MS4-LFR-...-B

Filter regulator

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Operating instructions

8160211

2021-06a

[8160213]

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1Applicable documents

All available documents for the product è www.festo.com/sp.

Documents Product, type Table of contents

Assembly instructions Mounting bracket, MS4/6-WR –

Tab. 1: Applicable documents

2Safety

2.1 Safety instructions

–Only use the product in original status without unauthorised modifications.

–Only use the product if it is in perfect technical condition.

–Observe labelling on the product.

–Take into consideration the ambient conditions at the location of use.

–Prior to mounting, installation and maintenance work: Switch off compressed

air supply and secure it from being switched back on.

2.2 Intended use

The filter regulator LFR is designed to regulate the compressed air in the down-

stream string to the set outlet pressure. The filter regulator LFR smooths pressure

fluctuations and removes dirt particles and condensate from the compressed air.

2.3 Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can

evaluate the work and detect dangers. The qualified personnel have knowledge

and experience in pneumatics.

3Additional information

–Contact the regional Festo contact if you have technical problems

è www.festo.com.

–Accessories è www.festo.com/catalogue.

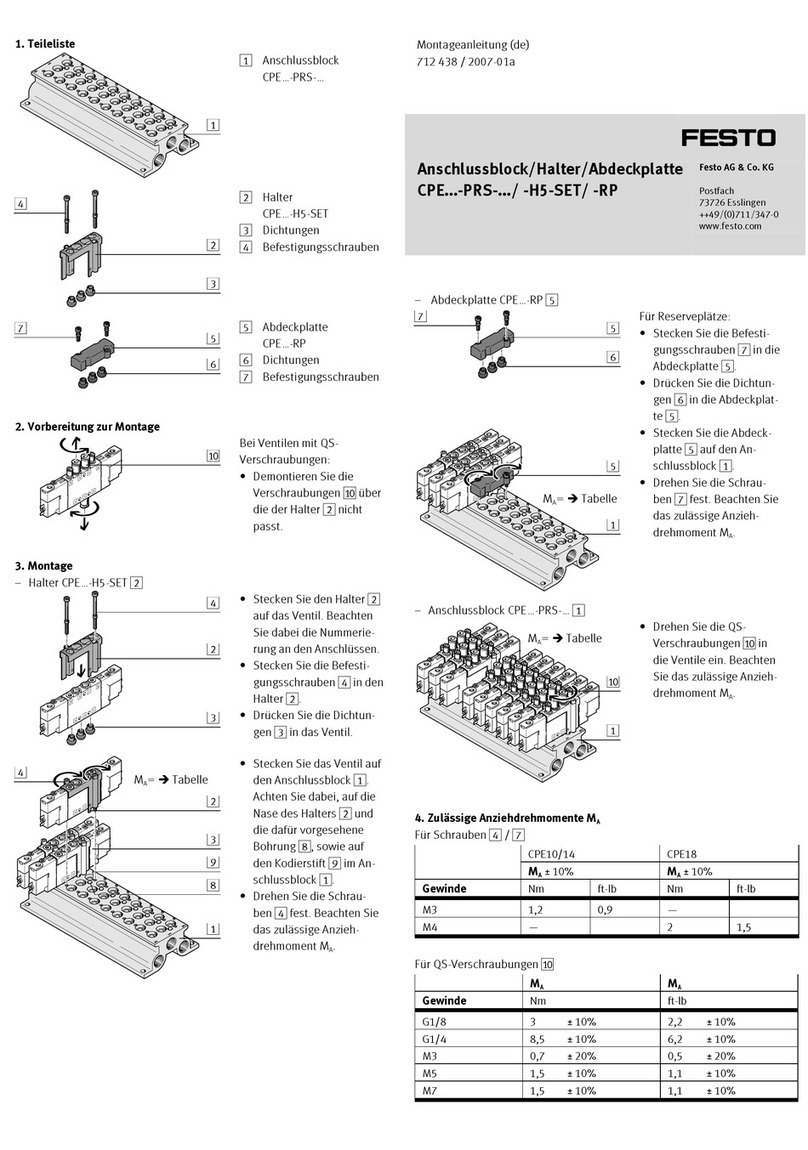

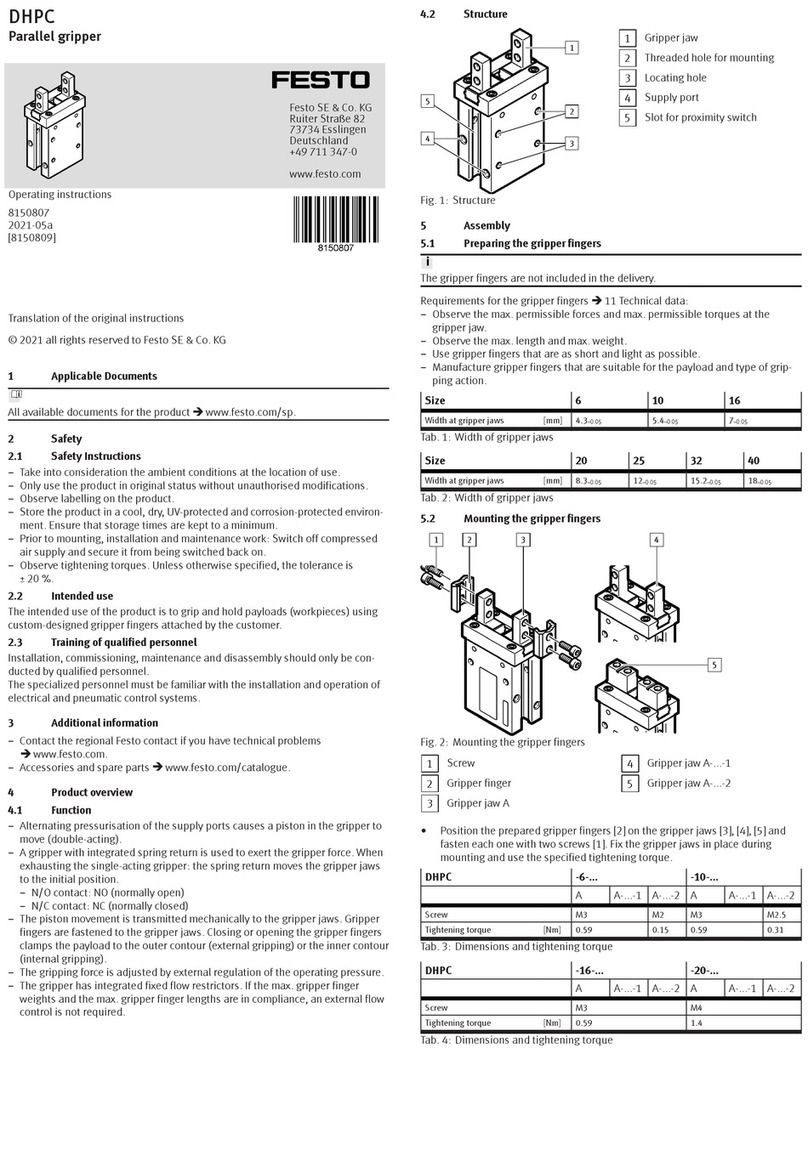

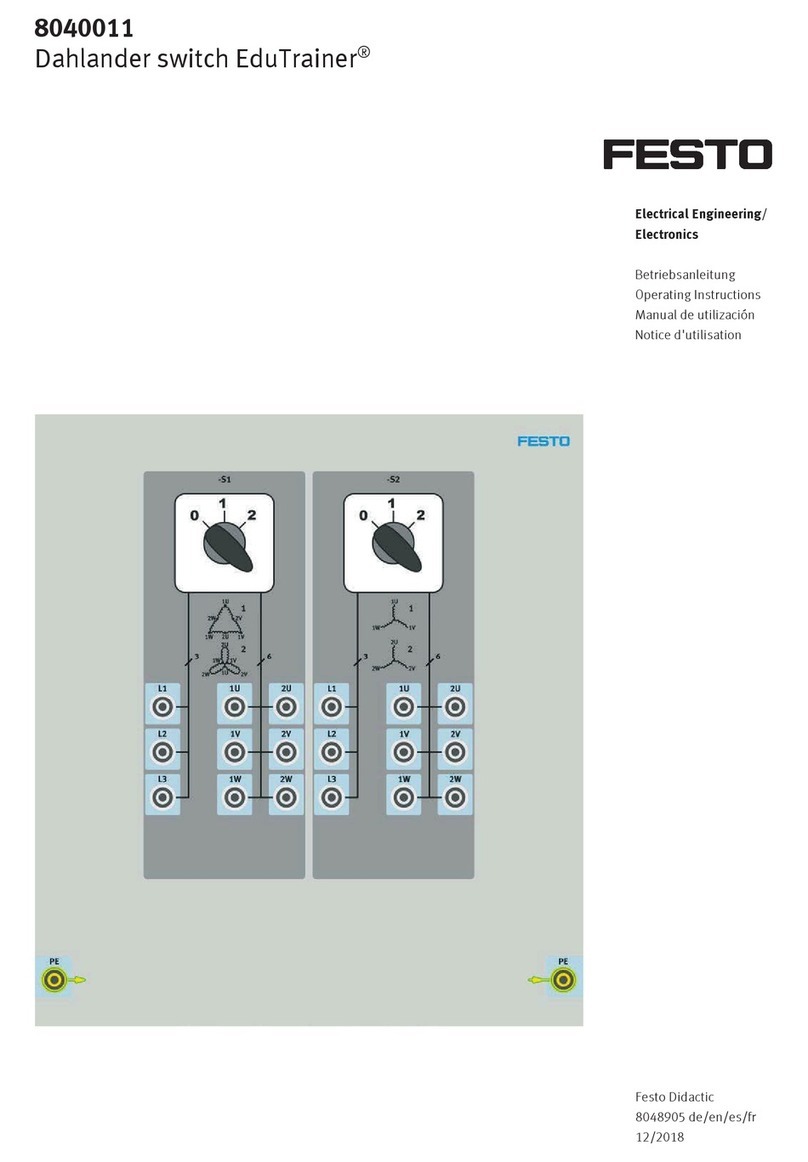

4Product design

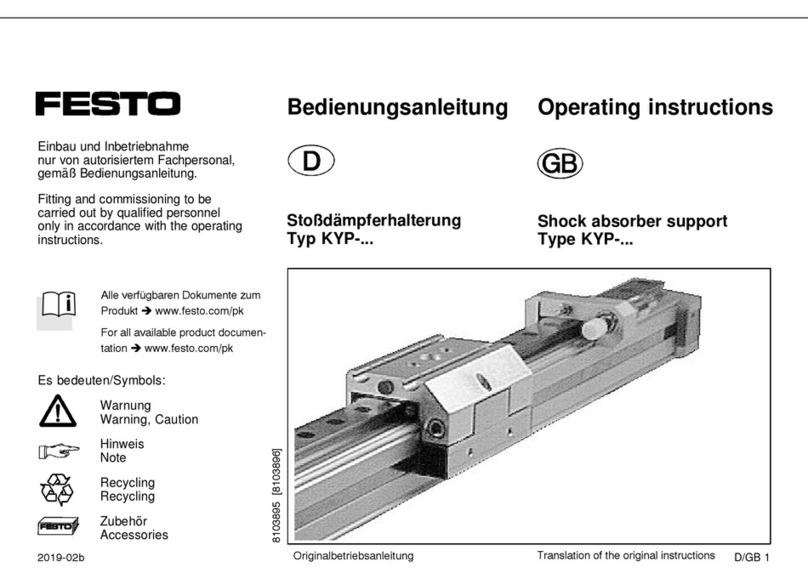

Fig. 1: Product design

Rotary knob

Pneumatic connection P2

Filter bowl

Drain screw

Release button

Pressure gauge

Pneumatic connection P1

5 Assembly

5.1 Mounting distances

• Maintain sufficient space around the product.

–Space required above the product: ³ 20 mm

–Space required under the product: ³ 30 mm

–Space required left and right of the product: ³ 30 mm

With sheet metal mounting:

–Mount product vertically.

–Observe the maximum permissible wall thickness. Wall thickness: £ 2.5 mm

5.2 Types of Mounting

Mount product with one of the following types of mountings depending on the

purpose:

Type of mounting Continuing description

Wall mounting with mounting bracket –Assembly instructions è 1 Applicable docu-

ments

–è 5.4 Installation

Sheet metal mounting –è 5.1 Mounting distances

–Accessories è www.festo.com/catalogue

Tab. 2: Types of Mounting

5.3 Preparation

1. Observe the mounting position è Technical data.

2. Note the flow direction as shown by the numbers on the housing: from 1 to 2.

3. To exhaust the system for maintenance:

Use shut-off valves in the compressed air supply line.

4. Use mounting accessories from the Festo catalogue

è www.festo.com/catalogue.

5. Note types of mounting.

5.4 Installation

1. Place product at the installation site.

2. Note the flow direction as shown by the numbers on the housing: from 1 to 2.

3. Observe mounting clearances è 5.1 Mounting distances.

4. Place the mounting bracket on the product.

5. Tighten mounting bracket with nut è 1 Applicable documents .

6. Secure mounting bracket to the mounting surface.

6 Installation, pneumatic

1. Use fittings, seals and suitable tubing from the Festo catalogue

è www.festo.com/catalogue.

2. Screw fittings into the pneumatic ports.

3. Note maximum screw-in depth of the connector thread. Screwing in deeper

will reduce the flow rate. Screw-in depth: £ 6.5 mm

4. Push suitable tubing into the fitting up to the stop.

–Position tubing axial to the pneumatic ports.

–Do not bend the tubing more than the minimum bending radius.

7 Commissioning

7.1 Setting the output pressure

1. Unlock rotary knob [1] (pull).

2. Turn rotary knob [1] completely in the "z" direction.

3. Pressurise system slowly: turn the rotary knob in the "+" direction until the

desired pressure is reached.

Maintain permissible pressure regulation range è Technical data.

The input pressure p1 should always be at least 0.1 MPa (1 bar, 15 psi) higher

than the set output pressure p2.

4. Lock rotary knob [1] (press).

8 Maintenance

8.1 Draining the condensate

Draining the condensate manually

If the condensate reaches a level approx. 10 mm below the filter element:

1. Turn drain screw [4] anticlockwise as seen from below.

ÄThe condensate flows out.

2. Turn drain screw [4] clockwise as seen from below.

Draining condensate automatically

The filter drains automatically.

8.2 Changing the filter

Replace the filter cartridge if the flow rate is reduced even though the pressure

setting is unchanged.

1. Exhaust product.

2. Pull the release button [5] on the filter bowl down.

3. Turn filter bowl [3] anticlockwise manually (as seen from below) until the stop

can be felt.

4. Pull filter bowl [3] from the housing.

5. Unlock the latch on the support module by pressing in on the upper edge.

6. Pull the support module upwards.

7. Unscrew the spin disc and remove the filter support.

8. Install new filter cartridge: