Fogco FogCannon HD 160 Operating instructions

Fogco FogCannon ™

HD 160 / HD 230 / HD 300

Pole / Trailer

FOGCO Environmental Solutions

600 S 56

th

Street

Chandler, AZ 85226

Phone: 800-607-6478

Fax: 480-838-2232

Website: www.fogco.com

e-mail: info@fogco.com

Rev080818

Version 1.0

PURPOSE OF USER AND MAINTENANCE MANUAL

Make the operators aware of safety issues;

Install, handle, and use the Machine in safe conditions;

Gain in-depth knowledge on its operation and limits;

Perform maintenance work, correctly and safely,

This document assumes that the safety and hygiene work regulations are observed in the plants, where the

Machine has been located.

The instructions, drawings and documents contained in this Manual are of a confidential and technical

nature, of strict ownership of the manufacturer and cannot be reproduced in any way without prior consent

from the manufacturer.

The Instruction Manual should be kept with the Machine at all times. Copies available at www.fogco.com.

The Manufacturer reserves the right to modify the design and make improvements to the Machine without

communicating it to the Customer and without updating the manual already delivered to the user.

PICTOGRAMS

Sym.

Description

General unskilled worker: operator with no specific skill,

able to perform simple tasks upon orders of qualified

technicians.

Operator of lifting and handling: operator familiar with

the use of lifting and handling of materials and machines

(following the instructions of the manufacturer), in

accordance with the laws in force in the country of use of

the machine.

Machine operator - 1st level: operator without specific

skill, able to perform only simple tasks such as the

operation of the machine using the buttons on the Machine

panel or Remote, operations of loading and unloading the

Machine with the protection guards installed and active.

Machine operator - 2

nd

level: operator able to perform

tasks of 1st level operator and also able to perform simple

functions of start, stop and reset following stoppage and

adjustment of the Machine.

Mechanical maintenance worker: qualified technician

able to operate the machine in normal conditions, intervene

on mechanical parts to perform adjustments, or

maintenance work and necessary repair work but. Not able

to work on wiring systems when live.

Electrical maintenance worker: qualified technician able

to operate the machine in normal conditions, intervene in

electrical work of adjustment, maintenance work and

necessary repair work and is capable of working in the

presence of voltage within electrical cabinets and

junction boxes.

Manufacturer’s technician: qualified technician made

available by the manufacturer to perform operations of a

complex nature in specific situations, or in any case, when

agreed with the user. The skills are, depending on the

case, mechanical and/or electrical and/or electronic.

The descriptions preceded by this symbol contain

important information regarding safety.

Failure to respect them can result in danger for the physical safety of the operators; lapse

of warranty; elimination of any manufacturer’s responsiblity.

PICTOGRAMS RELATING TO MACHINE STATUS

The pictograms contained in a square / rectangle provide INFORMATION.

Sym.

Machine status;

Machine off: with electrical and pneumatic power cut

off.

Machine on: with electrical and pneumatic power

connected and in safe stop condition through mobile

protection guards open (specifying which ones); fixed

protectors closed.

Machine on: with electrical and pneumatic power

connected and in safe stop position through mushroom

emergency button in a held position or other control for

this purpose, located close to the intervention zone

(specifying the mushroom or part to use).

Machine in movement: with automatic function, mobile

protection guards closed with relevant blocking device

activated and fixed protector guards closed.

Machine in movement: mobile protector guards closed

with relevant blocking devices activated and fixed

protector guards closed.

Machine in movement: one or more mobile excludable

protection guards open (specifying which) with relevant

interlocking devices deactivated, any remaining mobile

protector guard closed with relevant interlocking devices

activated and fixed protection guards closed.

Machine on: stopped and ready to start (standby

condition) through activation by functional consent (e.g.

presence of product), mobile protection guards closed

with safety device included and fixed protection guards

closed.

PICTOGRAMS RELATING TO SAFETY

The pictograms contained in a triangle indicate DANGER.

The pictograms contained in a circle impose a RESTRICTION OR OBLIGATION.

Sym. Name

Dangerous electrical tension.

Crushing of upper limbs.

Getting caught.

Dragging.

Access forbidden to unauthorized persons.

Do not remove safety devices.

Prohibited to clean, oil, grease, repair or adjust moving

parts by hand.

General danger.

Protection gloves required.

Safety shoes required.

Hard hat required.

Obligation to cut off power before starting repair work

MANUFACTURER DATA

WLP S.r.l.

Via Broletti, 18

38050 Castelnuovo (Trento)

www.wlpdust.com

Exclusive US Partner:

Fogco Environmental Solutions

600 S 56th Street, Unit 9

Chandler, AZ 85226

www.fogco.com

IDENTIFICATION DATA AND MACHINE PLATES

Each Machine is identified by a metal plate that provides the following information:

Machine Product Range

Machine Model Number

Year of Manufacture

Serial Number

Power Requirements

Horsepower

Amp Load

INFORMATION ON TECHNICAL ASSISTANCE

The Machines are covered by warranty as required by general conditions of sale. If the Machine should stop

working smoothly or parts become faulty according to the cases indicated by the warranty, the Manufacturer,

after having made appropriate verifications on the Machine, will repair or replace the faulty parts.

Work performed by the user to alter the machine, without explicit written authorization of the manufacturer,

shall void the warranty and the manufacturer shall not be held liable for damage caused by the faulty

product.

ARRANGEMENTS TO BE PROVIDED BY CUSTOMER

The following are the sole responsibility of the end user:

Arrangement of the site, including any structural work and/or channelling required;

Electrical power of the Machine, according to the laws in force in the country of use;

Grounding of the electrical power when a generator is being used;

Hydraulic power of the Machine, according to the laws in force in the country of use;

Any Pneumatic Power with compressed air.

Pre-filtration for non-potable water use

TRANSPORT AND HANDLING

Before carrying out any operation, it is mandatory to read the entire Instruction Manual.

The transport and the handling of the Machine must be performed in one of the following ways:

HANDLING WITH FORK LIFT: suitable for both TRAILER and POLE versions with base.

A fork lift with lifting force of at least 2200 lbs. and with minimum fork length of 55 inches must be used.

Insert the forks in the proper roll over protective spaces.

HANDLING WITH CRANE: suitable for both TRAILER and POLE versions with or without base.

Use chains or bands with lifting force of at least 2200 lbs. and complete with two lifting hooks. Verify that the

bands or the chains are long enough to avoid them touching the metal parts of the Machine.

Hook and fix the band or the chain to the provided blocking pins only.

INSTALLATION

Before the installation, verify that the ground is adequate to support the weight of the Machine and in the

case of POLE versions verify that the ground is flat and even. The installation must be carried out only by

qualified and authorized staff.

OPERATING PRINCIPLE

The HD 160, HD 230, and HD 300 are dust suppression systems. These machines use water atomization to

capture dust particles (including silica) in the atmosphere.

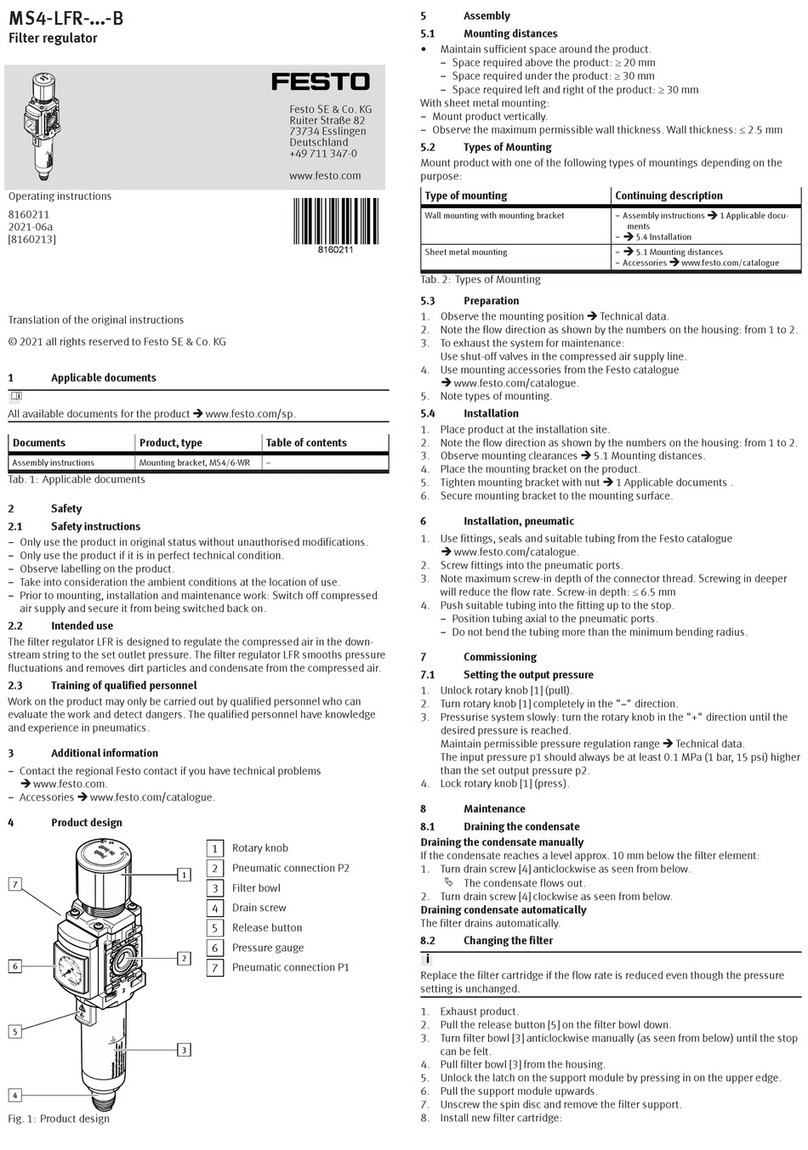

MAIN COMPONENTS

The machine includes a Cannon, a Multi-Zone Crown, a Column Frame, a Filter, Zone Valves (electric

versions are optional) a PLC Control Panel, and a Pump.

Cannon and Multi-Zone Crown

The ventilation and spray system unit have sufficient water flow to accommodate the air volume and thrust

created from the cannon propeller. The water spray nozzles are located along the circumference of the

crowns. A heating kit (optional) can be installed in order to prevent icing.

Column Frame

The FogCannon is installed on a column frame where the raising and rotation devices are also mounted.

These devices, which can be controlled electrically, manually or in Remote mode, serve to adjust the rotation

angle and to make the fogcannon work within the selected angles set up at the user’s own discretion.

Filter

The unit is fitted with a 100 mesh filter that removes impurities that can clog the nozzles. An additional pre-

filter may be recommended for some applications.

Zone Valves

Manual or electric (optional) valves control the water flow to the various zones on the crown. The HD range

includes a crown that has 2 or 3 zones depending on the machine design. The unit can operate with

individual zones or all zones simultaneously. The water flow depends on the number of zones working, the

nozzle size in each zone, and the operating pressure of the pump. See the OPERATING FLOW OPTIONS

table below.

The electric zone valves (optional) are controlled from the PLC panel or from the Remote Control

Transmitter. When the electric valves are turned off, they automatically drain any remaining water in the

zone lines. It is recommended to open all drain ports on the unit after each use.

PLC Control Panel

The PLC control panel allows the starting of the fan, the pump, the electric zone valves (optional), and

control the electric oscillation and electric tilt (optional) of the FogCannon. The panel also allows for

programming the cycling of the unit.

Pump

The pump is housed on the outer column frame and is used to increase the water supply pressure.

Increased pressure will improve the atomization of the water droplets and the effectiveness of the unit. The

pump is equipped with a pressure gauge and pressure switch which will terminate the pumps operation if the

water supply is insufficient.

CONTROL PANEL DISPLAY

The System status can be viewed on the various pages of the control panel display. Push the key on

the keypad to select the page to view.

PAGE 1

SYS (System): shows if the system is in Manual (MAN) or Automatic (AUT) mode

EV (Electric Valve): shows if the electric valves (1,2,3) are On (1) or Off (0).

ACQ (Acquisition): shows the positions of the acquired rotation points; (0) the machine will search for the 0

point; (1) first point of the angle; (2) second point of the angle.

PAGE 2

PMP (PUMP): Shows if the pump is Off (OFF), On (MAN) or in Auto (AUT)

RADIO (RADIOCOMAND): Shows if the radio is On (ON) or Off (OFF)

HEATER (HEATING SYSTEM): Shows if the heater is On (ON) or Off (OFF).

PAGE 3

TIM (TIMER WORK/PAUSE): Shows if the timer is On (ON) or Off (OFF)

TIM.ON (WORKING TIME) The first column shows the working time in minutes (from 5 to 30 minutes). If the

timer is On, the second column shows the remaining On time.

TIM.OFF (PAUSE TIME) The first column shows the pause time in minutes (from 5 to 30 minutes). If the

timer is On, the second column shows the remaining pause time.

CONTROL PANEL BUTTONS

Turns the fan ON or OFF. Also turns the pump ON or OFF if the pump is in AUTO mode.

Turns the system to AUTO or MANUAL mode.

Turns the pump OFF, AUTO, or ON. AUTO is the recommended default setting.

Raises the cannon if fitted with Electric Tilt.

Changes the Page view between pages 1, 2, and 3.

Turns the electric valve for zone 1 ON or OFF (1/0) if fitted with Electric Valves.

Turns the Radio Control ON/OFF if fitted with REMOTE CONTROL.

Oscillates the cannon to the left.

Sets the auto oscillation rotation angle (See SET THE ROTATION ANGLE instructions below).

Oscillates the cannon to the right.

Turns the electric valve for zone 2 ON or OFF (1/0) if fitted with Electric Valves.

Turns the timer ON/OFF.

Initiates the system at start up and resets any Alarms.

Lowers the cannon if fitted with Electric Tilt.

Shows the required Service.

Turns the electric valve for zone 3 ON or OFF (1/0) if fitted with Electric Valves.

Sets the Time ON for cycling operation.

Sets the Time OFF for cycling operation.

Changes the Heating System settings (when included) only from Page 2.

Shows the required Service.

Raising and lowering of the cannon and opening and closing of the valves is done manually if the unit

is not equipped with Electric Tilt or Electric Valves.

Manually raise/lower the cannon by loosening the cannon Tilt Handle located on the tilt assembly next to the

main control panel; raise or lower the cannon as needed; tighten the Tilt Handle.

Manually open/close the valves for the individual zones on the crown.

CONFIRM FAN ROTATION

After CONNECTING TO THE APPROPRIATE POWER AND WATER SUPPLIES, verify that the primary

selector switch on the FogCannon is ON. Press the blue button on the control panel and press the F1

button on the keypad. The red Tower light stops flashing and the machine is ready for use

Before using the machine, confirm the correct direction of rotation of the Fan by pressing the Fan

ON/OFF key and verify that it turns counter-clockwise or in the direction of the arrow on the backside

of the cannon. If not, pull the plug from the power source and reverse two of the wires. This should

only be done by a qualified electrician.

SET THE ROTATION ANGLE

It is possible to set a rotation angle anywhere between 0° and 340° where the fogcannon oscillates

automatically.

Start by pressing the ACQ key. The fogcannon will rotate clockwise until point 0. Once the cannon

stops at Point 0, press and hold the Left Arrow key until the desired RIGHT stopping point is reached.

Press the ACQ key to set first set point. Press and hold the Left Arrow key until the desired LEFT

stopping point is reached. Press the ACQ key to set the second set point. The ACQ value shown on the

control panel display will show 0 meaning that the desired angle has been set up correctly and that the

machine is ready to operate in the AUTO mode.

After setting the rotation angle, the machine will oscillate automatically when the System (SYS) is set to the

AUTO mode.

OPERATE THE SYSTEM IN MANUAL MODE (manual oscillation)

Use the key to toggle between the 3 pages.

Check the settings on Page 1. SYS should be MAN and all EV should be set to 0;

Check the settings on Page 2. PMP should be AUTO and RADIO should be OFF

Check the settings on Page 3. TIM should be OFF

Press the FAN key to turn the Fan and Pump ON

Press the Electric Valve , , and/or keys (or rotate the manual zone valves if the unit is not

equipped with Electric Valves) to open the appropriate zone(s) on the crown.

The cannon can be rotated by pressing the LEFT and RIGHT arrows. The cannon can be

raised/lowered by pressing the UP and DOWN arrows (or raised and lowered manually if the unit is

not equipped with Electric Tilt).

To terminate the operation, press the FAN key once and press the appropriate Electric Valve , ,

and/or keys once (or rotate the manual zone valves if the unit is not equipped with Electric Valves).

OPERATE THE SYSTEM IN AUTO MODE (auto oscillation)

The Rotation Angle must be set before operating the system in the AUTO mode.

Use the PAGE key to toggle between the 3 pages.

Check the settings on Page 1. SYS should be in MAN; and all EV should be set to 0;

Check the settings on Page 2. PMP should be in AUTO and RADIO should be OFF

Check the settings on Page 3. TIM should be OFF.

Press the Electric Valve , , and/or keys (or rotate the manual zone valves if the unit is not

equipped with Electric Valves) to open the appropriate zone(s) on the crown.

Press the SISTEM key to change the system from MAN to AUTO.

The buzzer will sound for 3 seconds and the cannon will rotate to the 0 position. The cannon will then rotate

to the 1 position. The fan will turn ON. The cannon will continue to rotate to the 2 position. The Pump will

turn ON.

The system will continue to oscillate between position 1 and position 2 until the SISTEM key is pressed

again.

Once the SISTEM key is pressed again, the oscillation, the Fan, the Pump will turn OFF immediately.

All valve (Electric and Manual) must be turned Off separately.

NOTES:

When the system is in AUTO, only the following keys on the display key pad will operate:

The UP and DOWN arrows for raising and lowering the cannon (if equipped with Electric Tilt)

The Electric Valve (EV) keys (if equipped with Electric Zone Valves)

SETTING THE TIMER

It is possible to set up TIME ON and TIME OFF times for the system.

Press the PAGE key on the keypad to select Page 3.

Press the TIM ON key to increase the TIME ON setting (left-hand column) in 5-minute increments from 5

to 30 minutes.

Press the TIM OFF key to increase the TIME OFF setting (left-hand column) in 5-minute increments

from 5 to 30 minutes.

After setting the TIM ON and TIM OFF, the timer can be activated by pushing the TIMER key.

While the machine is operating, the value in the right-hand column for the TIM.ON decreases starting from

the maximum value shown on the left until 0 is reached. Identical procedure is valid for the pause time.

SETTING THE PUMP FUNCTION

Use the key on the keypad to toggle between the 3 pages

Check the settings on Page 1. SYS should be MAN and all EV should be set to 0;

Check the settings on Page 2. PMP should be OFF and Radio should be OFF

Check the settings on Page 3. TIM should be OFF

Press the PUMP key to switch between OFF, AUT, and MAN

When the PMP is set to OFF, it will be deactivated.

When the PMP is set to AUT, it will start automatically whenever the fan is activated and will continue to run

until the fan operation is terminated.

When the PMP is set to MAN, it will start immediately and run until the PMP is set to OFF.

NOTE: The Electric Valves will NOT be automatically activated whenever the pump is running. They must

be turned on seperately by pressing the appropriate EV key on the keypad. The electric valves will NOT be

deactivated when the pump is turned OFF. They must be turned OFF manually by pressing the appropriate

EV key on the display.

SETTING RADIO CONTROL

Transmitter Button controls:

First Row: Tilt UP and DOWN

Second Row: Oscillate Left and Right

Third Row: Fan ON/OFF and Electric Valve 1 ON/OFF

Fourth Row: Electric Valve 2 ON/OFF and Electric Valve 3 ON/OFF

Fifth Row:Not Used

Sixth Row: ON/SYSTEM AUTO mode and Pump ON/OFF

Use the PAGE key to toggle between the 3 pages.

Check the settings on Page 1. SYS should be in MAN; and all EV should be set to 1.

Check the settings on Page 2. PMP should be AUTO and Radio should be OFF.

Check the settings on Page 3. TIM should be OFF.

Press the key on the keypad to select the page 2.

Press the RADIO key to switch from OFF to ON.

Once the RADIO on the machine control panel is set to ON, only the PAGE and RADIO keys will function.

Insert a fully charged battery into the Radio Transmitter

Pull out the red tab on the top of the Transmitter.

Briefly press the Transmitter ON button (bottom left hand position on the Transmitter)

Then hold the same button down until the LED light begins flashing green.

The transmitter is now ready to use and provides the following functions:

SYSTEM AUTO mode is initiated by pressing and holding the SYSTEM AUTO button for 3 seconds.

SYSTEM AUTO mode is terminated by pressing the SYSTEM AUTO button again.

Turn OFF the RADIO mode by pressing the RADIO button on the control panel keypad.

Turn OFF the Radio Transmitter by pushing the red tab on the top of the Transmitter inward.

OPERATING FLOW OPTIONS

The individual zones on the crown can be operated seperately or simultaneously creating a wide range of

flow options for the unit. The table below provides approximate flow given the standard nozzles and the

number of zones being used.

GPM Flow Using Various Zones

HD 160 HD230

HD 300

Zone 1 6 4.2 4.2

Zone 2 9 8.3 8.3

Zone 3 N/A 12.5 12.5

Zone 1/2 15 12.5 12.5

Zone 1/3 N/A 16.7 16.7

Zone 2/3 N/A 20.8 20.8

Zone 1/2/3 N/A 25 25

HD 160: Dual Zone with 36-10 GPH and 36-15 GPH nozzles

HD230: Triple Zone with 50 - 5 GPH, 50-10 GPH; and 50-15 GPH nozzles

HD300: Triple Zone with 50 - 5 GPH, 50-10 GPH; and 50-15 GPH nozzles

ALARMS

The page EMERGENCY STOP indicates that the emergency stop button, which is placed on the side

of the control panel, has been pushed manually or that a malfunctioning occurred causing the safety

relay to stop the machine. The red Tower Light starts flashing.

SOLUTION: Verify the origin of the malfunction and if necessary, contact Fogco Technical Assistance.

Only after that the malfunction is solved, pull the emergency stop button and reset the internal breaker

as described below.

The alarm WRONG ROTATION – INVERT PHASE indicates that one of the electrical phases is

inverted. In this case, the angle cannot be set up in automatic mode.

SOLUTION: Contact a qualified electrician to invert the phases.

The alarm appears when the automatic mode had been selected and the angle had not been set up.

SOLUTION: Follow the SET THE ROTATION ANGLE instructions above.

This alarm indicates that the pump is not supplied with enough water. The pump stops and the red

and yellow Tower Lights mounted on the frame start flashing for three minutes.

SOLUTION: The machine starts working again automatically if the pump receives the correct water

quantity again within three minutes. The machine stops automatically if the water flow is not restored

within three minutes. Verify the origin of the malfunction. Press the F1 to reset key only after solving

the malfunction.

This alarm appears when a problem at one of the motors arises. The corresponding safety switch

blows.

SOLUTION: Check the origin of the malfunction and contact a qualified electrician. If the malfunction

can be attributed to a loss of current, restore the machine by turning the motor start selector switch in

position 1. If the malfunctioning persists, contact the authorized Technical Assistance Service.

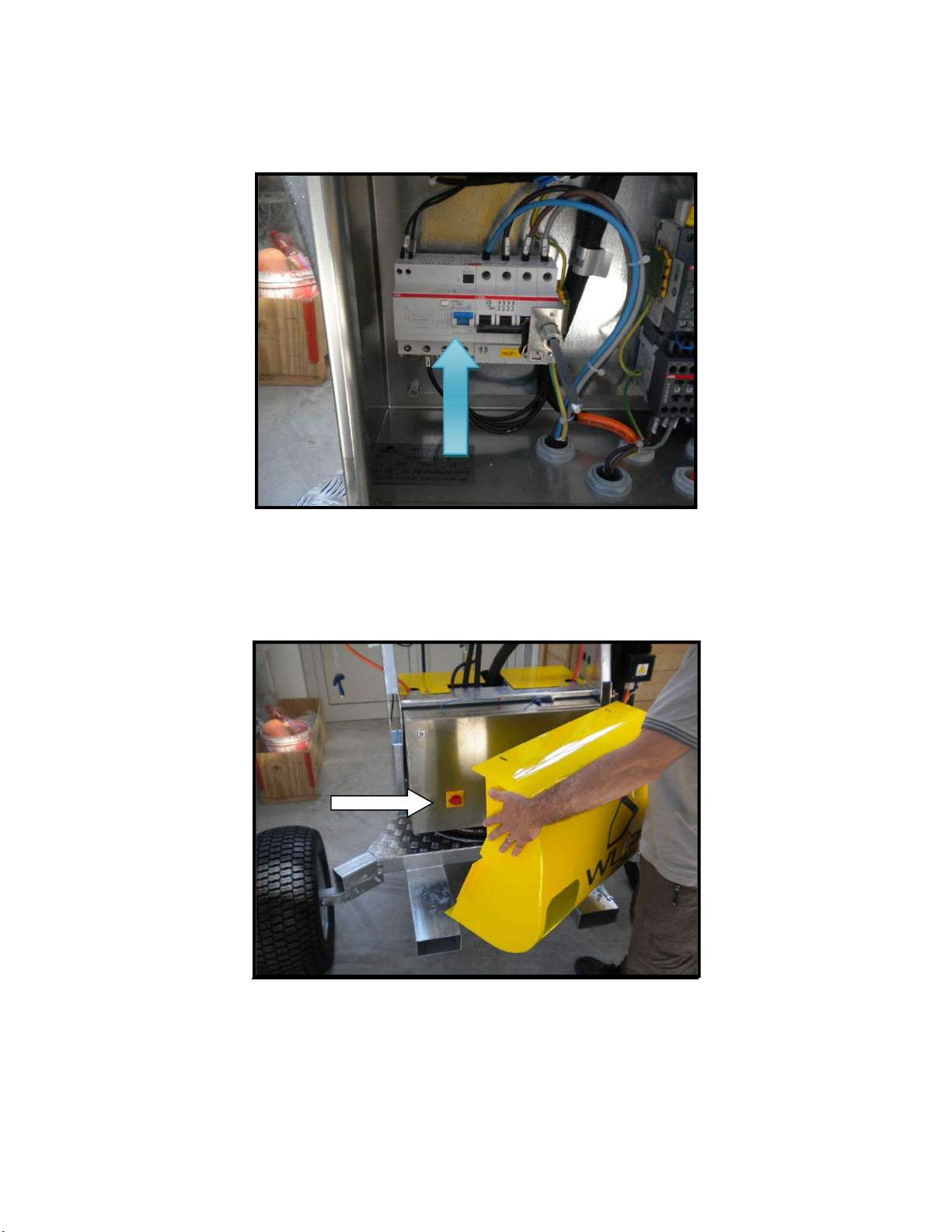

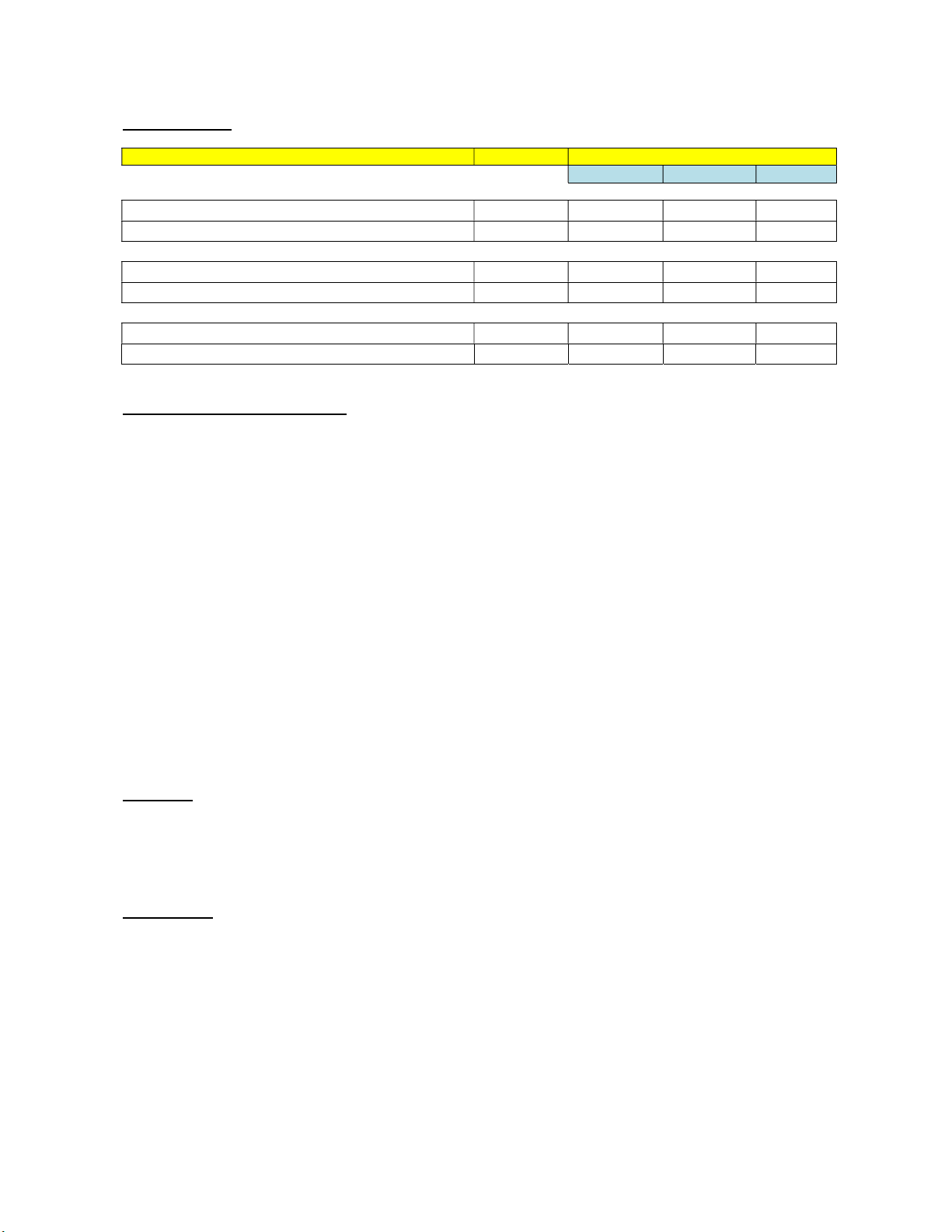

SWITCH-ON THE CIRCUIT-BREAKER

When the machine is stopped with the emergency stop it requires to switch-on the circuit-breaker with the

following procedure:

Restore the emergency stop.

Dismount the front protection using a 10 mm wrench

Remove the front protection and switch off the main switch (white arrow)

Open the electric cabinet and look for the blue colored circuit breaker (orange arrow)

Lift –up the switch as shown in picture (blue arrow)

Close the electric cabinet and the front protection.

Switch –on the main switch (white arrow)

3. DIMENSIONS

MODEL

WEIGHT (

Lbs

)

DIMENSIONS (

inches

)

H

L

W

HD 160 Pole with iron base 1455 103 48 48

HD 160 Trailer 950 88 98 75

HD 230 Pole with iron base 1630 103 48 52

HD 230 Trailer 1125 88 98 75

HD 300 Pole with iron base 1720 103 48 52

HD 300 Trailer 1215 103 98 75

ENVIRONMENTAL CONDITIONS

The Machine does not need to work in specific environmental conditions. It can be installed in an industrial

building where the electrical equipment has at least IP55 protection, the ventilation is good and the floor is

solid and level.

ATTENTION – the machine must not be used in environments with an explosive or corrosive atmosphere.

The machine may be used in environments with:

Temperatures between 40° F and 100° F, with a mean temperature of 90° F;

Relative humidity ranging from 30 to 95%.

The machine may not be used in environments with:

A corrosive atmosphere;

A risk of fire;

An explosive atmosphere;

A risk of stones being ejected;

Water and chemical substances that could mix and create hazards.

LIGHTING

The installation area must be illuminated in accordance to the local codes or regulations in force. The lighting

should ensure good all-round visibility, create no dangerous reflections, make it possible to read the writing

on the control panels clearly and easily and locate the emergency buttons without trouble.

VIBRATIONS

The vibrations do not generate any risk of danger if the machine is used properly according to the manual

instruction. If you are planning to install the machine in an area where there is a strong risk of vibration, you

should fit vibration dampeners of adequate size between the machine and the source of vibration. The

dampeners require a written declaration of approval issued by Fogco.

TECHNICAL DATA

Description HD 160 HD 230 HD300 Volts

Fan Motor HP 7.5 15 25 480 VAC / 60 Hz

Pump Motor HP 3 5 5 480 VAC / 60 Hz

Oscillation Motor HP .1 .1 .1 24 VDC

Full Load Amps 21 32 45

STANDARD SUPPLY

The machine is supplied ready for use and includes the User’s Manual and Data plate with Machine

technical information;

GENERAL SAFETY WARNINGS

The manufacturer has done his utmost in designing this Machine to be INTRINSICALLY SAFE and is fitted

with all necessary protective and safety devices and is supplied with the information for its proper use.

The user can appropriately integrate the information provided by the manufacturer with supplementary work

instructions to ensure safe use of the Machine and must not be in contrast with the instructions given in this

Manual,

It is forbidden to operate the Machine in Auto mode with the fixed/mobile protection devices dismantled;

It is forbidden to inhibit the safety devices installed on the Machine;

It is forbidden to stand in front of the Machine when it is in operation;

Before carrying out any repair or maintenance, the Machine must be switched off and disconnected from

the water and power supply networks;

All maintenance operations must be performed by qualified and authorized staff;

It is mandatory to wear the necessary personal protection devices;

It is mandatory to respect and observe all alarms and warnings;

In the event of a malfunction of a component, the failed component must be replaced with and exact

duplicate. The manufacturer shall not be held liable for the consequences when generic parts are used

to replace factory authorized parts. Modification requests must be directed to the manufacturer;

Clean the machine, panels and controls with soft dry cloth or slightly soaked in a neutral detergent

solution. Do not use any type of solvent, such as alcohol or petrol, as the surfaces could be damaged;

The washing operations must be performed with the electrical and pneumatic separation devices cut off;

it’s strictly forbidden to use high pressure systems for washing the machine and/or its inner parts.

It is absolutely forbidden to move the machine when operating with lifting means

of any nature and kind. The machine can be moved exclusively with hydraulic

and electrical devices uncoupled and the frame must be blocked with the

appropriate pins to the lift forks. The spring pins must be inserted into the

blocking pins.

USE POTABLE WATER ONLY

Before putting the Machine into operation carefully read the instructions set out in this

Manual and follow the indications provided in it.

General instructions

All the safety devices mounted on the mobile parts to avoid accidents and to ensure safety cannot be altered

or removed and they must be properly protected. Users must inform immediately their employers or direct

supervisors about any defect or anomaly found on the mobile parts.

Checks and verifications

The Machine must be thoroughly inspected prior to each use. If worn or faulty parts are not promptly

replaced, the manufacturer will not be responsible for damage or accidents which could occur.

The verifications must be performed by qualified staff and must be of visual and functional kind, with the

purpose of guaranteeing the machine safety. They include:

verification of all the supporting structures, which must not present any crack, breakage, damage,

deformation, corrosion, wear, or alteration compared with the original characteristics;

verification of all mechanical parts;

verification of all safety devices installed on the machine;

verification of all the connections with pins and screws;

functional verification of the machine;

verification of machine status;

verification of seal and efficiency of the pneumatic system.

If the person performing the verification finds cracks or dangerous anomalies, he is obliged to give prompt

communication of this to the manufacturer. The Machine must be taken out of service until operating

anomalies are verified and corrected or repaired.

Certify that there are no objects between the Machine parts.

Check that no object remains between the moving parts after any maintenance work.

To guarantee the maximum safety in handling the Machine it is FORBIDDEN to:

Alter any Machine part;

Leave the moving elements unprotected;

Use the machine in operation, but not in complete efficiency,

Alter the machine to change the established original use, without explicit authorisation of the

Manufacturer or without assuming full responsibility set by D.P.R. 459/96 (Machine Directives);

Handle moving parts manually in case of lack of energy;

IMPORTANT !

The Manufacturer shall

NOT be

liable for any damage caused by the

Machine in case of:

- use of the Machine by staff without necessary training;

- improper use of the machine;

- faults in electrical, hydraulic or pneumatic power;

- incorrect installation;

- failure to perform maintenance work required;

- unauthorized alterations or work;

- use of spares that are not original or not specific to the model;

- partial or total failure to observe the instructions;

- use contrary to national specific legislation;

- calamities and force majeure or extraordinary events.

ATTENTION!

If anomalies are found, they must be eliminated before starting the machine again, and

the expert who performs the verification must make a note of it on the repair sheet, giving

his

consent to use the machine.

INTENDED USE

The machine has been designed to work as a system to suppress dust on worksites and quarries by the

exclusive use of potable water. Any use with products/materials other than that mentioned is considered

incorrect or improper, can damage the machine and create dangerous situations for the operator and/or

persons close to the Machine.

CONTRAINDICATIONS

The Machine must not be used:

For uses other than those set out in this Manual;

In explosive or corrosive atmosphere, with oily substances in suspension in air;

With water supply pressure greater than 140 PSI;

In atmosphere with risk of fire;

With safety devices cut off or not operating;

With electric bridges and/or mechanical means which exclude utilities/parts of the Machine itself;

DANGEROUS ZONES

Dangerous zones include but are not limited to electrical substation or areas where there are electrical parts

with IP level lower than IP 55 and/or areas where there is the risk of explosion

SAFETY DEVICES

In the Machine the following safety devices are installed:

1. Emergency shutdown from the main control panel as well as the other emergency shutdown devices of

the Machine.

RESIDUAL RISKS

DEFINITION OF RESIDUAL RISK:

“ danger not totally traceable through the design and technique of protection, or rather, potential non

evident danger”

It is necessary to pay attention to the following residual risks which are present upon use of the machine and

cannot be eliminated.

CAUTION: DANGEROUS MOVEMENTS

No people other than the operator must stay around the machine. In the presence of

third people, immediately stop the machine and force them to move away.

CAUTION: ELECTRICAL RISKS FOR LIVE PARTS

CAUTION: ELECTRICAL RISKS FOR RESIDUAL VOLTAGE

Other residual risks can be identified by introducing bodies within the fan when it is in operation and when it

is off. The introduction of solid bodies can cause immediate breakage of the fan with consequent projection

of the parts outside the machine. This situation can endanger people and cause damage to things within the

range of action of the machine.

GENERAL MAINTENANCE INSTRUCTIONS

The HD 160, HD 230, and HD 300 require the following maintenance:

Water filter: Check the condition of the filter each time before starting up the

machine. Unthread the filter cannister to access the filter. Clean the filter with a jet

of water. As necessary, remove the O-ring and soak the filter in nozzle cleaner for

30 minutes. Flush with hot water. Re-install. Any traces of iron oxide (rust), scale or

other form of oxidization on the surface of the filter are a result of poor water quality.

Additional filtration may be needed.

Remove any residue of organic substances, such as small algae, using neutral

soap. Do not use cleaning solvents as these can damage the O-rings on the filters.

Make sure the filter is properly in place before threading on the cannister. Check the

condition of the seals before putting the machine into service.

Nozzles: Remove the nozzles by hand using a 5/8” socket. Disassemble the

nozzles using a 5/8” socket/wrench and a 5/32 Allen wrench. Brush slots on the top

of the nozzle inserts with a stainless steel wire brush to remove all debris. Remove

the O-ring from the nozzle body. Soak the nozzle body and insert in nozzle cleaner

for 30 minutes. Flush with hot water and then compressed air. Re-assemble.

Inspect nozzle threads Clean the nozzle and crown threads as necessary. Thread

the nozzle into the crown (hand tight only).

Plumbing: Flush with potable water and drain the unit after each use. Periodically

(or under freezing conditions), clean and drain the unit plumbing by removing the

hose that feeds the nozzle crown and flush the units plumbing by running the pump

with potable water for 30 seconds. Remove the top nozzle from each crown and

insert a pressurized water supply into the open nozzle port to flush the crown.

Repeat with compressed air. Replace the nozzle. Replace the feed hose. Open all

drain valves.

Water pump: consult the respective manual.

Keep the system clean at all times.

Before putting the machine into

operation,

it is mandatory to

read this manual carefully and

to make sure you understand all the instructions.

All

information and instructions provided in this manual must be respected and

observed.

Record all maintenance in the maintenance table.

Contact the Technical Assistance Service or the Manufacturer before carrying out

any repair, change of the Machine and/or extraordinary maintenance operations.

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

NANOTEC

NANOTEC PD4-C Technical manual

Siemens

Siemens SINAMICS G120 instruction manual

Schulte

Schulte FLX-1510 Operator's manual

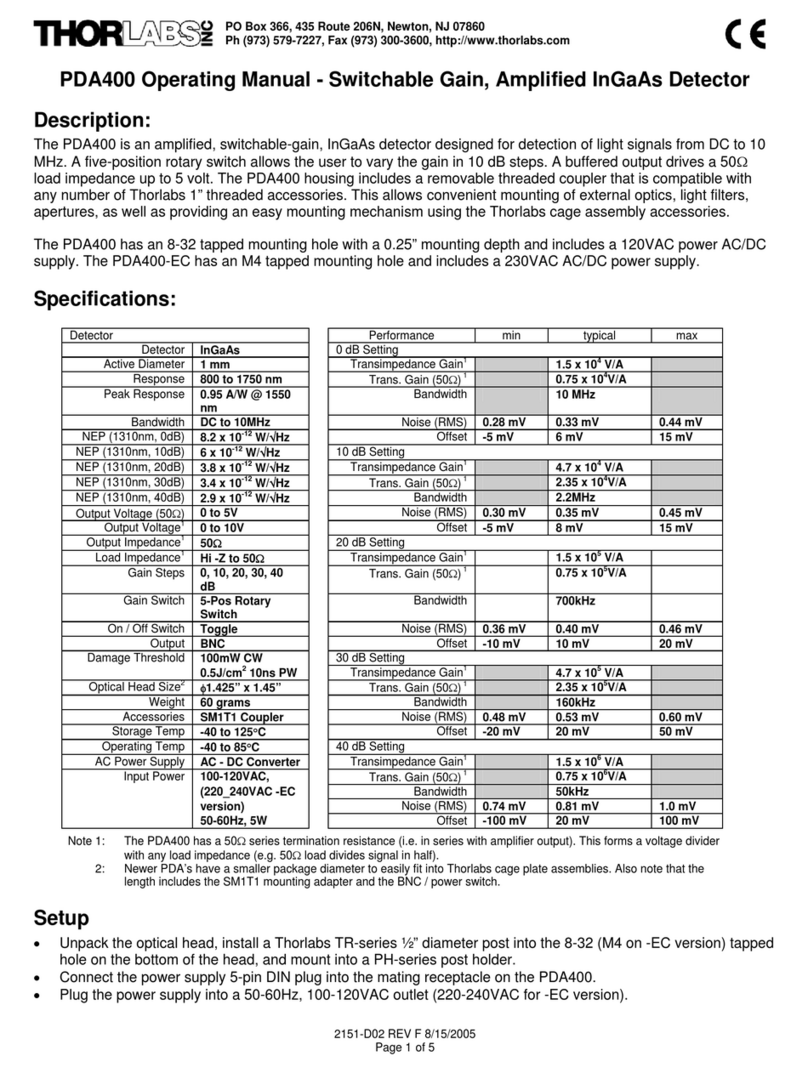

THORLABS

THORLABS PDA400 operating manual

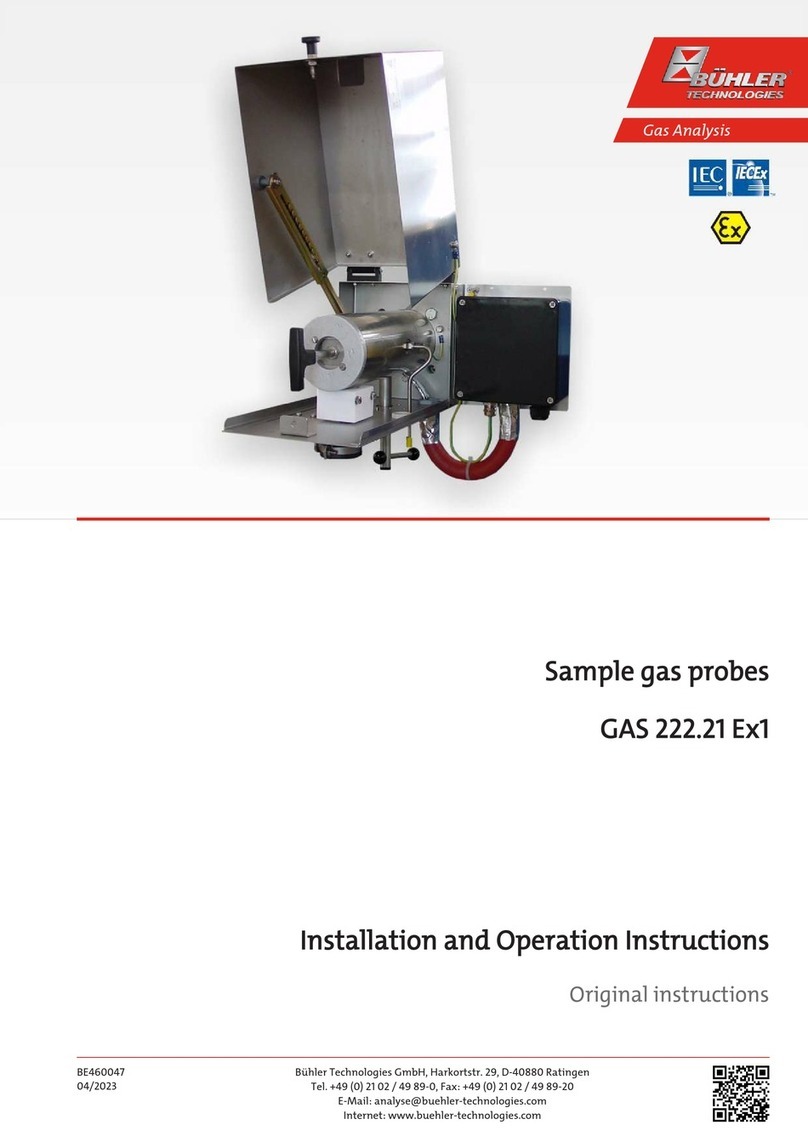

Bühler technologies

Bühler technologies GAS 222.21 E 2 Series Installation and operation instruction

Universal

Universal Radial 8 Reference manual