Fonrich FR-DCMG-MMPY User manual

1

User Manual

Version 4.2

DC System Monitor:FR-DCMG-MMPY

丰郅(上海)新能源科技有限公司

Fonrich (Shanghai) New Energy Technology Co., Ltd.

Add: 1st Floor, Building 5, No.999 Jiangyue Road, Minhang District,Shanghai

Web: www.fonrich.com

Tel: +86 21 61679671

Email: [email protected]

2

Table of Contents

Product description.......................................................................................................................................... 3

The main function..................................................................................................................................... 3

Documentation statement......................................................................................................................3

Terminal definition....................................................................................................................................4

Controller connection diagram............................................................................................................. 5

Ground connection and communication shield............................................................................... 6

Operation interface display............................................................................................................................ 7

Key operation............................................................................................................................................. 7

Initial interface display............................................................................................................................. 7

Histogram interface.......................................................................................................................... 7

Channel current and power generation display interface..................................................... 9

Parameter setting interface..................................................................................................................10

Current calibration setting interface..........................................................................................10

Software version number display interface............................................................................. 10

Alarm status display interface............................................................................................................. 11

Channel arc fault alarm interface................................................................................................11

Fault alarm clear interface............................................................................................................ 11

Items that can generate alarms can be set..............................................................................12

Alarm conditions..................................................................................................................................... 12

Alarm message................................................................................................................................ 13

MODBUS Protocol definition.......................................................................................................................14

Communication format configuration...................................................................................... 14

Data frame format description (refer to Modbus RTU standard)......................................14

Function code description............................................................................................................ 14

Register description........................................................................................................................15

Register description in bit units (function code 02)

......................................................... 15

Register description in word unit (function code 03 04 06)

..........................................28

Appendix........................................................................................................................................................... 34

FAQ..............................................................................................................................................................34

Document revision record.................................................................................................................... 35

Contact us................................................................................................................................................. 37

3

Product description

FR-DCMG DC monitor products are mainly used in DC power transmission and distribution,

such as photovoltaic combiner boxes, DC cabinets, telecommunications equipment rooms

and communication base stations. It communicates with the host computer through RS485

or industrial wireless. Its main function is to monitor the current of each branch in the DC

system, the bus voltage, the temperature of the cabinet, the status of the lightning arrester

and the status of the DC breaker. It can realize automatic alarm for abnormal conditions and

real-time detection of the presence of harmful arcs in the DC circuit.

The main function

•

Monitoring function: Real-time monitoring of the generation current, voltage,

temperature of the combiner box, lightning arrester status, DC circuit breaker status,

and DC arc fault status of each photovoltaic string in the combiner box, and

communicate with the host computer through RS485.

•

Display content: For the detected voltage, current, temperature, switching state,

power generation and other data, the FR-DCMG-MMPY can display a histogram

interface through the LCD to read the current and other data more intuitively.

•

Alarm function: It can be configured to open or close the alarm according to the

actual needs of the scene. When the alarm occurs, the interface will pop up an alarm

message.

•

Current calibration: identify zero drift and improve the accuracy of current

identification. (Default off)

•

Compatibility:Program compatible model FR-DCMG-MMPD products

Documentation statement

This manual is applicable to the monitoring host whose model is FR-DCMG-MMPY.

The software version is A0F2.

See page 11 for software version viewing method

4

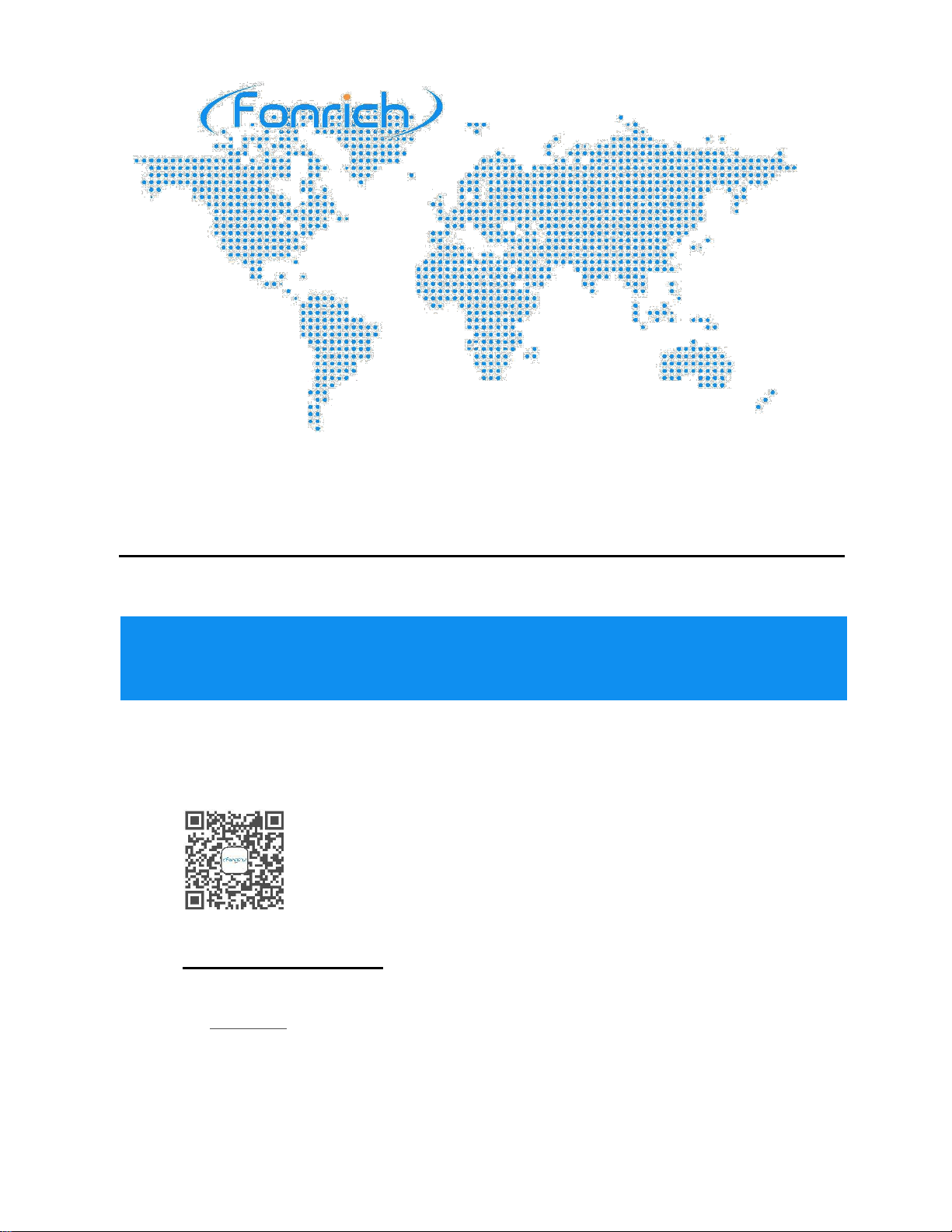

Terminal definition

Symbol

Meaning

PV+ . PV-

PV DC bus power supply terminal

NC

Not connecion

S

Not connecion

A.B

RS485 Communication terminal

FG

Fixed Ground terminal

TS1.TS2

Externally connected temperature sensor terminals

SG

Temperature sensor and digital input ground terminal

DI1.DI2.DI3.DI4

4 digital input terminals

FUC

Can connect modules with FUC interface

FMB

Modules with an FMB interface can be connected, such as the FR-DCMG-AS4A

DC Arc Detector.

5

Controller connection diagram

6

Ground connection and communication shield

The FG terminal of the FR-DCMG must be grounded, otherwise communication will

interfere and the reliability of the device will decrease. The grounding wire should be

grounded nearby. The grounding wire should be no more than 15cm from the “FG”

terminal to the bottom of the combiner box. It is recommended to be within 10cm. The

shorter the better, the thicker the better. The bottom of the combiner box should be

connected to the ground. The main control unit module is fixed on a standard guide rail

with a width of 3.5 cm.

The wiring specifications of the communication shielded wire are shown in the figure above:

The wiring of on-site communication lines requires that the communication shield can only

be grounded at a single point, otherwise there will be a risk of lightning surge damage to

all equipment on the entire communication line during a lightning strike;

If you encounter a situation where communication line interference is too large to

communicate, you can refer to the figure above, and insert a high voltage capacitor C

<100nF between the shielded wire of each combiner box and the ground wire, and use

this capacitor to filter the shielding layer interference.

7

Operation interface display

Key operation

FR-DCMG-MMPY has four keys “ESC”, “-”, “+”, and “SET”.

"ESC" key is used to return to the default interface and cancel parameter setting;

“SET”key is used to enter the parameter setting mode, select the parameter to be set and

complete the setting of the parameter;

The "+" and "-" keys are used to scroll the screen and adjust parameters;

Press the "+" and "-" keys at the same time to display the software version interface;

Press the "ESC" and "-" keys simultaneously to display the current calibration interface;

If there is no key operation for 10 seconds, the interface will automatically jump to the

default interface of the current mode, and the brightness will decrease after 5 seconds.

Initial interface display

The factory default is Modbus mode. When the host computer is connected to the

device via RS485 and communicates, the LED lights “R” and “P / T” will flash

alternately to indicate normal communication. When the device is not connected to

communication, it restarts by default every 5 minutes, or you can turn off the default

restart function, which can be turned off through the 0xF003 register.

Histogram interface

The histogram interface is the default display interface of Modbus mode, as shown

below:

The histogram in the figure shows the current value detected by each channel. The

initial interface display range is: -2A ~ 10A. You can also set register 0x0B16, which

displays -2A ~ 20A and -2A ~ 30A. Because a six-channel Hall sensor is connected, every

8

six channels are distinguished during display, and the current channels are from 1 to 24 in

order from left to right. The order of the current channels can also be set in reverse order.

The lightning icon in the upper left corner indicates that the FR-DCMG-MMPY horn-

connected Hall sensor with arc monitoring function; "24" indicates the current online arc

and current channel number; "1111" indicates the real-time status of the digital input DI1

~ DI4; "1250V" Represents the real-time voltage value of the bus. If there is no key

operation within 5 seconds, the screen brightness will decrease.

9

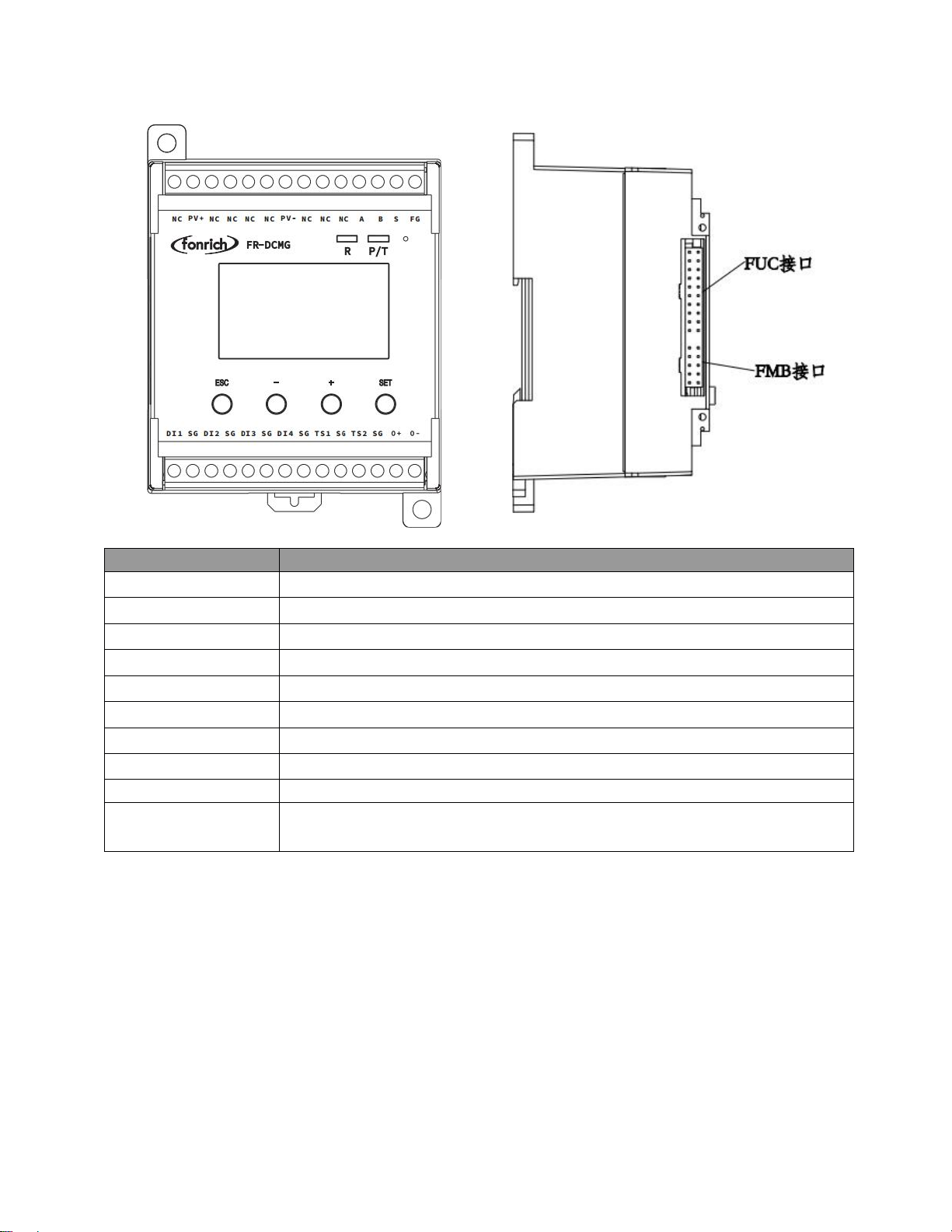

Channel current and power generation display interface

In the histogram mode, press the "+" or "-" key to enter the channel current and

power generation display interface. The current value and cumulative power generation of

each channel are displayed on the screen. When the "+" key is pressed first, the digital

value of the current is displayed first, and when the "-" is pressed first, the digital value of

the current is displayed first

The value of cumulative power generation. When viewing the values of current and

cumulative power generation, you can scroll through the screen by continuing to press the

"+" or "-" key. After the current display is completed, continue to press the "+" key to start

displaying the cumulative power generation. The figure above shows the current display

interface. “CH1:” in the figure indicates that the current value monitored by channel 1 in

real time is “6.929A”, and so on.

The figure below shows the cumulative power generation display interface. "CH1:" in

the figure indicates that the cumulative power generation of channel 1 is "6.929kwh", and

so on.

10

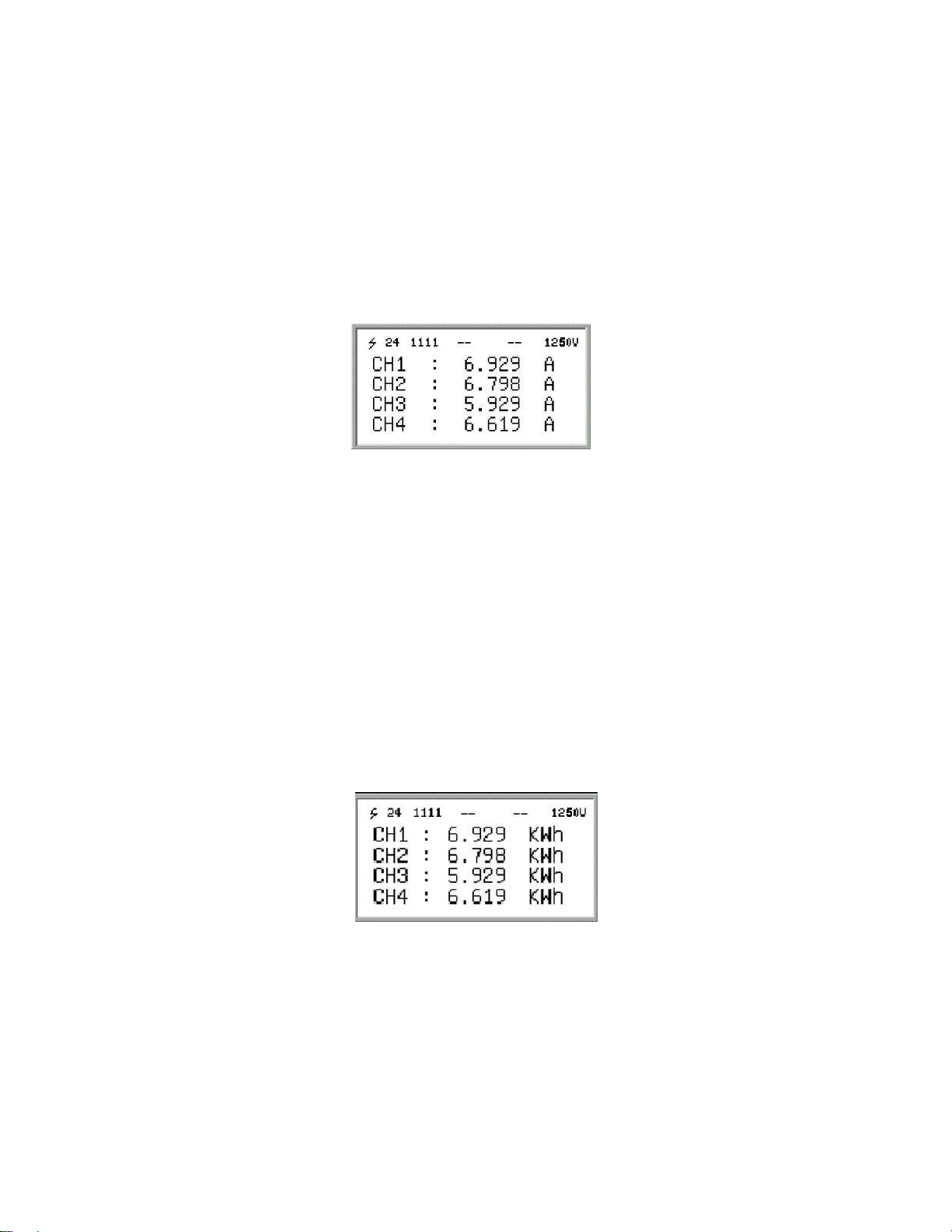

Parameter setting interface

In the histogram interface, press the "SET" key to enter the Modbus parameter

setting interface. The Modbus parameter setting is as follows:

•

ADDR: The communication address of the Modbus slave node, the range is 1 ~ 247 (default is

247).

•

PAR: The data verification method of Modbus communication. The optional parity (None), odd

parity (Odd), even parity (Even), and no parity by default.

•

BPS: Baud rate for Modbus communication. The selectable baud rates are 2400, 4800, 9600

(default), 19200, 38400.

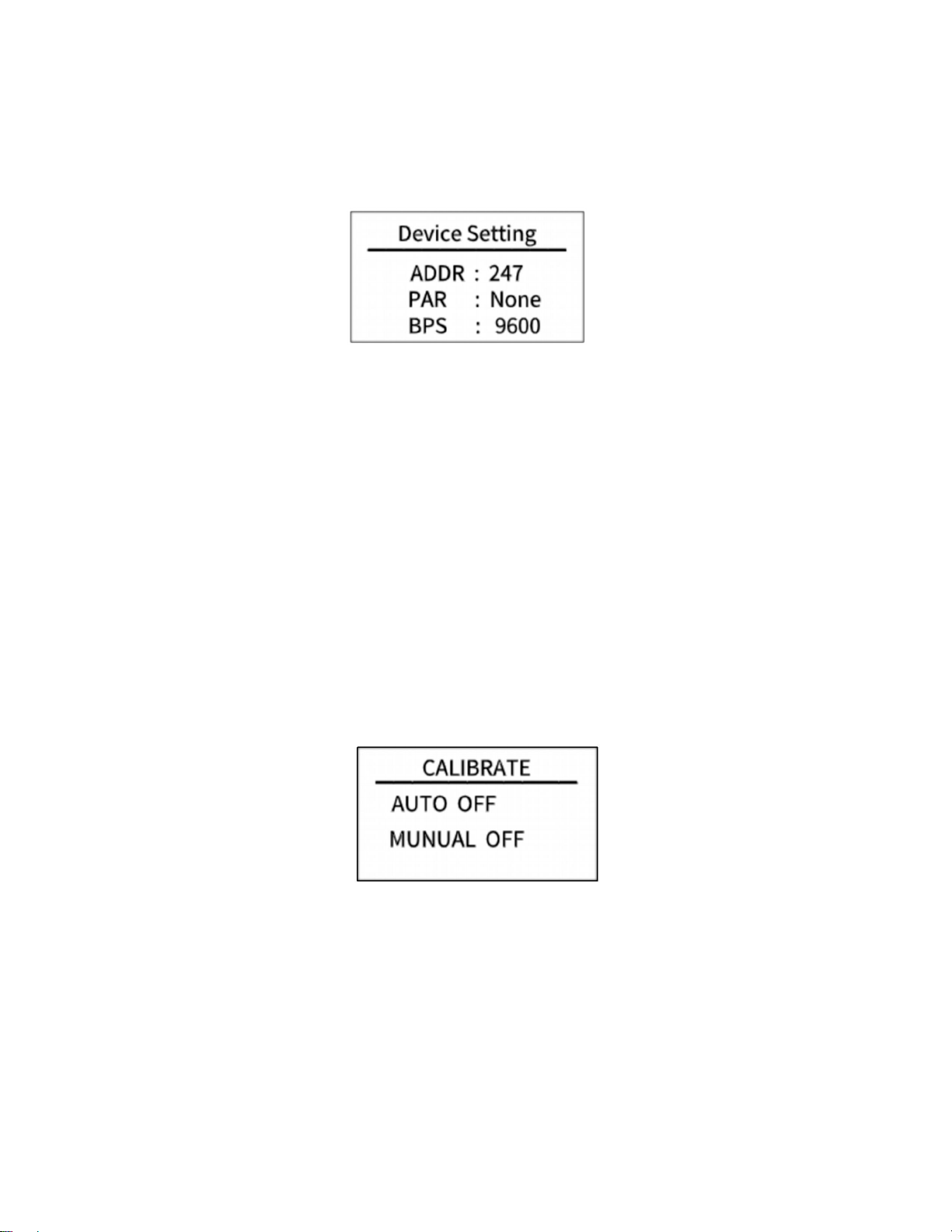

Current calibration setting interface

Press the "ESC" and "-" keys at the same time to enter the current calibration setting

interface, as shown below:

To use this feature, please contact the company's technical support staff.

Software version number display interface

In the histogram interface, press the "+" and "-" keys at the same time to enter the

software version number display interface, as shown below:

11

•

HV:Keep

•

SV:Software version number

•

ST:Keep

Alarm status display interface

Alarm messages can be cleared remotely and manually. Manual clearing requires

long-pressing the host's "ESC" key for 2 seconds, remote clearing requires writing "1" to

register 0x0079 to clear. If an arc alarm occurs, it must be cleared manually or remotely.

Restarting the host will still display the alarm message.

Channel arc fault alarm interface

After the DC arc sensor detects the occurrence of a fault arc, the alarm information

interface of the host is as shown below.

In the figure above: "02" means channel arc fault alarm, and "4" means that the fault

arc alarm channel is 4.

Fault alarm clear interface

The host sends an alarm when it detects a fault, and the user can choose to handle it

locally or remotely. By long-pressing the "ESC" key for about 2 seconds locally, the

12

system jumps out of the interface as shown below, indicating that the alarm status has

been cleared; remote processing needs to write "1" to 0x0079 to clear, and the interface

shown below will be displayed after clearing successfully.

Items that can generate alarms can be set

Voltage is too high

Voltage is too low

Temperature is too high

Channel reverse current

Total reverse current is too high

Total current is too high

Total current is too low

Channel without current

Low channel current

High channel current

Channel current value undercurrent

Channel current value overcurrent

Lightning Arrester Status (DI1)

circuit breaker status (DI2)

Switch DI3 status

Switch DI4 status

Alarm conditions

13

1.

Current reverse, no current, under current, over current, low current, high current, etc.

a. Only when the average value of the channel current is greater than the

set alarm threshold of the current channel, the alarm function of the above

current-related items is activated; otherwise, the alarm status is forcibly

cleared to 0.

b. As for whether the alarm needs to be separately met the respective alarm

conditions (above or below the respective alarm threshold).Alarm message

c. Check if the corresponding alarm register is open, closed by default

Alarm message

•

Undercurrent alarm. After the channel average current value is subtracted from the

overcurrent / undercurrent alarm threshold, the current value is still less than or

equal to the current channel start alarm start threshold. The overcurrent /

undercurrent alarm threshold will change as the average current changes.Alarm

message

•

Over current alarm. After the channel average current value plus the over current /

under current alarm threshold, the current value is still greater than or equal to the

current channel start alarm start threshold. The over current / under current alarm

threshold will change as the average current changes.Alarm message

•

Low current alarm, when the current is less than or equal to the channel current low

alarm threshold, an alarm occurs.Alarm message

•

High current alarm. When the current is greater than or equal to the channel current

high alarm threshold, an alarm occurs.Alarm message

•

No current alarm, when the absolute value of the current is less than 250mA, an alarm

occurs.Alarm message

14

MODBUS Protocol definition

Communication format configuration

•

Modbus communication mode: RTU mode

•

Address of the slave device: range form 1 to 247 (default 247)

•

Baud rate (bps): 2400, 4800, 9600 (default), 19200, 38400

•

Byte check mode: odd check, even check, no check (default)

Data frame format description (refer to Modbus RTU standard)

The byte in the communication frame composed by 1 start bit, 8 bits data bit, 1 parity

bit, 1 stop bit like the below table(Refer to standard modbus RTU protocol):

Table 1: Data frame format table

Address Code

Function Code

Data Area

Check Zone

1byte

1byte

N*1byte

2bytes

The address code is used to identify the slave that receives the data frame and the

response frame sent by that slave. The function code indicates how the master requires

the slave to respond and the slave responds to that function code. Data area The content

can be the address value, the number of registers, the data from the slave response and

the data sent by the master to the slave, etc., which can hold up to 252 bytes of data. The

check area uses CRC cyclic redundancy to check whether a frame of data is wrong. The

high byte of the data frame comes first, and the low byte comes after.

Function code description

Register reads and writes in bits

•

Function code 01 used to read the contents of the bit register

•

Function code 02 used to reads the contents of the bit register

•

Function code 05 used to write single bit-type registers

15

The contents represented by the register in bits are: switch value, alarm information,

etc.

Register read and write in word units

•

Function codes 03、04 are used to read multiple word-type registers

•

Function code 06 is used to write single word-type registers

•

Function code 16 is used to multiple word-type registers

The content of the word-type registers can be voltage, current, generated energy, etc

Register description

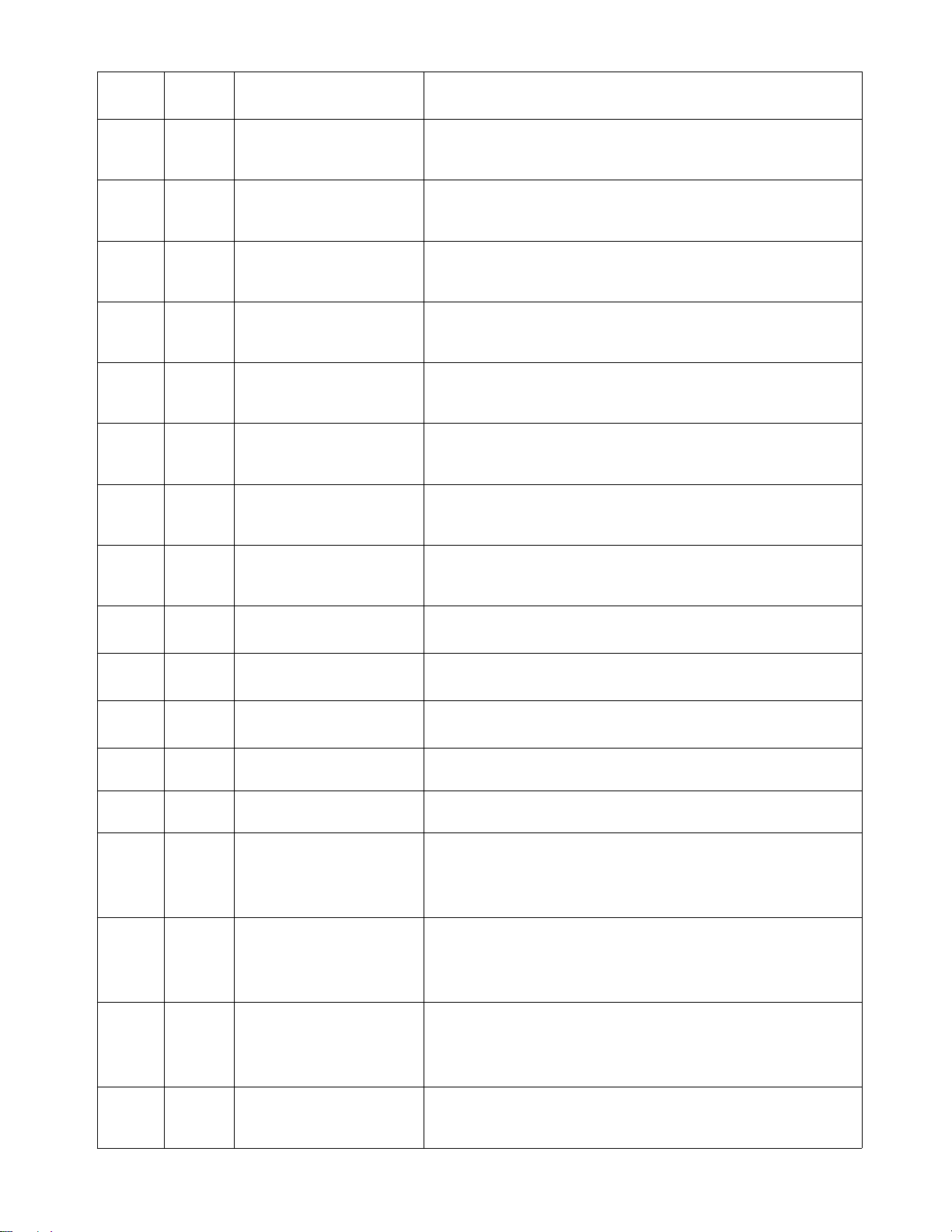

Register description in bit units (function code 02)

Bit address

Functional description

remark

Hex

Decimal

0x021E

542

-

-

0x0230

560

-

-

0x0231

561

Channel arc alarm status

This bit is set when the channel arc strength is above the alarm

threshold. Clear the alarm and set it to 0.

0x0232

562

Bus voltage too low alarm

status

This bit is set when the bus voltage is below the alarm

threshold. Cleared below the alarm release threshold

0x0233

563

Bus voltage to high alarm

status

This bit is set when the bus voltage exceeds the alarm

threshold. Cleared below the alarm release threshold

0x0234

564

Temperature sensor 1

high temperature alarm

status

This bit is set when the temperature sensor 1 temperature

exceeds the alarm threshold. Cleared below the alarm release

threshold

0x0235

565

Temperature sensor 2

high temperature alarm

status

This bit is set when the temperature sensor 2 temperature

exceeds the alarm threshold. Cleared below the alarm release

threshold

0x0236

566

Channel reverse current

When the reverse current is generated in the channel, the

16

alarm status

position is 1, and the alarm is cleared.

0x0237

567

Total reverse current

alarm status

This bit is set when the total reverse current exceeds the alarm

threshold. Cleared below the alarm release threshold

0x0238

568

Total current too low

alarm state

This bit is set when the total current exceeds the alarm

threshold. Cleared below the alarm release threshold

0x0239

569

Total current too high

alarm state

This bit is set when the total current exceeds the alarm

threshold. Cleared below the alarm release threshold

0x023A

570

Channel current value

zero

The channel has no current alarm and this bit is set to 1.

0x023B

571

Channel current value

undercurrent

Channel undercurrent alarm, this bit is set to 1

0x023C

572

Channel current value

overcurrent

Channel overcurrent alarm, this bit is set to 1.

0x023D

573

Channel current value is

too low

Channel current low alarm, this bit is set to 1

0x023E

574

Channel current value is

too high

Channel current high alarm, this bit is set to 1

0x0240

576

Switch 1 alarm status

The state of the device's input switch DI1, 0: open, 1: closed

0x0241

577

Switch 2 alarm status

The state of the device's input switch DI2, 0: open, 1: closed

0x0242

578

Switch 3 alarm status

The state of the device's input switch DI3, 0: open, 1: closed

0x0243

579

Switch 4 alarm status

The state of the device's input switch DI4, 0: open, 1: closed

.......

..........

....................

..........................

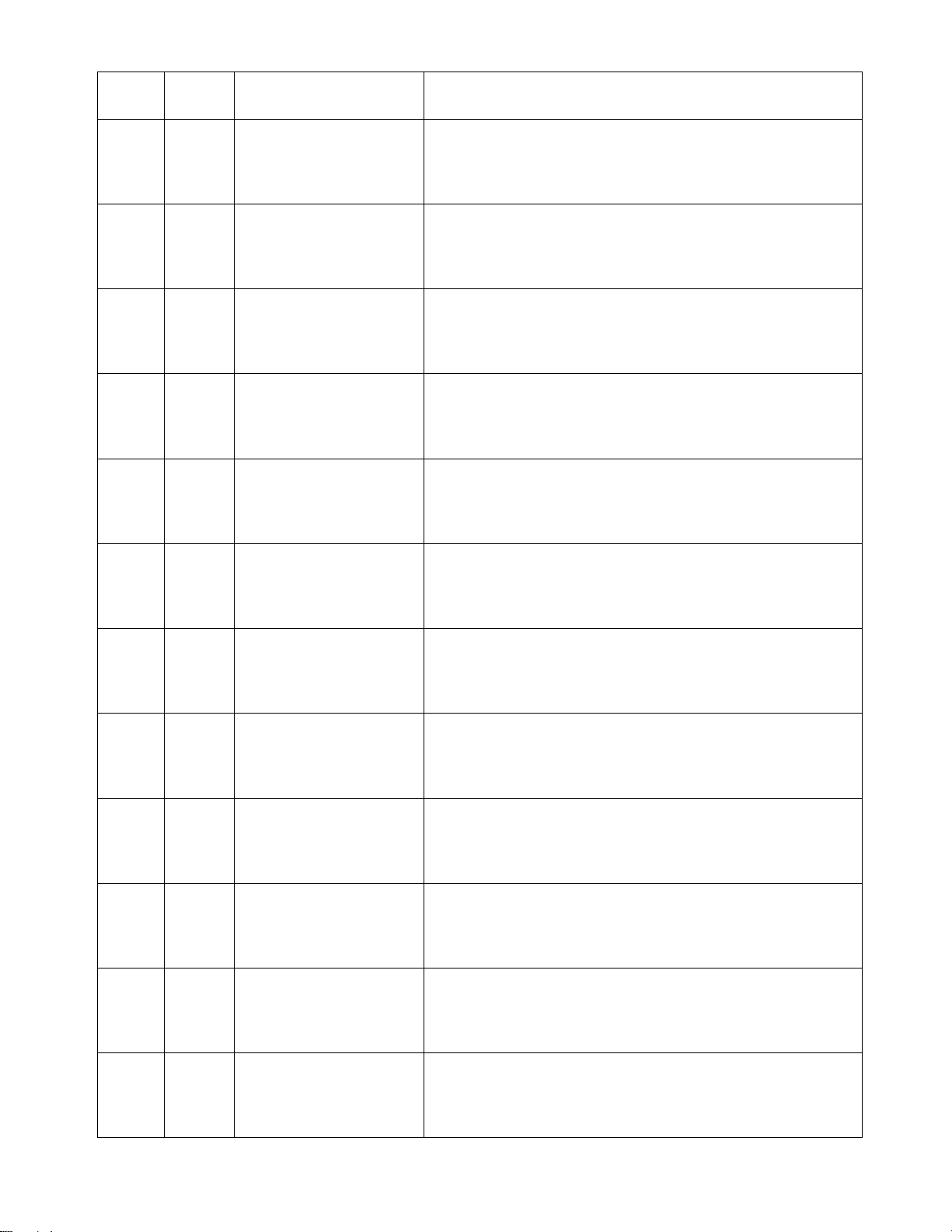

0x0260

608

Channel 1 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0261

609

Channel 2 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0262

610

Channel 3 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0263

611

Channel 4 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

17

0

0x0264

612

Channel 5 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0265

613

Channel 6 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0266

614

Channel 7 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0267

615

Channel 8 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0268

616

Channel 9 arc alarm status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0269

617

Channel 10 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026A

618

Channel 11 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026B

619

Channel 12 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026C

620

Channel 13 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026D

621

Channel 14 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026E

622

Channel 15 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x026F

623

Channel 16 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

18

0x0270

624

Channel 17 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0271

625

Channel 18 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0272

626

Channel 19 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0273

627

Channel 20 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0274

628

Channel 21 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0275

629

Channel 22 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0276

630

Channel 23 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

0x0277

631

Channel 24 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

.......

........

.................

.......................

0x027F

639

Channel 32 arc alarm

status

When the arc intensity of the channel is greater than the alarm

threshold, this bit is set to 1; after clearing the alarm, it is set to

0

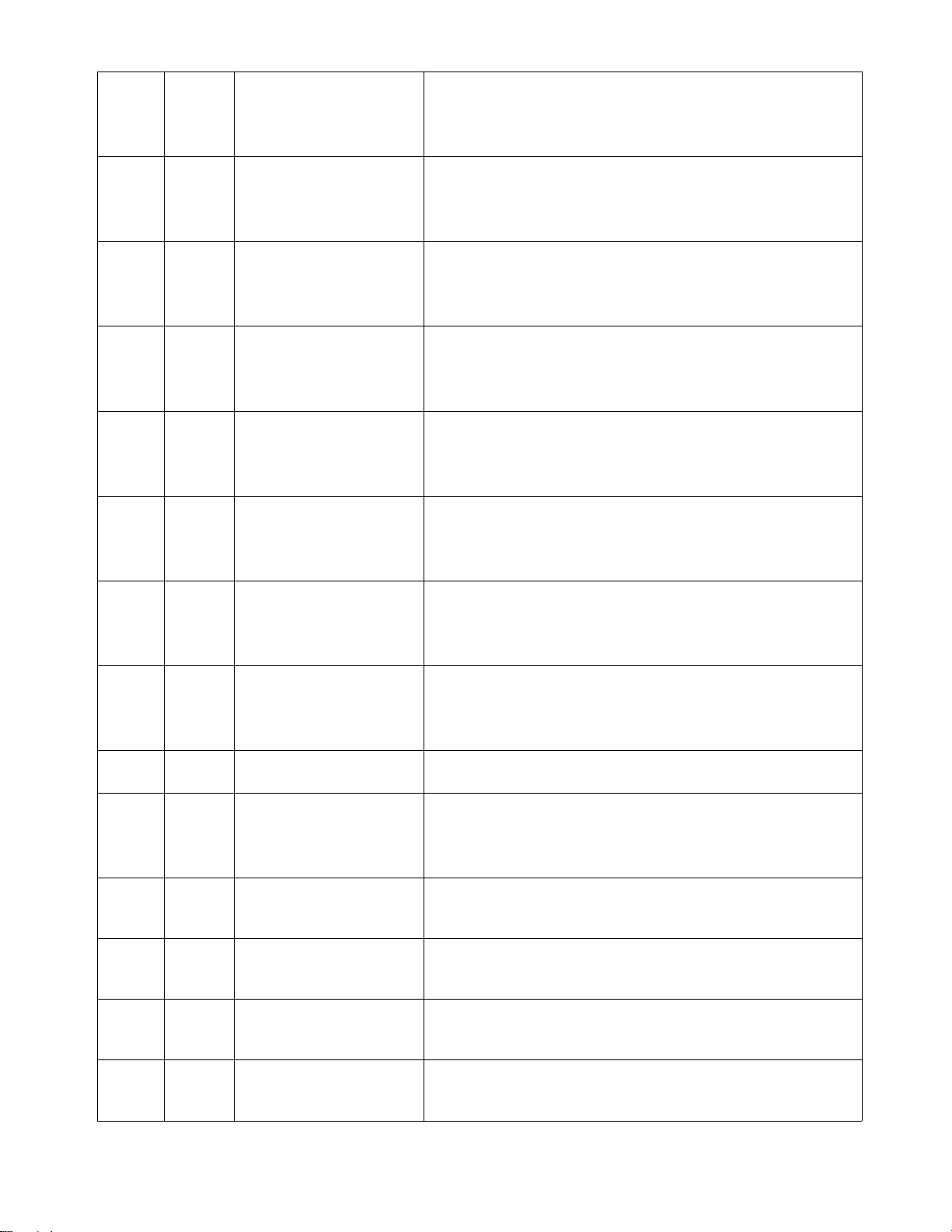

0x0280

640

Channel 1 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0281

641

Channel 2 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0282

642

Channel 3 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0283

643

Channel 4 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

19

0x0284

644

Channel 5 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0285

645

Channel 6 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0286

646

Channel 7 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0287

647

Channel 8 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0288

648

Channel 9 current reverse

alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0289

649

Channel 10 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028A

650

Channel 11 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028B

651

Channel 12 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028C

652

Channel 13 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028D

653

Channel 14 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028E

654

Channel 15 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x028F

655

Channel 16 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0290

656

Channel 17 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0291

657

Channel 18 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0292

658

Channel 19 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0293

659

Channel 20 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0294

660

Channel 21 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

20

0x0295

661

Channel 22 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0296

662

Channel 23 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x0297

663

Channel 24 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

.....

.......

.................

....................

0x029F

671

Channel 32 current

reverse alarm status

This bit is set when the channel current is reversed and greater

than the alarm threshold, otherwise cleared.

0x02A0

672

Channel 1 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A1

673

Channel 2 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A2

674

Channel 3 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A3

675

Channel 4 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A4

676

Channel 5 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A5

677

Channel 6 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A6

678

Channel 7 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A7

679

Channel 8 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A8

680

Channel 9 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02A9

681

Channel 10 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02AA

682

Channel 11 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02AB

683

Channel 12 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

0x02AC

684

Channel 13 no current

alarm status

This bit is set to 1 when there is no current in this channel,

otherwise cleared.

Table of contents

Other Fonrich Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

RS PRO

RS PRO RS-91 instruction manual

Tymate

Tymate M12-3 user manual

Watts

Watts HF scientific 28052 Owner's and user's manual

THORLABS

THORLABS PM200 Operation manual

Sherwood Scientific

Sherwood Scientific 410 Industrial Operator's manual

Keysight Technologies

Keysight Technologies N9320A RF Configuration guide

iSystem

iSystem iC5000 Hardware reference

Sierra

Sierra InnovaMass 240i Series instruction manual

Streetwize

Streetwize leisurewize TPMS1 manual

MAHA

MAHA SKM 2 Original operating instructions

Hanna Instruments

Hanna Instruments HI 98713 instruction manual

Analytical Technology

Analytical Technology Q46H/79PR manual