Focus Industries Handler I User manual

1Handler I, II & III Operator’s Manual - October 2008

Table of Contents

Warranty 3

Warranty Registration/Inspection Form 4

Sign Off Form 5

Introduction 6

Safety 7

Safety Decal Information 8

Assembly & Installation 9

Handler I Installation 9

Handler II Installation 14

Handler III Installation 20

Operation 28

Troubleshooting 36

Handler I Manifold Venturi Package Breakdown 38

Handler I Threaded Venturi Package Breakdown 39

2” Handler II & III Manifold Venturi Package Breakdown 40

3” Handler III Manifold Venturi Package Breakdown 41

Handler I, II & III Tank Parts Breakdown 42

System Specifications 43

Plumbing Package Assembly 44

Plumbing Package Operation 46

3Handler I, II & III Operator’s Manual - October 2008

Warranty

Focus Industries Inc. products are warranted for one year from date of purchase against

defects in material and workmanship and to perform according to specifications when

such products are properly assembled, installed, used and maintained. Warranty is

granted to original owner only.

Our obligation under this warranty is limited to repairing or replacing, at our option,

and excluding pumps, within 12 months of the retail delivery date. This obligation shall

not include any transportation charges or costs, or any liabilities for direct, indirect or

consequential damage or delay.

Warranty Limited or Void

Any use for purposes other than those for which the product was designed, operation be-

yond rated capacity, substitution of parts not approved by focus industries Inc., or altera-

tion or repair by others in such manner as in our judgment affects the product materially

and adversely shall void this warranty.

Warranty does not apply to any machine or part which has been repaired or altered in

any way so as in the company’s judgment affects its reliability, or which has been sub-

ject to misuse, negligence or accident.

Furthermore, component parts, equipment, accessories and items not fabricated by

Focus Industries Inc. are warranted only to the extent of the original manufacturer’s

warranty.

The gas and diesil engines, electric and hydraulic motors that are included with our pumps

are warrantied by the engine manufacturer, not by Focus Industries Inc. Please refer all

engine warranties to the authorized engine dealer near you.

Focus Industries Inc. reserves the right to make improvement changes on any of our

products without notice.

Warranty Claims Procedure

A warranty claim form must be completed at your handler dealer.

Defective parts for which a warranty claim is made must be returned to the dealer

within 15 days from the claim date.

1.

2.

4 Handler I, II & III Operator’s Manual - October 2008

Warranty Registration/Inspection Form

Warranty Registration

This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery.

Customers Name Dealer Name

Address Address

City, State, Code City, State, Code

Phone Number Phone Number

Delivery Date Check One: Commercial Use Farm Use

Serial Number of Unit

Dealer Inspection Report Safety

Frame Fasteners Tight All Decals Installed

Chemical Hoses Tight Review Operating & Safety Instructions

Oil in Engine

I

the operator’s Manuel content, equipment care, adjustments, safe operation and applicable warranty policy.

Date Dealer’s Rep. Signature

Th

safe operation and applicable warranty policy.

Date Owner’s Signature

5Handler I, II & III Operator’s Manual - October 2008

Focus Industries Inc. follows the safety standard specified by the

American Society for Agricultural Engineers (ASAE) and the

Occupational Safety and Health Administration (OSHA). Any-

one who will be operating and/or maintaining the Handler must

read and clearly understand ALL safety, operating and mainte-

nance information presented in this manual.

Do not operate or allow anyone else to operate this equipment

until such information has been reviewed. Annually review this

information before season start up.

Make these periodic reviews of Safety and Operation a standard

practice for all equipment. We feel that an untrained operator is

unqualified to operate this equipment.

A sign off form is provided for your record keeping to show that

all personnel who will be working with the equipment have read

and understood the information in the Operator’s Manual and

have been instructed in the operation of the equipment.

Sign Off Form

Date Employee Name Employee Signature

6 Handler I, II & III Operator’s Manual - October 2008

Introduction

Congratulations on your choice of a Focus Industries Inc.

Handler.

Safe, efficient and trouble-free operation of your Handler

requires that you and anyone else, who will be operating

or maintaining the system, read and understand the safety,

operation, maintenance, and troubleshooting information

contained in the Operator’s Manual.

Keep this manual handy for frequent reference and to pass on to

new operators and owners.

Operator Orientation

The directions left, right, front, and rear, as mentioned

throughout this manual, are seen from the operator’s position

facing the front of the Handler tank. With the proper orientation,

the Handler name will be clearly visible on the front of the tank.

Safety

Safety Alert Symbol

Why is SAFETY important to you?

This Safety Alert symbol means Attention! Become Alert! Your

Safety is involved!

The Safety Alert symbol identifies important safety messages on

the Focus Industries Inc. Handler. When you see this symbol,

be alert to the possibility of personal injury or death. Follow the

instructions in the safety message.

3 Big Reasons

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

Signal Words

1.

2.

3.

Left Right

7Handler I, II & III Operator’s Manual - October 2008

Note the use of the signal words Danger, Warning and Caution

with the safety messages. The appropriate word for each mes-

sage has been selected using the following message has been

selected using the following guidelines:

You are responsible for the safe operation and maintenance of

your Focus Industries Inc. Handler. Ensure that you and anyone

else who is going to operate, maintain, or work around the Han-

dler be familiar with the operating and maintenance procedures

and related safey information contained in this manual. This

manual will take you step by step through your working day and

alert you to all good safety practices while operating the Han-

dler.

Remember you are the key to safety. Good safety practices not

only protect you but also the people around you. Make these

practices a working part of your safety program. Be certain that

everyone operating this machine is familiar with the procedures

recommended and follows safety precautions. Remember, most

accidents can be prevented. Do not risk injury or death by ignor-

ing good safety practices.

Handler owners must give operating instructions to operators or

employees before allowing them to operate the Handler. Con-

tinue doing this on an annual basis.

The most important safety device on this equipment is a safe op-

erator. It is the operator’s responsibility to read and understand

all safety and operating instructions in the manual and to follow

them. All accidents can be avoided.

A person who has not read and understood all operating and

safety instructions is not qualified to operate the machine. An

untrained operator exposes himself and bystanders to possible

serious injury or death.

Do not modify the equipment in any way. Unauthorized modifi-

cation may impair the function and/or safety and could affect the

life of the equipment.

Think Safety! Work Safely!

General Safety

Read and understand the Operator’s Manual and all safety

signs before operating, maintaining, adjusting or unplugging

the Handler.

Only trained competent persons shall use the Handler. An

untrained operator is not qualified to use the tank.

Have a first aid kit available should the need arise and know

how to use it.

Have a first aid kit available

Wear appropriate protective gear. This includes, but is not

limited to:

A Hard Hat

Protective shoes with slip resistant soles

Protective glasses or goggles

Rubber or neoprene gloves

Wet weather gear

Hearing protection

Respirator or filter mask

Wear appropriate gear

Before starting, read chemical manufacturers’ warnings,

instructions and procedures and follow them exactly.

Post the Poison Control Emergency telephone number for

your area on your sprayer before using Agricultural prod-

ucts. The appropriate number can be found in the inside

of your telephone book. Have container label handy when

seeking medical attention.

Review all safety related instructions with all personnel

annually.

Do not put hands into the Handler when adding products.

Wear safety goggles, rubber gloves and protective clothing

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

8 Handler I, II & III Operator’s Manual - October 2008

whenever working with the Handler or on a machine or a

component containing toxic product.

Keep all shields and guards in place when operating.

Clear the area of all bystanders, especially children, before

starting.

Review safety instructions annually

Safety Decals

Keep safety decals and signs clean and legible at all times.

Replace safety decals that are missing or have become illeg-

ible.

Replaced parts must have current safety decal.

Safety decals or signs are available from your dealer parts

department.

How to Install Safety Decals

Be sure that the installation area is clean and dry.

Decide on the exact position before you remove the backing

paper.

Remove the smallest portion of the split backing paper.

Align the decal over specified area and carefully press the

small portion with the exposed sticky backing in place.

Slowly peel back the remaining paper and carefully smooth

the remaining portion of the decal in place.

Small air pockets can be pierced with a pin and smoothed

out using the piece of decal backing paper.

Safety Decal Information

The types of decals on the equipment are shown in the illustra-

tions below. Good safety requires that you familiarize yourself

with the various safety decals, the type of warning and the area,

or particular function related to that area that requires your safety

awareness.

•

•

•

•

•

•

•

1.

2.

3.

4.

5.

6.

Handler safety decals

Think Safety! Work Safely!

9Handler I, II & III Operator’s Manual - October 2008

Assembly & Installation

About Your Handler

Model Type

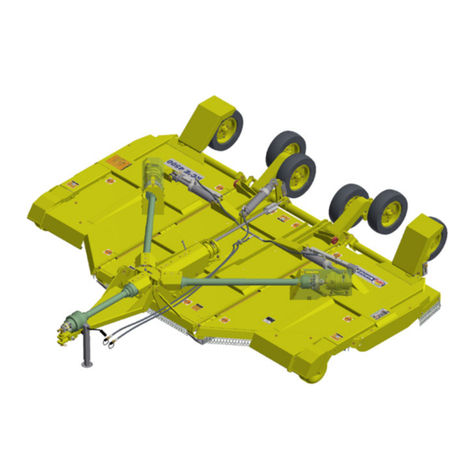

You have purchased a Handler I, Handler II or Handler III. All

components required to install the unit are included in the pack-

age except for the fittings used to join the Handler tank to the

existing sprayer lines. Purchase these from your dealer as the

size may vary between make and model of sprayer.

Valve System

All systems have been equipped with a venturi or plumbing

valve system. Identify precisely the model type and valve system

you have purchased before you begin assembly and installation

Assembly and installation procedures are specific to each model

type and valve system. Because installation varies, the assembly

instructions and illustrations will separately detail the installation

of each model type.

Handler I Assembly

Overview

Assembly and instructions of your Handler 1-i15T threaded ver-

sion follows five basic steps:

Install agitation and rinse valve assemblies onto side of

tanks.

Install venturi valve assembly with venturi onto bottom of

tank.

Install venturi bracket onto Handler frame.

Install bypass valve assembly.

Install hoses and clamps.

Assembly and instructions of your Handler 1-i15M Manifold

version follows five basic steps:

Assemble and install agitation and rinse valve assemblies

onto side of tanks.

Assemble and install venturi valve assembly with venturi

onto bottom of tank.

Assemble and install remaining manifold fittings.

Install venturi bracket onto Handler frame and bolt down

manifold fittings to bracket.

Install hoses and clamps.

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

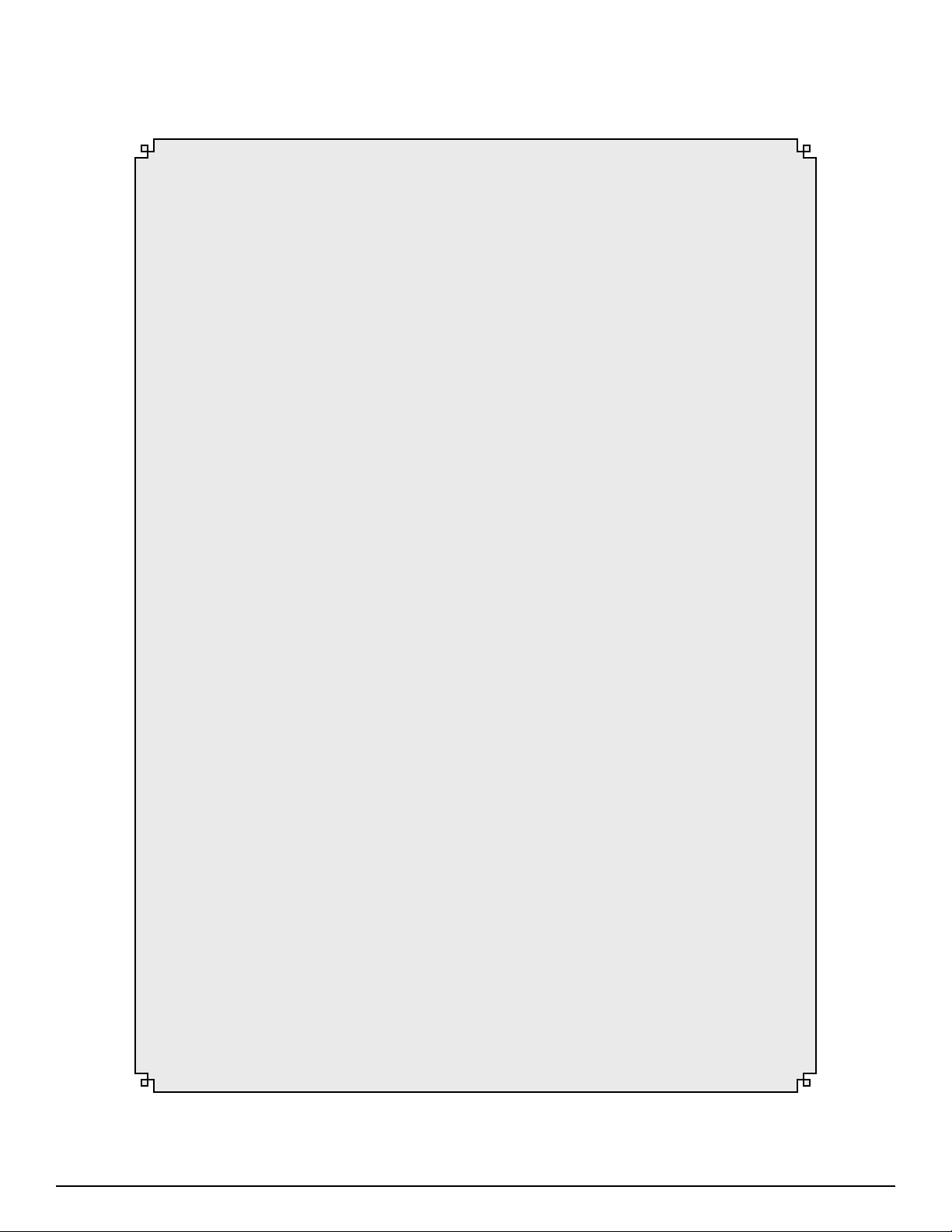

Threaded System

Step 1

Agitation and rinse valve installation

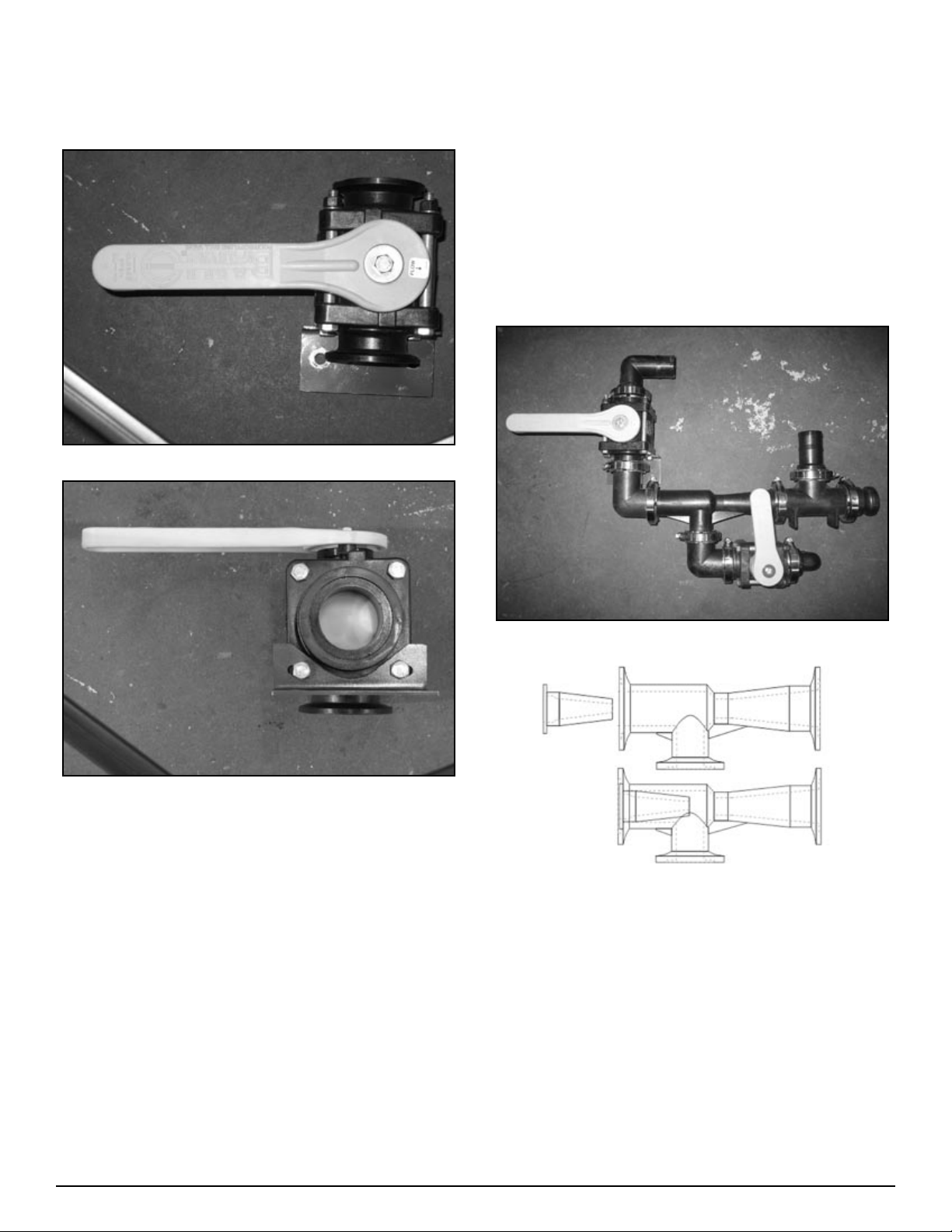

Figure H1-4.1

Figure H1-4.2

Thread agitation valve assembly (See Fig. H1-4.1) into the

¾ bulkhead on the left side of the tank. (See Fig. H1-4.2)

Note: Apply sealant before installing (as per sealant

notes on page 37.)

Install assemblies so that the hose barb points to the front.

(Bracket side of tank.) (See Fig. H1-4.2)

Thread rinse valve assembly (See Fig. H1-4.1) into the ¾”

bulkhead on the right side of the tank. (See Fig. H1-4.2)

Note: Apply sealant before installing (as per sealant

notes on page 37.)

Install assemblies so that the hose barb points to the front.

(Bracket side of tank.) (See Fig. H1-4.2)

1.

•

2.

3.

•

4.

10 Handler I, II & III Operator’s Manual - October 2008

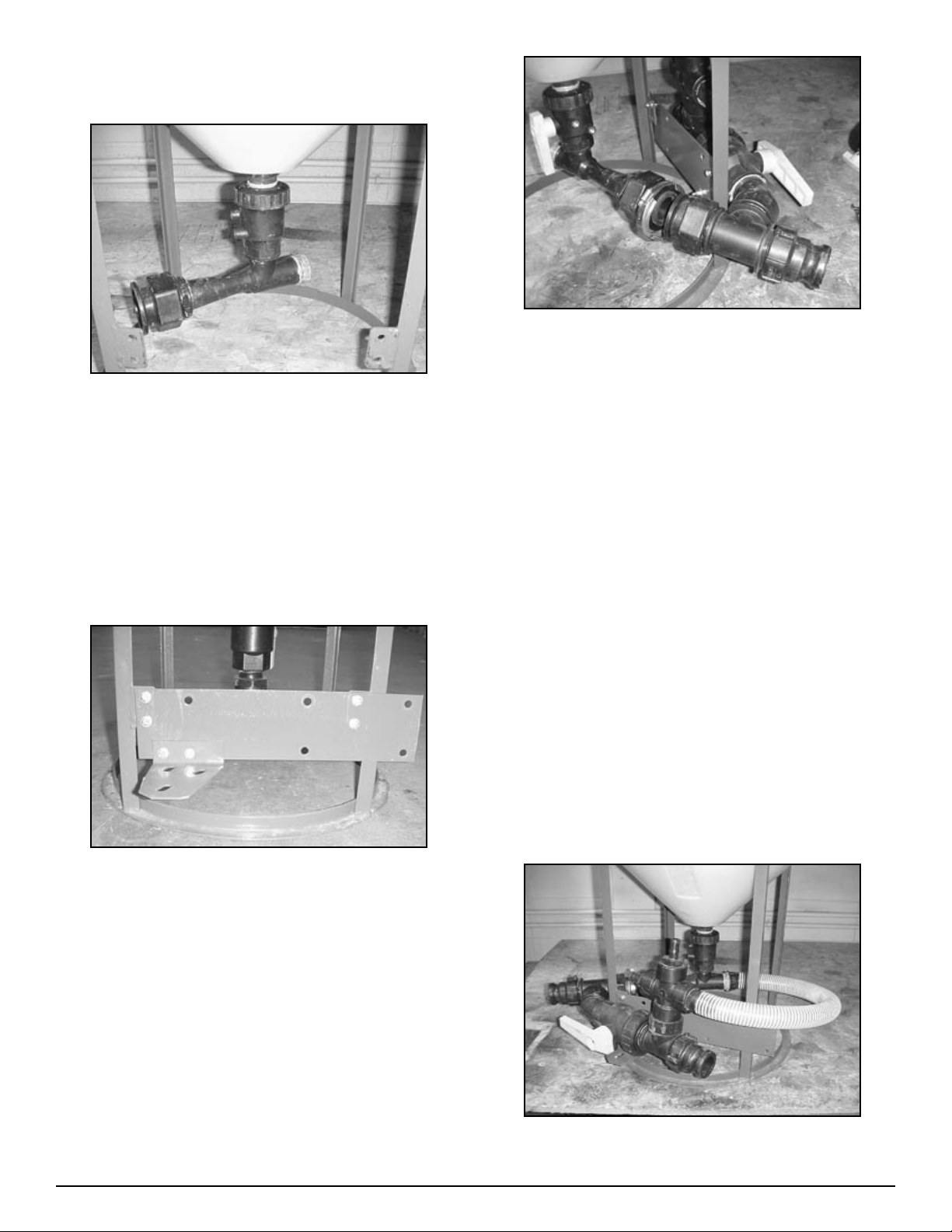

Step 2

Venturi package assembly

Figure H1-4.3

Thread venturi assembly to anti-vortex fitting on tank bot-

tom. Be sure to use sealant as per instructions.

NOTE: the discharge end of the venturi once installed

should point to the left hand side behind tabs. (See Fig.

H1-4.3)

Step 3

Bracket installation

Figure H1-4.4

Install venturi bracket to tabs on the Handler frame as

shown in Fig. H1-4.4 using ¼” x 1” bolts. Do not tighten

completely yet.

Install smaller ball valve support bracket on to venturi

bracket using 5/16” x ¾” bolts. Do not tighten completely

yet. (See Fig. H1-4.4)

1.

•

2.

3.

Figure H1-4.5

Attach bypass valve assembly to venturi assembly using

stainless steel flange clamp (25-FC200) and gasket (25-

150G) making sure that the 2” ball valve (10-10230) sits on

the support bracket. Do not tighten clamp completely yet.

(See Fig. H1-4.5)

Step 4

Bypass valve installation

Fasten 2” ball valve to support bracket using 5/16” x ¾”

bolts, 3/8 flat and 5/16 lock washer.

Tighten all bolts and clamps.

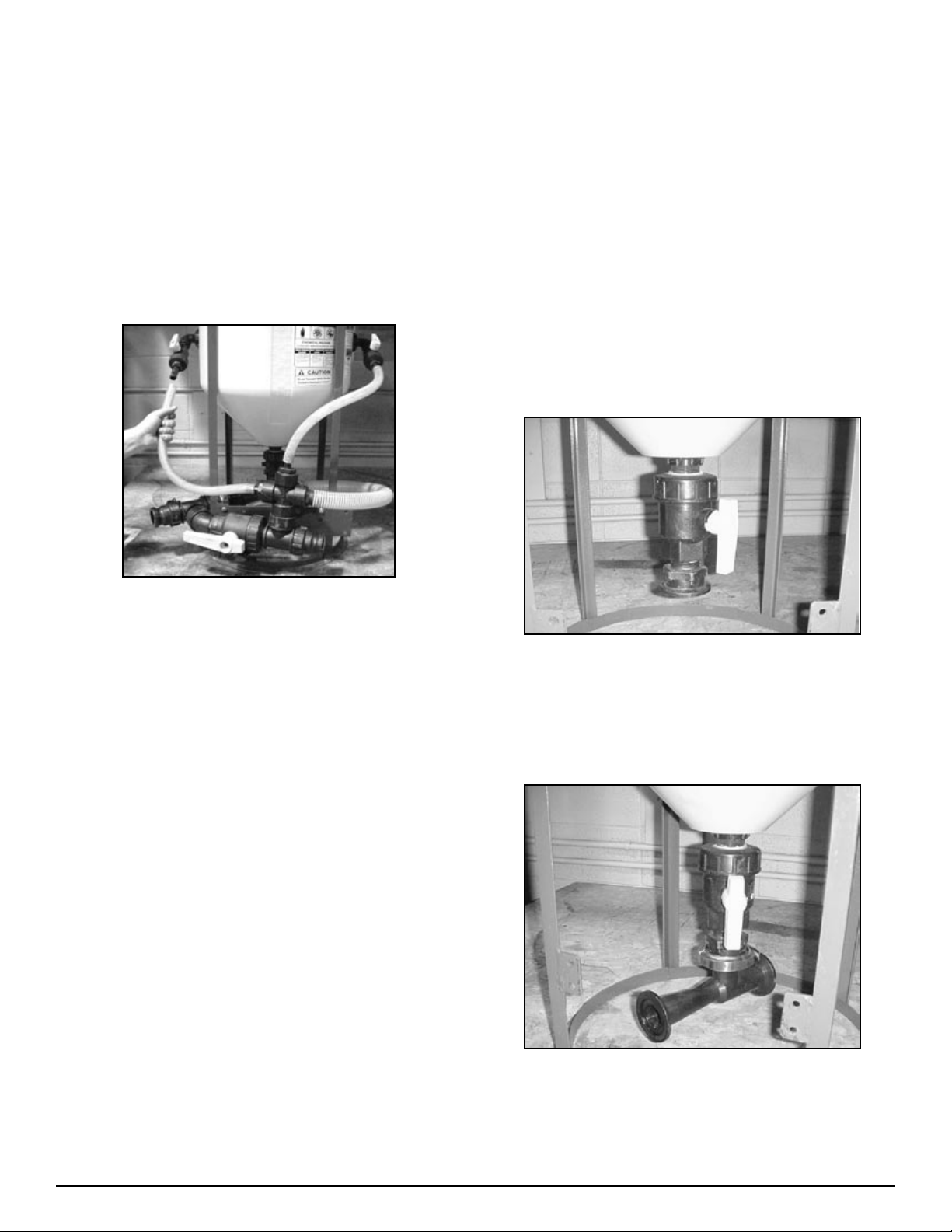

Step 5

Hose and clamp installation

Thread female end of hose barb on venturi hose assembly

on the intake side of the venturi (86-HV150).

Note: Use Sealant on both male and female threads.

Important: Make sure venturi nozzle is in place before

installing venturi hose.

Figure H1-4.6

4.

1.

2.

1.

•

11Handler I, II & III Operator’s Manual - October 2008

Attach the other end of the venturi hose assembly to the

bypass assembly. (See Fig. H1-4.6) Fasten hose with MC24

hose clamps (54-75624)

Cut and attach the appropriate length of ¾” hose (54-79200)

to connect the hose barb on the agitation valve assembly to

the hose barb on the top left hand side of the bypass assem-

bly. (See Fig. H1-4.7) Fasten hose with MC12 hose clamps

(53-75612)

Step 5

Hose and Clamp Installation

Figure H1-4.7

Cut and attach the appropriate length of ¾” hose to connect

the hose barb on the rinse valve assembly to the hose barb

on the top of the bypass assembly. (See Fig. H1-4.7) Again

fasten hose with MC12 hose clamps.

Tighten all fittings, bolts and hose clamps as necessary.

NOTE: Also check fly nut on anti-vortex fitting on tank

bottom. Tighten as necessary using pump pliers.

Your Handler 1-i15T is now completely assembled. Instructions

for the manifold package will follow. You may now continue to

the operation section of the manual starting on page 28.

2.

3.

1.

2.

•

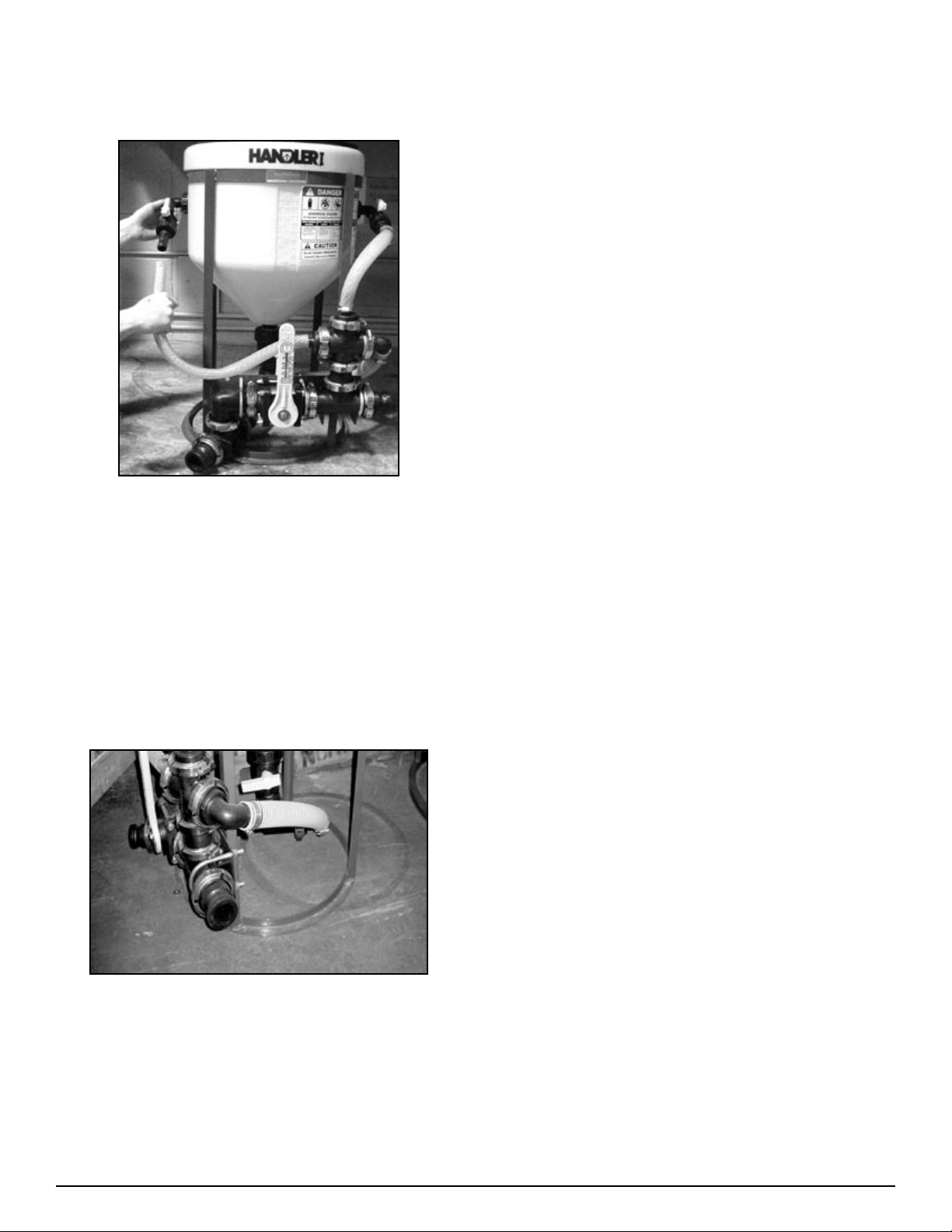

Manifold System

Step 1

Agitation & rinse valve installation

Assemble and thread agitation valve assembly (see Fig.

H1-4.1) into the ¾ bulkhead on the left side of the tank. (See

Fig.4.2 H1-4.2)

Note: Apply sealant before installing.

Install assemblies so that the hose barb points to the front.

(Bracket side of tank.) (See Fig. H1-4.2

Thread rinse valve assembly (See Fig. H1-4.1) into the ¾”

bulkhead on the right side of the tank. (See Fig. H1-4.2)

Step 2

Venturi assembly

Figure H1-4.8

Thread venturi valve assembly on to anti-vortex fitting on

tank bottom. Position valve handle for easy access.

(See Fig H1-4.8)

NOTE: Be sure to use sealant as per instructions

Figure H1-4.9

Attach venturi to valve assembly flange with clamp and gas-

ket. Do not tighten completely yet. Position discharge end

of venturi so it points to the front left (in-between the tabs

welded on the frame). (See Fig H1-4.9)

1.

•

2.

3.

1.

•

2.

12 Handler I, II & III Operator’s Manual - October 2008

Step 3

Bypass valve installation

Attach coupler (25-M220200CPG) to discharge end of ven-

turi using (25-FC200) flange clamp and (25-150G) gasket.

Attach 2” manifold tee (25-M220TEE) to coupler using (25-

FC220) flange clamp and (25-200G) gasket. Make sure stem

of tee is pointed upwards.

Figure H1-4.10

Position manifold tee so it is tight against the left hand side

of the front (in-between tabs welded on the frame.) (See Fig.

H1-4.10)

Continue attaching manifold fittings using the appropriate

clamps and gaskets as shown. (See Fig. H1-4.10)

Note: Make sure venturi nozzle is in place before install-

ing venturi hose. Make sure arrow on venturi (Flow

direction) is pointed to the front.

Venturi Nozzle Placement

1.

2.

3.

4.

•

Step 4

Bracket installation

Figure H1-4.11

Install venturi bracket (86-H1i15VBPO) to tabs on Handler

frame as shown in Fig. H1-4.11 using ¼” x 1” bolts. Do not

tighten completely yet. (See Fig. H1-4.11)

Figure H1-4.12

Attach completed assembly to venturi bracket (86-

H1i15VBPO) using 3/8”x 2 ½” U-bolts (67-UB38-250)

(See Fig. H1-4.12)

Tighten all bolts and clamps

1.

2.

3.

13Handler I, II & III Operator’s Manual - October 2008

Step 5

Hose and clamp installation

Figure H1-4.13

Cut and attach the appropriate length of 1” hose (57-79210)

to connect the hose barb on the top left hand side of the

bypass assembly. Fasten hose with MC12 hose clamps (53-

75612) (See Fig. H1-4.13)

Cut and attach the appropriate length of 1” hose to connect

the hose barb on the rinse valve assembly to hose barb on

the rinse valve assembly to the hose barb on the top of the

bypass assembly. Again fasten hose with MC12 clamps.

(See Fig. H1-4.13)

Figure H1-4.14

Measure, then cut and attach the appropriate length of 1 ½”

PVC suction hose (54-79050) to connect the venturi to the

manifold fitting assembly. (See Fig. H1-4.14) Fasten with

MC24 hose clamps (53-75624).

Hint: warm hose ends and barbs before trying to install the

hose. In addition, silicone spray can be applied to hose ends

to make installation easier.

1.

2.

3.

4.

Tighten all fittings, bolts and hose clamps as necessary.

Note: Also check flynut on anti-vortex fitting on tank bot-

tom. Tighten as necessary using pump pliers.

The assembly of your Handler 1-i15M is now complete.

Continue to the operation section of the manual on page 28.

5.

6.

14 Handler I, II & III Operator’s Manual - October 2008

Handler II Assembly

Overview

Assembly of your Handler 2 (without pump) follows four basic

steps:

Rinse valve and agitation fitting assembly and installation.

Venturi bracket and plate installation.

Three way valve support bracket installation

Venturi package assembly and installation.

If you have purchased a Handler 2 with a pump or recirculation

package then there are two additional Steps:

Pump bracket installation.

Pump and recirculation package installation.

Step 1

Rinse valve and agitation fitting assembly

and installation

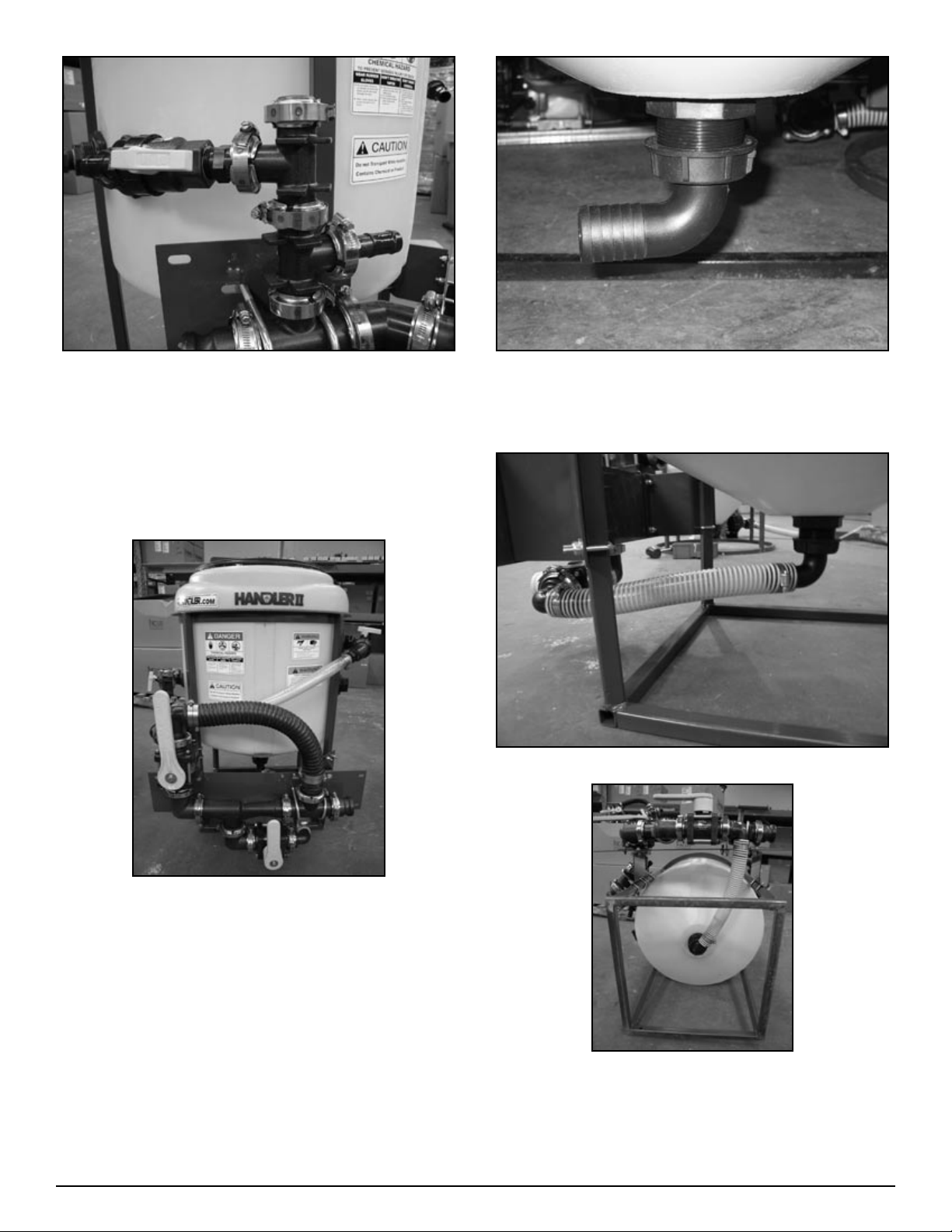

FIgure H2-4.1

Agitation Fitting Installation (Figure H2-4.1, “A”).

Install 1” MPT X 1” HB 90 (25-HB100-90) on to 1” bulk-

head on left side of tank. See figure H2-4.2. (Apply sealant

before assembling - see notes on page 37)

1.

2.

3.

4.

1.

2.

1.

Figure H2-4.2

Rinse Valve Assembly (Figure H2-4.1, “B”)

Install one 1” MPT X 1” MPT elbow (10-10980) on to 1”

single union ball valve (25-UV100FP) on end opposite of

union. (Apply sealant before assembling - see notes on

page 37)

Install 1” MPT X 1” Hose Barb (25-HB100) onto end of

street elbow.

Install 1” street elbow 45 degree (25-SL100-45) into union

side of ball valve.

Attach the above assembly to 1” bulkhead on right side of

tank (see figure H2-4.3).

Figure H2-4.3

1.

2.

3.

4.

A

B

15Handler I, II & III Operator’s Manual - October 2008

Step 2

Venturi bracket and plate installation

Figure H2-4.4

Mount angled frame brackets (86-HAFB) to frame as shown

in figure H2-4.4. Use two 1” U-bolts (67-UB025-100) per

bracket. Bottom of bracket should be 7” from bottom of

frame. NOTE: Tighten only enough to prevent slipping.

Figure H2-4.5

Mount venturi mounting plate (86-HVMP) on to angled

frame brackets as shown in figure H2-4.5 . Use three 5/16”

X 1” bolts (67-CSH5C516-1p) – two on the right side and

one on the lower left side. Do not tighten completely yet.

Hint: if angle frame brackets are not perpendicular to frame

tap with a mallet to align them.

1.

2.

Figure H2-4.6

Figure H2-4.7

Mount intake support plate (86-HISP) to frame 14 1/2” from

the base as shown in figure H2-4.6 and H2-4.7. Use two 1”

U-bolts (67-UB025-100). Do not tighten completely yet.

Go to next step (Three way valve support bracket installa-

tion).

3.

4.

16 Handler I, II & III Operator’s Manual - October 2008

Step 3

Three way valve support bracket

installation

Figure H2-4.22

Figure H2-4.23

Install 2” three way valve support bracket (86-VASB2) on

to three way valve as shown in Figure H2-4.22 and H2-4.23

NOTE: handle operation should have closed position to left

when looking at front of valve.

Go to next Step (Venturi package assembly and installa-

tion).

Step 4

Venturi package assembly and installation

Hints:

Lay all parts out first.

Open FC200 and FC220 clamps slightly larger to make as-

sembly easier.

Open FC100 clamps completely to make assembly easier.

1.

2.

•

•

•

Part Number 25-M220CPG90 has long and short side. At-

tach short side to venturi and long side to 3 way ball valve

(25-MV220BL) as shown in figure H2-4.8

Start assembly at discharge end and work towards other end

(intake).

Venturi comes with nozzle insert, will not run without.

Do not install 2” bypass hose (54-79250) until last.

Warm hoses before installing – use heat gun or pail of hot

water.

Lubricate hose barbs with liquid dish soap or silicone based

lubricant to make installation easier.

Assemble and install 1” fittings last.

Figure H2-4.8

Venturi Nozzle Placement

Assemble manifold venturi package as shown in figure H2,

H3-4.8. Do not tighten completely yet.

•

•

•

•

•

•

•

1.

17Handler I, II & III Operator’s Manual - October 2008

Figure H2-4.9

Install partial assembly on to venturi mounting plate as

shown in figure H2-4.9. Use two 5/16” X 1” bolts. Do not

tighten completely yet.

Install two 2 ½” U-bolts (67-UB038-250) to hold assembly

to plate. Do not tighten completely yet.

Figure H2-4.10

Assemble remaining 2” fittings as shown in figure H2-4.10.

2.

3.

4.

Figure H2-4.11

Mount second assembly to first as shown in figure H2-4.11

(use 25-FC220 clamp and 25-200G gasket). Do not tighten

completely yet.

Install 2 ½” U-bolts (67-UB038-250) to hold second as-

sembly to intake support plate. See figure H2-4.11. Do not

tighten completely yet.

Figure H2-4.12

Assemble 1” fittings as shown in figure H2-4.12.

5.

6.

7.

18 Handler I, II & III Operator’s Manual - October 2008

Figure H2-4.13

Install 1” fitting assembly as shown in figure H2-4.13. Do

not tighten completely yet.

Tighten flange clamps on 2” fittings.

Tighten U-bolts.

Tighten remaining bolts.

Align 1” fittings and tighten flange clamps.

Figure H2-4.14

Install 2” bypass hose (54-79250) and secure with two

clamps (53-75632) per end as in figure H2-4.14.

Hint: Install hose at bottom end and ensure proper length.

Heat other end and install hose barb. Attach hose barb to

assembly.

Measure, cut and install 1” clear braided hose (54-79210)

for agitation and rinse lines. Secure with clamps (53-756-

12).

8.

9.

10.

11.

12.

13.

14.

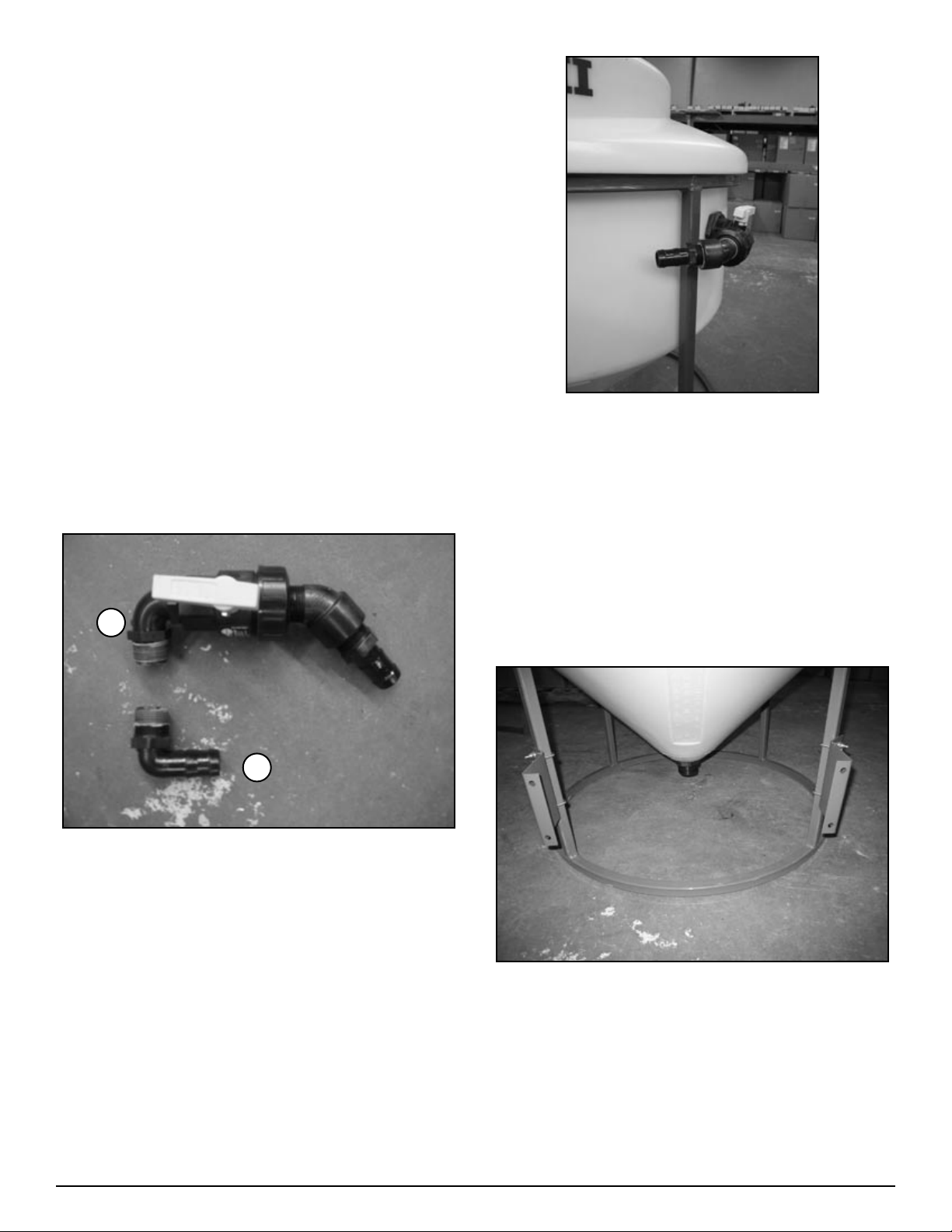

Figure H2-4.15

Install 2” FPT X 1 ½” HB 90 degree fitting (10-10910)on to

bottom of tank, see figure H2-4.15

Figure H2-4.16

Figure H2-4.17

Measure, cut, and install 1 ½” PVC suction hose (54-79050)

that goes between tank and venturi valve. Secure with

clamps (53-75624). See figure H2-4.16 and H2-4.17.

15.

16.

19Handler I, II & III Operator’s Manual - October 2008

Step 5

Pump bracket installation

Figure H2-4.18

Fit pump bracket into bottom of tank frame (see figure H2-

4.18).

Use two 5/16” X 1 1/2’” bolts and two 5/16” locking nuts to

secure bracket to frame.

Step 6

Pump and recirculation

package installation

Mount pump to pump bracket using four 5/16” X 1 ½”L

bolts, four 5/16” locking nuts and eight flat washers.

Figure H2-4.19

Install 2” Tee (10-11100) to bottom of tank (use pipe seal-

ant) see figure H2-4.19.

1.

2.

1.

2.

Figure H2-4.20

Figure H2-4.21

Install fittings as shown in figure H2-4.20 and H2-4.21.

If using a pump/motor combination different than shown in

the above figures may require repositioning of the pump to

direct exhaust away from the tank. This may require drill-

ing extra holes in plate.

3.

4.

20 Handler I, II & III Operator’s Manual - October 2008

Handler III Assembly

Overview

Assembly of your Handler 3 (without pump) follows four basic

steps:

Rinse valve and agitation fitting assembly and installation.

Venturi bracket and plate installation.

Three way valve support bracket installation.

Venturi package assembly and installation.

If you have purchased a Handler 3 with a pump or recirculation

package then there are two additional steps:

Pump bracket installation.

Pump and recirculation package installation.

Step 1

Rinse valve/agitation fitting assembly and

installation

Figure H3-4.1

Agitation Fitting Installation (figure H3-4.1, “A”).

Install 1” MPT X 1” HB 90 (25-HB100-90) on to 1” bulk-

head on left side of tank. See figure H3-4.2. (Apply sealant

before assembling - see notes on page 37)

Rinse Valve Assembly (figure H3-4.1, “B”)

Install one 1” MPT X 1” MPT elbow (10-10980) on to 1”

single union ball valve (25-UV100FP) on end opposite of

union. (Apply sealant before assembling - see notes on

page 37)

1.

2.

3.

4.

1.

2.

1.

1.

Figure H3-4.3

Install 1” street elbow 45 degree (25-SL100-45) into union

side of ball valve.

Install 1” MPT X 1” Hose Barb (25-HB100) onto end of

street elbow.

Attach the above assembly to 1” bulkhead on right side of

tank (see figure H3-4.3).

Step 2

Venturi bracket and plate installation

Figure H3-4.4

Mount angled frame brackets (86-HAFB) to frame as shown

in figure H3-4.4. Use two 1” U-bolts (67-UB025-100) per

bracket. Bottom of bracket should be 7” from bottom of

frame. NOTE: Tighten only enough to prevent slipping.

2.

3.

4.

1.

A

B

This manual suits for next models

2

Table of contents

Popular Farm Equipment manuals by other brands

Tatu Marchesan

Tatu Marchesan RC2E 4500 instruction manual

Pottinger

Pottinger TERRASEM 3000 T Standardline Mounting instructions

ORKEL

ORKEL GP 1260 Operator's manual

Vicon

Vicon Extra 328 operating manual

IXOM

IXOM SolarBee SB2500PW owner's manual

Stocks AG

Stocks AG Fan Jet Mini 65 Original Operating Manual and parts list