FMT 18115 User manual

Operating Instruction

Digital Grease Meter

Art.no. 18 115

82 319 A801

2

GOperating Instruction Digital Grease Meter

3

Operating Instruction Digital Grease Meter G

Content

General details1. ______________________________________________________________________4

History of documents1.1. _________________________________________________________________4

Intended operation1.2. __________________________________________________________________4

Construction and description of operation1.3. ________________________________________________4

Technical details1.4. _____________________________________________________________________4

General safety advises2. ________________________________________________________________5

Advises for the saftey at work2.1. __________________________________________________________5

Explanation of the saftey advises2.2. _______________________________________________________5

Safety advises for the correct handling of the grease meter2.3. __________________________________5

Mounting3. __________________________________________________________________________5

Installation4. _________________________________________________________________________6

Daily use5. ___________________________________________________________________________6

Measuring details5.1. ____________________________________________________________________6

Operation /Function5.2. __________________________________________________________________6

Activating5.3. __________________________________________________________________________6

Switch-o5.4. __________________________________________________________________________6

Main display5.5. ________________________________________________________________________6

Total5.6. ______________________________________________________________________________6

Partial volume5.7. ______________________________________________________________________6

Termination by timeout / switch-o5.8. _____________________________________________________7

Calibration6. _________________________________________________________________________7

Registration of the actual value6.1. _________________________________________________________7

Change of the preset K-factor6.2. __________________________________________________________7

Reset of the calibration factor to factory value (1.000)6.3. _______________________________________7

Wartung7. ___________________________________________________________________________8

Auswechseln der Batterien7.1. ____________________________________________________________8

Reinigung7.2. __________________________________________________________________________8

Troubleshooting8. _____________________________________________________________________9

Repair/service9. _______________________________________________________________________9

Manufacturers declaration10. _____________________________________________________________9

Explosion drawing11. __________________________________________________________________10

Parts list12. ___________________________________________________________________________11

4

GOperating Instruction Digital Grease Meter

General details1.

History of documents1.1

Date Name Version Modication

24.04.2009 TK 1.00 Creation

10.06.2009 TK 1.01. Re-designed after completition

19.02.2009 KN 1.02 Revise of programming

15.04.2010 TK 1.03 Extended manual K-factor calibration,

time-controlled reset to TOTAL

Intended operation1.2

The grease meter has been developed and constructed for accurate measurement and registration of

volumes of various greases.

The grease meter is designed for the use with manual grease guns and grease supply systems.

Construction and description of operation1.3

The grease meter is designed as an oval-gear meter with an integral electronic counting mechanism

and a digital display.

The ow of grease rotates the oval gear-wheels transferring utilising a Reed-switch the impulses to

the electronic counting mechanism. The impulses will be converted based on a pre-set factor into the

eective volume and indicated on the display.

The factor is pre-set by the manufacturer on an average volume which can be individually adjusted to

a user oriented calibration by use of a key combination.

The total volume will be registered as well and can be controlled pressing the pushbutton (TOTAL).

For the operation use two membrane-keybuttons only. Reset and TOTAL.

Technical details1.4

Description

Connection 1 G 1/8 " female

Connection 2 G 1/8 " female

Designed for use with greases NLGI 1-2

Units Calibratable in litres or cm³

Performance 0-1000 cm³/min

Max. operating pressure (bar) 700

Burst pressure (bar) 1000

Temperature range (°C) -20/+60

Material of housing Aluminium

Repeat accuracy 0-300 bar ±1%

Display partial volumes and totalisator

Height of digits 13 mm

Power supply (V) 2,3 – 3,3

Power consumption (A) max. 800 μA

Batteries 2 pcs.

Type of batteries 1,5V Lady LR1

Life time of battery approx. 2 years

5-digits display, partial volume and totalisator, resettable

Dimensions LxWxH (mm) 85x73x57

Weight (kg) 0,3

5

Operating Instruction Digital Grease Meter G

General safety advises2.

Advises for the saftey at work2.1

The grease meter has been designed and manufactured with respect to the general safety and health

requirements of the relevant EU directives.

However this product might be dangerous if it is not operated according to the intentions of the

product or with the required care.

The grease meter should be operated according to the local safety regulation and rules for accident

prevention of this operating instruction in any case.

Explanation of the saftey advises2.2

The safety advise in this operating instruction indicates following grade of danger. This grade of danger is

indicated with following signal word and pictogram.

Pictogram Signal word Consequences, in case saftey instructions will not be observed

Attention Potential light or medium personal injuries or damages

Moreover an additional advise oering general recommendations for the operation of the product can be

utililized.

Pictogram Signal word Meaning

Advice Background knowledge or advises for the correct use of the product.

Safety advises for the correct handling of the grease meter2.3

Attention!

The grease meter is designed to be used with ame resistant greases only.

Do not use the grease meter in explosive ambiance.

Advice

Please make sure that any grease supply system utilizing the grease meter is assembled and

operated according to local regulation.

For maintenance and operation please refer to local regulation.

Mounting3.

The grease meter will be supplied completely assembled.

Depending on the version supplied accessories must be mounted possibly.

Advice

Look out for a clean mounting and pay attention to a careful and exact thread connection and

sealing.

6

GOperating Instruction Digital Grease Meter

Installation4.

The grease meter shows a straight inlet and outlet with G 1/8“ female thread connection on both sides.

The grease meter can be installed in any position, as part of a xed in-line installation or as a mobile

installation connected to a grease gun.

The grease meter is preset to a xed ow direction. Both connections can be utililized as inlet or as outlet.

Daily use5.

Measuring details5.1

A change of the measurement units is not provided. The measurement will be eected based on a

special relation of impulses to the displayed volume. Based on this the displayed volume will be shown

accordingly. This is an unchangeable part of the rmware and denes the measuring unit. Volume units

will be measured. It makes sense therefore to dene the units in cm³ or litres. Units in KG are optional

requiring a constant density of the grease to be measured. The release is (a decimal point will be preset):

Partial volume: Display 0000,0 cm³, this means 0,1g or 0,1 cm³.

Exceeding of 9999,9 cm³ the release will change to 1 cm³

Total: Display 00,000 TON (1000 l), this means 0,001 – 1 l or 1000 cm³

When exceeding the measurement totals the decimal point will be adjusted accordingly.

The display symbol“L“ stands for“TON“ or 1000 l,“I“ for gramme or cm³

Operation /Function5.2

See the description of the function in the following.

Explanation of the pushbuttons:

RESET Press the right pushbutton labelled with‚RESET‘ for a short time

RESET press for a long time. Press the right pushbutton longer than 1 sec.

TOTAL Press the left pushbutton labelled with‚TOTAL‘ for a short time

TOTAL press for a long time. Press the left pushbutton longer than 1 sec.

RESET + TOTAL simulteaneous longer pressing (1 sec) of both pushbuttons.

Activating5.3

The meter will be activated automatically when pressing any pushbutton or a measuring process starts.

When activating the meter by pressing of a pushbutton the previous measuring result will not be deleted.

Switch-o5.4

The meter automatically switches to stand-by mode after an inactivity of 10 minutes

Main display5.5

The meter can display“partial volume“ or “total volume“ (TOTAL) alternatively. The pushbutton TOTAL

alternates between the bothe displays“Total“ and “partial volume“. The symbol “TOTAL“ activates

automatically in the display depending on the volume requested. The pushbuttons are blocked for 3

seconds when measuring (continuous display, measuring impulses).

Total5.6

This display shows the symbol TOTAL. The grease meter adds the total of all measurements with max.

3 decimal places. The decimal point when starting a measuring process starts with“0,000“ and will be

adjusted automatically depending on the volume to be measured. The displayed volume can be reset

by pressing of the pushbutton RESET for long time. TOTAL short switches to the display“partial volume“.

RESET short switches to display“partial volume“ and delets the displayed partial volume for a new

measuring process.

Partial volume5.7

In this display the symbol TOTAL is not visible. The counter“partial volume“ accounts the current

measurement with one decimal. The decimal point will be adjusted to the display and starts with “0,0“.

7

Operating Instruction Digital Grease Meter G

The pushbutton TOTAL switches the display to TOTAL.

RESET short resets the counter partial volume back to zero to start a new measuring process. The partial

volume will be displayed automatically when dispensing. 5 seconds after dispensing or after the manual

switch to partial volume (using TOTAL short) the display will automaticlly reset to Total.

Termination by timeout / switch-o5.8

The main display switches o after 10 minutes activating the stand-by mode automatically, if not re-

activated by pressing a pushbutton or a starting measuring process.

Calibration6.

Registration of the actual value6.1

RESET + TOTAL simulteaneous longer pressing (1 sec) of both pushbuttons activates the calibration mode.

The symbol“Cal“ appears. The display switches to“partial quantity“ resetting the display to 0,0.

A denite volume can be dispensed acting furthermore as actual value.

RESET short resets the partial volume dispensed at any time to repeat the measuring process.

RESET long terminates the calibration.

TOTAL long stores the volume dispensed. The last digit (right) starts blinking.

RESET short highlights the blinking digit or resets 9 to zero.

TOTAL short stores the value of the digit and switches to the next digit

begining to blink going back to the last digit on the right.

TOTAL long stores the preset value as nominal value and calculates the K-factor showing it for 1 second

before changing to the main display again.

Change of the preset K-factor6.2

RESET + TOTAL simulteaneous longer pressing (1 sec) of both pushbuttons activates the calibration mode.

The symbol“Cal“ appears. The display switches to“partial quantity“ resetting the display to 0,0.

A short pressing of TOTAL shows the preset calibration factor.

RESET short highlights the blinking digit or resets 9 to zero.

TOTAL short stores the value of the digit and switches to the next left digit starting to blink. It possibly

switches back to the last right digit.

TOTAL long stores the preset value as new K-factor showing it for 1 second before switching back to main

display.

RESET long terminates the calibration and returns to main display..

Reset of the calibration factor to factory value (1.000)6.3

RESET + TOTAL simulteaneous longer pressing (1 sec) of both pushbuttons activates the calibration mode.

The symbol“Cal“ appears. The display switches to“partial quantity“ resetting the display to 0,0.

Long pressing of pushbutton TOTAL starts the last (right) digt blinking.

RESET + TOTAL simulteaneous longer pressing (1 sec) of both pushbuttons resets to the factory preset

calibration: K = 1.000.

This calibration factor will be shown for 1 second. After that it switches back to the main display.

The calibration will be terminated without storing if no action takes place in 30 seconds.

8

GOperating Instruction Digital Grease Meter

Maintenance7.

The grease meter is designed for a utilization requiring low maintenance eorts, only. See the following

details:

Exchange of empty batteries.

Exchange of batteries7.1

The meter will be supplied with two 1,5V alcaline batteries.

Attention!

Please dispose the empty batteries according to local regulation, only.

For changing of batteries proceed as follows (Reference to the position of the spare parts list):

Remove the locking screw (pos. 17).

Remove the empty batteries.

Replace the old batteries by the new ones. Take care that the position of the positive pole corresponds

the illustration of the explosion drawing.

Tighten the locking screw carefully. Take care for a correct re-positioning of the O-ring (pos. 16) and of

the spring (pos. 15).

The meter re-starts automatically. The normal operation can be started again.

After the change of the batteries all data for resetable dispensed volumes, for total and for partial volumes

will be displayed as before.

The meter will utilize the same calibration factor after the change of the batteries or after an electrical

power blackout as before. The is no re-calibration reqired.

Cleaning7.2

The metering chamber of the grease meter can be cleaned even if the meter is connected to a grease gun

or installed in a grease distribution line.

Attention!

Take care a every time that the meter is not perssurized prior to any cleaning process.

Die Reinigung der Kammer erfolgt folgendermaßen (Verweis auf die Position der Ersatzteilliste):

For cleaning of the meter proceed as follows ((Reference to the position of the spare parts list):

Remove the four screws of the lower cover (pos. 13).

Remove the cover (pos. 12) and the O-ring (pos.10)

Take out the oval gear wheels (pos. 9).

Proceed with the cleaning. We recommend the use of a suitable brush or of a pointed tool, i.e. a small

screw driver.

Clean carefully so the gear wheels will not be damaged.

For the re-assembly follow the a.m. advises vice versa.

Attention!

Take care for a correct re-assembly of the gear wheels (see explosion drwaing).

9

Operating Instruction Digital Grease Meter G

Troubleshooting8.

Fault Reason Solution

LCD: no display Losse connection of batteries. Check of battery contacts.

Unsucient measuring accuracy Incorrect K-factor Check of K-factor see part

6.3

Unsucient or no dispensing volume Blocked gear wheels Clening of measuring

chamber

The meter does not account — the

dispensing volume is normal.

Incorrect installation of gear wheels

after cleaning

Repeat of the re-

installation steps

Possible problems with the electronic

card.

Contact your dealer

Repair/service9.

The grease meter has been designed and manufactured with respect to the highest quality standards.

Should a quality problem appear despite of all qualtity precautions please contact our customer’s service.

FMT Swiss AG

Tel +49 9462 17-216

Fax +49 9462 1063

Manufacturers declaration10.

We herewith declare, that the product described in the following has been designed in the manufactured

version according to general regulation. If the product is not used according to its intention this

declaration will automatically loose its validity.

Product Oval gear wheel meter

In accordance with the regulation: 89/336/EWG (electromagnetic compatibility)

and the following adjustments

Relating European regulation EN 61000-6-1

EN 61000-6-3

EN 55014-1-2000

EN 55014-2-97

26.05.2010 FMT Swiss AG

Dipl.-Ing. Rudolf Schlenker

10

GOperating Instruction Digital Grease Meter

Explosion drawing11.

1

3

4

2

5

6

8

10

11

12

13

14

15

16

17

19

18

7

9

20

11

Operating Instruction Digital Grease Meter G

Parts list12.

Nr. Quantity Description Art. No.

11 Rubber protection 84 548

21 Display protection 82 305

3 2 Lens head screw M3x6 85 572

42 Buttons 85 600

51 Blank 84 219

61 Housing 82 310

72 Cylinder bolt 3m6x16 82 315

8 2 Magnets 03 003

92 Oval gearwheel 82 314

10 1 O-ring 24 x2 87 224

11 2 Cylinder bolt 4m6x10 82 316

12 1 Cover 82 311

13 4 Cylinder head screw M6 x12 82 317

14 2 Battery LR1 Lady 88 431

15 1 Compression spring 0,6 x 4,6 – 8,6 x 9 03 181

16 1 O-ring 11 x 1,5 87 406

17 1 Locking screw 82 318

18 1 Retention G1/8 " i - M10x1 a 12 016

19 1 Angled spout 2 x R1/8 " male 02 427

20 1 Retention R1/8 " a - M10x1 female 12 086

FMT Swiss AG

Fluid Management Technologies Swiss AG

Gewerbestraße 6

6330 Cham / Schweiz

Tel. +41 41 712 05 37

Fax +41 41 720 26 21

info@fmtag.ch

www.fmtag.ch

Table of contents

Other FMT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Allendale Electronics

Allendale Electronics AE-MAN-DS user manual

SMA

SMA SUNNY HOME MANAGER 2.0 Quick reference guide

Elcomponent

Elcomponent AEM33 instructions

TESTO

TESTO 108 instruction manual

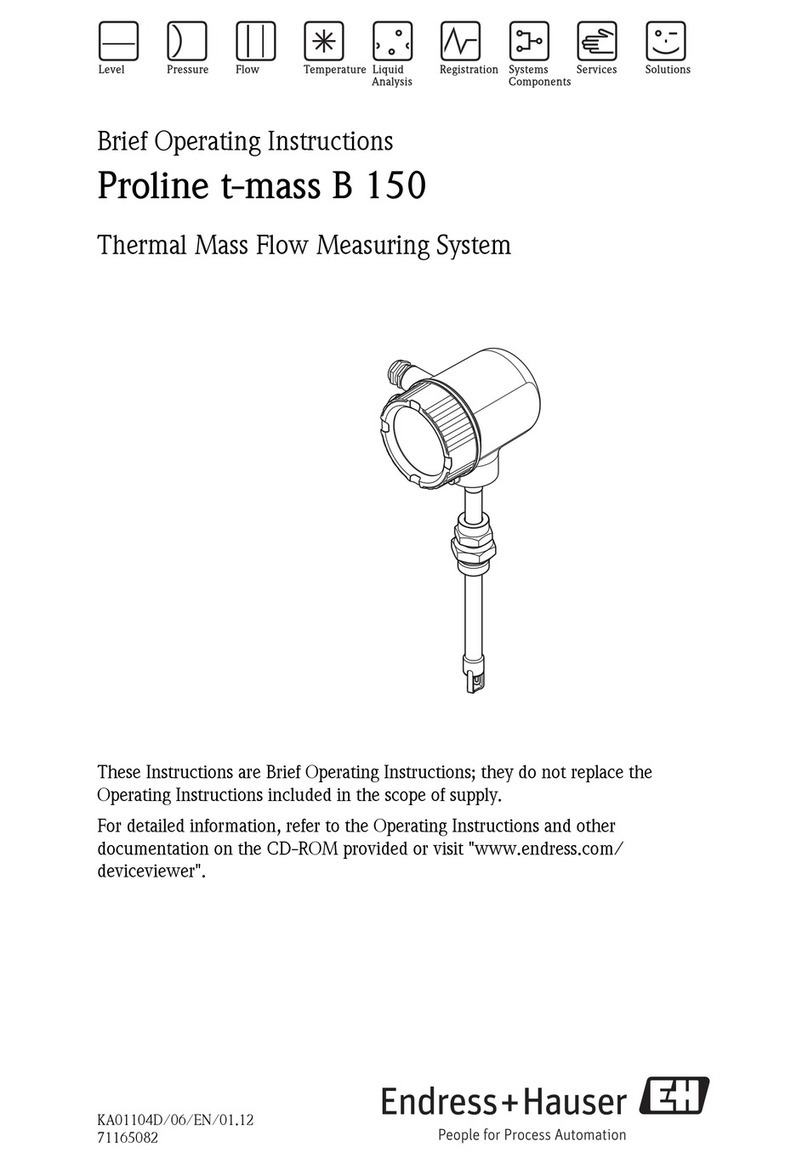

Endress+Hauser

Endress+Hauser Proline t-mass B 150 Brief operating instructions

multicomp pro

multicomp pro MP780859 quick start guide