FlySynthesis Wallaby User manual

MAINTENANCE MANUAL

TWO SEATERS ULTRA LIGHT

WALLABY

EQUIPPED WITH:

ROTAX 503

ENGINE

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-2

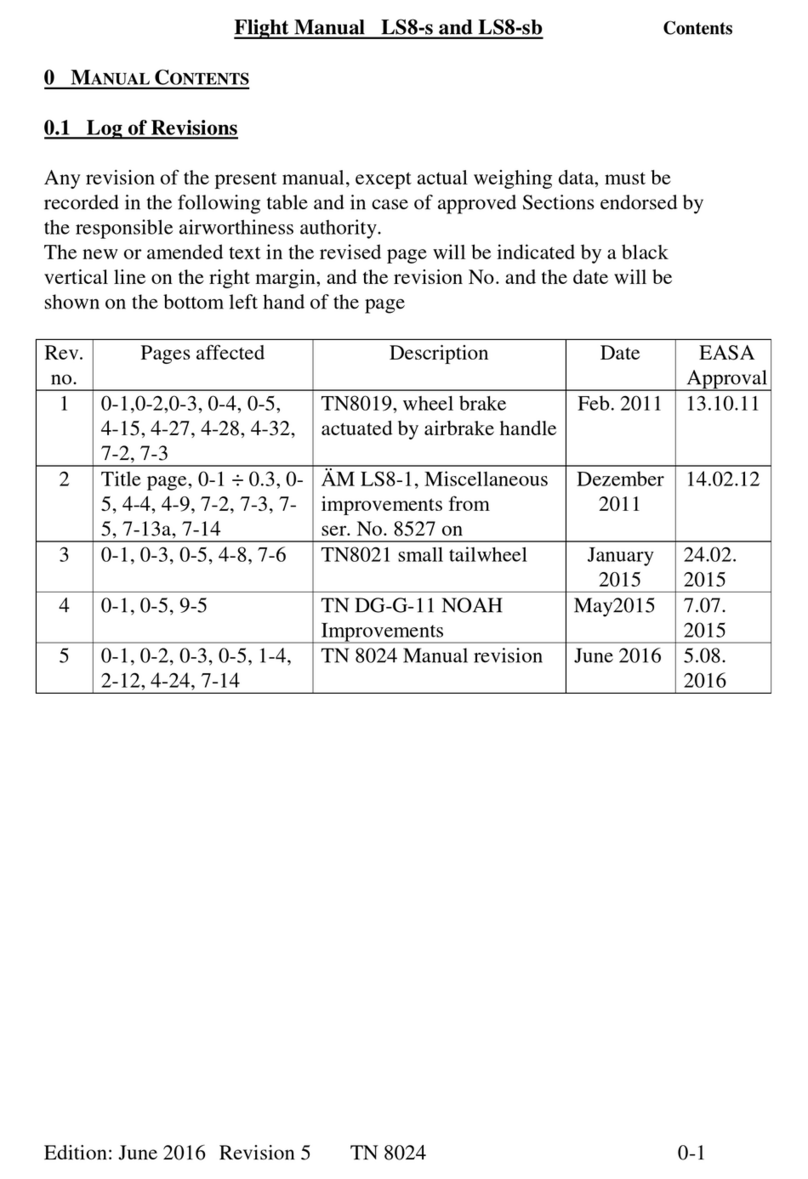

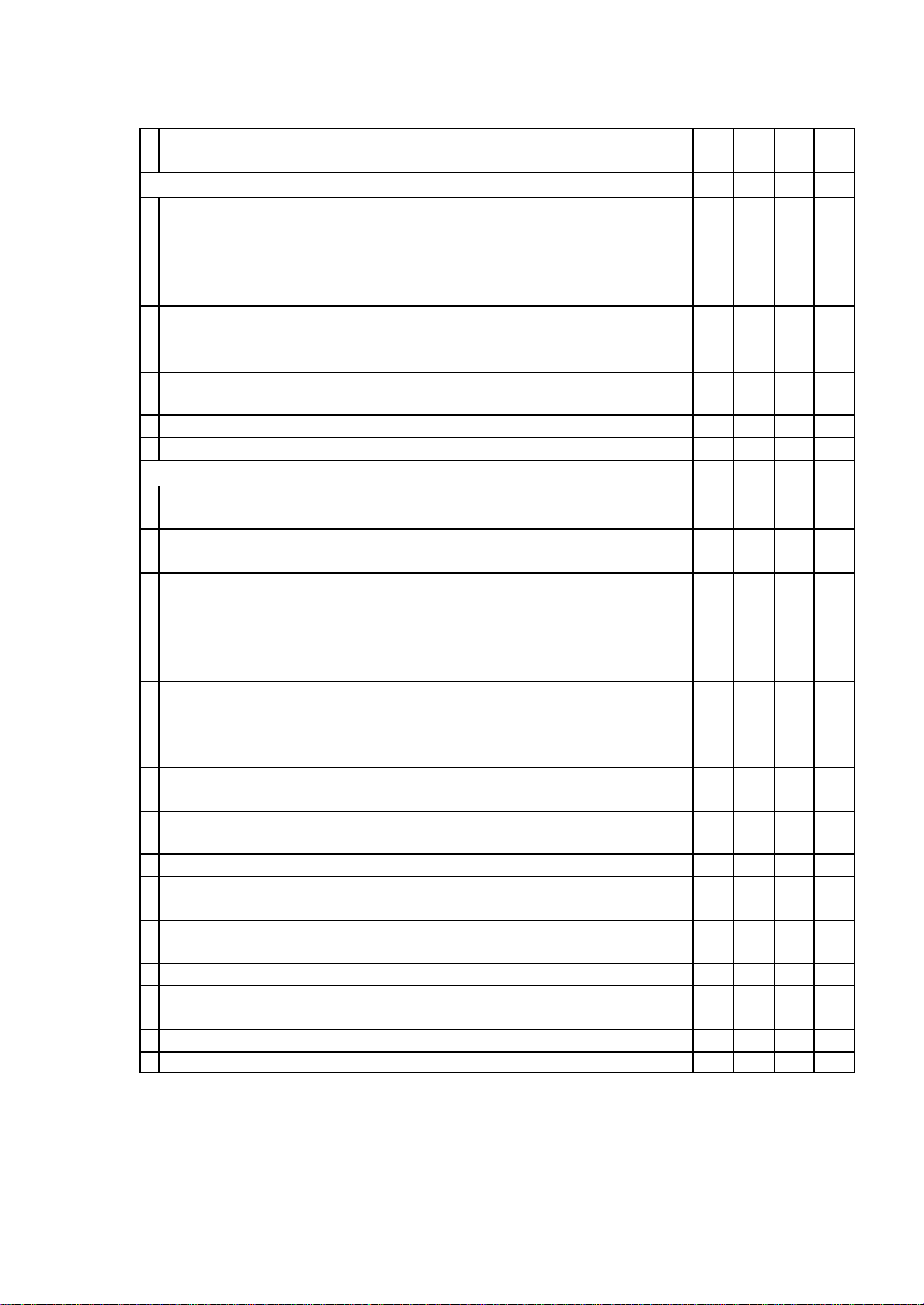

3.1 LOG OF REVISIONS

All revisions to this Maintenance Manual must be recorded in the following table.

Revision Number Revision Highlight and Pages affected Date Signature

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-3

MAINTENANCE manual

TABLE OF CONTENT

Paragraph Page

3.1 LOG OF REVISIONS 2

MAINTENANCE MANUAL 4

3.2 INTRODUCTION 4

3.3 SCHEDULED MAINTENANCE4

3.4 AIRPLANE PREPARATION FOR FLIGHT 5

REFUELING 5

FUEL DRAINING 5

PRE FLIGHT INSPECTION5

3.5 DETAILED SCHEDULED INSPECTIONS 8

3.6 TORQUE FOR BOLTS AND NUTS 13

3.7 MAINTENANCE PER PERIOD OF TIME 13

SCHEDULED INSPECTION 13

TIME LIMITED COMPONENTS 13

3.8 NON SCHEDULED MAINTENANCE 13

HEAVY LANDING 13

DAMAGE TO THE COMPOSITE STRUCTURE 14

EXCEEDING ENGINE LIMITS 14

PAINTING THE AIRPLANE14

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-4

MAINTENANCE MANUAL

3.2 INTRODUCTION

In order to maintain the airplane in an airworthy condition, to enjoy a safe flight and

save on repair expenses, maintenance tasks must be carried out.

Maintenance instructions are divided to scheduled and non-scheduled tasks.

Scheduled tasks are carried per time, either flight hours or period, like once a year.

Non-scheduled tasks are per airplane condition after damage is discovered or some

unusual happening like a heavy landing.

3.3 SCHEDULED MAINTENANCE

Scheduled maintenance is composed of the following:

Preparation of the airplane for flight includes refueling, fuel system draining and pre

flight inspection.

Scheduled inspections per flight time are planed in a cycle of 50 flight hours, to match

the engine manufacturer requirements, these are composed of the following

inspection types: 25 hours inspection; 50 hours inspection; 100 hours inspection and

200 hours inspection.

The normal cycle repeats itself per following table:

Flight Time 25 50 100 150 200 250 300 350 400

Inspection Type 25 50 100 50 200 50 100 50 200

Flight Time 450 500 550 600 650 700 750 800

Inspection Type 50 100 50 200 50 100 50 200

Flight Time 850 900 950 1000 1050 1100 1150 1200

Inspection Type 50 100 50 200 50 100 50 Overhaul

The 25 hours inspection should be carried out only once after the first 25 flying hours

of the airplane. It is also done once after an engine change, engine or airplane

overhaul or major repair due an accident or other major damage.

Scheduled maintenance per period is done after one year or two years, if the airplane

did not reach certain time of flight.

Other limited periods for certain equipment are listed separately.

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-5

3.4 AIRPLANE PREPARATION FOR FLIGHT

REFUELING

Magnetos OFF check

Master switch ON

Fuel quantity check

Master switch OFF

Fill the required amount of fuel per flight plan

Master switch ON check

fuel quantity

Master switch OFF

Record amount of fuel in airplane log

FUEL DRAINING

Fuel drainage should be carried out once a day before the first flight, and 10 minutes

after each refueling of the tank. Fuel drainage should also be repeated if the airplane

was parked for more than three hours.

CAUTION

Before attempting any service or inspection on the airplane, check that the Magnetos

and Master Switch (key) are OFF

Use transparent container to drain into. If water is found in the drained fuel, repeat

fuel drain operation.

Fuel drainage should be performed before moving the airplane from it’s parking place,

to avoid condensed water present on tank Bottom to emulsify with fuel.

PRE FLIGHT INSPECTION

The pre flight inspection should be carried out BEFORE EACH FLIGHT, even if the

previous flight was very short. The pilot should carry out the inspection.

The inspection does not require any tools; only a clean rag is needed. It is important

to verify by sight and touch that there are no failures, defects, excessive clearances

or play.

For the detailed Pre Flight Inspection see Section IV of the AFM.

If a Daily Inspection was just completed, pre flight Inspection is not required.

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-6

Nose wheel

Axle locking nuts check tight

Tire and wheel undamaged, inflated properly.

Gear strut no distortion.

Gear support frame locking nuts tightened no distortion.

Propeller

Blades and hub undamaged and cleaned.

Spinner undamaged, fixed tight

Engine

Exhaust and mufflers no damaged or cracks, retaining spring hooked,

Fuel pipes undamaged.

Electric and ignition line undamaged.

Throttle and choke function properly, smooth movement

R.H. main landing gear

Strut no distortion, locking nuts tightened, and visible

welding no cracks is evident

Tire undamaged, inflated properly

R.H. wing

Skin undamaged-absence of swellings and depressions,

no delamination

Wing-fuselage top fairing secure.

Airspeed probe undamaged, aligned, pressure tubes securely

connected

Leading edge undamaged,

Wings tip undamaged, fixed tight

Trailing edge undamaged

Aileron undamaged, freedom of movement, no excessive

hinge slack, all split pins in place hinges securely

connected to the wing, balance weight fixed tight, no

play

R.H. Fuselage

Skin undamaged, no sign of swellings or delamination

Tail

Vertical fin undamaged, no depressions or delamination,

Rudder structure and skin undamaged, hinges secured

Lower the aircraft tail in order to lift the nose wheel from the ground, check rudder

free movement, no play on lower hinges.

Control cables secured, freedom of oscillating eye-ends.

Balance weights fixed tight, no play

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-7

Elevator (Stabilator)

Structure and skin undamaged, no delamination, leading edge. Attached

firmly through out its length

Elevator free movement up and down

Elevator hinge plate undamaged, attached firmly, no play

Balance weights fixed tight, no play

Hinges pins tight and safe tied

Trim tab undamaged, attached properly, correct operation.

L.H. Fuselage

Skin undamaged, no sign of swellings or delamination,

Inspection doors closed

L.H. wing

Skin undamaged-absence of swellings and pressings, no

delamination

Leading edge undamaged,

Wings tip undamaged, fixed tight

Trailing edge undamaged

Aileron undamaged, freedom of movement, no excessive

hinge slack, all split pins in place hinges securely

connected to the wing, balance weight fixed tight, no

play

L.H. main landing gear

Strut no distortion, locking nuts tightened, and visible

welding no cracks is evident

Tire undamaged, inflated properly

Fairing undamaged, fixed tight and clean.

Cockpit checks

Instrument panel fixed tight,

Master switch (key) ON all instruments operate as required

Master switch OFF instruments indicate zero or as required

Control sticks control rods connected securely (visible part only)

free and full movement

Rudder pedals no distortion, rudder and nose wheel aligned,

nose wheel control rods and rudder control cables, securely attached, condition,

spring centering cables condition

Throttle and choke free and smooth movement, installed securely

Brake lever brake lever operates smoothly, correct feel.

Trim lever installed securely, smooth movement

Seat belts undamaged, locking device locks and releases freely

Seats Fixed.

Windshield clean, fixed securely

Weight and balance calculate.

Aircraft log book record the Daily Inspection in the book.

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-8

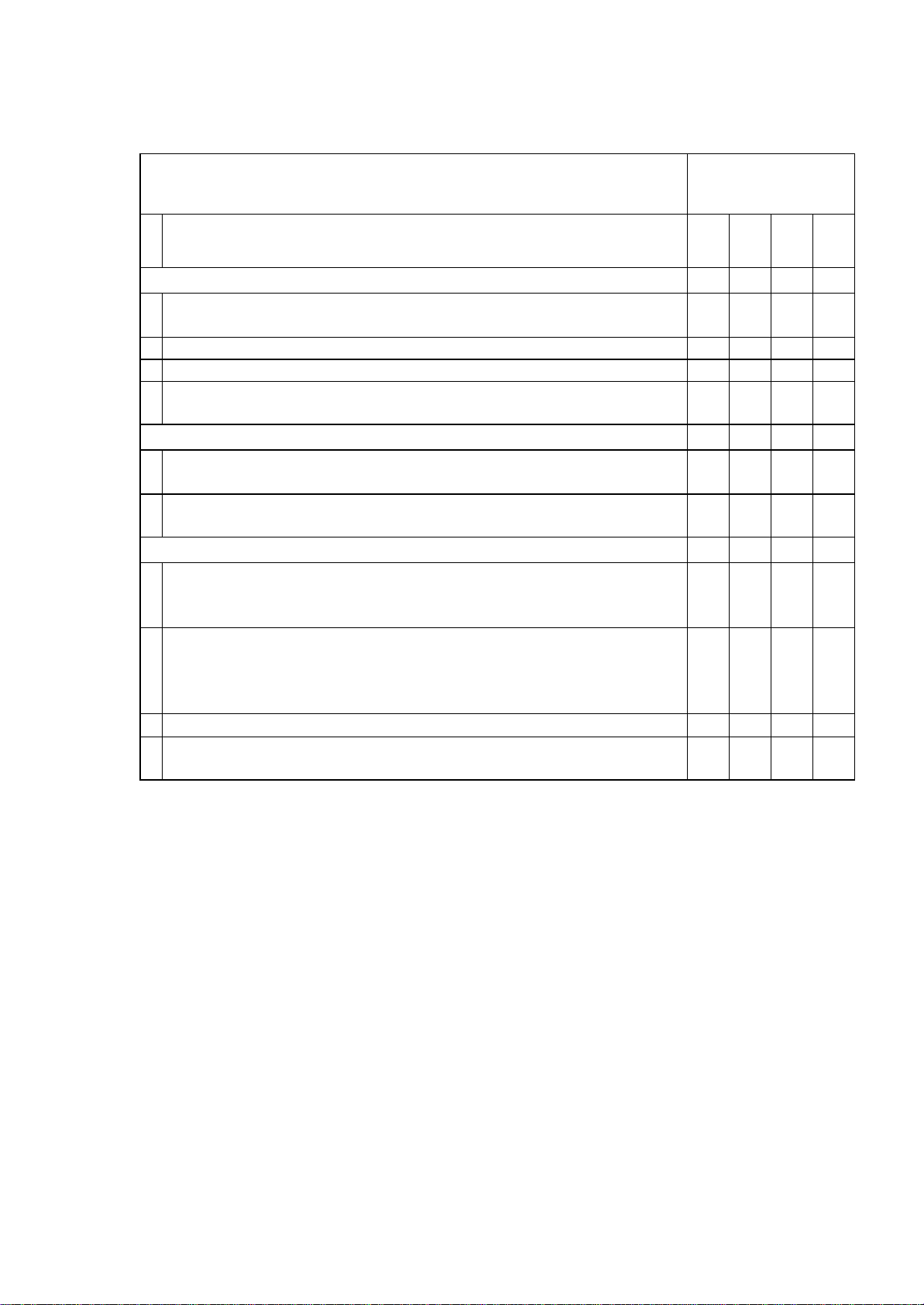

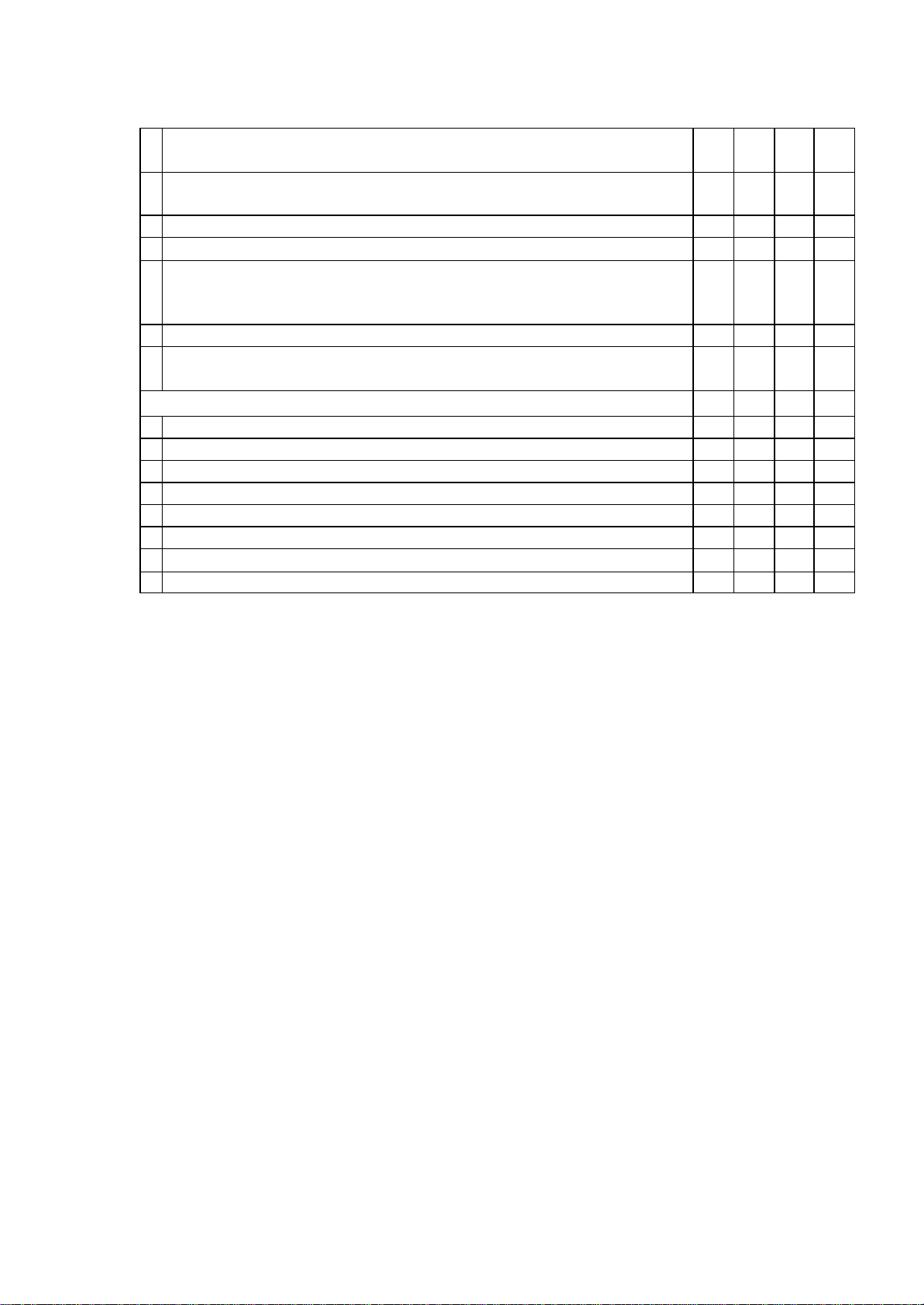

3.5 DETAILED SCHEDULED INSPECTIONS

SCHEDULED INSPECTIONS –PROGRAM INSPECTION

TYPE

TASKS TO BE PERFORMED

25

50

100

200

general

Ensure that ignition switches are OFF and master switch

(key) is REMOVED XXXX

Remove seats and seat back XXXX

Remove fuselage –wing top fairing XXXX

Check all rivets to detect loose rivets. Any loose rivet shall be

replaced with oversize rivet XXXX

propeller

Inspect the prop blade for crack, stone blow and other Defect,

small defect smooth with fine glass paper and Apply lack XXXX

Check propeller bolts tightness, Torque 15 Nm, check safe

tying if required. XXXX

fuselage

Inspect fuselage for condition and other sign of defect. Check

skin for delamination, inner structure bulkheads to be glued to

skin with no cracks or separation

XXXX

Check main landing gear frame (steel tube spar) for

condition, no cracks. Four areas of connection to fuselage

structure, no delamination or skin separation, bolts and nuts

tightness

XXX

Check wing connection for bolts tightness, no cracks XXX

Front windshield, clean and check condition, check

Attachment to the structure XXXX

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-9

TASKS TO BE PERFORMED

25

50

100

200

Flight controls

Check aileron surfaces for condition, smooth and free

movement, no play up or down, side play acceptable. XXXX

Check bolts and nuts attaching the aileron hinges for

tightness. Check hinge pin tightness XXXX

Check elevator surface for condition, smooth and free

movement, and no play up or down. XXXX

Check bolts and nuts attaching the elevator support plate

mechanism for tightness, no play. XXXX

Check rudder control surface for condition, smooth and free

movement, no side play, XXXX

Check bolts and nuts attaching the rudder hinges for

tightness, no play. XXXX

Check aileron push pull rods and rod ends for condition no

distortion, free clearances all around in full movement XXXX

Check elevator flex-ball push-pull cables and ends for

condition no distortion, free clearances all around in full

movement.

XXXX

Check rudder control flexible push-pull cables and cable ends

for condition, replace if necessary. XXXX

Check trim lever for secure installation. XXXX

Check trim cable for condition, smooth and free movement,

end connections. XXXX

Check trim surface for secure installation XXXX

Check ailerons surface angles both left and right sides, XXX

Check elevator surface angles, XXX

Check rudder surface angles, left and right XXX

Check anti-servo-tab surface angles, XXX

Check trim surface angles, XXX

Lubricate lightly all movable part and hinges. XXXX

Check tightening of nuts securing aileron hinges (support

plates) in wings. XXX

Check tightening of self-locking nuts securing the aileron

control rod end ball joints (fuselage/ wing). XXX

Check aileron push pull rods support in fuselage for tightness

of nuts. XXX

Wing

Check for loose rivets In wing tip connection upper and lower

surface, XXXX

Inspect wing surfaces condition for defect, no delamination or

scratches XXXX

Check fuel tank and outlet for security and leaks. Check the

fuel lines from and to the tank to engine for condition and

support.

XXXX

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-10

TASKS TO BE PERFORMED

25

50

100

200

Cockpit

Carefully inspect all operating levers for damage, wear,

abnormal play and security of attachment. Clean and lubricate

as required.

XXXX

Check electric wiring and electric component installation, for

condition and attachment XXXX

Clean the floor XXXX

Inspect pilot seat belts. Check operation of locking

mechanism. Check bolts and nuts securing the seat belts. XXXX

Check instrument panel and instruments attachment. Check

instruments connection, static and dynamic line. XXXX

Drain static and dynamic line. XXXX

Check windshield, no scratches or damage. Clean it. XXXX

Landing gear

Check nose landing gear structure for cracks and alignment,

attachment and bolt tightness. XXXX

Disassemble nose gear strut, check attachment of nose gear

to strut, reassemble, check bolts tightness. XX

Check nose wheel and tire condition. Inflation pressure

17.2 psi (1.2 bar). XXXX

Support the aircraft. Remove the main landing gear wheels

and check the brake linings for wear. Replace lining if

necessary.

XXXX

Remove the main landing gear RH and LH struts. Clean the

strut housings in the tubular framework. Clean the axle

assemblies. Lubricate strut housings for corrosion prevention.

Replace struts with 300 hours. Check struts for linearity.

XX

Reinstall the main landing gear struts and check the nuts for

tightness, both to wheel axle and to frame. XX

Check main landing gear RH and LH struts installation on

fuselage for tightness and safe tying. XXXX

Check self-locking nuts for tightening XX

Check brake system condition, replace if necessary. Check

brake self-locking nuts for tightness. XXXX

Check wheel and tire condition. Inflation pressure 32 to 35 psi

(2.2 to 2.4 bar). XXXX

Reinstall the wheels. Check nut for tightness, safe tying XXXX

Ensure that wheel bearings are not noisy and turn free and

smoothly without play. XXXX

Check main wheel alignment. XXX

Install strut XXXX

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-11

TASKS TO BE PERFORMED

25

50

100

200

Engine

All Engine maintenance is to be performed according to

ROTAX Maintenance manual

This maintenance schedule covers only the airframe

manufacturer installation in the engine compartment

XXXX

Check the fuel lines in the engine compartment for condition

and secure attachment. Replace if necessary. XXXX

Remove and clean the fuel filter. XXXX

Check throttle and choke control cables for proper installation,

tension and Interference with other equipment. Full free

smooth movement. Clean and lubricate the cables

XXX

Check the carburetors for leaks and proper adjustment, clean

if necessary. XXX

Clean the carburetors XX

Replace or clean the air filter per ROTAX instructions. XXX

Inspect carburetor-mounting flange for leakage. XXX

Replace carburetor-mounting flanges. X

Using a 10X magnifying glass inspect all welding of the engine

mount for cracks. Check for distortion. XX

Check for proper torque of the nuts securing the engine to the

engine mount. XXX

Check for proper torque the self-locking nuts securing the

Shock absorbers to the engine mount and supporting plate of

shock adsorbed to ribs.

XXX

Check the nuts securing the exhaust pipe XXX

Check all exhaust system for gas leaks, cracks, and

serviceability of retaining spring and rubber buffers. XXXX

Replace exhaust system-retaining springs X

Replace the 2 Muffler buffers. X

Check all the electrical system wiring in the engine

Compartment. XXXX

Check engine for leaks.XXXX

Check all fuel hose connection for security. XXXX

Check all components attached in engine area/compartment

for security. XXXX

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-12

TASKS TO BE PERFORMED

25

50

100

200

Check instrument pick-up attachments to engine for proper

condition. XXXX

Check all electric harness for proper condition. XXXX

Check the electrolyte level in the battery, add if required XXXX

Check battery base and securing straps for condition,

attachment and cleanliness from battery fluids. Look for

evidence of electrolyte leak.

XXXX

Check battery cables. XXXX

Check engine mount vibration pads and the proper torque of

the attaching nuts XXXX

FINISHING

Check if all the tools were removed from the airplane. XXXX

Close all inspection panels in the fuselage and wings. XXXX

Clean the cockpit XXXX

Install seats and seat backs. XXXX

Install fuselage-wing top fairing. XXXX

Check if all system, operate properly. XXXX

Refuel the tank and drain. XXXX

Run the engine. XXXX

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-13

3.6 TORQUE FOR BOLTS AND NUTS

Use the required torque of the different assemblies in the airplane.

Bolts used on airplane are galvanized of 8.8 class.

The requirement for this type of bolts is:

Diameter Tightening force applied Nm (kgm)

M5 4,1 (0,42)

M6 7,4 (0,75)

M7 15 (1,5)

M8 24 (2,4)

M10 45 (4,6)

3.7 MAINTENANCE PER PERIOD OF TIME

Scheduled inspection

If the airplane does not reach 100 flight hours within consecutive 12 months, a 100

hours inspection must be carried out before renewal

of its permit to fly.

If the airplane did not reach 200 flight hours within 24 months, a 200 hours inspection

must be carried out.

Time limited components

The following components must be removed for inspection and complete overhaul

after the time specified have expired:

Engine ROTAX 503 300 hours, or 10 years, whichever comes first, see

ROTAX manual

Propeller see propeller manual supplied with the propeller

Main landing gear strut replace at 300 hours

Engine exhaust retaining springs replace at 200 hours

Engine exhaust muffler buffers replace at 200 hours

3.8 NON SCHEDULED MAINTENANCE

HEAVY LANDING

1. A heavy landing event should be recorded in the airplane logbook by the pilot

or technician observing landing gear damage. Following inspection must be

carried out:

2. Check nose-landing gear structure for cracks and alignment, attachment and

bolt tightness.

3. Support the airplane, remove main landing gear wheels, check axle welding,

and check struts for linearity scratches and cracks. Replace struts if bent or

damaged.

4. Install wheels, Check main wheel alignment.

5. Check engine mount for distortion.

FLYSYNTHESIS WALLABY SECTION VIII

MAINTENANCE MANUAL

English Edition 2003-03-28 Page VIII-14

DAMAGE TO THE COMPOSITE STRUCTURE

Consult factory for more information

EXCEEDING ENGINE LIMITS

Any time an engine limit is exceeded, RPM, time limit, pressure or temperature,

record the event in the airplane logbook and consult the ROTAX Maintenance

Manual.

PAINTING THE AIRPLANE

The airplane when delivered is painted white all over.

It is prohibited to paint the upper surfaces of the wings and fuselage with any dark

paint, as this will increase the heat absorption from the sun, which may lead to

damage to the composite material structure.

Note

Consult the airplane manufacturer before painting the surfaces.

Table of contents

Other FlySynthesis Aircraft manuals