FMI VLDV43NE Quick start guide

Other manuals for VLDV43NE

1

This manual suits for next models

3

Other FMI Indoor Fireplace manuals

FMI

FMI (V)GM36 Series Safety guide

FMI

FMI VTDGT24NE User manual

FMI

FMI DVF36 Quick start guide

FMI

FMI GL36PN Quick start guide

FMI

FMI UVC-ST 36 Quick start guide

FMI

FMI VT32N-A Quick start guide

FMI

FMI DVFE34 Quick start guide

FMI

FMI 36EMW-RBC Quick start guide

FMI

FMI CD32M-LS Quick start guide

FMI

FMI DVF-36NS-HA Quick start guide

FMI

FMI VM36 Series Quick start guide

FMI

FMI DVF36NSR-C Quick start guide

FMI

FMI UV32C Quick start guide

FMI

FMI TC36N Series Operating instructions

FMI

FMI (V)G42/50 Safety guide

FMI

FMI (V)GL36CR(E) Quick start guide

FMI

FMI B36 Quick start guide

FMI

FMI VUM Series Quick start guide

FMI

FMI C42MW-LS Quick start guide

FMI

FMI (V)G42 Quick start guide

Popular Indoor Fireplace manuals by other brands

Argo

Argo Wave operating instructions

Napoleon

Napoleon BGNV42N Installation and operation instructions

Stellar Hearth

Stellar Hearth GALAXY Series Installation and operating manual

WANDERS

WANDERS Tali User guide and installation manual

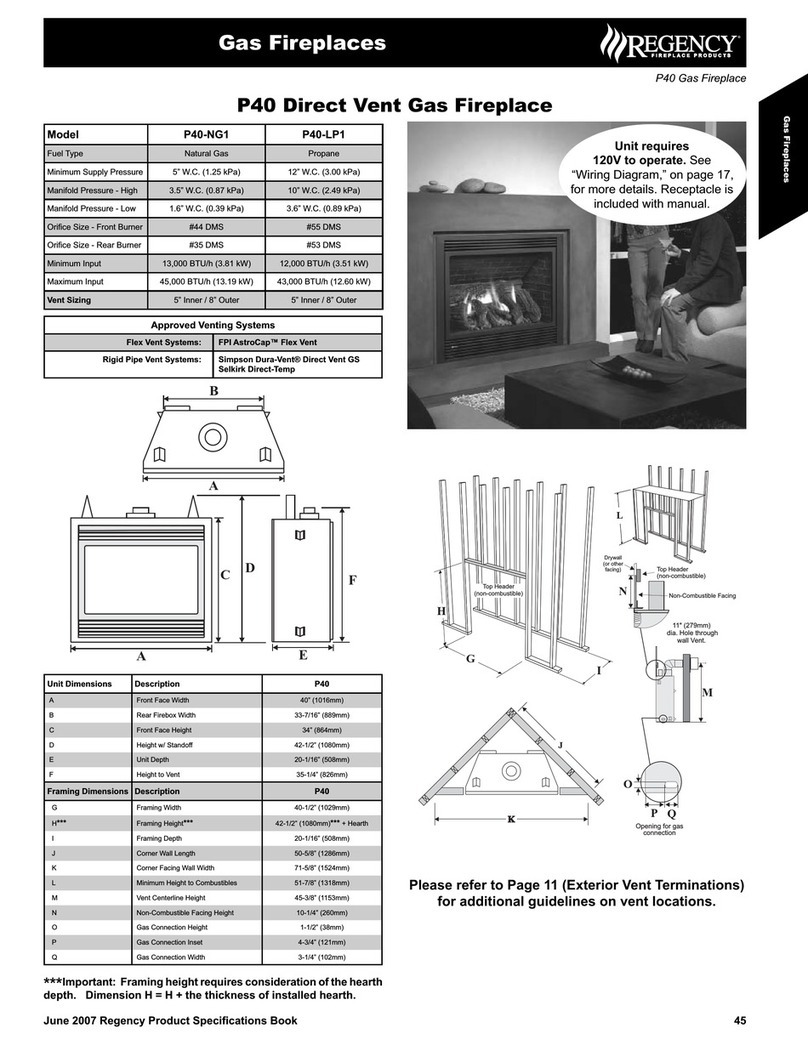

Regency

Regency Panorama P40 Specification sheet

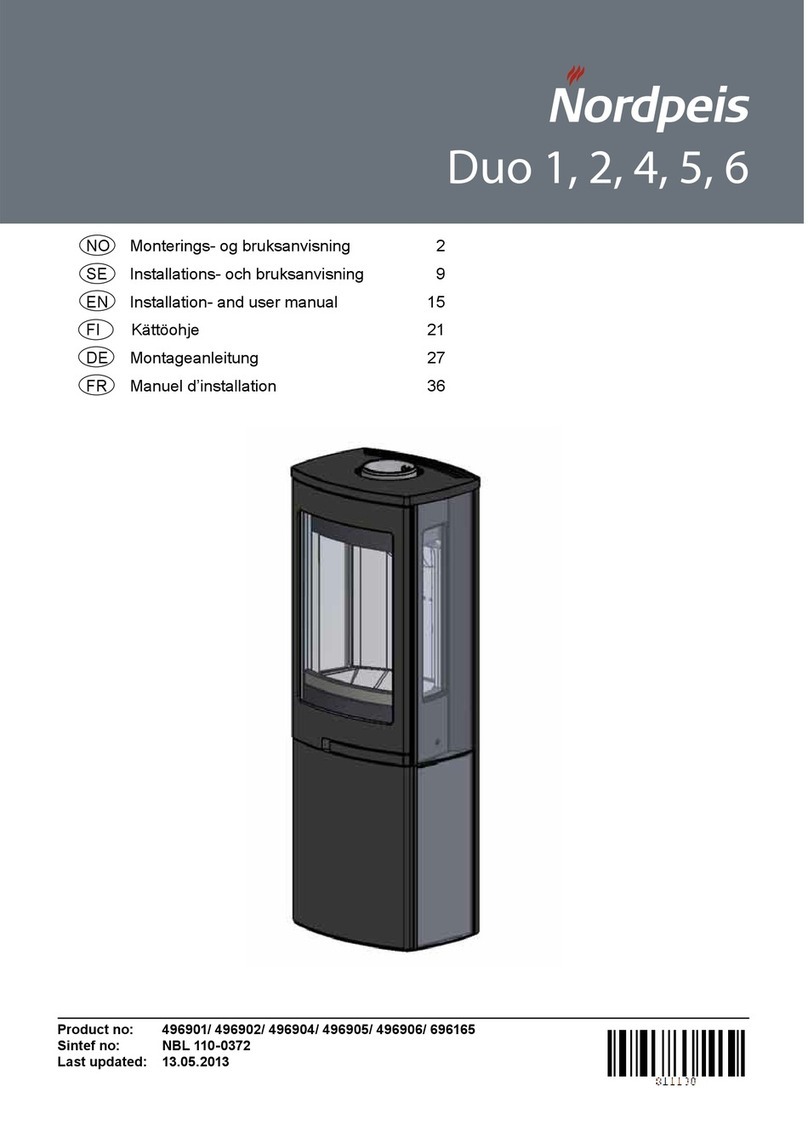

Nordpe

Nordpe Duo 1 Installation and user manual

Amantii

Amantii 2939-TRU-VIEW-XL Installation and operation instructions

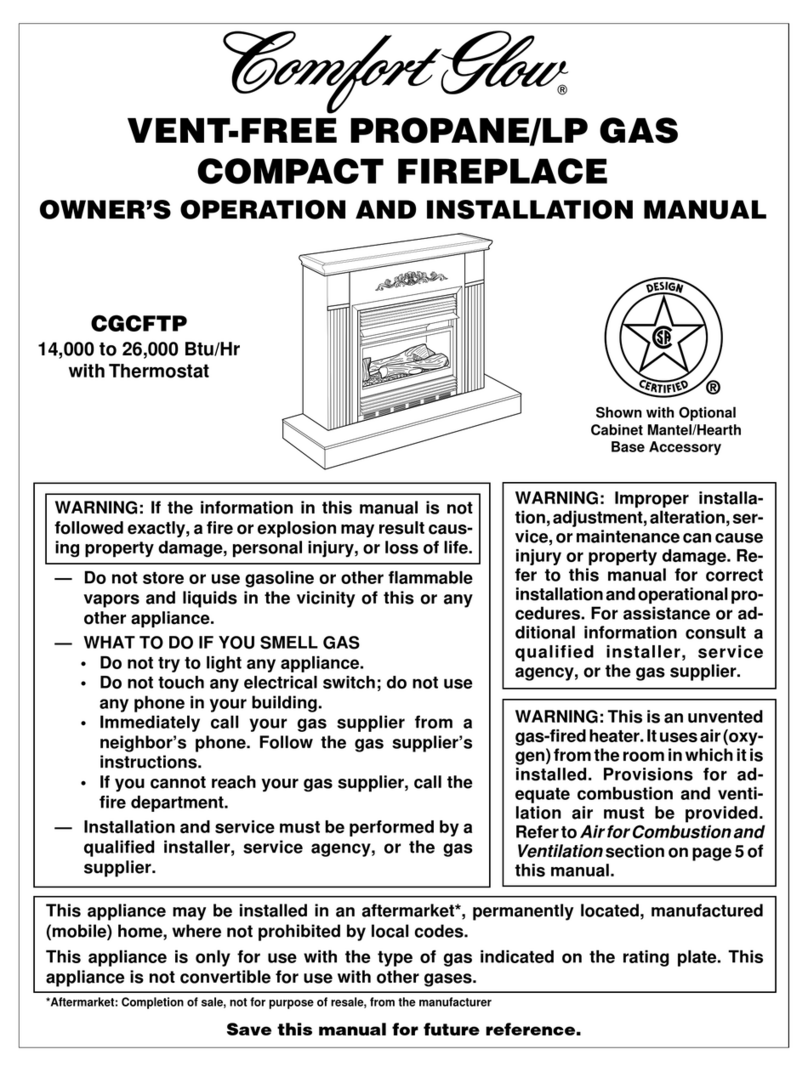

Comfort Glow

Comfort Glow 000 to 26 OWNER'S OPERATION AND INSTALLATION MANUAL

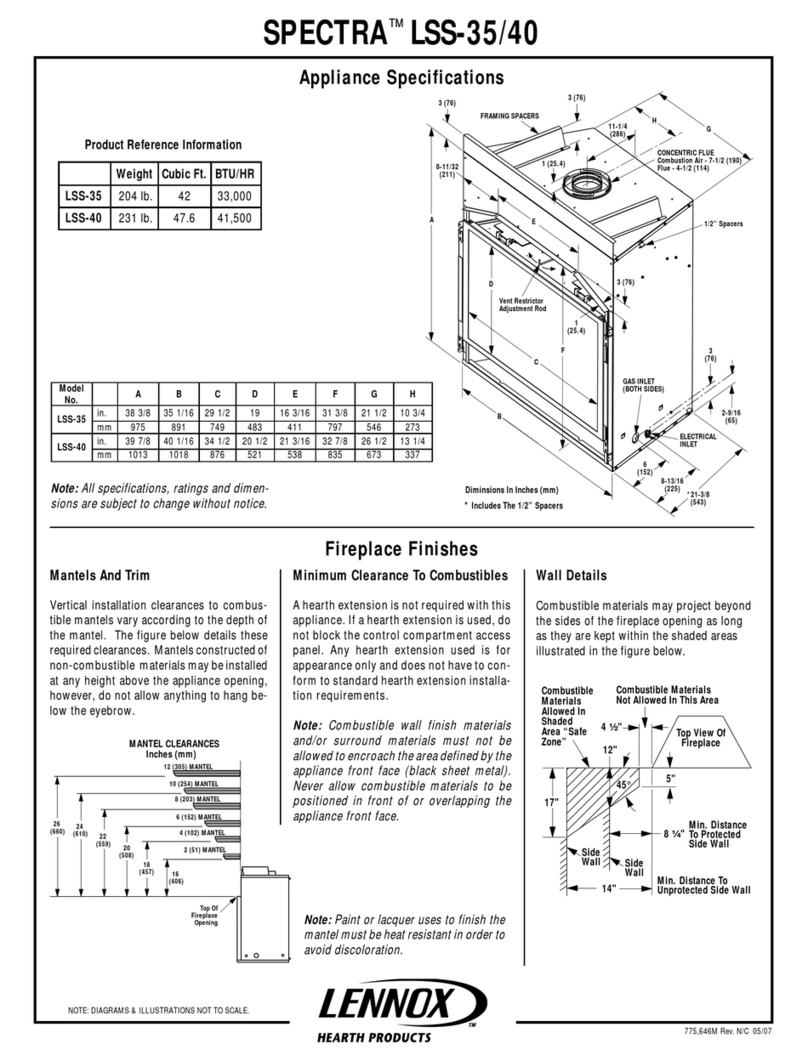

Lennox Hearth Products

Lennox Hearth Products SPECTRA LSS-35 Detailed Planning Dimensions

Charnwood

Charnwood ARC 7 Operating & installation instructions

Quadra-Fire

Quadra-Fire COLBAY-INS owner's manual

Valor

Valor BR622 owner's guide

Desa

Desa (V)DVF36 OWNER'S OPERATION AND INSTALLATION MANUAL

Touchstone

Touchstone 80018 owner's manual

Empire

Empire VFP36SB2EL-2 Installation instructions and owner's manua

hergom

hergom STILKAMIN S-460 Installation, use and maintenance instructions

Vermont Castings

Vermont Castings DFS3224A Installation and operating instructions

Twin-Star International

Twin-Star International 26MM4155 Instruction manual enclosed