Model 922-MES –User Manual

Focal Technologies Corporation Page iii

A Moog Inc. Company Document No. 922-0662-00, Rev 1.0

TABLE OF CONTENTS

1.0 Introduction........................................................................................................................................... 1-1

2.0 Specifications....................................................................................................................................... 2-1

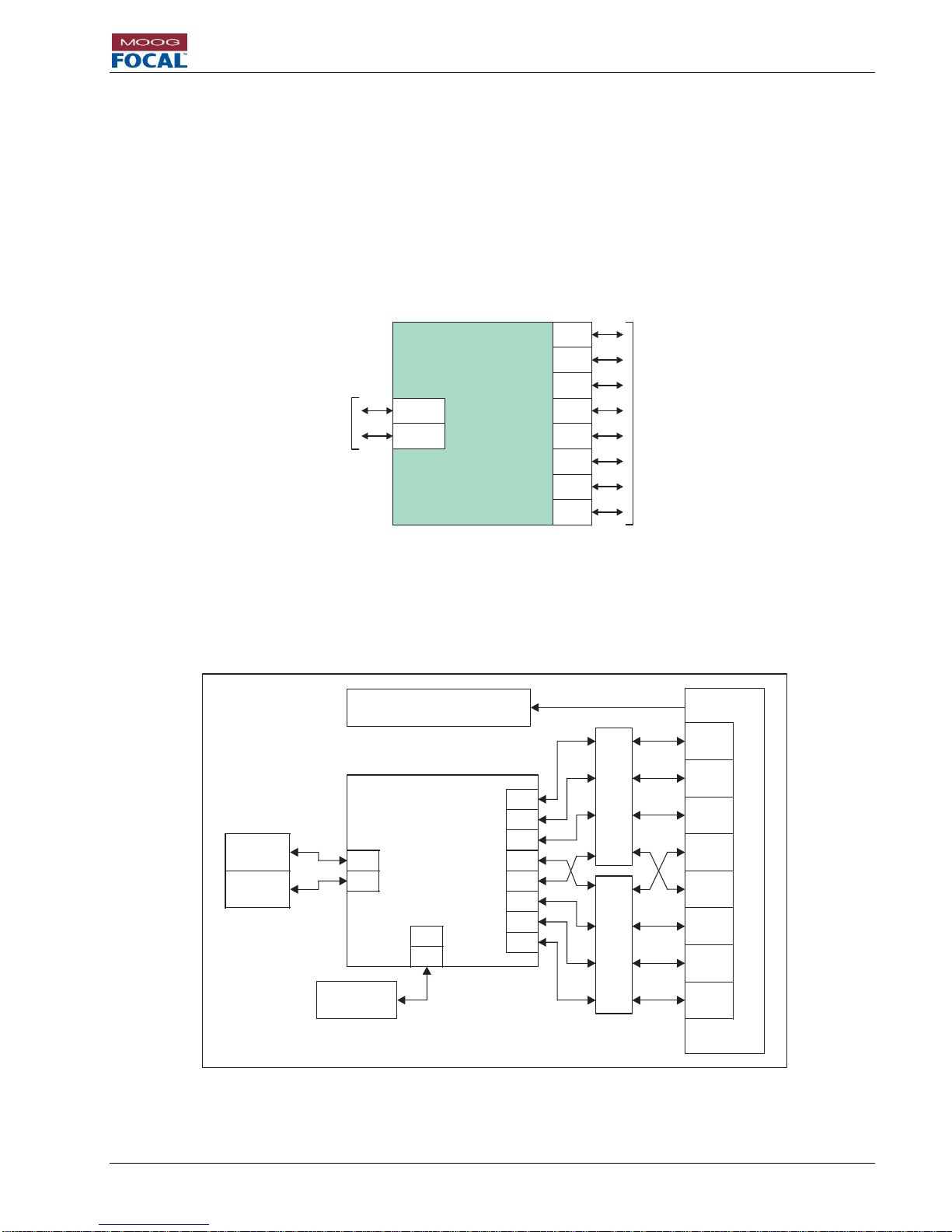

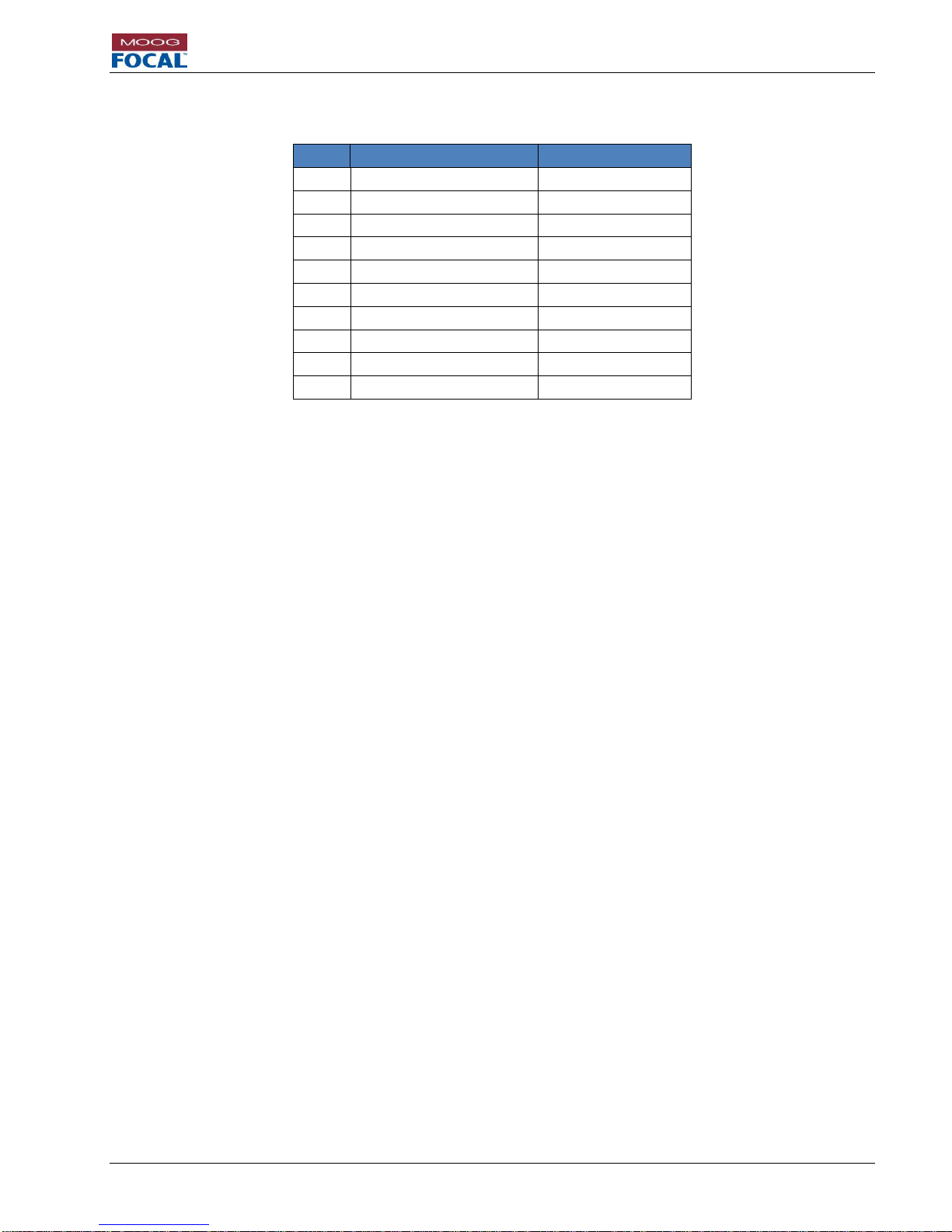

3.0 Architecture Overview ......................................................................................................................... 3-1

3.1Example Optical Topologies......................................................................................................... 3-3

4.0 Configuration........................................................................................................................................ 4-1

4.1 Factory Default Settings ............................................................................................................... 4-2

4.2 Initial User Setup .......................................................................................................................... 4-4

4.2.1 Initial Card Configuration via Telnet ................................................................................ 4-4

4.2.2 Initial Card Configuration via GUI.................................................................................... 4-5

5.0 Hardware............................................................................................................................................... 5-1

5.1 Card with Front Panel................................................................................................................... 5-1

5.2Card with No Front Panel ............................................................................................................. 5-2

5.3 General Board Handling............................................................................................................... 5-2

6.0 Connectors and Pin Descriptions ...................................................................................................... 6-1

6.1 Part Locations............................................................................................................................... 6-1

6.2 Diagnostic LEDs........................................................................................................................... 6-3

6.3 Jumpers........................................................................................................................................ 6-3

6.4 Connector Part Numbers.............................................................................................................. 6-4

6.5 96-pin DIN 41612 Backplane Connector (J11)............................................................................. 6-4

6.6 3.5 mm Jack Factory Diagnostics Port (J3).................................................................................. 6-5

6.7 LED Connector J5 ........................................................................................................................ 6-5

6.8 Electrical Interfaces ...................................................................................................................... 6-6

6.8.1 +24V Power Input............................................................................................................ 6-6

6.8.2 Ethernet Interface............................................................................................................ 6-6

6.8.3 Isolation and Grounding .................................................................................................. 6-7

7.0 Optical Interface ................................................................................................................................... 7-1

7.1 Optical Transceivers and Wavelength.......................................................................................... 7-1

7.2 Optical Fiber ................................................................................................................................. 7-1

7.3 Optical Budget, Range, and Bit Error Rate (BER)........................................................................ 7-2

7.4 Return Loss Tolerance ................................................................................................................. 7-2

7.5 Optical Power ............................................................................................................................... 7-2

7.6 Optical Connectors....................................................................................................................... 7-3

8.0 Functionality......................................................................................................................................... 8-1

8.1 Network Settings and Accessibility............................................................................................... 8-1

8.1.1 IP Address Configuration................................................................................................. 8-1

8.1.2 IP Connectivity................................................................................................................. 8-1

8.2 Redundancy Configuration........................................................................................................... 8-2

8.2.1 Media Redundancy Protocol (MRP)................................................................................ 8-2

8.2.2 Rapid Spanning Tree Protocol (RSTP)........................................................................... 8-3

8.2.3 HSR/PRP......................................................................................................................... 8-3

8.3 MES Core Features...................................................................................................................... 8-3

8.4 System Features .......................................................................................................................... 8-5

8.4.1 Remote Firmware Upgrade............................................................................................. 8-5

8.4.2 Saving User Switch Configuration................................................................................... 8-5