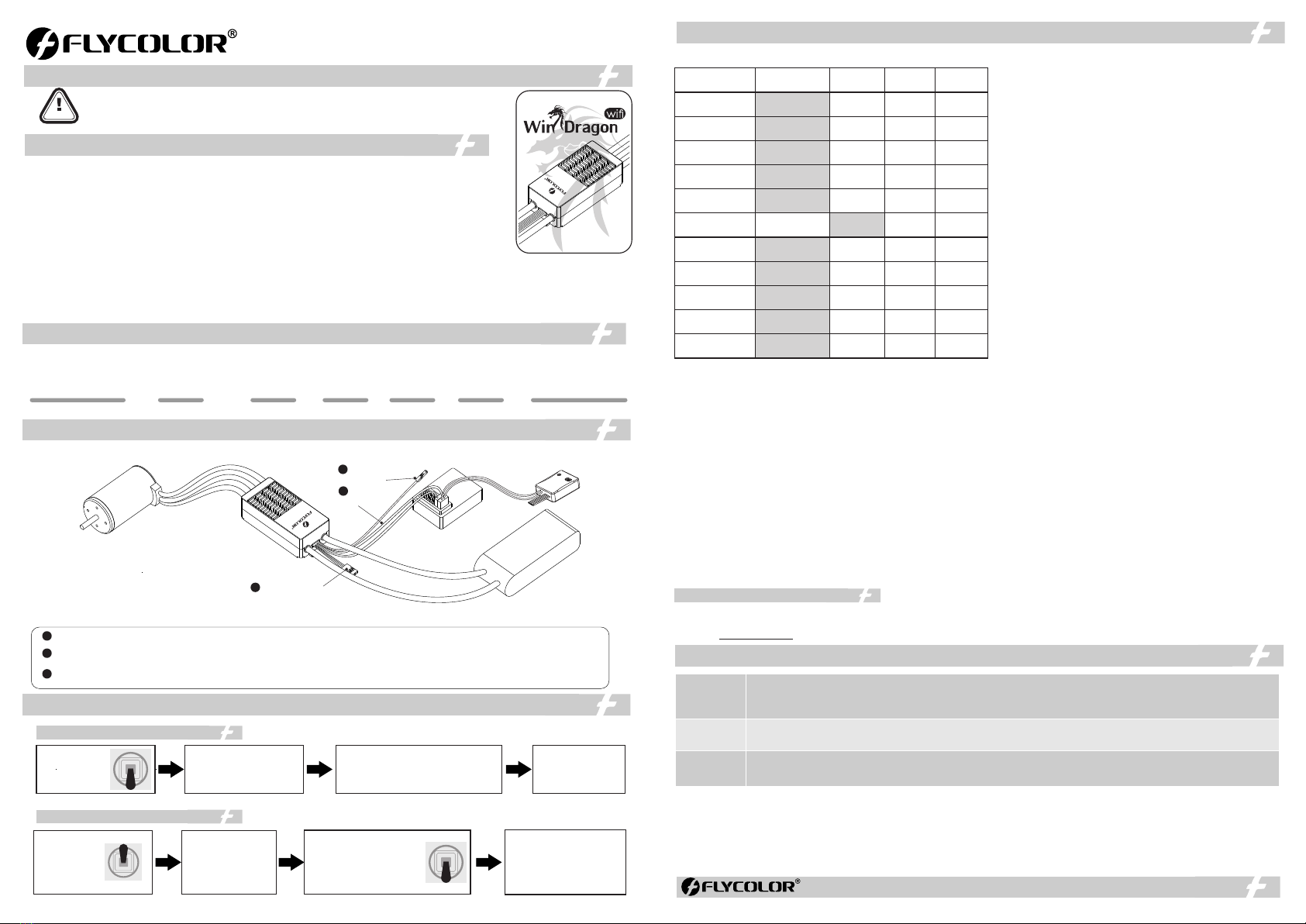

2

Throttle signal wire

Reverse signal wire

1

BEC

WiFi Trans wire

3

ESC

Motor

Battery

Receiver

ATTENTION

User Manual

Brushless ESC For Airplane

01 Main features

03 Wiring Diagram

Thank you for using our product. Any improper operation may cause personal injury or damage the

product and relevant equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

02 Specifications

Burst Current

(Good heat dissipation)B EC Size

(For reference)

Model

LiPo

Weight

(For reference)

Con. Current

(Good heat dissipation)

200A 250A 285g 108.5x46.5x32.6mm

5-14S

WinDragon wifi 200A

NO

● Use powerful & high performance microprocessor, compatible with various brushless motors. Unique

circuit design, strong anti-interference.

● Supporting maximum 210K erpm.

● Start mode can be set, throttle response fast, speed regulation linear stability. Compatible with fixed wing

aircraft and helicopters.

● Multiple protections ensure the equipments safety.

● High power safety performance, when power up the motor will not start immediately wherever the throttle

stick is.

● Beeping alarm can indicate working condition.

● ASC F (Active Switch Continued Flow)technology, higher efficiency, reduce heat generation massively.

● Wifi Trans for programming, programming via mobile phone AP P (extra Flycolor Wi-Fi Trans needed).

● Supporting close-range monitoring and recording of real-time flight data via mobile phone APP (extra Flycolor Wi-Fi Trans needed);

● Reverse function, supports to reverse the motor rotation during the flight to achieve deceleration.

● Aluminum covers, effective heat dissipation, slow down temperature rise.

1

2

3

Reverse signal wire: plug it into an two-stage switch channel on the receiver ,to reverse the motor rotation during the flight.

Throttle signal wire: plug it into the throttle channel on the receiver, the white wire is for transmitting throttle signal, the black wire is

ground wire.

Wi-Fi Trans wire: connect with Flycolor Wi-Fi Trans, supports programming and detection of real-time data at close range via mobile

phone APP.

1.Normal start-up

2.Throttle Range calibration

Turn on the

transmitter,

move the

throttle stick to

the top position.

Connect E SC with

battery. Wait for 2

seconds, after motor

emits 2 short "BEEP-

BEEP",the full throttle

position is memorized.

Move the throttle stick to

the bottom position in 3

seconds. Then waits for 1

second, the“zero throttle“

position is memorized.

Motor emits short " BEE P-"

few times, sound times is

Lipo battery cells.

Wait fo r 1 seco nd, It m eans

“No Brake” when motor emit

continuously 1 long an d 1

short tone . It mea n s “Brake

is availab le” when motor

emits a long tone. ES C is

ready for working now.

Turn on the

transmitter,

move the throttle

stick to the

bottom position.

Connect ESC with battery,

wait for 2 seconds,motor

emits short "BEEP-" few times,

sound times is Lipo battery

cells.

ESC is ready for

working now

Wait fo r 1 seco nd, It m eans “No Brake”

when motor emit contin u ously 1 long and

1 short tone.

It means “Brake is a vailable” when motor

emits a long tone.

Parameter programming via AP P

Start-up

Protection

Over heat

protection

ESC will cut off output if it fails to start the motor within 3 seconds by accelerating throttle. you need to move the throttle

stick back to the bottom position and restart the motor.( The possible causes : Bad connection or disconnection between

ESC & motor , propellers are blocked, etc)

When ESC temperature is higher than 100 ℃,it will reduce output power (throttle will be limited below 40%) for protection,

leave some power for motor to land , when the temperature Reduced to 80℃ , ESC recover to normal running mode.

When ESC detects the loss of throttle signal for over 1 seconds, it will cut off power or output immediately to avoid an

even greater loss caused by the continuous high speed rotation of propellers. E S C will resume the corresponding output

after the normal signal is restored.

Throttle Signal

Loss Protection

06 Protections

Alarm tone: (To judge the abnormal cases via alarm tone )

1.Alarm tone of signal loss : when E S C detects no signal , motor will emit the alarm tone “Beep-、Beep、-Beep-”(alarm tone

emits every 2 seconds).

2.Alarm tone of throttle not in the zero throttle position: throttle not in the zero throttle position, motor will emit

“Beep-Beep-Beep-Beep-Beep-” ( urgent single short tone).

3. Alert tone of narrower throttle range: when throttle range is set too narrow, motor emits “Beep-Beep-Beep”(harried alarm tone

emits last for 2 seconds). You must throttle range again.calibrate

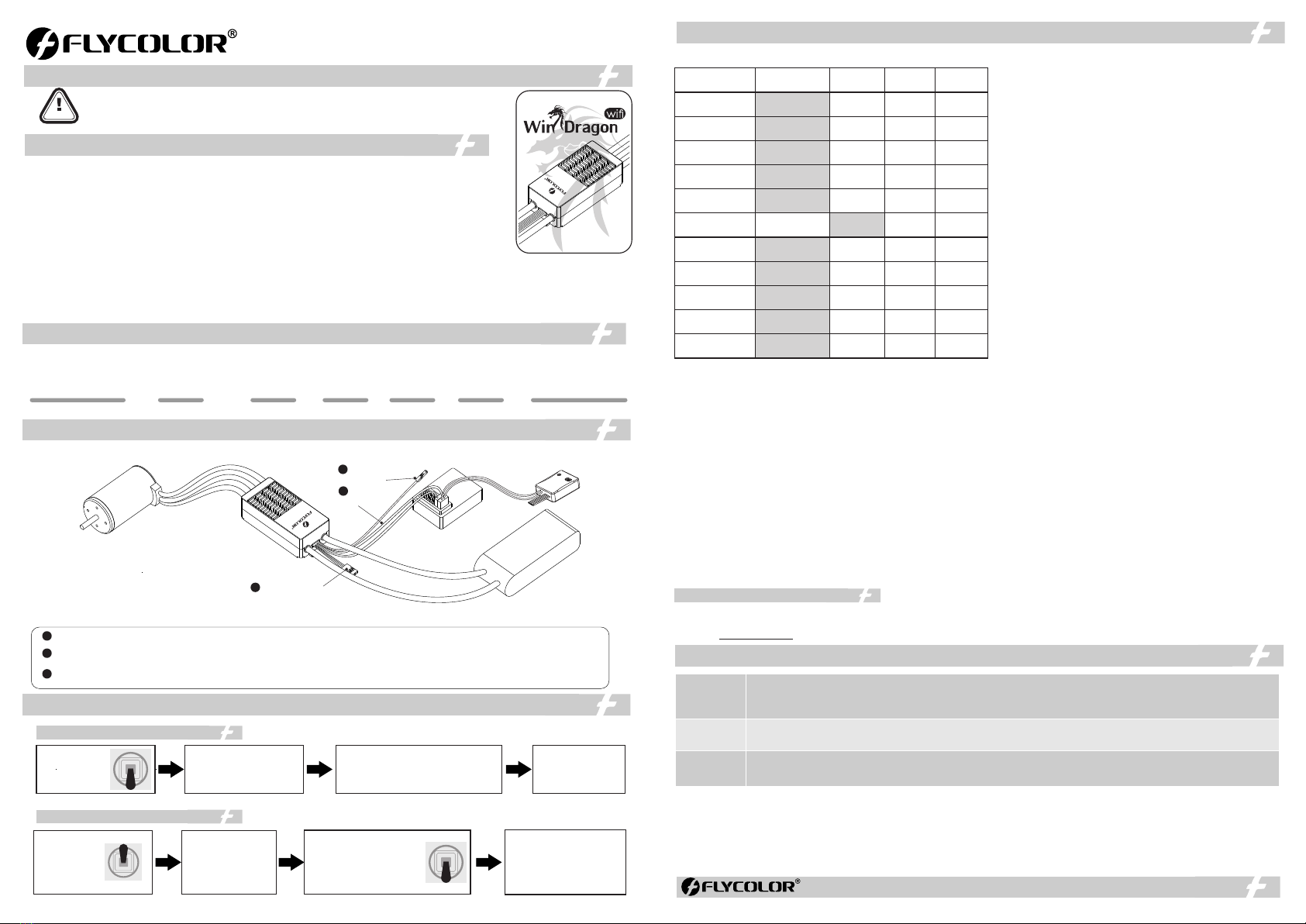

[1]NO(Default) [2]Soft [3]Heavy [4]Very heavy. 1. Brake:

2. Cutoff voltage: 2.8V - 3.8V (Default 3.0V).

3. Timing:0° - 30° (Default 15°).

4. Startup Mode: Start up with linear accelerator.

[1] Normal: No delay in throttle response. (Default).

[2] Soft: It will take 6 seconds from 0% to 100% throttle.

[3] Very soft: It will take 12 seconds from 0% to 100% throttle.

5.Governor mode :

If the Governor mode is activated, E SC will try to keep the

motor in a fixed speed ( usually the throttle curve is a horizontal

line, you can change the preset motor speed by changing the

height of the line).

[1] OFF (Default)

[2] Low , "Low constant speed" mode , 10000-20000RPM for

two poles brushless motor .

[3] High, "High constant speed" mode , above 20000RPM for

two poles brushless motor .

Note: Governor mode function is automatically disabled if the

throttle value less than 60%.

6. PWM frequency: [1]8KHz [2]16KHz(Default) [3]24KHz

For some motors with many poles and high speed, the higher

PW M frequency can make motor run smoother, but at the same

time, the switch loss is increased and the temperature rise is

higher .

*Shadow parts are factory default value

234

NO Soft

16KHz8KHz

5S-14S

24KHz

2.8V-3.8V

( 3.0V)Default

0°- 30°

( 15°)Default

1. Brake

1

Heavy Very Heavy

Normal Soft Very Soft

OFF Low High

Reduce

cutoff Cut off

Auto

Iterm

9 Motor rotation.Normal

Reversed

10.AS CF OF F ON

2.Cutoff voltage

3.Timing

4.Startup mode

5.Governor mode

6.PWM frequency

7.Voltage cutoff

option

8.Battery cells

11.Reverse

function

OFF ON

7. Voltage cutoff option:

[1] Reduce cutoff(Default ): the voltage drops to the set low-voltage protection threshold , ESC will reduce the power then cut off the

motor output.

[2] Cut off: the voltage drops to the set low-voltage protection threshold , ESC will cut off the motor output immediately.

Battery cells [1] Automatic calculate(Default) [2]5S -14S .8. :

You select automatic calculate, and also can select the options according to your battery cells.

9.Motor rotation:

[1]Normal(Default):Default direction of motor rotation;

[2]Reversed:Change the motor rotation.

10.Active Switch Continued Flow [1]Off (Default) [2]On :

ASC F (Active Switch Continued Flow) technology, higher efficiency, reduce heat generation massively.

11.Reverse function [1]Off (default) [2]On :

Plug reverse signal wire into an two-stage switch channel on the receiver ,to reverse the motor rotation during the flight to decelerate.

The lowest point of the pulse width range of the 2-stage switch channel must be less than the lowest point of throttle. (e.g. the lowest point of

throttle is 1000, then the lowest point of pulse width of 2-stage switch channel should be less than 1000).

Effective conditions : 1. Reverse function - on; 2. Governor mode - off; 3. Brake - on.

Flycolor Wifi Trans is used for programming via Flycolor App; Flycolor App V1.2 version or higher is required for this product.

Please see Flycolor Wifi Trans and Flycolor App instructions for details.

Or visit www.flycolor.net for more information.