FMC 872 Rack User manual

MODEL 870/872 Rack

Installation Guide/Parts Reference

Form 5208

Page 2

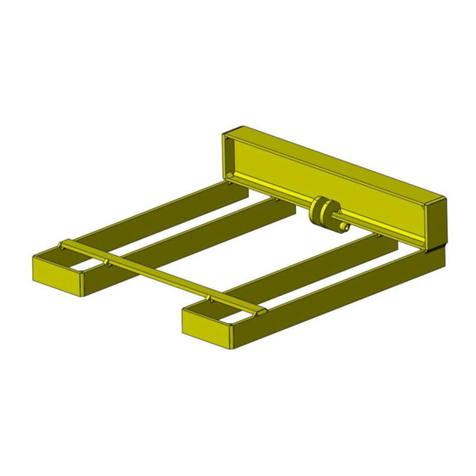

INSTALLBOLSTERPLATEANDHARDWARE

1. Mount bolster plate to the hoist cylinder (single or double) using hardware supplied with the bolster

kit. In most cases the bolt pattern in the top of the cylinder will determine how the bolster is to be

oriented, however, the bolster plate for a single post type will usually be symmetrical. The symmetrical

pattern permits the bolster to be mounted with the offset to the front or rear, depending on floor space

requirements (or limitations). The single post bolster will have a measured spacing between inner

runway bolt holes of 47-1/8" (1 19.7cm). This same spacing must be maintained when twin-post bol-

sters are installed, but the precise spacing is gained through slight adjustments provided by oversized

mounting holes. Be sure that both bolsters are parallel with each other by checking diagonal distances

between front and rear holes in the mounting pads.

2. When dimensions A and B are 47-1/8", and dimensions A and B are also equal, tighten bolster

mounting bolts to the cylinders. Recheck measurements.

IMPORTANT: The cylinders must lower to the floor without any binding before the runways are

assembled to the bolster plate(s).

3. Lower cylinder to bottom of travel. If hoist does not go all the way to the floor, loosen bolts holding

the synchronizing mechanism to the bolster plate. Move synchronizing mechanism and retighten bolts

so there is no binding as the hoist is lowered to the floor.

If the hoist still won’t go all the way to the floor, it is probably because one cylinder is reaching bottom

of its travel before the other. To correct for this condition, add shims between the synchronizing mecha-

nism and bolster plate to cause the cylinders to lower equally.

Page 3

INSTALLRUNWAYS

1. Locate the following hardware:

NOTE: Part of loose parts pack 68289

QUANTITY PART NO. DESCRIPTION

81100073 Screw HHCS 3/4-10x2-1,

81100248 Lockwasher 3/4"

859683 Special Washer

2. Assemble runways to bolster plate(s) and level runways at the four points where the vehicles will

rest (turntables should be set in the saddles). Bring rack to comfortable working height and check level

condition of runways at all points. Add shims as necessary between the runway mounting bosses and

bolster plate mounting pads.

ADJUSTSTOPBOLTSONLEVELINGLEGS

Raise the hoist about three feet above floor. Set the stop bolt for each leg by letting the leg down and

adjusting the point of contact just as the locking pin drops into place. Tighten the jam nut. This keeps

the leg from having a chance to swing farther once it is in the lock position.

INSTALLFLOORSTOPS

1 . Locate the following hardware:

Parts below packed in bag with runway mounting hardware:

QUANTITY PART NO. DESCRIPTION

8N/D Screw HHCS 7/8-9x10"

81121557 Hex Nut 7/8-9

2. Install above hardware at four corners of each runway as shown below:

Raise the leveling legs and lower hoist, observing when minimum distance from top of jack rail to the

floor is 7-7/8". Stop hoist at this point and lower the floor stops (all eight) so they contact the floor and

tighten all jam nuts.

INSTALL TIE BAR

1 . Locate the following hardware (in bag attached to tie bar) :

QTY. PART NO. DESCRIPTION

168924 Tie bar

21100064 Screw HHCS 1/2-13x1-1/2"

21121511 Hex Nut 1/2-13

2. Install tie bar between rear holes in runway rails with screws and nuts above, with jam nuts used to

hold screw in place.

Page 4

Adjust the screws so that the distance between the edges of the runway rails is 38-1/4". It may be

necessary to loosen the bolts attaching the runways to the bolster(s) so the runways can be moved in or

out to achieve this dimension. Tighten bolster bolts and tie bar jam nuts when correct.

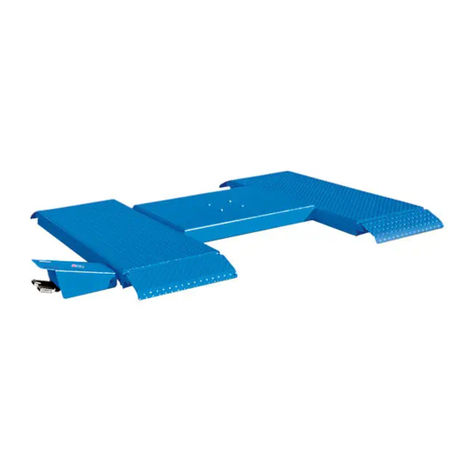

INSTALLREARAPPROACHRAMPSANDRAMPEXTENSIONS

1. Locate the following hardware (in cloth bag marked ”Ramp HDWR and Ramp Extension HDWR”):

QTY PART NO. DESCRIPTION

41100064 Screw HHCS 1/2-13x1-1/2"

41120242 ESNA Nut 1/2-13

81100257 Flat Washer 1 /2"

2. Position Ramp Extensions (68815) 11.0" behind end of runway top with rack lowered and mark

locations for floor holes. Drill 5/8" holes and secure each to the floor using stud anchors.

3. The ramps are to be connected to the runway extensions with the screws, nuts, and washers. They

need only be snug — not binding.

INSTALLOPTIONALREARROLLERJACKORJACKTRAY

NOTE: If either a 68 or 98 roller jack, or a jack tray is to be installed, it must be done before the tie bar,

rear ramps, or rail stops are installed. Likewise, if either is added later, it will be necessary to remove

the afore mentioned items to gain access to the rails.

1. Lower rack to floor and set roller jack or jack tray on rails at front of runways and roll toward center.

Make sure it rolls easily from front stop area to center.

2. Install stop nuts and screws listed below in second hole from rear on each rail.

QTY. PART NO. DESCRIPTION

21100064 Screw HHCS 1/2-13

41100245 Flat Washer 1/2"

21121511 Hex Nut 1/2-13

Page 5

ADJUSTLEVELINGLEGS

1 . Raise rack enough to clear leveling legs, and drop legs to full extension. Make sure all of them are

locking in place.

2. Lower rack to alignment height, then adjust leg extensions to contact floor at correct rack level.

Check level at 4 points (across turntables and front and rear). Tighten jam nuts on each leg bolt when

correct height is achieved.

INSTALLFRONTSTEPS

Locate front steps and bag of loose hardware attached. Insert front step in slots under turntable saddles.

Slide in until tapped hole is accessible through hole in runway. Thread two 1/4-20 nuts onto 1/4-20x1/

2" hex socket head screws. Thread above into the tapped hole in each step and tighten jam nuts.

INSTALLOPTIONALREARSLIPPLATESANDTURNTABLERISERS

1 . Locate roller retainer 68779 and retainer nuts (in hardware bag). Lay retainer over four slot cutouts

at rear of runway.

2. Apply a liberal coat of dry lube to slots of roller retainer, then place rollers (32 per retainer) in slots.

3. Lay rear slip plate weldment 68601 (studs down) into four slots in runway.

4. Remove turntables and attach spacer to their underside using 1/4-20x1/2" screws and 1/4" lock-

washers. Replace square top plate with tapered plate supplied with rear slip plate shipment. The turn-

tables will now be elevated to equal the added height of the rear slip plates.

This manual suits for next models

1

Table of contents

Popular Lifting System manuals by other brands

Ravaglioli

Ravaglioli RAV 1380 manual

John Bean

John Bean EELR538A Installation, operation & maintenance manual

Blitz

Blitz Master Gear MGE 1.0 manual

Adam Hall

Adam Hall STAGELIFT100 user manual

BlueSky Mast

BlueSky Mast AL350G Series Quick reference sheet

Versus-Omega

Versus-Omega PENTA WAVE AXCES user manual

probst

probst WEZ-2 operating instructions

R. Beck Maschinenbau

R. Beck Maschinenbau HS 1000 operating manual

BANDELIN

BANDELIN SONOREX TECHNIK MB operating manual

Scheppach

Scheppach TBL400 Translation of original instruction manual

Jet

Jet SLT-330F Operating instructions and parts manual

Sunex Tools

Sunex Tools 4412 owner's manual