Installation Manual RMGZ200

17.01.2017 8

4Design and Functionality

4.1 Functional Description

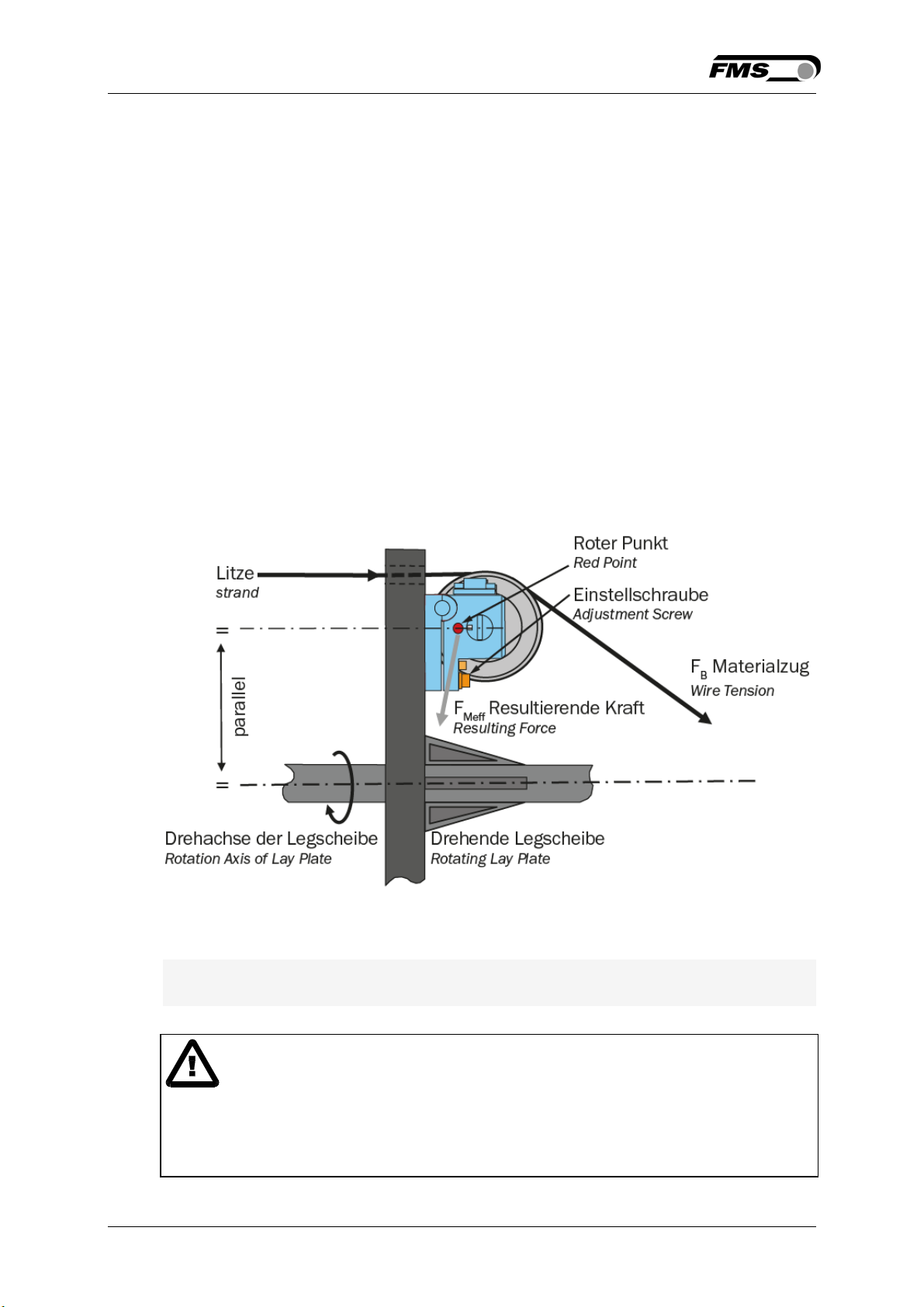

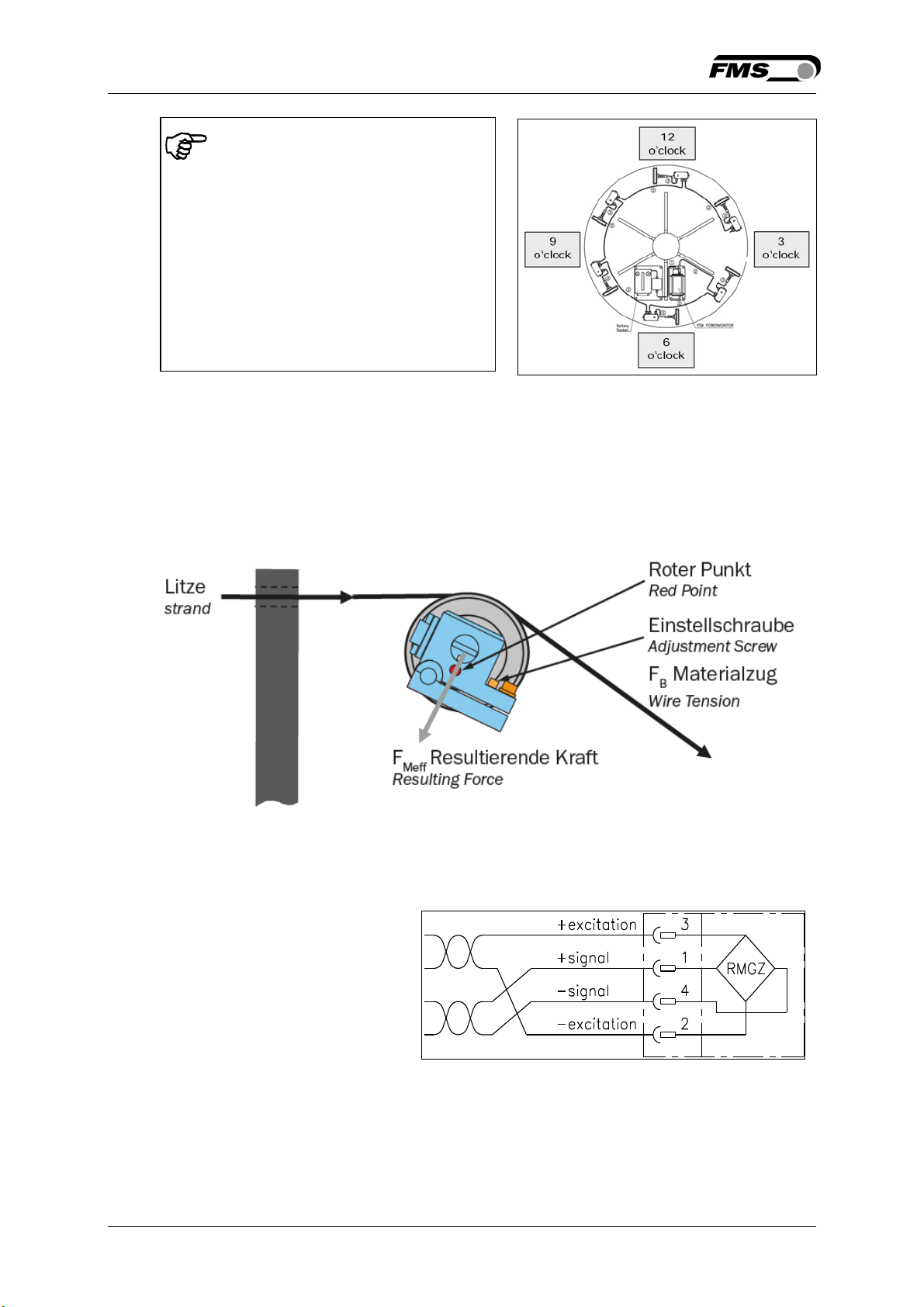

The Force Measuring Roller RMGZ200 series is used to measure the material

tension in wire and cable producing machinery such as planetary cage, tubular,

rigid frame stranding machines, bunchers and twisters. Its basic design is that of

the RMGZ100B sensor but incorporating an accurate mechanism for the “Red

Point” adjustment.

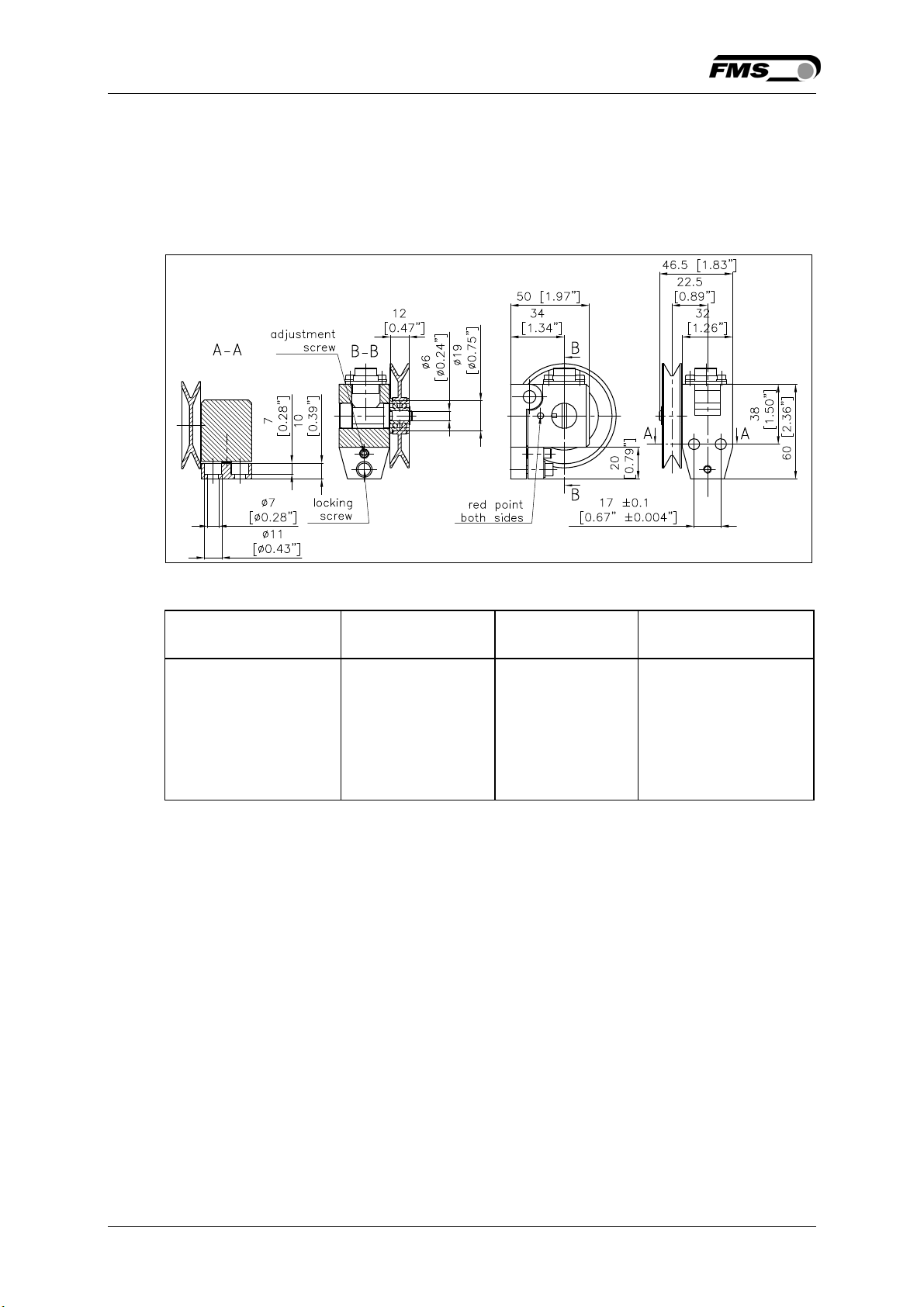

The Force Measuring Roller is equipped with two lifetime lubricated deep groove

ball bearings. The customer specific sheave is mounted to them. The RMGZ200

works according to the principle of a dual flexion beam design. A quadruple foil

type strain gauge mounted in a full Wheatstone bridge configuration performs

the actual tension measurement. Overload protection devices prevent

deformation of the wires caused by overload. The load must always be applied in

the middle of the two bearings to ensure reproducible measuring results.

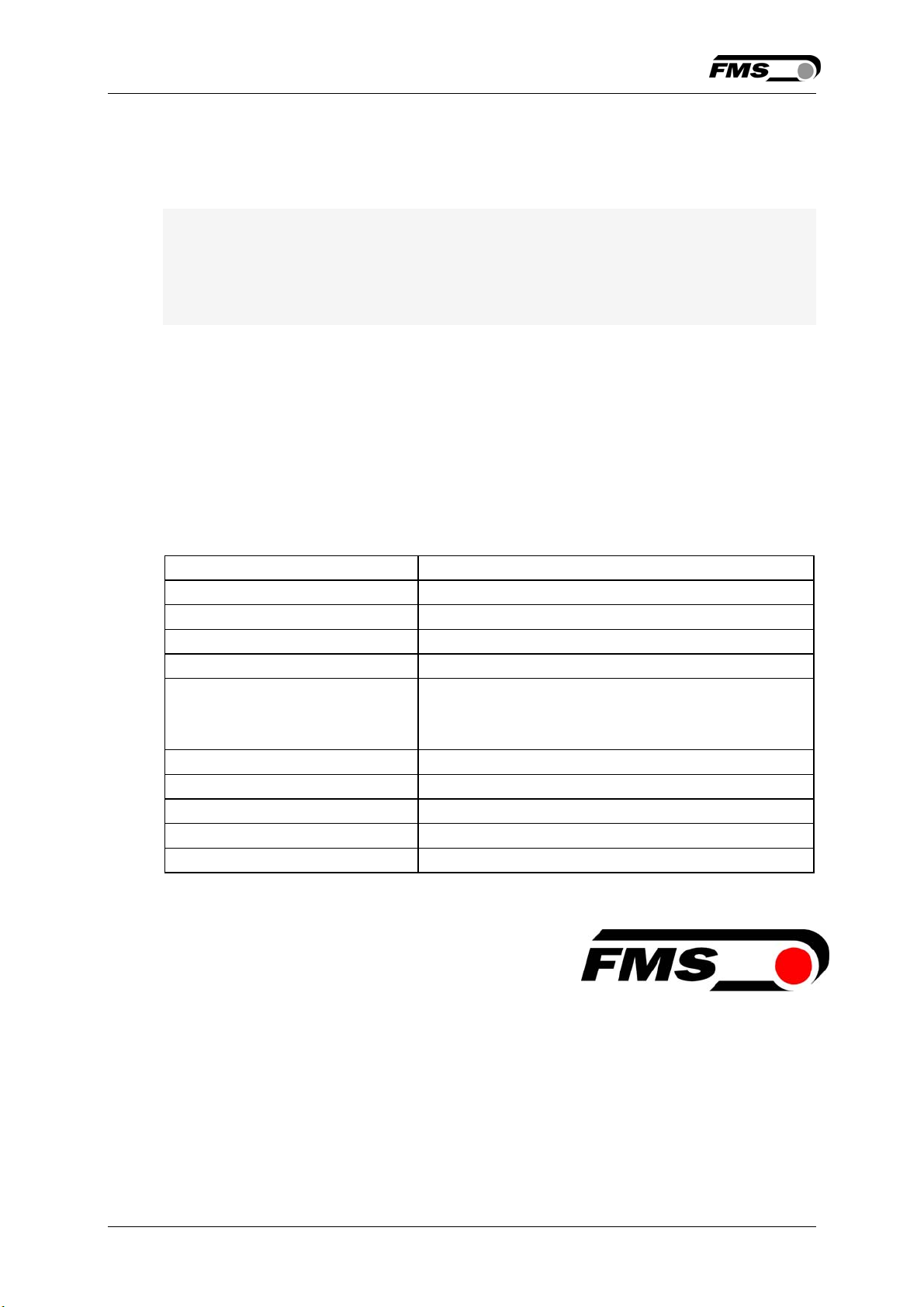

4.2 Technical Data

Sensitivity 1.8mV/V

Tolerance of sensitivity < ±0.2%

Accuracy class ±0.5%

Load rating of bearing C dynamic. = 4.61 kN [1036 lbf]

Temperature coefficient ±0.1% / 10K [±0.0055% / °F]

Temperature range –10...+60°C [14...140°F]

Option H16:

–10...+120°C [14...248°F]

Input resistance 350 Ω

Supply voltage 1...12VDC

Overload protection > 10 times nominal force

Protection class Protected against dust (IP42)

Sensor Material Stainless steel

FMS Force Measuring Systems AG

Aspstrasse 6

8154 Oberglatt (Switzerland)

Tel. +41 44 852 80 80

Fax +41 44 850 60 06

www.fms-technology.com

FMS Italy

Via Baranzate 67

I-20026 Novate Milanese

Tel: +39 02 39487035

Fax: +39 02 39487035

fmsit@fms-

technology.com

FMS USA, Inc.

2155 Stonington Ave. Suite 119

Hoffman Estates, IL 60169 USA

Tel. +1 847 519 4400

Fax +1 847 519 4401

FMS UK

Highfield, Atch Lench Road

Church Lench

Evesham WR11 4UG, Great Britain

Tel. +44 1386 871023

Fax +44 1386 871021