2015OPERATIONSMANUAL

8

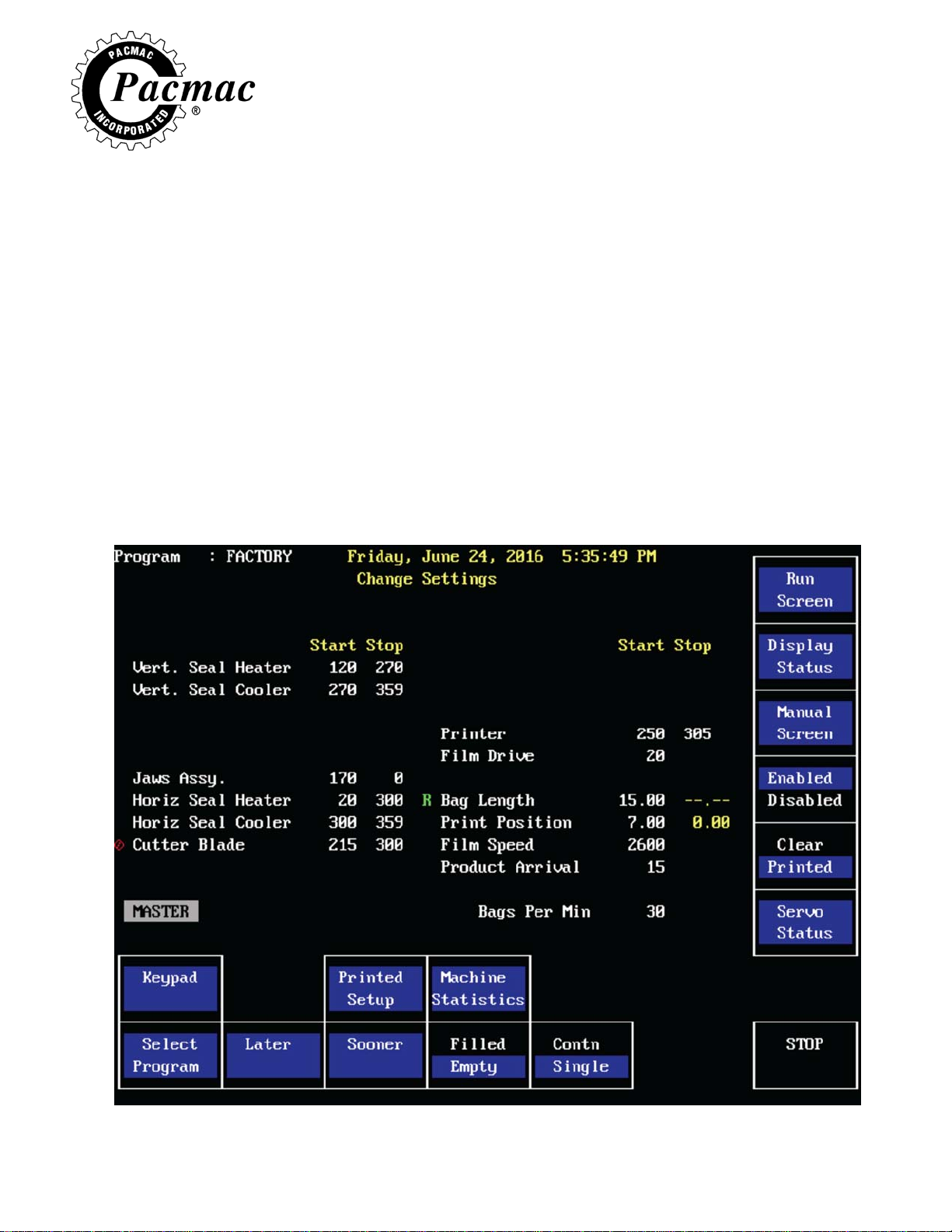

THE CHANGE SCREEN FUNCTIONS ARE THE SAME AS THE RUN

SCREEN IN ADDITION TO THE FOLLOWING.

RENAME A PROGRAM

TOUCHING THE PROGRAM NAME IN THE TOP LEFT-HAND

CORNER OF THE SCREEN ALLOWS THE OPERATOR TO RENAME

THE SELECTED PROGRAM.

SELECT PRINTED OR CLEAR FILM

PRINTED OR CLEAR FILM IS SELECTED BY TOUCHING THE

APPROPRIATE WORD IN THE CLEAR/PRINTED BUTTON.

WHEN PRINTED FILM IS SELECTED, THE MACHINE CONTROL IS

NOW SET TO LOOK FOR A REGISTRATION INPUT. THIS INPUT IS

TYPICALLY THE REGISTRATION MARK ON THE FILM.

THE EYE, WHICH SENSES THE MARK, IS LOCATED DIRECTLY BEHIND

THE NIP AND DRIVE ROLLER ALONG THE FILM PATH.

BAG LENGTH AND PRINT POSITION WILL BE DISPLAYED ON THE

SCREEN.

BAG LENGTH IS SET DURING PRINTED SETUP AND PRINT POSITION

ADJUSTS THE PRINT IN RELATIONSHIP TO THE JAW CUT.

WHEN CLEAR FILM IS SELECTED FILM LENGTH WILL BE DISPLAYED.

THE OPERATOR CAN CHANGE THE FILM LENGTH BY TOUCHING

THE NUMBER AND THEN TOUCHING THE COUNT UP OR COUNT

DOWN BUTTON TO ENTER THE DESIRED LENGTH.

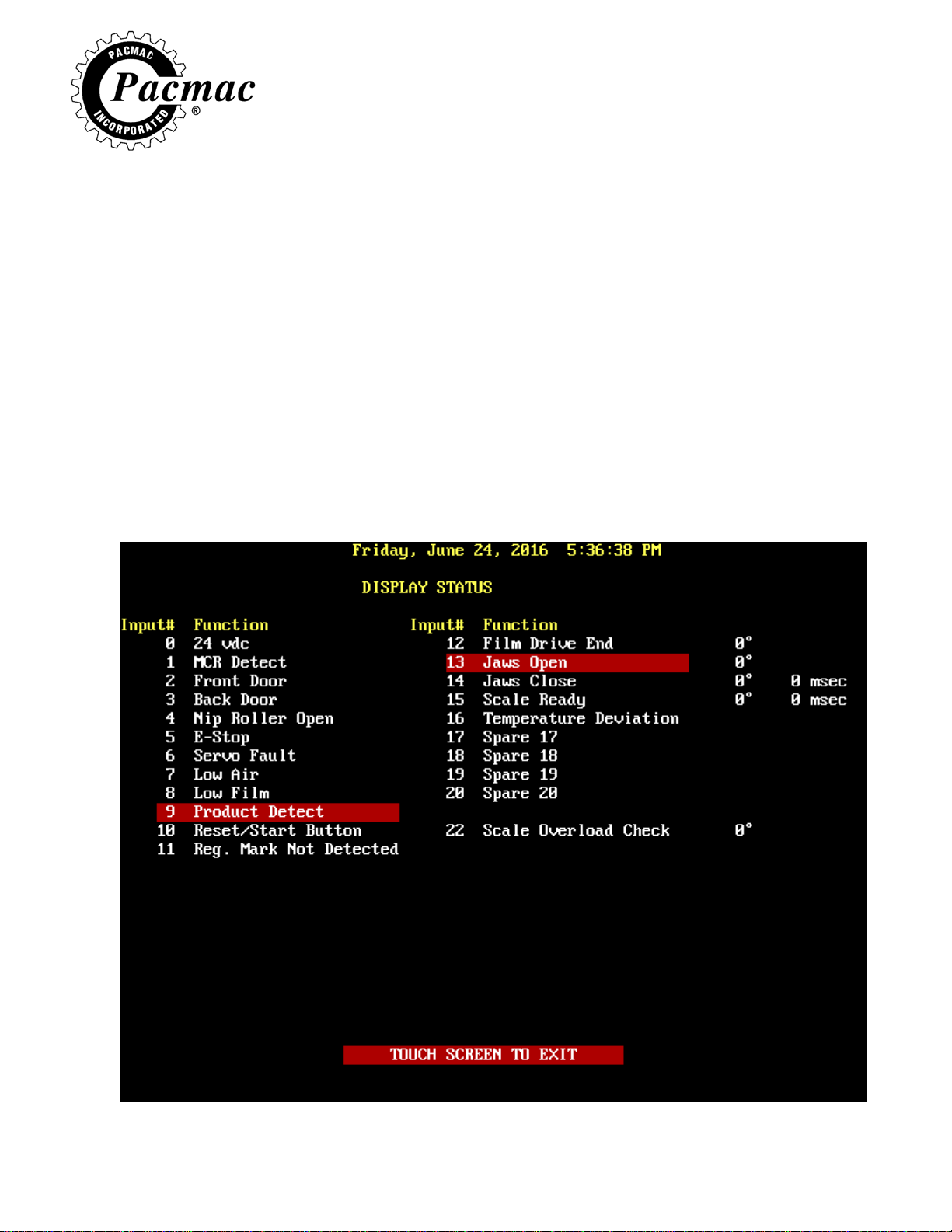

ENABLE/DISABLE ANY FUNCTION

THE OPERATOR MUST FIRST SELECT THE FUNCTION BY TOUCHING

THE NUMBER TO THE RIGHT OF THE NAME.

BY USING THE ENABLE/DISABLE BUTTON, THE OPERATOR CAN

DISABLE THE SELECTED FUNCTION.

WHEN A FUNCTION IS DISABLED, A RED MARK WILL BE DISPLAYED

NEXT TO THE DISABLE FUNCTION.

YOU CAN DISABLE ALL FUNCTIONS FROM THE KEYPAD.

CHANGING SETTINGS

EACH FUNCTION START, AND STOP TIME CAN BE ADJUSTED BY

TOUCHING THE APPROPRIATE NUMBER TO THE RIGHT OF THE

FUNCTION NAME. THIS NUMBER WILL HIGHLIGHT IN RED.