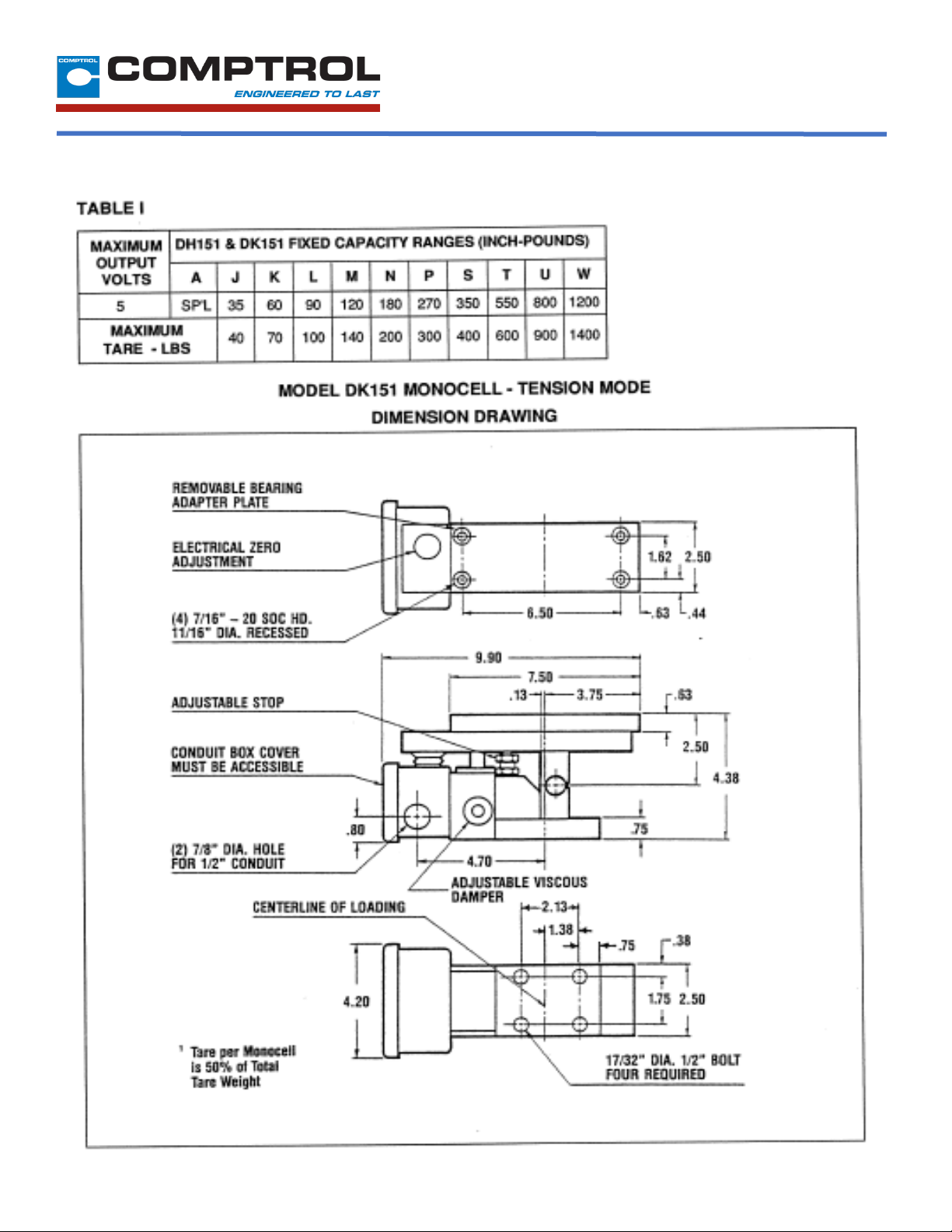

SERIES DH151/DK151

SINGLE RANGE MONOCELLS

INSTRUCTION MANUAL D-131

8

Copyright 2023 - Revised, Comptrol All Rights Reserved

5.

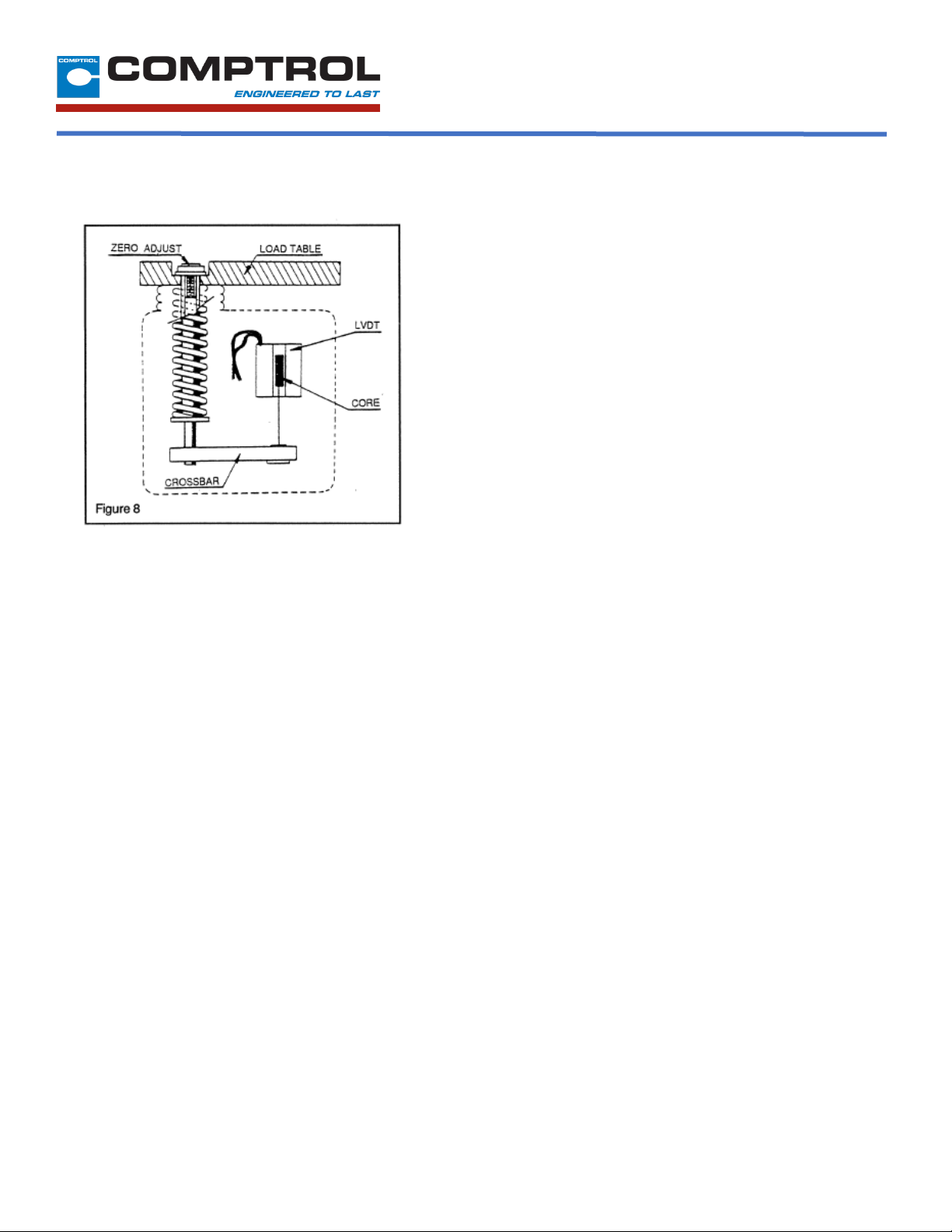

If the output is not zero, remove the dust cap located

on the load table to gain access to the zero

adjustment screw. (See Figure 8)

6.

Using a 7/64-inch hex key, turn the zero-

adjustment screw several turns counter clockwise

(CCW). Then, slowly turn the adjusting screw

clockwise (CW) until a zero reading is obtained on

the voltmeter. If the zero position is passed, turn

the adjusting screw counter clockwise (CCW) pass

the zero point. Then turn the adjusting screw back

in a clockwise (CW) direction until the meter reads

zero volt.

7.

Deflect the Load Table of the loadcell by applying

pressure in the direction the tension force will be

applied. This may be done manually or with a

lever. A change in the output voltage signal should

be noticed.

NOTE: The polarity of the output signal will be

positive (+) for deflection in the Compression

Mode, and negative (-) for deflection in the Tension

Mode.

8.

Release the force applied to the Load Table should

allow the output signal to return to zero.

If the output signal does not return to zero, make

sure the measuring roll rotates freely. Check for

improper alignment of the measuring roll and for

friction or binding with the pillow block bearing.

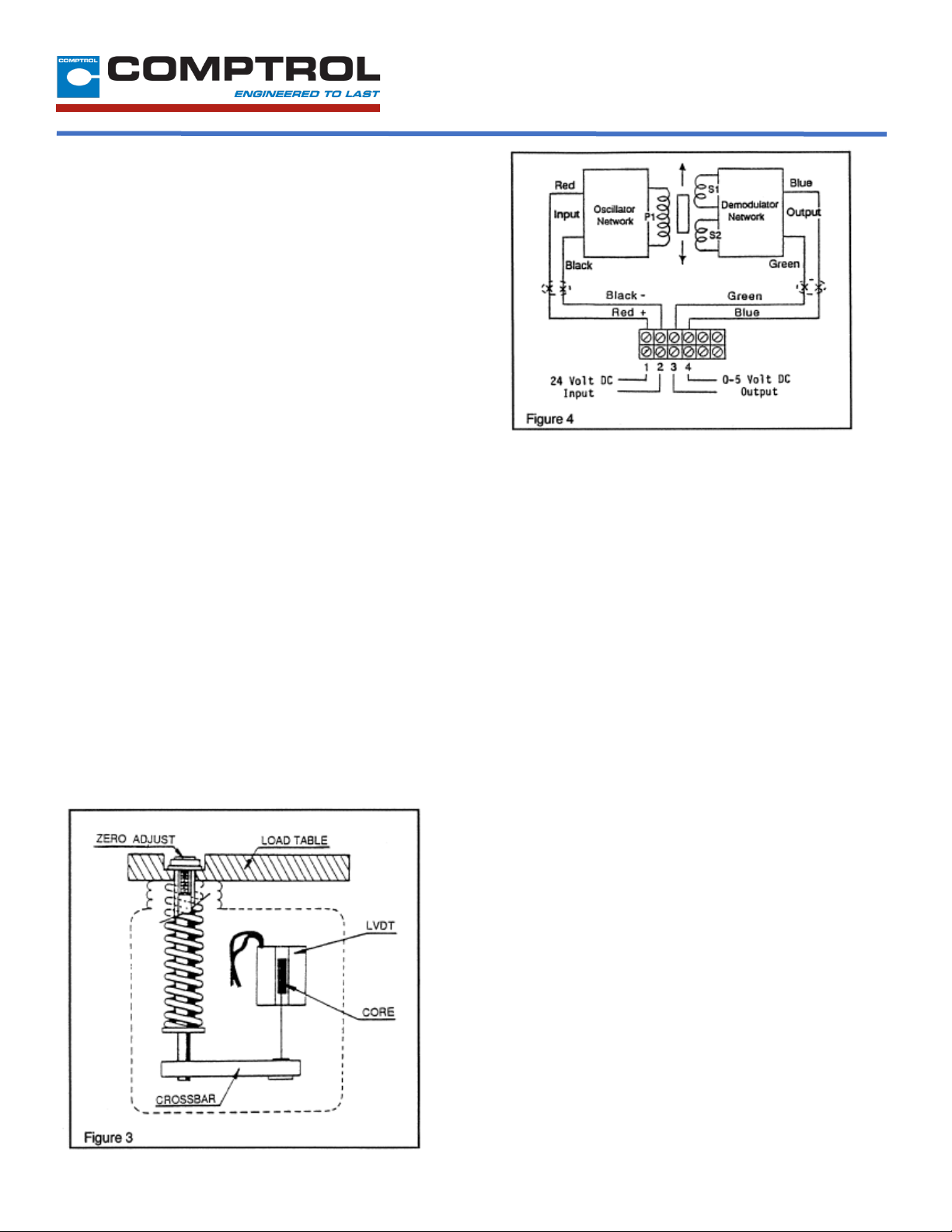

Also check that the LVDT crossbar assembly is

free of any interference. Repeat Steps 1 through 8.

If the output signal still does not return to zero,

contact Comptrol.

9.

Repeat Steps 1 through 8 for the loadcell mounted

on the opposite end of the measuring roll.

II-H FULL LOAD ADJUSTMENT

After the loadcell has been zeroed, a pull test can be

made to check the output voltage of the loadcell at full

load. (See calibration sheet for voltage output)

1. Run a non-stretchable rope over the center of the

tension roll simulating the web path. (NOTE: the rolls

should be free to turn)

2. With one end of the rope secured, hang a known

weight, equally over the roll so that the total tension is

equal to the maximum strip tension specified on the

calibration sheet, at the other end. (See Figure 9A)

For larger tension where dead weights would be too

large, a crane scale can be used to simulate maximum

strip tension. (See Figure 9B)

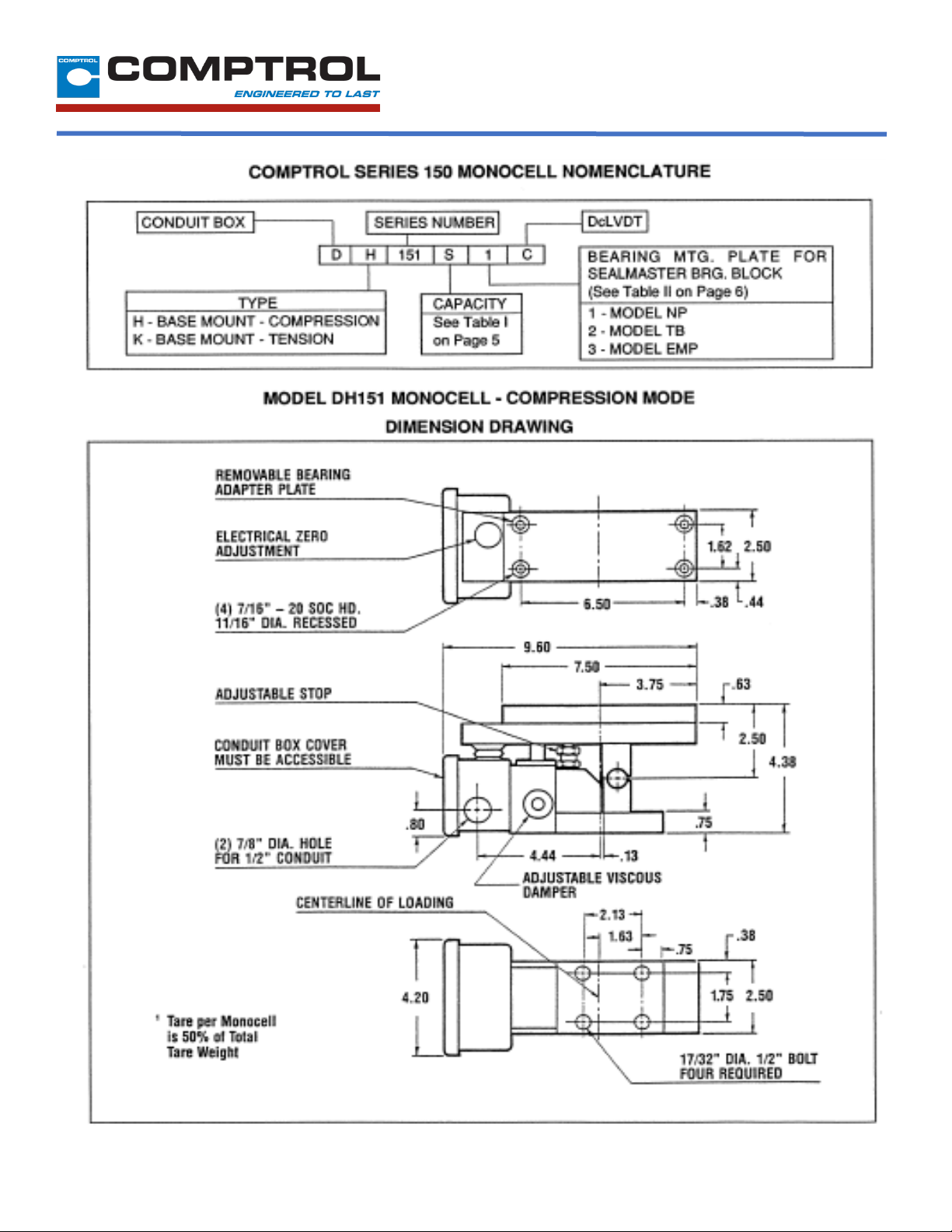

3. With a voltmeter connected to the bottom Terminals 3

and 4 of the Terminal Board, maximum output voltage

will be observed.

4. Repeat Step3 for the loadcell mounted on the opposite

end of the measuring roll.

5. Recheck to make certain that all leads are dressed

away from the LVDT crossbar assembly on both

loadcells and replace both conduit box covers.

Comptrol loadcells instrumentation provides the required

signal conditioning and a reliable high level output signal

for use as feedback control of a tension drive system.

The feedback signal is directly proportional to the strip

tension applied. If a Comptrol control is used, refer to the

control manual for further calibration.

Although the electrical output of Comptrol Monocells are

sufficient to drive most electrical indicators, substantial

signal conditioning is normally required for effective

tension instrumentation system control. Refer to the

documentation available from the instrumentation

supplier for more information.