IMT 12916 User manual

Manual # 99905833

Model 12916 Crane

Parts & Specifications

Effective August 2014

IOWA MOLD TOOLING CO., INC.

PO Box 189

Garner, IA 50438

Tel: 641-923-3711 FAX: 641-923-2424

Website: http://www.imt.com

Copyright © 2014 Iowa Mold Tooling Co., Inc.

All rights reserved

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording or otherwise without the

prior written permission of Iowa Mold Tooling Co., Inc.

Iowa Mold Tooling Co., Inc. is an Oshkosh Corporation Company.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

i

Contents

Revisions .................................................................................................................................................... iii

Introduction 5

Specifications 7

Model 12916 Specifications.........................................................................................................................8

Geometric Configuration............................................................................................................................10

Minimum Chassis Specifications for 12916 Crane ....................................................................................12

Reference 13

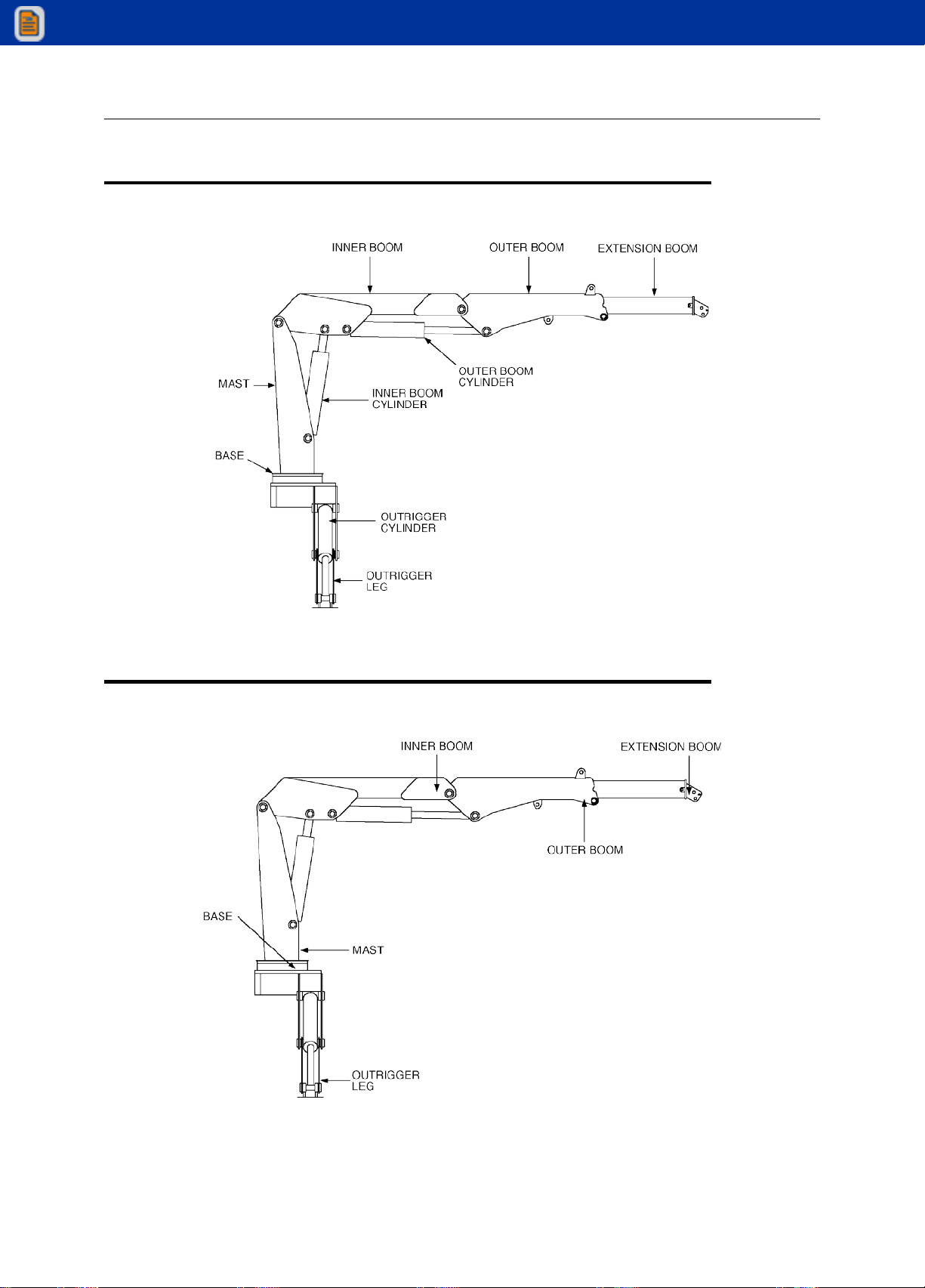

Major Crane Assemblies ............................................................................................................................14

Weldment Part Number Locations .............................................................................................................14

Grease Zerk Locations & Lubricant Requirements ....................................................................................15

Installation..................................................................................................................................................16

Parts 19

Parts Information........................................................................................................................................20

Base & Out Assembly (40725982).............................................................................................................22

Stabilizer Cylinder (3C283801)..................................................................................................................26

Mast Assembly (40725983)........................................................................................................................27

Inner Boom Assembly (40725984) ............................................................................................................28

Inner Cylinder (3C194614).........................................................................................................................29

Outer Boom Assembly (40725985)............................................................................................................30

Outer Cylinder (3C195613)........................................................................................................................32

Extension Boom Assembly (40725986).....................................................................................................33

Extension Cylinder (51718065)..................................................................................................................34

Hydraulic Diagram, Radio Remote (99905792).........................................................................................36

Hydraulic Diagram, Radio Remote (99905792).........................................................................................38

Relief Valve Assembly, 12V Radio (73055278)........................................................................................39

Control Kit – Manual 8 Function (90704441)............................................................................................40

Valvebank Assembly – 8 Section (51706642)............................................................................................42

Valvebank Assembly – 8 Section (51706643)............................................................................................43

Hydraulic Kit – 6 Section (91703946)........................................................................................................44

Hydraulic Overload Kit, 3-Function (51717130) .......................................................................................46

Electrical Control Cabinet (41718269-12V, 41718425-24V).....................................................................48

Electrical Control Box Assembly (41718269-12V, 41718425-24V) .........................................................50

Relay Fuse Box, 12V & 24V (77044935) ..................................................................................................52

Radio Remote.............................................................................................................................................53

Installation Kit-Manual Controls (93708876) ............................................................................................54

Decal Kit (95712299).................................................................................................................................56

Capacity Alert Kit – 2800 PSI (31717169) ................................................................................................58

Capacity Shutdown Kit – 2800 PSI (31717514).........................................................................................58

Light Kit – Crane Mast Mounted (51717977)............................................................................................59

Hydraulic Shutdown Kit (31713788) .........................................................................................................61

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

ii 12916 Parts & Specifications Manual #99905833

Option – Hook Assembly Kit (40726070)..................................................................................................63

12916 Recommended Spare Parts List.......................................................................................................64

General Reference 65

Inspection Checklist ...................................................................................................................................65

Deficiency / Recommendation / Corrective Action Report........................................................................70

Turntable Bearing Thread Tightening Sequence........................................................................................75

Turntable Bearing Inspection .....................................................................................................................76

Thread Torque Chart (English)...................................................................................................................78

Thread Torque Chart (Metric) ....................................................................................................................79

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

iii

Revisions

DATE

LOCATION

DESCRIPTION

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

5

This volume deals with information applicable to your particular crane. For operating,

maintenance and repair instructions, refer to Volume 1, OPERATION, MAINTENANCE AND

REPAIR.

We recommend that this volume be kept in a safe place in the office.

This manual is provided to assist you with ordering parts for your IMT crane. It also contains

additional instructions regarding your particular installation.

In addition to reading the manual, it is your responsibility to become familiar with government

regulations, hazards, and the specific operation of your equipment. Use caution and common

sense while operating and maintaining the equipment and follow all safety procedures and

regulations. Treat this equipment with respect and service it regularly.

MODIFICATIONS

Modifications to your equipment must be performed with IMT approved accessories, parts and

optional equipment. If in doubt, contact IMT prior to making any modifications. DO NOT alter or

modify any safety device! All safety devices must be inspected, tested and maintained in proper

working condition.

Decals regarding safety and operation are considered safety equipment, and must be kept clean

and legible.

The equipment owner and/or designated employee is responsible for informing all operators,

maintenance personnel, and others involved in equipment operation about the safe operation

and maintenance of the equipment. If questions arise concerning safe operation, contact IMT or

your IMT distributor for clarification.

WARRANTY

Warranty of this unit will be void on any part of the unit subjected to misuse due to overloading,

abuse, lack of maintenance and unauthorized modifications. No warranty - verbal, written or

implied - other than the official, published IMT new machinery and equipment warranty will be

valid with this unit.

NOTICE TO THE OWNER / USER

If your equipment is involved in a property damage accident, contact your IMT distributor

immediately and provide them with the details of the accident and the serial number of the

equipment. If an accident involves personal injury, immediately notify your distributor and IMT

Technical Support at:

IOWA MOLD TOOLING CO., INC.

500 HWY 18 WEST

GARNER, IA 50438

641 - 923 - 3711

CHAPTER 1

Introduction

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

6 12916 Parts & Specifications Manual #99905833

RESPONSIBILITY

It is the user’s responsibility to maintain and operate this unit in a manner that will result in the

safest working conditions possible. In addition, it is the user’s responsibility to be aware of

existing Federal, State, and Local codes and regulations governing the safe use and

maintenance of this equipment.

MANUAL STRUCTURE

Throughout this manual, three means are used to draw the attention of personnel. They are

NOTEs, CAUTIONs and WARNINGs and are defined as follows:

CAUTION

ACAUTION is used when there is the

very strong possibility of damage to the

equipment or premature equipment

failure.

WARNING

A WARNING is used when there is the

potential for personal injury or death.

NOTE

ANOTE is used to either convey

additional information or to provide

further emphasis for a previous point.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

7

In This Chapter

Model 12916 Specifications......................................................8

Geometric Configurations.........................................................10

Minimum Chassis Specifications ..............................................12

CHAPTER 2

Specifications

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

8 12916 Parts & Specifications Manual #99905833

Model 12916 Specifications

GENERAL SPECIFICATIONS

*CRANE RATING (ANSI B30.22)

129,000 FT-LBS

*MAXIMUM CRANE RATING

129,000 FT-LBS

HORIZONTAL REACH

from centerline of rotation

16’-2”

HYDRAULIC EXTENSION

40”

MANUAL EXTENSION

NONE

VERTICAL REACH

from mounting surface

23’-1”

VERTICAL REACH

from ground/41” frame ht.

26’-6”

CRANE WEIGHT

6,040 LBS

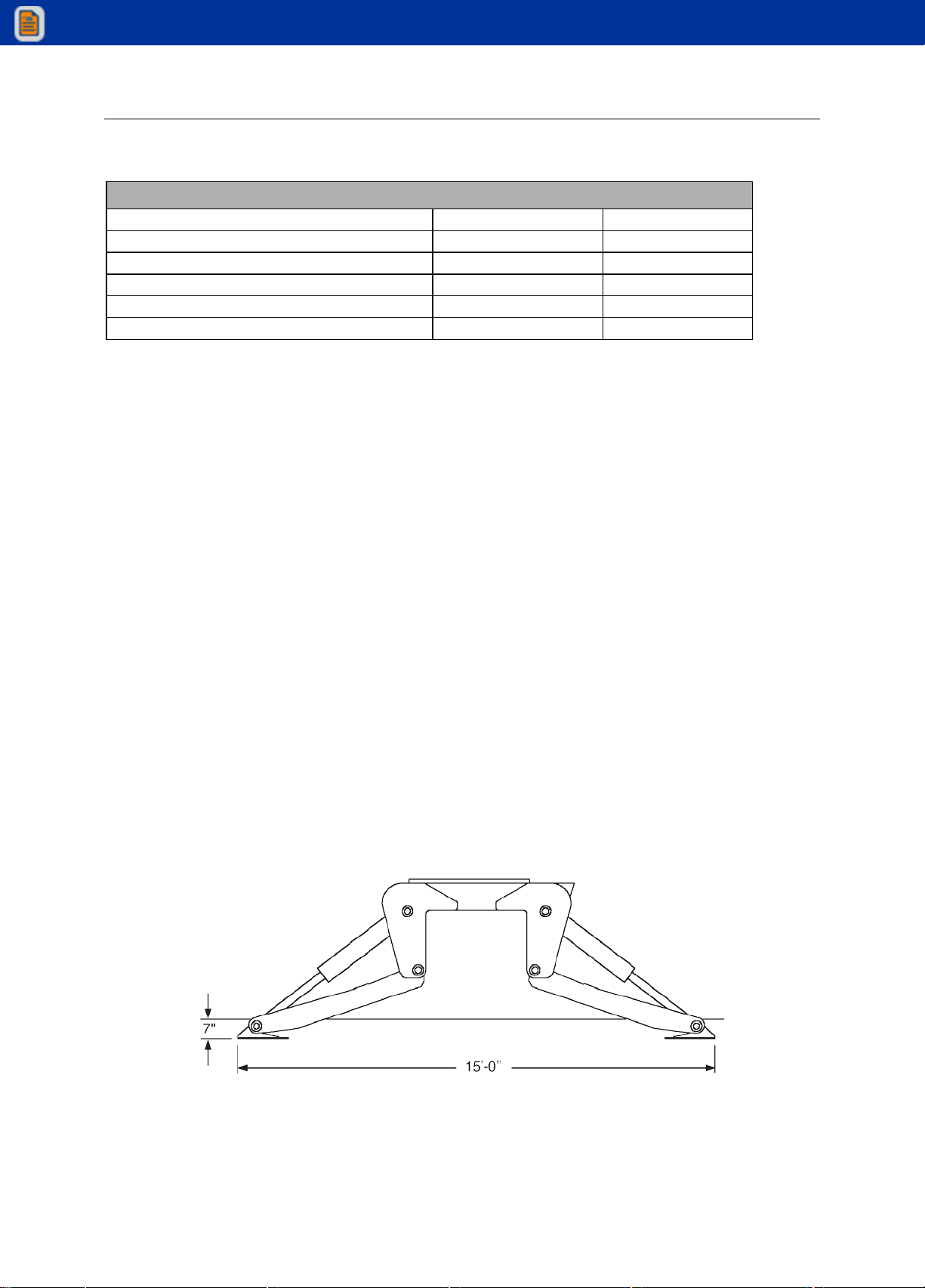

STABILIZER SPAN

15’-0”

STABILIZER PADS

12” X 19”

CRANE STORAGE HEIGHT

from mounting surface

8’-2”

CRANE STORAGE HEIGHT

from ground/41” frame ht.

11’-7”

**MOUNTING SPACE REQUIRED

32”

ROTATIONAL TORQUE

16,200 FT-LBS

OPTIMUM PUMP CAPACITY

13 U.S. GPM

SYSTEM OPERATING PRESSURE

2300 PSI

OIL RESERVOIR CAPACITY

21 U.S. GALLONS

HOOK APPROACH-HORIZONTAL

from centerline of rotation

5’-10”

HOOK APPROACH-VERTICAL

from mounting surface

9’-8”

* Maximum Crane Rating (ft-lbs) is defined as that rated load (lbs) which when multiplied by its respective distance

(ft) from centerline of rotation gives the greatest ft-lb value.

ANSI B30.22 Crane Rating (ft-lbs)= With all extensions retracted and inner plus outer boom in a horizontal position,

rated load (lbs) X respective distance (ft) from centerline of rotation = nominal ft-lb value.

** Allow an additional 3” between the cab and crane base for swing clearance.

IMT reserves the right to change specifications and design without notice. Where applicable, specifications are in

accordance with SAE standards and ISO/DIS 3691-1, the international standard for Industrial Trucks - Safety

Requirements and Verification.

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711 FAX: 641-923-2424

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 9

PERFORMANCE CHARACTERISTICS

SPECIFICATIONS

SPEED

CRANE ROTATION WITH TIREHAND

370°

45 seconds

INNER BOOM ELEVATION

-23° to +67°

25 seconds

OUTER BOOM ARTICULATION

112°

19 seconds

EXTENSION BOOM

40”

6 seconds

STABILIZER EXTENSION

29-1/4”

40 seconds

POWER SOURCE

Integral-mounted hydraulic pump and PTO application. Other standard power sources may be

utilized-minimum power required is 21 horsepower.

CYLINDER HOLDING VALVES

The holding sides of all cylinders are equipped with integral-mounted holding or counter-balance

valves to prevent sudden cylinder collapse in case of hose or other hydraulic failure. The

stabilizer cylinders have positive, pilot-operated holding valves that open only on command.

The inner cylinders have single pilot-operated counter balance valves while the outer and

extension boom cylinders have double counter-balance valves. The counter-balance valve

serves several functions. First, it is a holding valve. Secondly, it is so constructed that it will

control the lowering function and allow that motion to be feathered while under load. Finally, if a

hose breaks, the only oil loss will be that in the hose.

ROTATION SYSTEM

Rotation of the crane is accomplished through a turntable bearing, powered by a high torque

hydraulic motor through a ring and pinion type spur gear train. Total gear reduction is 56.7 : 1.

HYDRAULIC SYSTEM (PTO DRIVEN)

The hydraulic system is an open-centered, full-pressure system that requires 13 GPM optimum

oil flow at 2300 PSI. Eight-spool, stack-type control valve, six of which are used for the standard

crane and the remaining two are plugged, but easily adapted for additional optional features.

Dual operational handles for six functions are located at both sides of the crane for convenient

operation. System includes hydraulic oil reservoir, suction-line strainer, pump, 8-section control

valve, return-line filter and all hoses and fittings.

STABILIZER DIMENSIONS

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

10 12916 Parts & Specifications Manual #99905833

Geometric Configuration

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 2 Specifications 11

MODEL

CRANE

12916 EXTENSION

RETRACTED

SECONDARY

BOOM

POSITION

EXTENSION

BOOM

641-923-37 11

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

12 12916 Parts & Specifications Manual #99905833

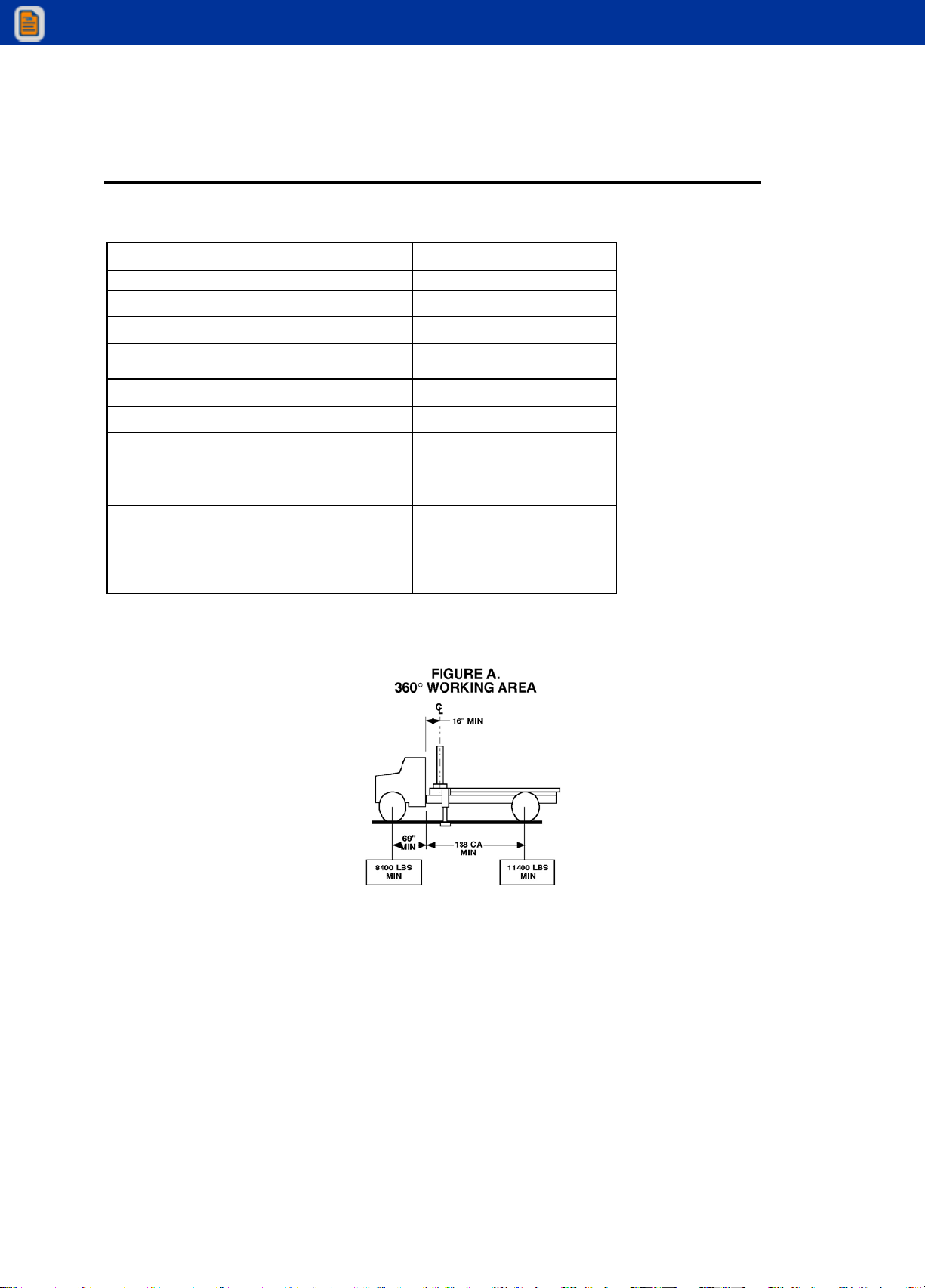

Minimum Chassis Specifications for 12916 Crane

CRANE MOUNT

Behind Cab

CRANE WORKING AREA

360°

CHASSIS STYLE

Conventional Cab

FRONT AXLE RATING (GAWR)

12,000 lbs

REAR AXLE RATING (GAWR)

Single Axle

21,000 lbs

WHEELBASE

207”

CAB-TO-AXLE

138”

OUTRIGGER WIDTH REQUIRED

15’-0”

RBM

Frame Selection Modules

Frame Yield Strength

1,664,000 in-lbs

26 cubic inches

50,000 psi

MINIMUM FINISHED UNIT WEIGHT TO

MAINTAIN VEHICLE STABILITY

Front Axle

Rear Axle

Total Finished Unit Weight

* 8,400 lbs

*11,400 lbs

19,800 lbs

*Allows lifting full capacity load in a 360° arc when crane in installed immediately behind the cab. Great

care should be taken when swinging the load from rear of vehicle to front of vehicle since the front axle

springs will compress, thus affecting the levelness of the vehicle.

NOTES:

1 GAWR means Gross Axle Weight Rating and is dependent on all components of the vehicle

such as axles, tires, wheels, springs, brakes, steering and frame strength meeting the

manufacturer’s recommendations. Always specify GAWR when purchasing a truck.

2 Minimum axle requirements may increase with use of diesel engines, longer wheelbase or

service bodies. Contact the factory for further information.

3 Weight distribution calculations are required to determine final axle loading.

4 All chassis and crane combinations must be stability tested to ensure stability per ANSI

B30.22.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

13

In This Chapter

Major Crane Assemblies ..........................................................14

Weldment Part Number Locations............................................14

Grease Zerk Locations & Lubricant Requirements ...................15

Installation................................................................................16

Crane Mounting........................................................................16

Hydraulic Installation ................................................................16

CHAPTER 3

Reference

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

14 12916 Parts & Specifications Manual #99905833

Major Crane Assemblies

Weldment Part Number Locations

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 3 Reference 15

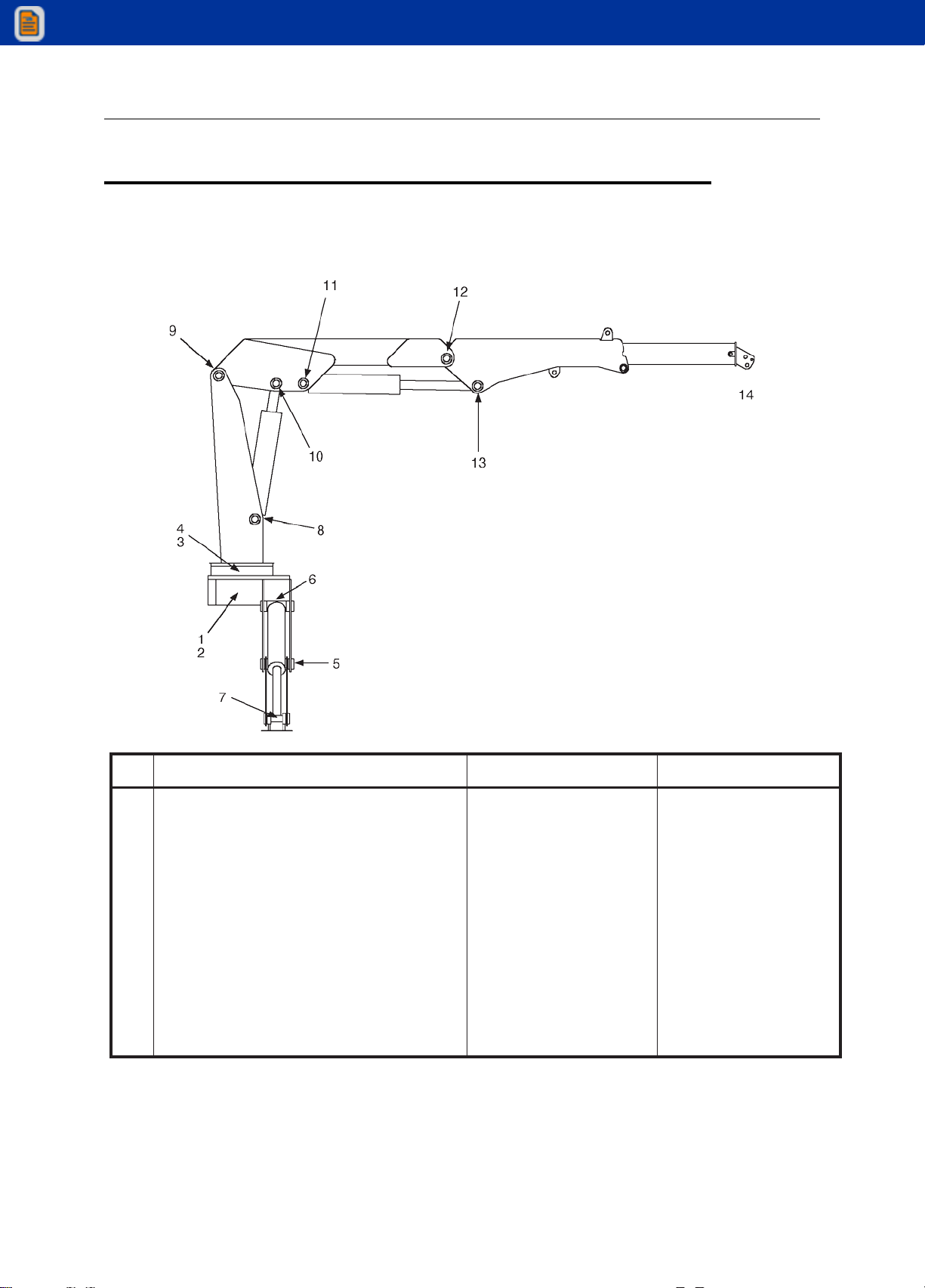

Grease Zerk Locations & Lubricant

Requirements

ITEM

LOCATION DESCRIPTION

LUBRICANT

FREQUENCY

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

TURNTABLE/BEARINGGREASEEXTENSION

*ROTATE CRANE WHILE

GREASING DRIVE GEAR

GREASE EXTENSION PINION

GEAR

PINIONCOVER

BASE/STABILIZERLEGHINGE

PIN STABILIZERCYLINDER

BASE STABILIZERCYLINDER

ROD INNER CYLINDER BASE

MAST/INNER BOOM HINGE

PIN INNER CYLINDER ROD

PIN OUTER CYLINDER BASE

INNER BOOM/OUTER BOOMHINGE

PIN OUTER CYLINDER ROD

ANY TIREHAND ATTACHMENT

SHELL ALVANIA 2EP

OR

SHELL RETINAX “A”

WEEKLY

NOTE: All application points must be greased weekly under normal workloads and moderate weather

conditions. Under severe operating conditions, lubrication should be performed more frequently. See Volume

1;Operation, Maintenanceand Repairforadditionallubricationrequirements.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

16 12916 Parts & Specifications Manual #99905833

Installation

GENERAL

This section contains specific instructions for the installation of your crane. Prior to installing the

crane and hydraulic components, make sure the chassis is ready to receive the crane (refer to

Volume 1, Installation).

CRANE MOUNTING

1. See SPECIFICATIONS in Section 1 for crane weight. Using an overhead hoist and

fabric slings of adequate capacity, lift the crane about a foot to see if the crane is

adequately balanced. If not, lower hoist and adjust slings. Re-check the balance and

reposition crane until mounting surface is level.

2. Install the truck frame support so that the tie-down studs pass through the supports

(Figure below). Cut the support to the inside dimensions of the truck frame. Allow about

1/16” extra. Grind the end of the support to fit inside the frame channel. Use a hammer

to drive it into position if necessary.

3. Allow sufficient clearance between the cab and crane base, at least 3” (7.6cm). Position

the crane on the chassis per the applicable installation drawing, centering the mounting

slots over the truck frame rails. While holding crane with hoist, start mounting hardware

per Figure. Note position of support weldments on truck frame. Hand-tighten nuts.

Observe underside of crane base. No clearance between base and frame is allowed.

4. Torque the 1 1/4”-7 UNC Grade 5 mounting hardware to 840 ft-lbs (116 kg-m). When

torqueing the mounting hardware the following precautions must be followed.

a. Never use lock washers.

b. Hardened washers must be used, and under the turning element, whether the

turning element is the nut or the head of the bolt.

c. Torque values specified are with residual oils or without special lubricants applied

to the threads. If special lubricants are used, such as Never-Seize compound

graphite and oil, molybdenum disulphite colloidal copper or white lead, reduce

torque values 10%. Torque values for threaded fasteners are not affected with

the use of Loctite.

d. Do not use rusty fasteners, the rust will alter torque values significantly.

CAUTION

Do NOT attempt toapply the same torque to

the tie rod and self-locking nuts as shown in

the torque data chart. Do NOT exceed 840

ft-lb (116 kg-m). Exceeding this torque value

could damage eitherthe chassis or crane

base.

Power wrenching is notrecommended until

the lead thread of the nutinsert is engaged

by hand turning.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Chapter 3 Reference 17

5. Install the tie-plate (Figure C-1) on the truck chassis. Drill four holes using the plate as a

template and install the bolts and lock nuts. Torque the bolts to 200 ft-lbs (28 kg-m).

Weld the tie-plate to the crane base with 3/8” continuous fillet weld.

6. Install the two tension bars with nuts and washers as shown. Tighten the outside nuts

first to about 200 ft-lbs (28 kg-m) to preload the tension bar. Then tighten the inner nuts

to 466 ft-lbs (65 kg-m).

7. Touch up paint on crane and chassis as necessary.

CRANE INSTALLATION

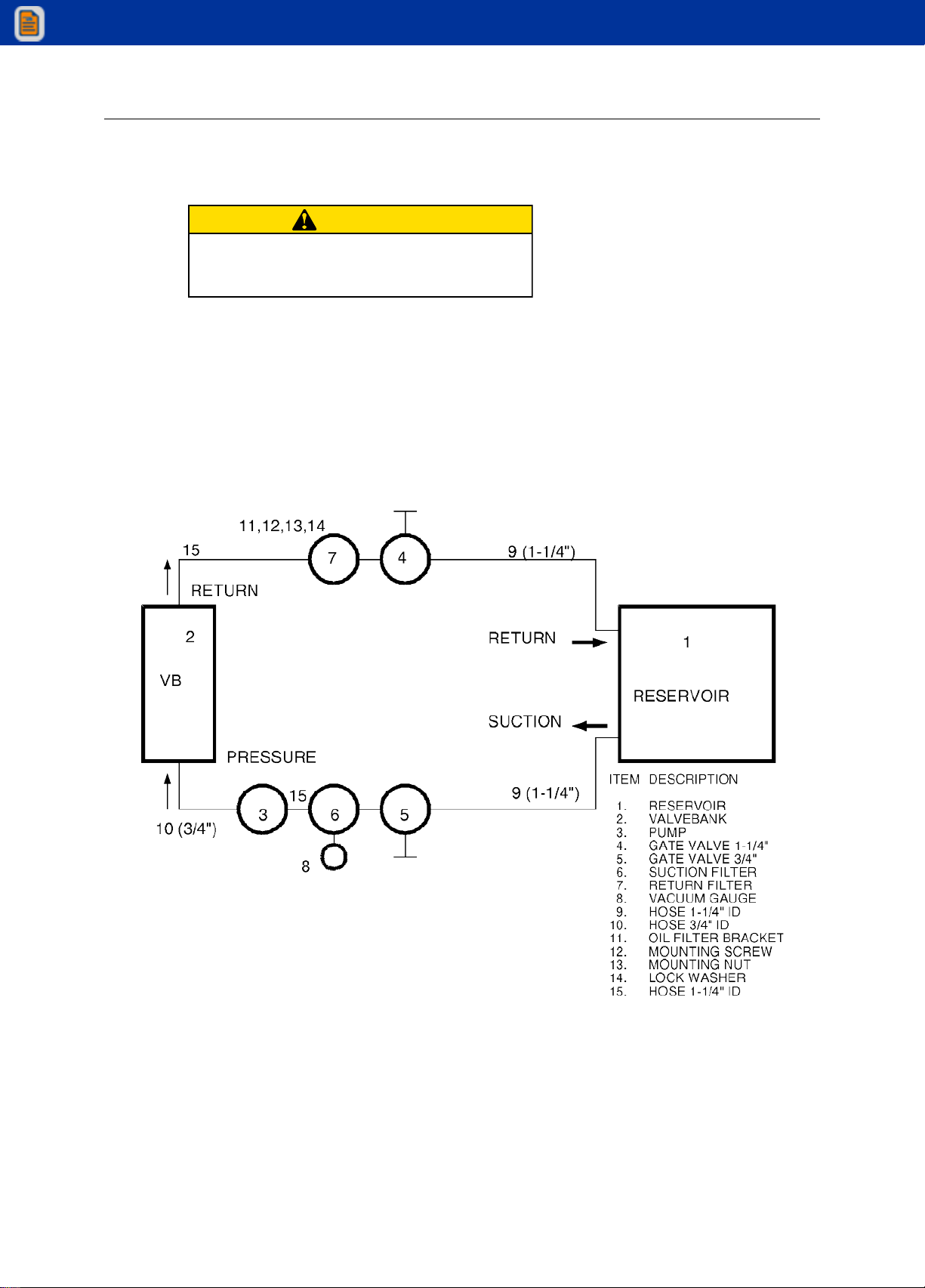

HYDRAULIC INSTALLATION

To install the hydraulic hoses, fittings, etc.:

1. Plumb the suction line filter as shown in Figure below.

2. Install the suction hose between the suction line filter and the pump inlet. Tighten the

hose clamps.

3. Install the pressure hose between the pump outlet and the inlet port on the valvebank.

4. Install the return line between the reservoir return line filter and valvebank (if

applicable).

5. Fill the hydraulic oil reservoir.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

18 12916 Parts & Specifications Manual #99905833

6. Open the gate valve at the suction-line filter.

7. Open the return gate valve.

8. Start the vehicle’s engine and engage the PTO. Allow the system to run for about five

minutes and then check the vacuum gauge on the suction-line filter (it should read 8”

mercury or less). If the vacuum reading is too high, check to make certain that the

gate valve is opened completely. If the valve is fully opened, check for a collapsed or

restricted suction line.

9. Cycle all hydraulic functions. Check for leaks, and refill the reservoir if necessary.

HYDRAULIC INSTALLATION

CAUTION

Failure to open the gate valve will result in a

dry running pump which may damage the

pump.

View thousands of Crane Specifications on FreeCraneSpecs.com

View thousands of Crane Specifications on FreeCraneSpecs.com

Table of contents

Other IMT Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Miller

Miller 17407 Instructions for use and maintenance

Fayat Group

Fayat Group BOMAG BW 226 DH-4 Service manual

Auto Crane

Auto Crane 4004EH owner's manual

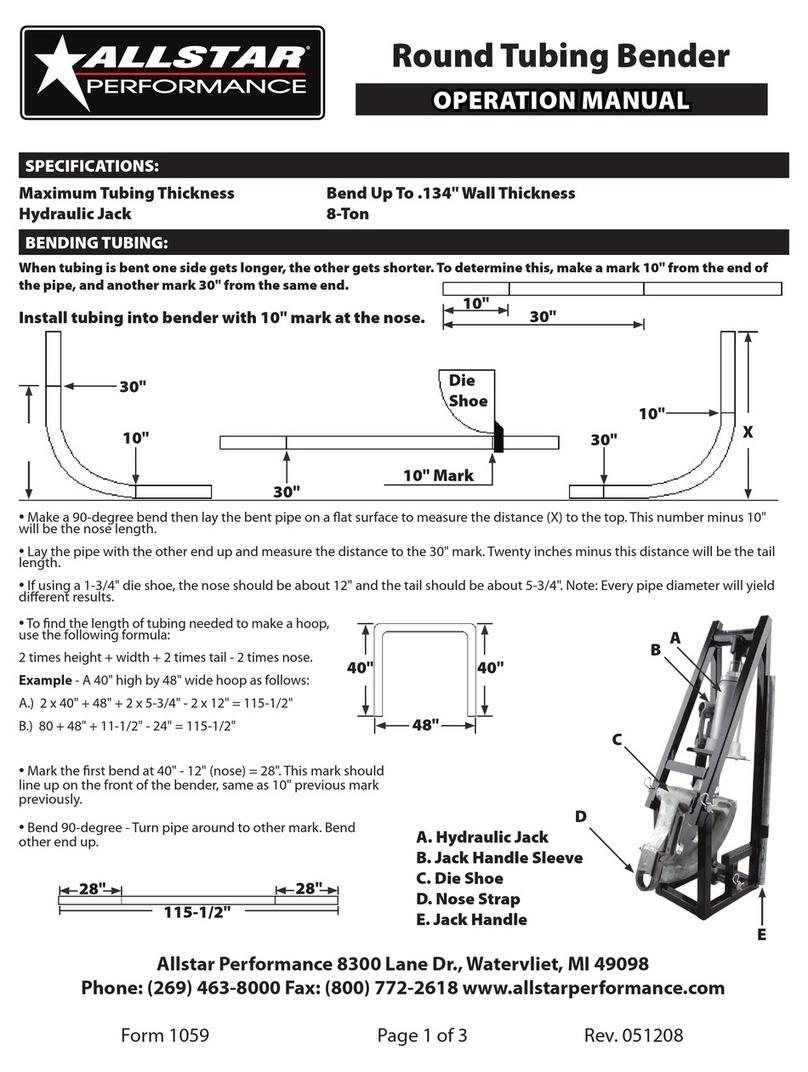

Allstar

Allstar ALL10300 Operation manual

Altrad Belle

Altrad Belle Minimix 130 Operator's manual

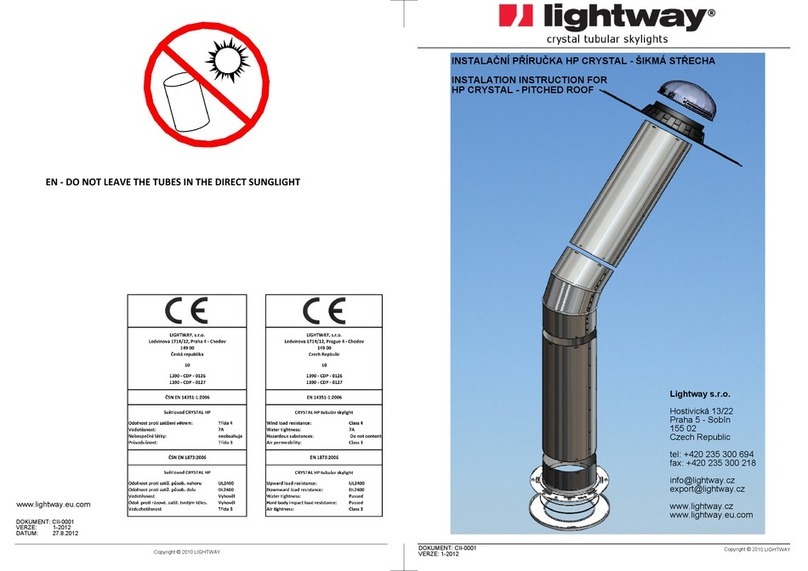

Lightway

Lightway HP CRYSTAL Series Installation instruction