Operating Manual CMGZ411/421

6

4Controller theory

Web tension control loops

When manufacturing and processing foils, wires, ropes, paper and fabric sheets, it is important that the product is under

constant tension when guided over the cylinders. Tension may change when humidity, temperature, winding or

unwinding diameters vary or when the material is being printed, coated, glued or pressed.

Tension is measured constantly and maintained at the correct value with the FMS force measuring and control system.

The system includes the following components:

- Force measuring bearings or Force measuring rollers for mechanical / electrical conversion of the force

- Amplifier providing the excitation and the amplifier for the mV signal of the sensors (integrated in CMGZ411).

- Control unit for the comparison of tension reference and feedback value and the PID controller.

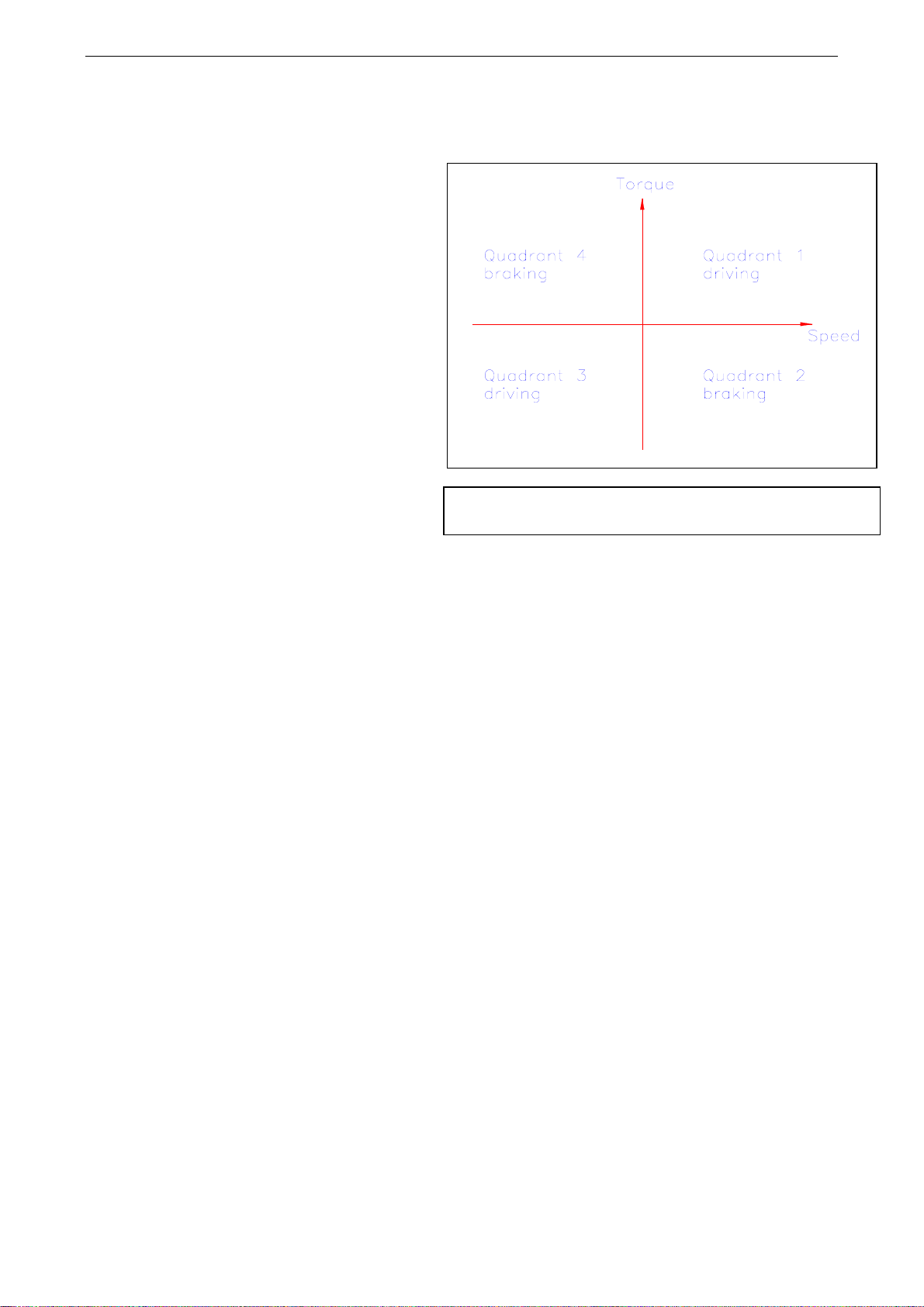

The output of the tension control unit drives either an electrical brake or a pneumatic brake via an electric/pneumatic

converter or an electric drive as a 1-quadrant or 4-quadrant model version. With a 4-quadrant electric drive, the tension

control unit is able to hold constant tension in both rotational directions as well as at standstill. As a tension control

loop prevents waste and tear of the band, this is a very economical solution for any kind of band material. The version

with compact steel housing (CMGZ411.E/421.E) allows to build a control system easily.

Control Unit

The function of any control loop is to maintain the feedback value exactly at the level of the reference and to minimize

the influence of any interference on the control loop.

In addition, the control loop must be stable under all operating conditions. These aims can only be achieved if the

dynamic behaviour of the control loop is adapted to the machine.

P Component

A controller with only a proportional component emits an output

signal that is proportional to the error. If the error equals to zero, the

output signal also equals to zero. A small error only can create a

small output signal which is not high enough to compensate the

complete error. That means that a controller with only a proportional

component will have a steady error depending on the p factor. The

characteristic value for a P controller is the proportional factor Xp.

I Component

A controller with an integral component integrates the error signal

continuously and emits the result as an output signal. The I controller

adds also very small differences between reference and feedback to

the output signal and thus, the output is adjusted until the error equals to zero. This output value is maintained until a

new error occurs. The integral component therefore allows zero error in steady state. The characteristic value for an I-

controller is the time Tn.

D Component

A controller with derivative component emits an output signal corresponding to the differentiated error signal.

Therefore, the value of this signal is proportional to the changing speed of the error signal. If the feedback value

deviates from the reference, the derivative component increases much faster than the proportional component. The

controller is able to react when even a small error occures, because it reacts already to a slightly changing error signal.

The characteristic value for a D controller is the time Tv.

Advantages of digital controllers compared with analog controllers

Digital controllers have exactly reproducible behaviour, because every parameter is known as an exact number. They

thus have very good long-term and temperature stability. This feature also allows one to interchange two units without

readjustments at the unit.

The initial adjustment usually is much easier, because numerical values are entered and no potentiometers have to be

turned a few degrees.

Digital units usually have a standard interface to a PLC, personal computer or other equipment. That makes it very easy

to integrate them into complex control systems. This concept simplifies initial operation and maintenance and allows

easy changement of some parameters when the processed goods are changing, etc.

Diagram:Step response of a PID

controller