2

Warning! Important safety instructions! Read carefully

before installation.

California Proposition 65 Warning:

This product and related accessories

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

Safe Drinking Water Act:

This product is to be used exclusively

for non-potable water services. This product is not

anticipated to be used for human consumption so is

not designed for the low lead levels stated in the Safe

Drinking Water Act. It is illegal to use this product for

potable water applications for human consumption,

such as drinking water, oral hygiene, hand washing,

food preparation and dishwashing.

Failure to follow these instructions and comply with

all codes may cause serious bodily injury and/or

property damage.

Before installing or servicing your pump, be

certain the pump power source is turned off

and disconnected.

All installation and electrical wiring must adhere

to state and local codes. Check with appropriate

community agencies or contact your local electrical

and pump professionals for help.

Call an electrician when in doubt. Pump must be

connected to a separate electrical circuit directly from

the entrance box. There must be an appropriately

sized fuse or circuit breaker in this line. Tying into

existing circuits may cause circuit overloading, blown

fuses, tripped circuit breakers or a burned-up motor.

Do not connect pump to a power supply until the

pump is grounded. For maximum safety, a ground

fault interrupter should be used. Caution: failure

to ground this unit properly may result in severe

electrical shock.

Warning: Reduced risk of electric shock during

operation of this pump requires the provision of

acceptable grounding. If the means of connection to

the supply-connection box is other than grounded

metal conduit, ground the pump back to the

service by connecting a copper conductor, at least

the size of the circuit conductors supplying the

pump, to the grounding screw provided within the

wiring compartment.

This pump is provided with a means for grounding.

To reduce the risk of electric shock from contact

with adjacent metal parts, bond supply box to the

pump-motor-grounding means and to all metal parts

accessible including metal discharge pipes and the

like, by means of a clamp, a weld or both if necessary,

secured to the equipment-grounding terminal.

The voltage and phase of the power supply must

match the voltage and phase of the pump.

Do not use an extension cord. Above ground joints

must be made in an approved junction box.

Do not work on this pump or switch while the power

is on.

Never operate a pump with a frayed or brittle power

cord, and always protect it from sharp objects, hot

surfaces, oil and chemicals. Avoid kinking the cord.

Never service a motor or power cord with wet hands

or while standing in or near water or damp ground.

The three phase units must be wired by a qualified

electrician, using an approved starter box and

switching device.

Do not use this pump in or near a swimming pool.

Single phase motors are equipped with automatic

resetting thermal protectors. The motor may restart

unexpectedly, causing the leads to energize or pump

to turn on. Three phase motors should be protected

by proper thermal and amperage protection. (Check

local codes.)

Check for nicks in the wire and pump insulation

by using an ohmmeter and checking resistance to

ground before installing the pump and after installing

the pump. If in doubt on the proper procedure, check

with a qualified electrician.

Do not pump gasoline, chemicals, corrosives or

flammable liquids; they could ignite, explode or

damage the pump, causing injury and voiding

the warranty.

Do not run this pump with discharge completely

closed. This will create superheated water, which

could damage the seal and shorten the life of the

motor. This superheated water could also cause

severe burns. Always use a pressure relief valve, set

below the rating of the tank system.

Do not run the pump dry, fail to protect the pump from

below freezing temperatures.

Never work on the pump or system without relieving

the internal pressure.

Do not pump water above 120° F.

Never exceed the pressure rating of any

system component.

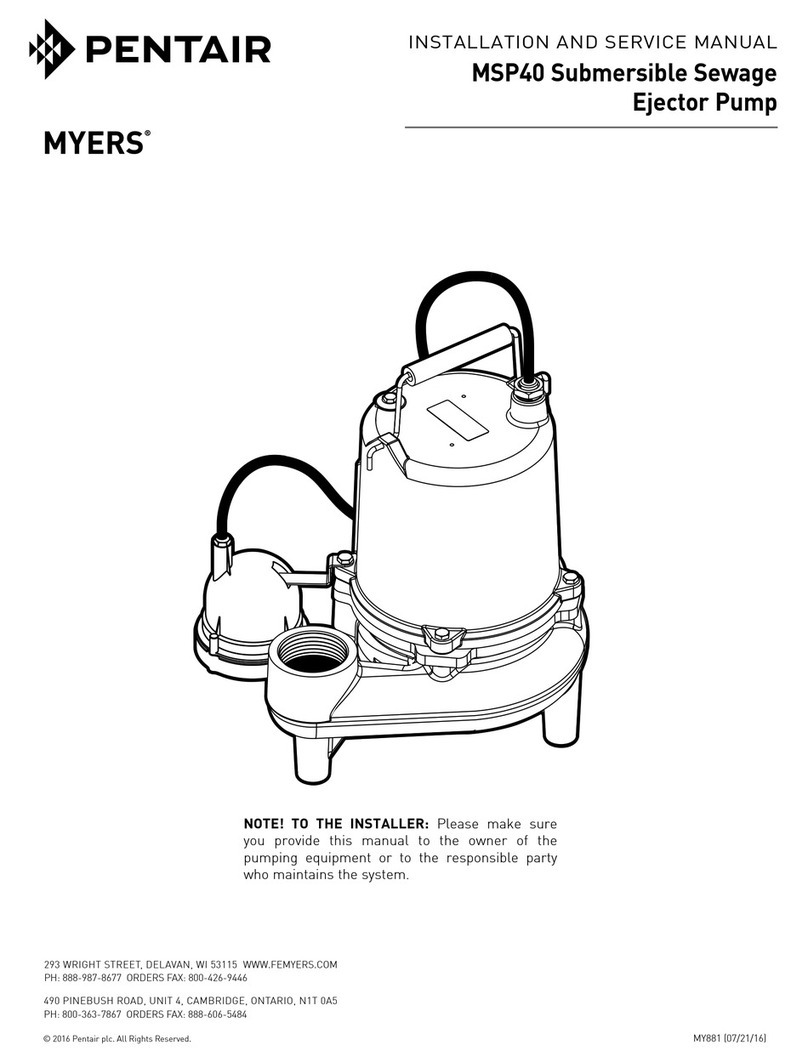

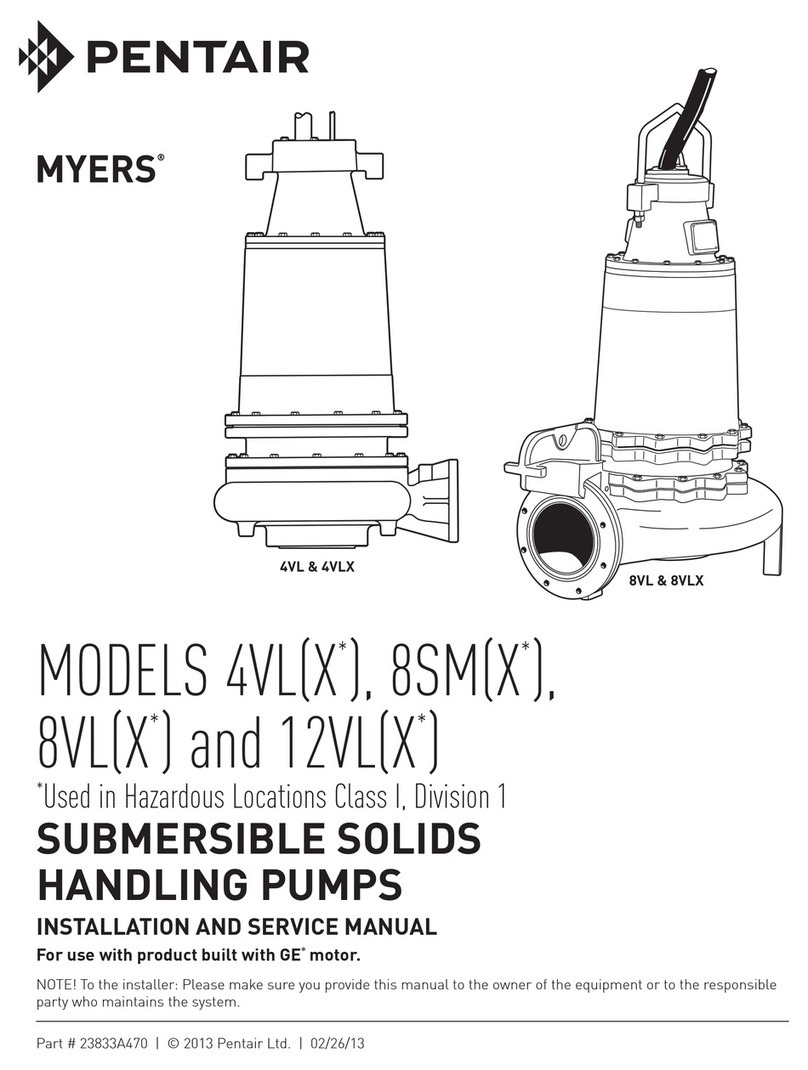

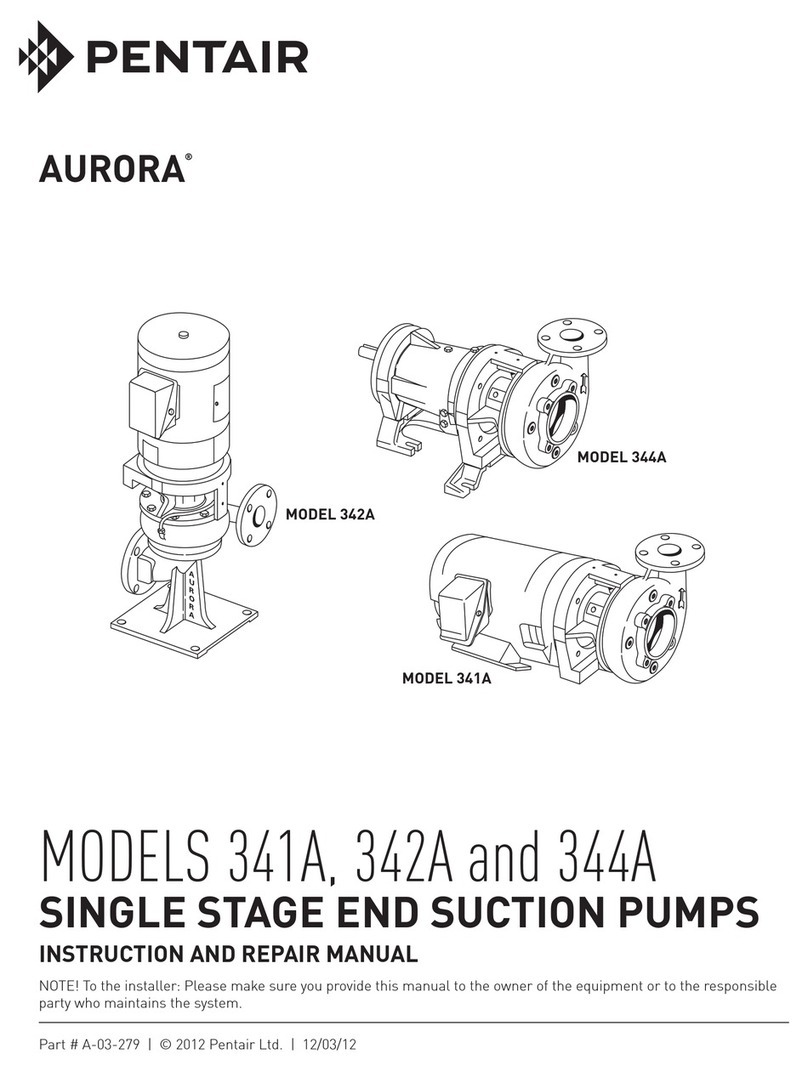

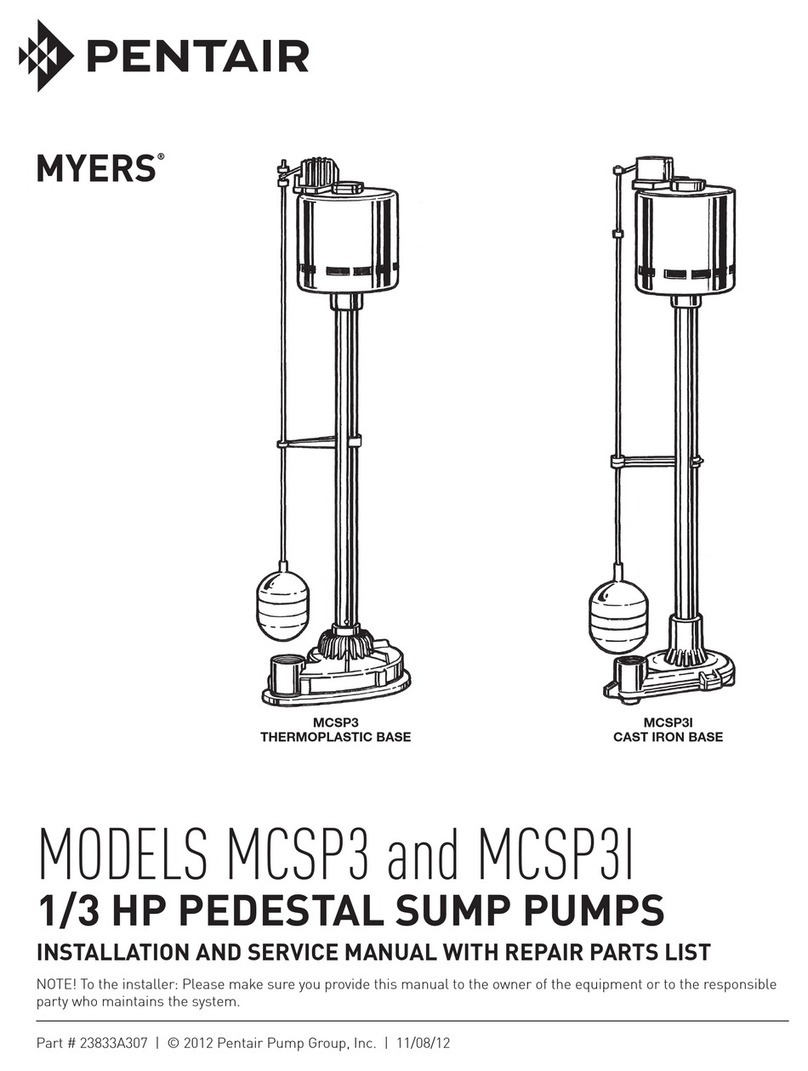

INSTALLATION

Package Contents

Each pump is carefully tested and packaged at

the factory.

Be sure all parts have been furnished and that nothing

has been damaged in shipment. Open packages and

make this check before going on job.