Folger Technologies 2020 Prusa i3 User manual

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 1 / 38

FOLGER TECHNOLOGIES, LLC

2020 i3 –3D Printer Kit

BUILD GUIDE

Rev. A

Thank you for your purchase!

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 2 / 38

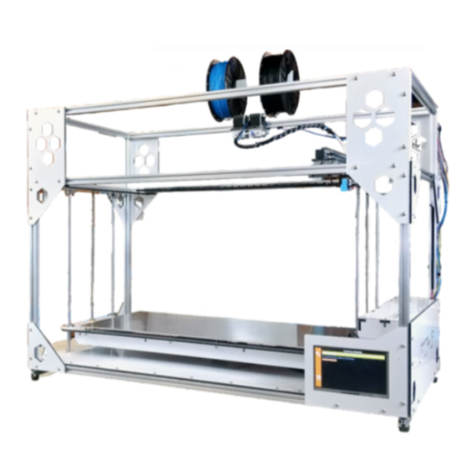

We are happy to announce this as our 3rd complete 3D printer kit. The Folger Tech

2020 i3 kit combines the simplicity of an erector set with the power of a much

more expensive desktop printer. This kit includes everything you need to

assemble the 8 cubic inch print area machine (with the exception of an 8x8” glass

surface & the tools required for assembly).

Note From the Author:

This guide was made from the perspective of someone that has never built

a 3D printer. I built the printer with only the prototype as a visual reference.

Taking pictures each step of the way and making small notations I was able to

put together the following guide over the next couple weeks. Once the first draft

was completed we had one of our warehouse girls take a kit and try to assemble

it. She had zero technical experience and made notes (lots of them) on each page

as she went along. She completed her first printer and I took the notes back to

my desk to complete this guide. This is the finished product. I look forward to

your feedback and hope you enjoy building this extremely fun i3 kit!

Thanks,

Dan

Folger Technologies

Offical RepRap Forum Thread:

http://forums.reprap.org/read.php?4,512329,512329#msg-512329

Visit us on IRC:

irc.freenode.net

#folgertech

If you feel you are missing items from your kit or have suggestions for

improvements to the build guide please email us at:

We are also planning on offering 2 upgrades for this kit:

1) Extended 200x300MM bed.

2) Auto bed leveling with proximity sensor and aluminum plate.

Step 1: Un-box everything and separate like parts into areas you can grab from.

Step 2: Get out your calipers or ruler and separate screws into different

piles based on size (believe us, it makes things much easier). Step 3:

Assemble Bottom Half Of Main Frame:

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 3 / 38

•Parts Needed: (2) 365MM 2020, (2) 375MM 2020, (4) SK8's, (1) Motor Mount, (2) 2020

corner brackets.

•Hardware Needed: (8) 2020 L Mounts w/ Set Screws, (8) 5mm T-Nuts, (4) 4mm T-Nuts,

(4) M4x8MM Pan Head Bolts, (8) M5x8MM Bolts.

1. Take the 375MM 2020 Beam and place it in front of you, we are going to attach the

corner brackets, and SK8's before continuing with the frame assembly. [Insert Picture

Here]

2. Using (2) 4MM T-Nuts & (2) 4Mx8MM Pan Head Bolts attach the 2020 corner brackets

to the center of the 375MM 2020 Beam spacing them about an inch apart. Note: this

will be adjusted later.

3. Slide (2) 5MM T-Nuts to the left of the corner brackets, and (2) 5MM T-Nuts to the right

of the corner brackets.

4. Attach the (2) SK8's to the M5 T-Nuts using the (4) M5x8MM Bolts. Note: the tension

screws for the SK8's should be facing outwards to make it easier to tighten them later.

5. Take the other 375MM 2020 Beam and place it in front of you, we are going to attach

the motor mount, and the remaining 2 SK8's.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 4 / 38

6. Repeat the process from step 3 to attach the remaining 2 SK8's by sliding (4) M5 TNuts

onto the top of the 2020 beam and attach the remaining (2) SK8's using (4) M5x8MM

Bolts.

7. Take the metal motor mount and attach it to the front face of the 375MM 2020 Beam in

between the SK8's using (2) M4 T-Nuts & (2) M4x8MM Pan Head Bolts. Note: this will

need to be moved left and right to adjust screws later so you can leave it loose for

now.

8. Now take (4) 2020 L Mounts & the remaining (2) 365MM 2020 Beams. Slide (2) 2020 L

Mounts back to back on the top of each of the 365MM 2020 Beams. Each one should

look like the picture below. Do not secure these in place as they will be moved later.

Note: Ignore the L Bracket in the left of the picture it shouldn't be there yet.

9. You can now use the remaining (4) 2020 L Mounts to secure the bottom frame

together. Tighten the set screws to lock them in place. Use the below pictures as

reference. Note: The motor mount is not pictured, but should be attached to the rear

2020 beam.

Step 4: Attach Y Carriage Rails & Bearings:

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 5 / 38

•Parts Needed: (2) 395MM Chrome Rods, (3) LM8UU Bearings, Bottom Frame Assembly.

•Hardware Needed: none

1. Place the bottom frame in front of you so the motor mount is at the back of the

printer. Note: This is the front position of the printer. The motor mount is missing from

this picture but should be attached to the rear 2020 beam.

2. Slide (1) 395MM Chrome Rod through the front right SK8 about half way through.

3. Carefully slide (2) LM8UU Bearings onto the Chrome Rod & finish pushing the Chrome

Rod through to the other SK8. Be careful not to hit the corner of the rod on the inside

of the LM8UU which can cause bearings to fall out.

4. Similar to step 3 slide the remaining (1) 395MM Chrome rod into the left side SK8 and

slide (1) LM8UU Bearing onto the rod.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 6 / 38

5. Be Sure to tighten the tension screws on the (4) SK8's to secure the chrome rod's in

place.

Step 5: Attach & Assemble The Upper Frame

Parts Needed: (2) 295MM 2020 Beam, (1)375MM 2020 Beam, Bottom Frame Assembly.

Hardware Needed: (3) 2020 L Mounts w/ Set Screws.

1. Take the (2)295MM 2020 Beams and attach them vertically to the left and right side of

the Bottom Frame Assembly using the (2) 2020 L Mount's on each side that we placed

in step 3:8. Before securing them make sure the back side of the beam is 90MM from

the back of the printer.

2. Before attaching the top we are going to attach (1) 2020 L Mount to the outside of the

left most vertical 295MM 2020 Beam for the Spool Holder which we will attach later.

3. Now attach the remaining (1) 375MM 2020 Beam to the top of the (2) vertical 295MM

2020 Beams using (2) 2020 L Mounts w/ Set Screws to secure them in place.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 7 / 38

Step 6: Assemble The Aluminum Heat Bed Plate

•Parts Needed: (1) Aluminum Bed Plate, (3) Printed Bearing Mounts, (1) Printed Belt

Carriage.

•Hardware Needed: (6) Small Zip Ties, (6) M3x20MM Bolts, (2) M3x12MM Bolts (8) M3

Nylock Nuts.

1. Remove the blue protective layer off both sides of the Aluminum Bed Mount.

2. Take the (3) Printed Bearing Mounts and attach (2) Small Zip Ties to each by sliding

the Zip Tie through the guide holes (as pictured).

3. Using the (6) M3x20MM Bolts & (6) M3 Nylock Nuts, attach the Printed Bearing Holders

to the Aluminum Bed Plate. Use the (2) M3x12MM Bolts and (2) M3 Nylock Nuts to

attach the Printed Belt Carriage to the Aluminum Bed Mount using the pre drilled holes.

Note: the opening on the Printed Belt Carriage is facing the side with 2 bearing holders.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 8 / 38

4. Now we are going to attach the Aluminum Bed Mount to the bearings on the Bottom

Frame Assembly of the printer by pushing them down into the LM8UU Bearings. Line up

the Printed Bearing Holders over the LM8UU's attached to the Chromed Rod and apply

enough pressure to snap the bearings into the Printed Bearing Mounts. Note: you

should feel a small pop as it sets into the grooves.

5. Tip the frame backward and close the Small Zip Ties that you previously attached to

the Printed Bearing Holders over the LM8UU Bearings securing them in place. Note:

Once tightened you can clip the excess material from the Small Zip Ties.

Step 7: Solder The MK2B Heated Bed & Attach Thermistor

•Parts Needed: (1) MK2B Heated Bed, (1) Thermistor, (1) xM Black 16 Gauge Wire, (1)

xM Red 16 Gauge Wire.

•Special Tools Needed: Soldering Iron, Solder, Kapton Tape

1. Prepare your MK2B Heated Bed to be soldered.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 9 / 38

2. Apply solder to contacts #1, #2, & #3.

3. Strip the ends off and apply solder to one end of both the Black & Red 16 Gauge Wire.

4. Solder the stripped and soldered end of the Black 16 Gauge Wire to both contacts #3 &

#2. Note: This is critical, if you do not make contact with both #3 & #2 you will only be

running at 12v and will not be able to reach max bed temp.

5. Solder the stripped and soldered end of the Red 16 Gauge Wire to contact #1.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 10 / 38

6. Place the glass of (1) Thermistor into the small hole in the center of the heated bed.

7. Using the provided Kapton Tape, secure both the Thermistor and the Red & Black 16

Gauge wire to the bottom of the heated bed. Note: use these pictures as a guideline

but you can use more/less tape and position the wires as you see fit.

Step 8: Attach the Heated Bed to the Aluminum Bed Plate.

•Parts Needed: (1) MK2B Heated Bed Pre Wired from Step 7

•Hardware Needed: (4) Springs, (4) Thumb Screws, (4) M3x16MM Bolts

1. Feed (1) M3X8MM Bolt through each corner hole on the MK2B Heated Bed > Spring >

Aluminum Bed Plate > Secure with (1) Thumb Screw. Note: wires should be coming

out the back of the printer. Thumb screws just need to be hand tight for now and can

be adjusted later.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 11 / 38

Step 9: Attach Motors & Motor Mounts

•Parts Needed: (2) Metal Motor Mounts, (2) Acrylic Rod Keepers, (1) 4.8 Motor, (2) 2.6

Motors

•Hardware Needed: (6) M4 T-Nuts, (6) M4x8MM Pan Head Bolts, (4) M3x8MM Bolts, (8)

M3x12MM Bolt, (12) Lock Washers

1. Gather the required parts & hardware.

2. Take the (2) Metal Motor Mounts and (2) Acrylic Rod Keepers and attach them to the

(2) 2.6 Motors using (8) M3x12MM Bolt & (8) Lock Washers. Note: one acrylic rod

keeper should have the small hole facing right, and one should have hole facing left, as

pictured. Wire harness should be facing the corner of the bracket.

3. Mount the (1) 4.8 Motor to the Metal Motor Mount that we attached to the Bottom

Frame Assembly earlier in the build guide using (4) M3x8MM Bolts & (4) M3 Lock

Washers.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 12 / 38

4. Attach the (2) Metal Motor Mounts with the attached motors and acrylic rod keepers to

the top right & left corners on the front of the 2020 Frame using (3) M4x8MM Pan Head

Bolts and (3) M4-T-Nuts per side. Note: the small holes in the acrylic rod keepers

should be facing the outside of the printer. These don't need to be secured to tightly as

we will be raising them later.

Step 10: Assemble Z Carriage

•Parts Needed: (7) LM8UU Bearings, (1) 2.6 Motor, (1) 3D Printed: Extruder Carriage,

(1)

3D Printed: Left Side, (1) 3D Printed: Right Side, (1) Folger Tech Direct Drive Extruder:

Pre Assembled, (2) F623Z Bearings, (1) 20T Pulley, (1)1M GT2 Belt, (2)365MM Chromed

Rod

•Hardware Needed: (3) M3x20MM Bolts, (1) M3X16MM Bolt, (4) M3 Nylock Nuts, (2) M5

Nuts, (8) Zip Ties

1. Insert (2) LM8UU Bearings into the (1) 3D Printed: Right Side by pressing them firmly.

Note: You can use the table to push them into place if more force is required.

2. Insert (1) M5 Nut into the pre cut slot provided.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 13 / 38

3. Attach the (1) 2.6 Motor to the (1) 3D Printed: Right Side using (3) M3x20MM Bolts.

Note you want the motor wire connectors to be facing up so using the picture as a

reference it would be facing the upper left.

4. Attach the (1) 20T Pulley onto the shaft of the (1) 2.6 Motor and secure with the set

screws. Set this aside for now. Note: Tooth side down on the pulley.

5. Take the (1) 3D Printed: Left Side and Place the 2 Bearings into the spot provided, just

like you did with the Right Side.

6. Place the remaining (1) M5 Nut into the spot provided on the (1) 3D Printed: Left Side.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 14 / 38

7. Take the (2) F623ZZ Bearings and using (1) M3X16MM Bolt and (1) M3 Nylock Nut to

secure the bearings into the (1) 3D Printed: Left Side as pictured. Set aside for now.

8. Take the (1) 3D Printed: Extruder Carriage and place (6) Zip Ties into the slots

provided to later secure the bearings.

9. Press (3) LM8UU Bearings into the (1) 3D Printed: Extruder Carriage. Secure into place

using the Zip Ties & Clip the ends off the Zip Ties. Note: Use the table to press the

bearings into place if you are having trouble getting them to lock in.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 15 / 38

10. Very carefully slide the (2) 365MM Chromed rod through the bearings in the (1) 3D

Printed: Extruder Carriage. Note: Be very careful when pushing the rod through the

bearings not to push out the ball bearings,

11.Take the 3D Printed Part: Extruder Carriage (with the rods and bearings attached, the

3D Printed Part: Left Side (assembled) and the 3D Printed Part: Right Side (assembled)

and set them in front of you. You should have the parts laid out in front of you as

pictured. Note: these are mirrored to how they will be when attached to the printer so

don't get confused with how we define left and right in the next step.

12.Push the 2 ends of the Chrome Rods on the left into the 2 holes in the 3D Printed: Right

Side. Push them in so they are snug, we will have to adjust this later.

13.Push the 2 ends of the Chrome Rods on the right into the 2 holes in the 3D Printed: Left

Side.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 16 / 38

14.Push the outside 3D Printed Left/Right together to snug up the assembly. The inner

diameter (inside the Right Plastic to the Inside Left Plastic) should be 300MM.

This is important to ensure it fits on the printer later.

15. We are now going to take 1M of GT2 and attach it to the back of the 3D Printed:

Extruder Carriage by looping it around the right side upper belt block as pictured below.

Note: allow a little extra slack we will secure this later with zip ties.

16. Now take the rest of the belt, feed it over the top of the FZ623ZZ Pulleys on the right

side and back to feed under and above the 20T Pulley on the motor on the left side.

Bring the belt back and attach to to the left side belt block the same way you did above

(but on the opposite side). Trim the extra belt. Note: you want the belt to be tight

but not to tight, we can always add a belt spring later to adjust tension.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 17 / 38

17. Now take (2) Zip Ties and secure the overhanging GT2 belt to the upper belt on each

side as picture below.

Step 11: Attach the Extruder to the X Carriage

•Parts Needed: (1) Extruder Assembly, (1)X Carriage (assembled in step 10) • Hardware

Needed: None.

1. Remove the 2 screws from the top of the motor is part of the Extruder Assembly.

2. Using the 2 screws removed in step 1, attach the motor to the X Carriage by screwing

it to the 3D Printed Part: Extruder Carriage as pictured.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 18 / 38

Step 12: Attach Chrome & Threaded rod to the assembled X Carriage.

•Parts Needed: (2) 235MM 5MM Threaded Rod, (2) 320MM 8MM Chrome Rod, (1)

Assembled X Carriage

•Hardware Needed: None

1. Take the Assembled X Carriage and the (2) xxMM 5MM Threaded Rod & the (2) xxMM

8MM Chromed rod and lay them out in front of you like so:

2. Thread the 235MM 5MM Threaded Rod through the 5mm nut that was previously

inserted into the Left and Right 3D Printed Parts. Thread it about half way through so

the same amount of thread is showing on the top and bottom of the part. Feed the

320MM 8MM Chrome Rod through the bearings on the Left and Right 3D Printed Parts

as pictured below. Note: Be careful when putting the chrome rod in not to push out the

ball bearings. Set this aside for later

Step 13: Assemble The Front Pulley Assembly

•Parts Needed: (2) F623Z Bearings, (1) 623ZZ Bearing

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 19 / 38

•Hardware Needed: (1) M3x30MM Bolt, (4) M4 Large Washers, (2) M3 Washers, (1)

M3 Nylock Nut, (2) M4x8MM Pan Head Bolts.

1. Assemble the hardware in the following order going through the 2020 corner brackets

you previously attached to the front of the frame during step 3 of assembly.

M3x30MM Bolt > M4 Large Washer > 2020 Corner Bracket > M4 Large Washer >

M3 Washer > F623ZZ Bearing (flange out) > 623ZZ Bearing > F623ZZ Bearing

(flange out) > M3 Washer > M4 Large Washer > 2020 Corner Bracket > M4 Large

Washer > Nylock Nut.

Step 14: Attach the Pulley and Belt to the Y carriage.

•Parts Needed: (1) 20T Pulley, (1) ~1M Meters GT2 Belt

•Hardware Needed: (2) Zip Ties

1. Attach the (1) 20T Pulley to the Large Motor attached to the bottom frame using the

set screws in the pulley to secure it in place. Note: Teeth on motor side.

2. Tip the printer back and using the same method used for the X Carriage belt

installation we are going to attach the (1) xM GT2 Belt to the Y carriage.

http://www.folgertech.com 2020 Prusa i3 | Build Guide Page: 20 / 38

3. Attach the belt to the back end of the 3D Printed: Belt Carriage on the bottom of the

Aluminum Mount plate, leaving enough slack to zip tie it later. Feed the belt around the

20T Pulley on the motor and then bring it to the front of the printer and go under and

above the F23ZZ bearing mount you assembled in Step 12. You can then feed it back

and attach it to the front part of the 3D Printed: Belt Carriage again leaving enough

slack for zip ties.

Step 15: Attach the Couplings and SHF8UU in preparation for the X Carriage to

be attached in the next step.

•Parts Needed: (2) 5x5 Couplings, (2) SHF8UU

•Hardware Needed: (4) M4x14MM Black Bolts, (2) M4 T-Nuts

1. Before we can attach the SHF8UU we need to remove 2 set screws from (2) 2020 L

Brackets that are attached to the frame. With the printer in front of you, remove the 2

set screws from the 2020 L Brackets that are securing the top frame to the bottom

frame on the front of the printer. Note: These are the set screws directly Below the

small motors on the bottom frame.

Table of contents

Other Folger Technologies 3D Printer manuals