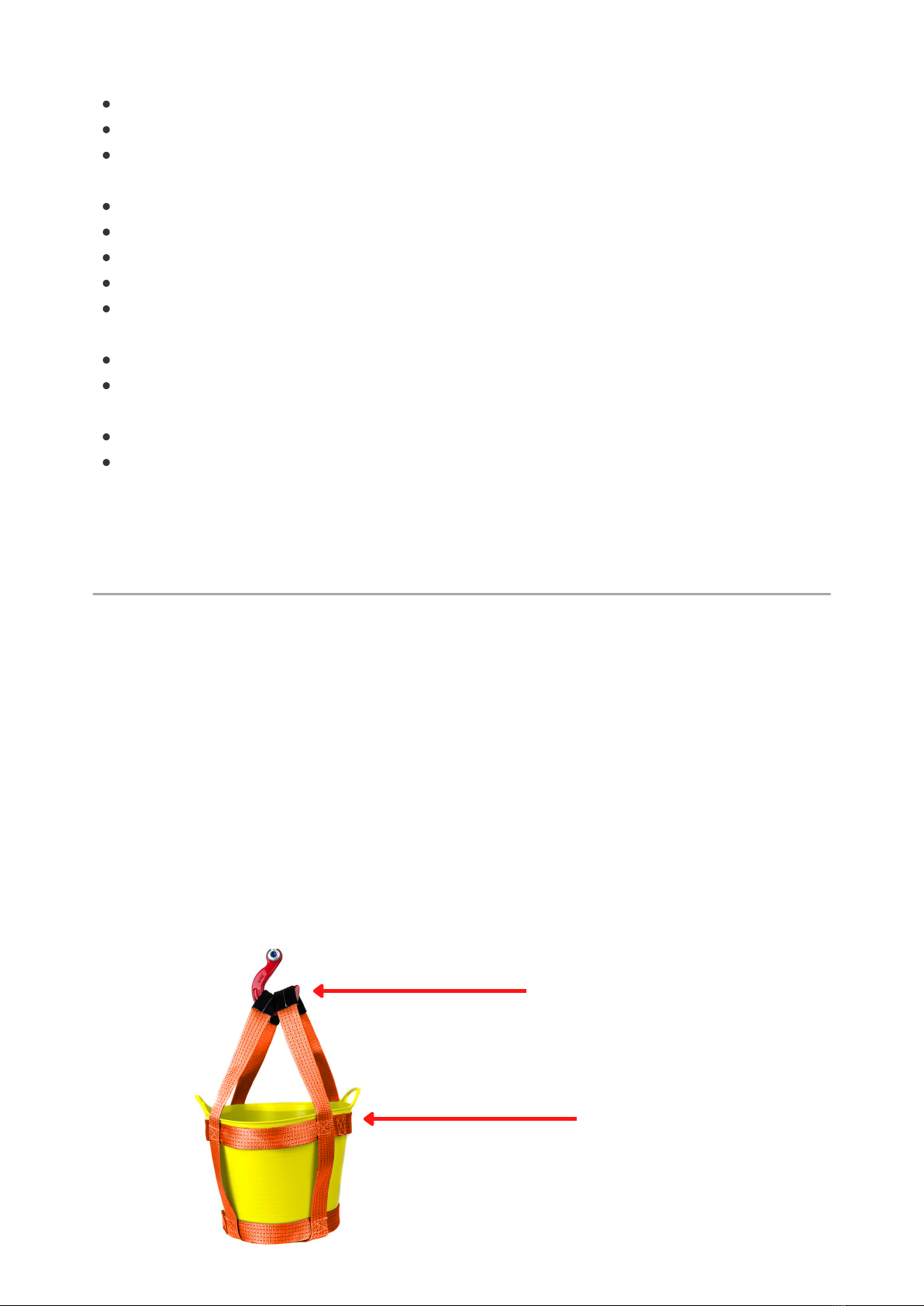

SAFETY INFORMATION

Label is missing or not readable

Holes, tears, cuts, snags or embedded materials.

Broken or worn stitches.

Knots in any parts of the strap

Acid or alkali burns

Melting, charring or weld spatter

Excessive abrasive wear

Signs of UV light degradation

Distortion, excessive pitting, corrosion

Any condition that causes doubt as to the strength of the strap

1. ALL BUCKET STRAP USERS MUST BE TRAINED AND KNOWLEDGABLE.

All bucket strap users must be properly trained on the proper use of strap, its

selection, inspection, cautions to personnel, effects of the environment and safe

lifting practices. It is important that all strap users be knowledgeable about the safe

and proper use and application of strap and be thoroughly familiar with the

manufacturer's recommendations and safety materials provided with each product.

If you are unsure whether you are properly trained and knowledgeable DO NOT USE

the bucket strap as lack of skill, knowledge and care can result in severe INJURY or

DEATH to you and/or others.

2. BUCKET STRAP MUST BE REGULARLY AND PROPERLY INSPECTED.

Even a minor damage to bucket strap can significantly reduce its capacity to hold or

lift objects and pose the risk that strap will fail during use. Therefore it is very

important that bucket strap is regularly and properly inspected before and after use

to ensure it meets all the requirements for its intended use. If you are not sure

whether strap is damaged DO NOT USE IT. You should perform a visual inspection of

the entire strap and also feel along the entire length, as some damage may be felt

more than seen. You should look and feel for any of the types of conditions listed

below, and if any are detected you MUST remove bucket strap from service.

Bucket strap must be removed from service if ANY of the following are detected:

If you identify ANY of these types of damage in a strap, remove it from service

immediately, even if the damage you see or feel is not very excessive. Straps that are

removed from service must be destroyed and rendered completely unusable. Never

ignore strap damage or attempt to perform temporary field repairs of damaged

strap. If you are not sure whether or not a strap is damaged DO NOT USE IT.

3. AVOID ACTIONS THAT CAUSE DAMAGE TO THE STRAP.

You should always avoid action that causes the types of damage identified above,

including:

6