Flygas F.050 Manual

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

1

INSTALLATION AND

MAINTENANCE MANUAL FOR

MECHANICAL FUEL PUMP

Cod. F.050 and F.051

Version 1.2 “Experimental”

All the information, the technical data and the specific drawings reported in this manual are owned by FLYGAS

and they cannot be reproduced neither entirely nor partially without previous agreement and written authorisation

by FLYGAS ITALIA.

Approval of translation to best knowledge and judgement –in any case the original text in Italian language is

authoritative. COPYRIGHT - FLYGAS

.

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

2

Index

1. FOREWORD.........................................................................................................................4

2. KIT FUEL PUMP FOR ROTAX DESCRIPTION OF THE PARTS ..................................8

3. TECHNICAL DATA ............................................................................................................8

4. INSTALLATION..................................................................................................................9

5. INSTALLATION ON ROTAX 914:..................................................................................10

6. OPERATION ......................................................................................................................16

7. FUEL SYSTEM ..................................................................................................................17

8. FIRST STARTING .............................................................................................................20

9. BEFORE EACH START....................................................................................................21

10. POSSIBLE FAILURES ......................................................................................................22

11. MAINTENANCE SYSTEM...............................................................................................23

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

3

WARNING !

This Manual is an integral part of your kit and shall be kept with it for

future reference.

Retain this Manual in a suitable place and when consulting it, take care

of not spoiling it.

Should your kit be resold, entrust it to the new owner who will obviously

need the information contained.

This Manual consists in 24 pages including cover.

RIGHT OF WITHDRAWAL

The buyer has the right to withdraw from the purchase of this kit if within 10

days of purchase, after received this kit, considers the unsuitability of their

vehicle to receive the installation of this system.

In this case Flygas reserves to repay the full amount paid (equal to the

invoice) and collect all the material, as long as it is intact in all its parts, not

altered or defaced and stored under appropriate conditions, without charge

or duty by the purchaser.

The material should be delivered free at the headquarters Flygas.

Insurance

No insurance is included in the purchase of our kit.

Please, note that the installation of our Mechanical Fuel Pump kit could be

change the basic characteristics of the engine and of the vehicle. It’s so

necessary to review the insurance contract verifying insurance coverage and,

in case, examine the possibility of creating a new insurance policy that

permits such changes.

In case of accident or in case of damages caused to property or third persons,

Flygas will not be liable in any way.

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

4

Congratulation for your choice to use this FLYGAS product.

Designed and built entirely by Flygas, it is the result of the long path that the company carried out

within motoring field. With the use of our system, designed and manufactured in Italy, you will be able

to increase the reliability of your engine.

Before starting with this kit read this manual carefully so as to understand the contents clearly: consult

it whenever any doubt arise.

The sections are proposed in order to know step by step all the functionalities of our product.

The texts are easy to be understood and accompanied by pictures.

This manual contains information which are useful for you safety. Please observe carefully the

indication contained and perform the recommended procedures which, if not properly observed, could

result in damage of the equipment or could cause personal injury.

Warrantee

The warranty is limited to the replacement of items that, send ex-works to Flygas, are considered

defective for reasons attributable to us; we exclude any responsibility for possible damages to

persons or properties. This product is guaranteed for one year from date of delivery or 50 hours of

flight.

Purchase date: __ / __ / ____

Flight hours at the moment of sale: ______________

Engine type: ________________

Serial Number : ________________

Within 30 days from the date of purchase the buyer must send to Flygas the sheet in which is

clearly indicated the date and the effective hours till the date of the installation.

Otherwise the warranty is void.

.1. FOREWORD

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

5

In order to make the reading and the comprehension of the manual easier, the important

information are marked by the following symbols:

The safety Alert Symbol means ATTENTION! Be careful! Carry out all

the precautionary measures to avoid damages for your personal

safety.

The in-observance of the instructions marked by the following symbol of

WARNING may result in serious damages of the vehicle, and could

cause injures to the operator or to the people involved in inspection or

repair of the vehicle.

A NOTE provides key information to make procedures easier and

clearer.

This manual is developed to provide you basic instructions for installing on your engine the

Mechanical Fuel Pump and its maintenance in order to prevent accidents and damages caused by

human error.

Our system is compatible to be installed on different models of engines; so this handbook should

necessarily be integrated with the manual of the engine on which it is installed.

This manual contains important safety information: follow the indications described and perform the

recommended procedures which, if not properly observed, could result in damages of the

equipment or could cause personal injury.

Regular inspections and careful maintenance will ensure you a safe and proper usage of this kit.

Read this manual carefully and completely before operating this kit. Do not

attempt to operate until you have attained a complete knowledge of its controls

and operating features; please carry out the first trial in complete safety

conditions to get acquainted with the several controls.

Regular inspection and maintenance will make your engine safe over time

without compromising reliability.

The information and the description contained in this Installation Manual are correct at the time of

publication. FLYGAS, however, maintains a policy of continuous improvement both in terms of the

performance and of reliability of its products, without imposing any obligation to install them to

update the products built previously.

FLYGAS reserves the right at any time to discontinue or change specifications, drawings, features,

models or equipment without incurring in any obligation.

For any questions concerning this manual, please contact Flygas Italia.

The kit can be installed exclusively by certified technicians, authorized by local aviation authorities

with the basic knowledge of this product.

Mechanical Fuel Pump fuel system, must be installed only on engines, where the

sudden shutdown does not cause any danger. If the kit is installed on aircraft,

never fly in unsafe conditions (altitude, speed, location...) or other unsafe

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

6

circumstances. In case of sudden power loss or switching off the engine pilots

must be able to make an emergency landing. Flying exclusively on flat areas and

open countryside without going over the airfield. The aircraft fitted with this kit has

to fly only in daytime light conditions and visibility (VFR - Visual flight rules -). It is

prohibited the installation on vehicles supported by rotary wing (as helicopter,

autogyro and other aircraft like these). It is strictly prohibited to install it on

acrobatics aircrafts (inverted flight, etc. ..). This kit is designed for a possible

application on aircraft used only under VFR conditions, which have the ability of

controlled landing even with the engine off or damaged.

Failure to observe these instructions excludes the system manufacturer from any liability.

For the variety of models, equipments, and types of aircrafts on which you can install the

Mechanical Fuel Pump FLYGAS gives no warranties or documentation about the adaptability of

this kit on a particular type of engine or vehicle.

Moreover, FLYGAS gives no warranties regarding the compatibility of this kit with any other parts,

element or system that can be chosen by the manufacturer / user for the application on the plane.

FLYGAS recommends you to select and install a proper aircraft instrumentation.

These tools are not included in the kit.

Before each flight be sure that all instruments of motor control are operational and reliable.

Make sure that they can be reached in case of emergency.

Before starting the engine with propeller installed, the pilot must ensure that the surrounding area

is clear of obstacles, people and other vehicles.

Start the engine with brakes and hand on the throttle control and follow the necessary heating

time.

Turn on the engine with propeller installed only in special open places away from people especially

if they are not employees!

Prevent use by unauthorized persons, inexperienced people or people who haven’t read and

understood this manual.

Certain geographical areas, altitudes and weather conditions presents a higher

risk than others. The Mechanical Fuel Pump may require more protection from

the weather as humidity, dust and sand, or an extra maintenance.

Improper installation, use of inappropriate electrical connectors and pipe fittings of non-standard

aircraft, discharge the manufacturer of the kit from any liability. Unauthorized modification plant fuel

automatically exclude the manufacturer of the kit from any liability.

Replacement parts must be the same authorized by FLYGAS and described in

this manual; the usage of non original spare or used parts discharges the

manufacturer from any responsibility.

This kit has not been tested for safety and durability standards for the aircraft. All

the risks involved will be borne by the user. The added weight of the kit varies

inevitably the centre of gravity and moment of inertia on the three axes aircraft.

Before you make a good flight it’s necessary to check what that change involves

and be sure to carry out all the consequent changes.

While refuelling, protect the engine and supply system from contamination and

exposure.

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

7

The kit Mechanical Fuel Pump can cancel the guarantees issued by the engines manufacturer.

In addition to compliance of the instructions contained in our manual and that of the engine

manufacturer, all the general measures of safety and accident prevention must be observed, as

well as legal laws and the rules of any aviation authorities.

Installation and maintenance manual for mechanical fuel pump FLYGAS –Version 1.2 Experimenter

8

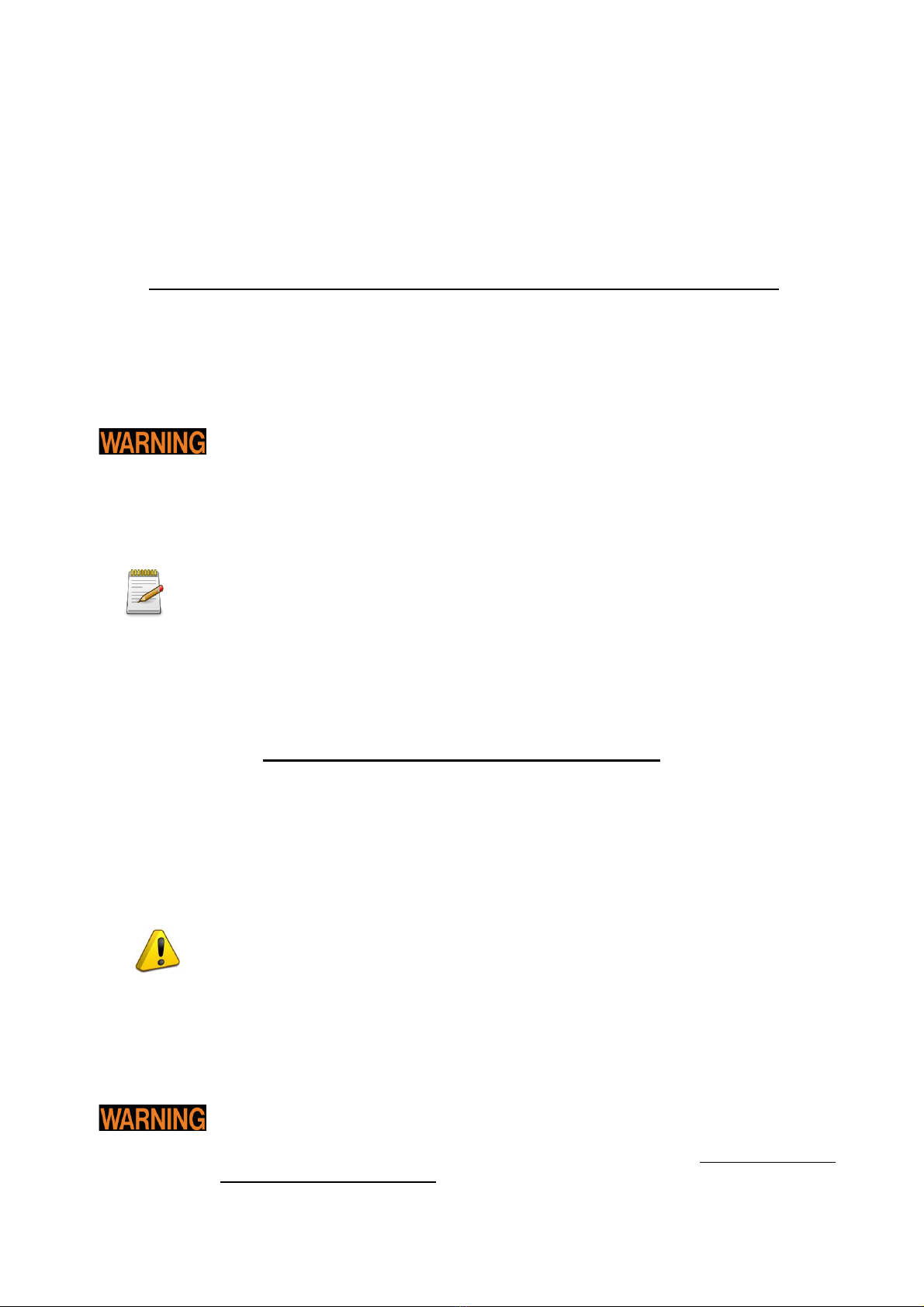

2. KIT FUEL PUMP FOR ROTAX

DESCRIPTION OF THE PARTS

Mechanical Fuel Pump Kit by Flygas consists of the following elements :

N 1 Maintenance and installation manual

N 1 Assembled and tested Fuel Pump By Flygas

N 1 Joint type Oldham

N 1 Aluminium screwed M46x1,5 driving joint

N 1 Aluminium “bell support”

N 1 Aluminium support plate

N 3 Allen screw M5 length 12mm

N 3 Allen screw M5 length 16mm

N 3 Allen screw M6 length 16mm

N 1 Diameter 6mm pin L14mm

N 2 Diameter 4mm pin L16mm

3. TECHNICAL DATA

Total weight installed 680 grams (about one mechanical fuel pump)

Maximum pressure reached 14Bar

Maximum continuative pressure 3Bar

Maximum Speed 7000 RPM

Maximum draft depth is 900mm

Pressure regulator of fuel, is required on the plan

Flow of gasoline in function of RPM and Pressure

None of these elements has been designed and built for flight. Their use on

aircraft is at the sole judgment of the user of the vehicle

.

9

4. INSTALLATION

Before installing read this book carefully. The manual provides basic information

for the correct installation of the entire system on the engine and its proper

maintenance. A lack of attention may cause serious damage to both structural

(weakening of the engine or mechanical parts directly linked to it) and physical.

Since the reading of the instructions will not eliminate the risks, the understanding and application

of the information listed below will allow proper installation, operation and maintenance.

At least ONE ELECTRICAL FUEL PUMP MUST BE INSTALLED for emergency

and safety reasons! This electrical fuel pump must be run in all condition where

eventually shut-off of mechanical fuel pump, could created an dangerous

situation.

The installation of the kit and its maintenance must be performed only by certified

technicians, qualified and authorized by local aviation authorities.

The illustrations in this manual show the basic construction. They cannot

represent all the details and the exact form or shape of all the components with

the same or similar function.

10

5. INSTALLATION ON ROTAX 914:

1) Dismount the battery from the vehicle.

First disconnect the negative terminal to prevent a sudden starting of the engine

or sudden sparks may cause fires. Reinstall the battery only after complete

installation.

2) Empty the tanks completely and close with taps

Pay particular attention to the escape of fuel during the disconnection of pipes

and fittings. In the section of pipe that goes from the fuel pump may be high

pressure. Do not work near heat, flame or sparks (the only rotation engine, if the

"magnets" are not grounded, causing sparks to high voltage, in the order of

15,000 Volts!).

3) Disassemble the propeller in order to prevent that the first test ignition or an

undesired ignition may hurt people.

6) Ensure all threaded parts through a special lock steel wire or thread lock product

by adopting all necessary measures to perfect fit against loosening caused by

vibration, expansion, etc. ...

The presence of particles of dirt may damage the various and important

mechanical seals causing the premature wear by abrasion. Therefore, avoid that

parts of products used as chemical sealing agents or Teflon enter the pipes

during installation and maintenance. Please notice that this material may damage

the mechanical seals and moreover could block the flowing of gasoline, air and

oil. Whenever you install a pipe, especially if new, it is essential to wash it; let

flow inside a substantial amount of fuel to remove dirt and waste.

The manufacturer guarantees the perfect performance and durability of

the components supplied only with gasoline which is unpolluted by water and dirt, and above all

the producer ensures the physical and chemical compatibility of its components only for gasoline

called "green" normally sold in Italy without any additives.

Any forcible action, intervention or replacement of parts without written permission from

Flygas, discharge the manufacturer from any liability in case of damage or malfunction of

the system

11

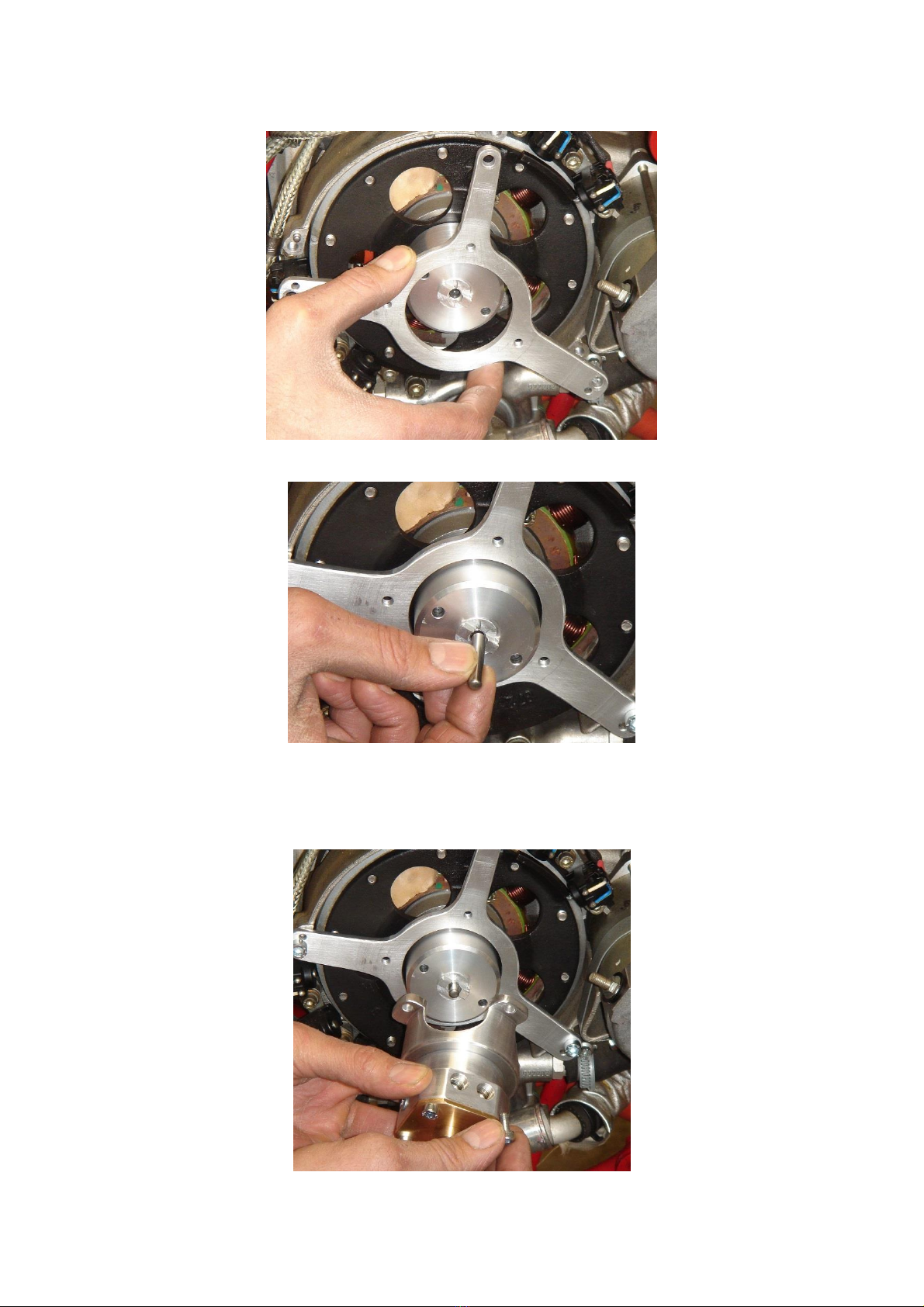

1. Install the Driving Joint with Loctite 243

2. Tight the Driving Joint with torque aprox 30Nm

3. Insert N°2 pin 4mm diameter in Rotax case

12

4. Install the support plate, with N°3 Allen screw M6

5. Insert the drive pin 6mm (That temporary operations is necessary to find a right

Axial Alignment between Fuel Pump and Crank-Shaft )

6. Install the Fuel Pump and Bell and screw with Loctite 243 the N°3 Allen Screw

M5 (after never remove more this N°3 Screw, otherwise will be necessary repeat

this operations)

13

7. Check the distance/space from the tooth of Drive Shaft and from tooth of Pump

Shaft; Minimum distance must be 0,65mm “0 Plus 0,1mm”

8. After remove the Plate, the Bell and the Pump without disconnect this 3

parts!

During installation and maintenance be sure that no pipe or electric cable is near

to potential electrical shortcuts, electrical shocks (always possible especially

coming from high voltage cables candles) and close to hot surfaces (above 50 °

C ..) Do not run pipes or wires inside holes on not properly protected sheets, do

not lean them on sharp edges or on any other cutting element. The thermal

expansion of materials and their vibrations during operation of the engine can

cause cuts, peeling and abrasion of the objects placed in contact with them.

If you have choose a Fuel Pump for Electronics Fuel Injection E.F.I., insert a

specific filter for injection systems which is resistant to injection pressure of 3 bar

between the output pump and the input rail of injectors in order to be able to

retain any dirty or waste

With regards to the connection of the pressure / vacuum, instead, use suitable pressure tube

resistant to pressure and especially to gasoline and oil.

14

Use the entire length of wedge to make the pipe as fit as possible to the plug.

In order to avoid the pipe to slip off from its housing accidentally, fasten it using the proper clamps

free from edges that may cut it.

If necessary, insert a anti pulsations. This will avoid excessive “stress” to the

gauge, the carburattors, the injector and all elements could be deteriorate if

pressure is not linear and constant enough.

The tests will be performed by experienced and qualified people with the use of

tools to carry out the controls properly.

9. Remove the pin 6mm and install instead the Oldham Joint with grease

15

10. Install again the Plate, The Belt and Fuel Pump and tight N°3 Allen Screw M6

at 10Nm

16

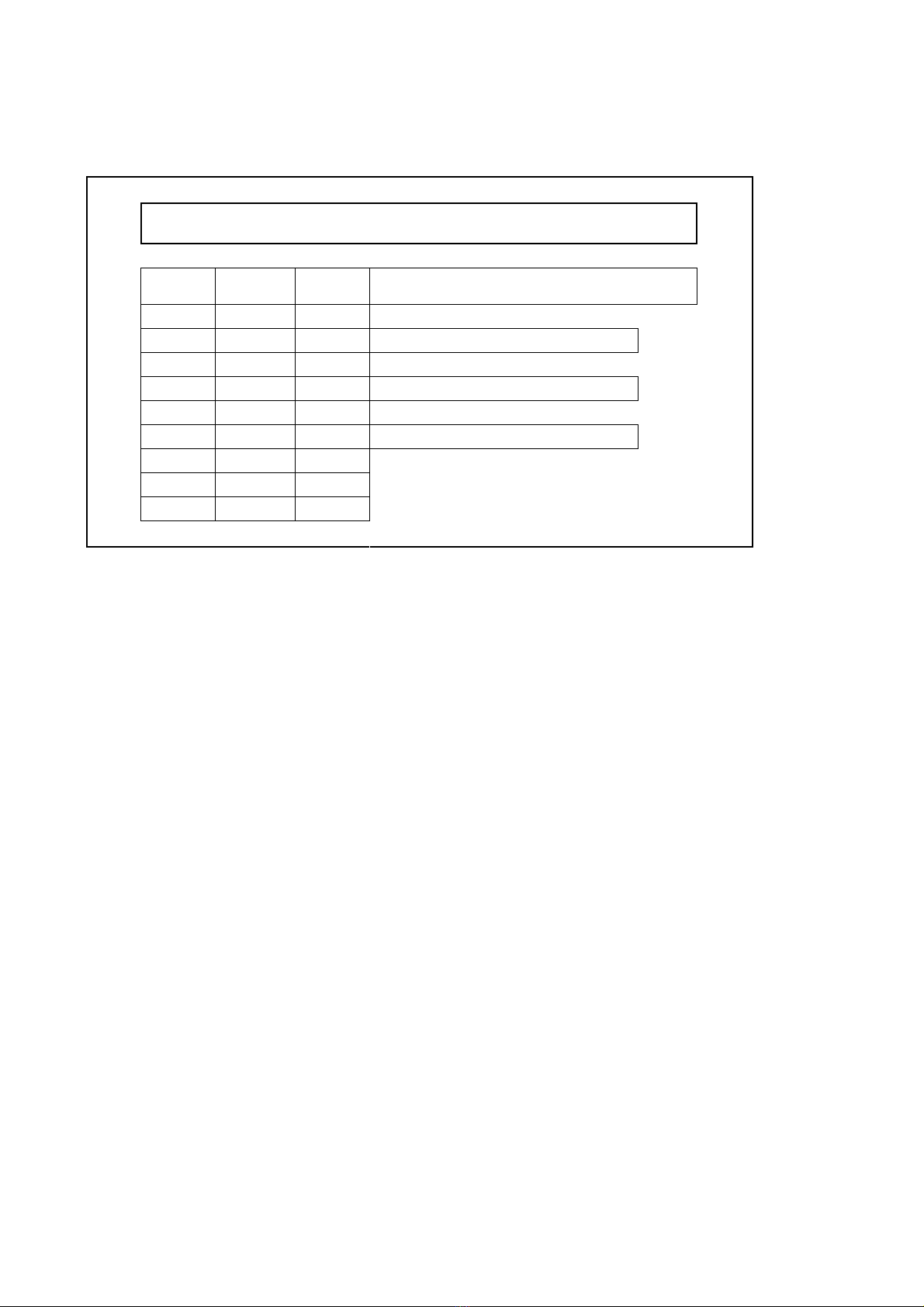

6. OPERATION

Performance Test of Mechanical Fuel Pump installed on your

engine

RPM

Pressure

Fuel

Flow

Draft Depth Fuel Level:

2000

2500

Fuel Temperature:

3000

3500

Hour/Km:

4000

4500

Data:

5000

5500

5800

Never carry out the steps during the flight only for testing. Perform tests on the ground

with tied or braked vehicle and be sure to observe all the safety instructions.

17

7. FUEL SYSTEM

Shape and arrangement of the fuel system must ensure the functioning of the engine within the

limits given.

Fuel pressure at the carburettor system in atmospheric conditions Rotax 914:

Maximum …..……………….......0,35bar

Minimum ……….…………........0,15bar

Nominal …….……….…….......…0,25bar

Minimum Flow …..95 Lt/hour @5800rpm

The exceeding of the specified maximum fuel pressure can lead to a overtaking

of the seal of the float valve inside the carburettor resulting in an engine

shutdown.

In supercharged or turbo engines, the “Boost Pressure” increase the maximum

fuel pressure in equal measure of boost pressure , thanks at “pressure fuel

regulator”.

Fuel pressure Electronics Fuel injection system:

Maximum …………......………..3Bar*

Minimum Flow ………..…100Lt /Hour*

* Measured with the pump @15°C Fuel temperature

The fuel lines must be designed according to the latest standards required by the

manufacturer as FAR or JAR aircraft. To prevent the formation of steam inside

the pipes, all the pumps and fuel lines must be isolated against heat and kept at

a suitable distance from all hot parts such as exhausts, air and oil cooling

system. In some cases it is necessary to direct a flow of fresh air.

During all operations on the fuel system, pay attention that gasoline do not spill

out during the pipe and joint disconnection. In the section of pipe that goes from

the fuel pump to the engine entrance may be high pressure. Do not work near

heat, open flames or sparks.

18

Connect one pipe from the 4mm diameter fitting on the bottom of the fuel pump, to outside. That

“emergency hose”, will bring far from exhaust or engine department, the eventual leakage of fuel.

The system carburettors will be re-checked completely, taking care to protect the components from

any kind of impurity, especially during installation and then make sure you have made all the

connections necessary to provide proper function.

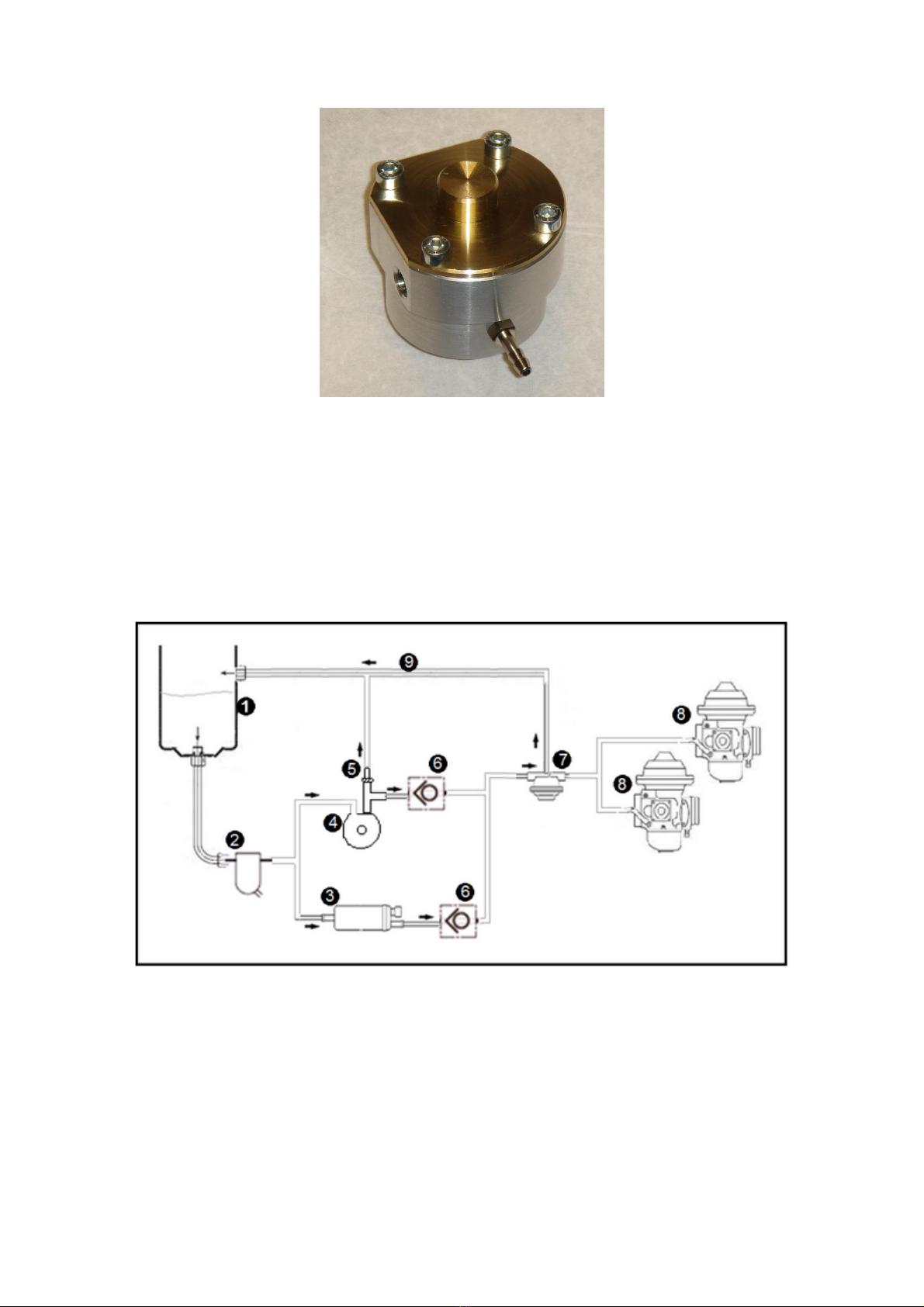

Example of installation scheme, work together electrical fuel pump:

1. Fuel Tank

2. Gascolator (filter and water trap)

3. Pierburg electrical 1bar Fuel pump

4. Flygas mechanical Fuel Pump

5. Optional: Restrictor Jet for air bubble (not plus of 1mm hole diameter)

6. Check Valves

7. Regulator Fuel Pressure

8. Carburattors

9. Fuel line return to tank (internal D. minimum 6mm)

19

Draft and possible run out of gasoline

Operation with low fuel in the tank or other operation that generates a air draft

from the injection pump (ex. caused by the shaking of the vehicle and then by the

oscillation of fuel in the tanks) leads to a sudden deterioration of the fuel pump

and the wear of the engine with the risk of possible breakage. In fact, the air

bubbles sucked do not come back in good percentage to the tank, but they must

be expelled through the injectors. (In a case of E.F.I. engine)

The disassembly and assembly of the mechanical fuel pumps MUST BE DONE

ONLY FROM FLYGAS. A disassembly of the pump without written authorization

from Flygas, lifts Flygas from any responsibility.

It is suggested to insert between tank and fuel pump a "Gascolator” (filter and

water decanter) with appropriately sized sections to separate presence of

moisture or water in gasoline and retain dirt in order to avoid the clog of the inlet

pumps filter.

Inspect frequently the cleanliness of the filter, considering that its eventual

blockage (because of the small total surface and the filtering fine pattern it may

happen), would reduce the passage of gasoline causing the wear of the engine

with the potential risk of breakage of the Oldham Joint and sudden turn off.

From the fuel pressure regulator to the tank

The fuel pressure regulator has an exit hole that returns to the tank to constantly dispose the

amount of exceeding gasoline. The connection pipe will have an internal section not less than 6

mm of diameter, if the length does not exceed 2 meters, otherwise we must increase the diameter

according to the increased length to re-establish the proper flow.

Use pipe and fittings of aircraft type (Aeroquip) resistant to 10 bar pressure and gasoline so called

" Green”, taking care that the connectors are mounted to the heads of the tubes in the correct way,

as indicated by manufacturer Aeroquip.

The return of the fuel must have a low resistance to the flow. From the pressure

regulator to the tanks the maximum tolerated pressure drop is 0.1 bar

Long periods of fuel pump inactivity or fuel pressure regulator can lead to a

deterioration of these elements and of their components. The downtime should

not exceed 30 consecutive days. The presence of water, even in very small

quantities, could irreparably damage the components compromising the function

of the complete system.

20

8. FIRST STARTING

Once the installation is completed, before the first starting is carried out, follow the instructions

below:

Recheck all the connections of the various pipes, gasoline and air.

Visually check that there are no electrical parts or pipes accidentally leaned (or very near)

against the engine exhausts since they reach within few seconds temperatures like 700/900

° C.

Visually check that there are no electrical parts or fittings leaned accidentally against sharp

edges.

Visually check that there are no electrical wires or pipes near the engine rotating parts.

Activate the fuel pumps and check that there are no leaks nor drips

Check that the carburettors butterflies are at the minimum (closed)

Adopt any other necessary precautions.

Proceed with the first starting (without propeller and with fly-wheel instead of propeller) with closed

accelerator in an open and proper place, away from people especially if not employees.

Whenever you turn the engine on without propeller it is necessary that a flywheel

must be installed in its housing; this flywheel must have the weight, the

dimensions and especially the moment of inertia similar to the propeller used, as

indicated by the engine manufacturer. Keep the throttle to minimum to avoid that

possible unusual revs could damage the engine.

After having completed all the controls to the minimum fix the plane in a fixed point, considering

that the propeller may develop a traction even of 250 / 300 kg. After having activated the brakes

and locked the plane, using wedges under the wheels or proper strings, simulate and check the

functionality of mechanical Fuel Pump, leave it work alone, with electrical fuel pump switch-off and

check the pressure and normal functionality of the engine

This manual suits for next models

1

Table of contents