Fonrich FR-DCMG Series User manual

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

FR-DCMG DC System Monitor

User Manual (V2.0)

Fonrich (Shanghai) New Energy Technology Co.,Ltd

Address: 1st Floor, B ilding 5, No.999 Jiangy e Road, Minhang District,Shanghai

Zip Code: 201112

Web: www.fonrich.com

Email: s [email protected], [email protected]

Service Hotline: +86-21-60717303

1

Table of contents

Table of contents

Ⅰ, Important Safety Instr ctions.........................................................................................................3

Ⅱ,Prod ct Brief................................................................................................................................4

Ⅲ Mechanical Dimensions & Str ct re..............................................................................................5

FR-DCMG-MMPA /FR-DCMG-MMPB /FR-DCMG-MMPT Main Unit......................................5

FR-DCMG-HS4A /FR-DCMG-AS4A Hall C rrent Sensor............................................................6

FR-DCMG-HS4T /FR-DCMG-AS4T Hall C rrent Sensor............................................................6

FR-PVMA-LHSA Leakage C rrent Sensor....................................................................................7

FR-PVMG-SHTPA /FR-PVMG-SHTPT Sh nt Trip Power Unit...................................................7

Ⅳ, Connection of Mod les and Definition of the Terminals...............................................................8

Connection of the hall sensor mod le..............................................................................................8

FR-DCMG-MMPA /FR-DCMG-MMPB /FR-DCMG-MMPT Main Unit......................................8

FR-PVMA-LHSA Leakage C rrent Sensor....................................................................................9

FR-PVMG-SHTPA /FR-PVMG-SHTPT Sh nt Trip Power Unit.................................................10

Earth connection............................................................................................................................10

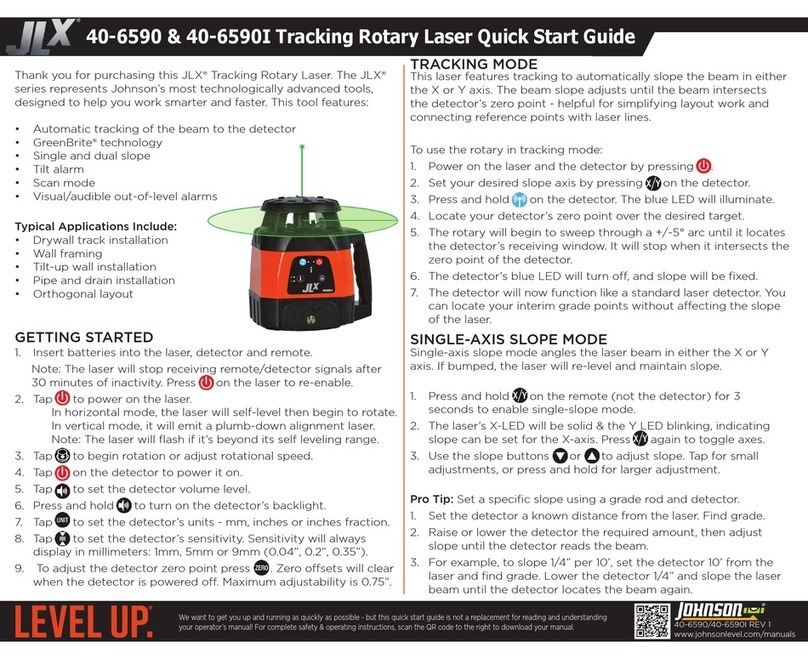

Ⅴ, Local Operation............................................................................................................................11

Instr ction of b ttons operation and display interface...................................................................11

Mode setting...................................................................................................................................11

MODBUS mode........................................................................................................................12

Histogram interface..............................................................................................................12

Parameters setting interface..................................................................................................13

Digital displaying interface..................................................................................................14

FWB NODE mode....................................................................................................................15

Histogram interface..............................................................................................................15

Parameters setting interface..................................................................................................15

Digital displaying interface..................................................................................................15

FWB GATEWAY mode............................................................................................................15

Wireless node connecting stat s interface............................................................................16

Histogram interface..............................................................................................................16

Digital displaying interface..................................................................................................16

Parameters setting interface..................................................................................................16

Arc Fa lt Detect Alarm F nction...................................................................................................17

Arc Fa lt Detect Alarm pict re.................................................................................................17

Sh nt Tripping Set p Interface.................................................................................................18

Ⅵ, Definition of the Modb s Protocol...............................................................................................19

Config ration of the modb s.........................................................................................................19

Description of the modb s frame...................................................................................................19

Description of the f nction codes..................................................................................................19

Read and write operations of the registers in bit.......................................................................19

Read and write operations of the registers in word...................................................................20

Description of the registers............................................................................................................20

Description of the registers in bit..............................................................................................20

Description of the registers in word..........................................................................................26

Ⅴ, Appendix.......................................................................................................................................39

Doc ment revision history.............................................................................................................39

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

Ⅰ, Important Safety Instructions

Please read this user manual carefully before product installation. Fonrich reserves the right

to refuse warranty claims for equipment damage if the user fails to install the equipment

according to the instructions in this manual.

Markings on the product

HIGH VOLTAGE:

The product works with high voltages. All work on the product must only be

performed as described in this document.

DOUBLE INSULATION:

The product protected throughout by Double Insulation.

CAT III MEASUREMENT CATEGORY:

MEAS REMENT CATEGORY is CATEGORY III .

UL MARK:

The product is approved by L certification.

3

Ⅱ,Product Brief

FR-DCMG is mainly used in the PV combiner box in PV power plants, to monitor the working

status of every PV string and send the status data to the monitor center of the PV power plant

through field bus or industrial wireless. Also a new function is detect arc fault in PV string or

DC bus-bar. If detected the arc fault, the main unit with send cut-signal to power unit to drive

the shunt tripping device. Then the current will cut-off, and avoid fire happen.

Main Features

•Arc fault detect: detect arc fault in PV string by channel and bus-bar.

•Monitoring: the current of every PV string, PV bus voltage, combiner box

temperature, status of SPD, status of DC circuit breaker.

•Support isulation leakage current monnitoring.

•Communication interfaces: Modbus RTU RS485 or robust industrial wireless.

•Max supports 24 channels PV string in Modbus communication mode, 20

channels of PV string in industrial wireless communication mode.

•ocal CD display. FR-DCMG supports current histogram display.

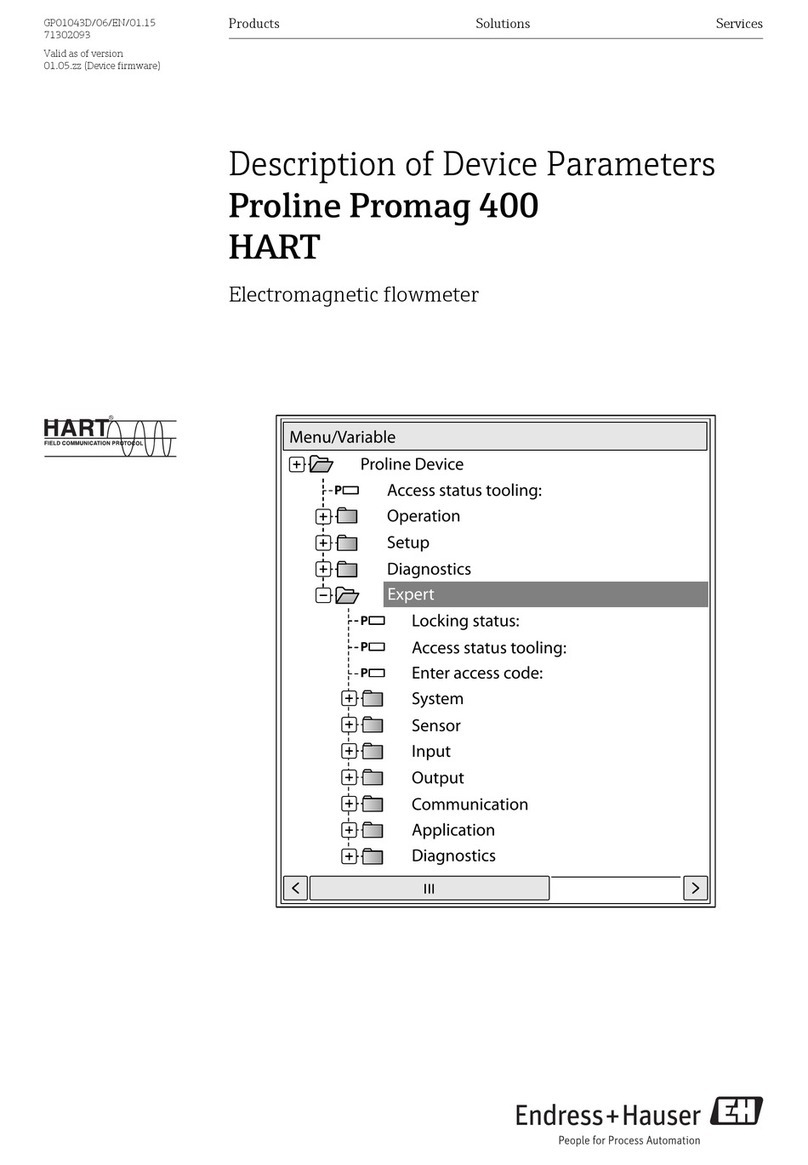

Block diagram:

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

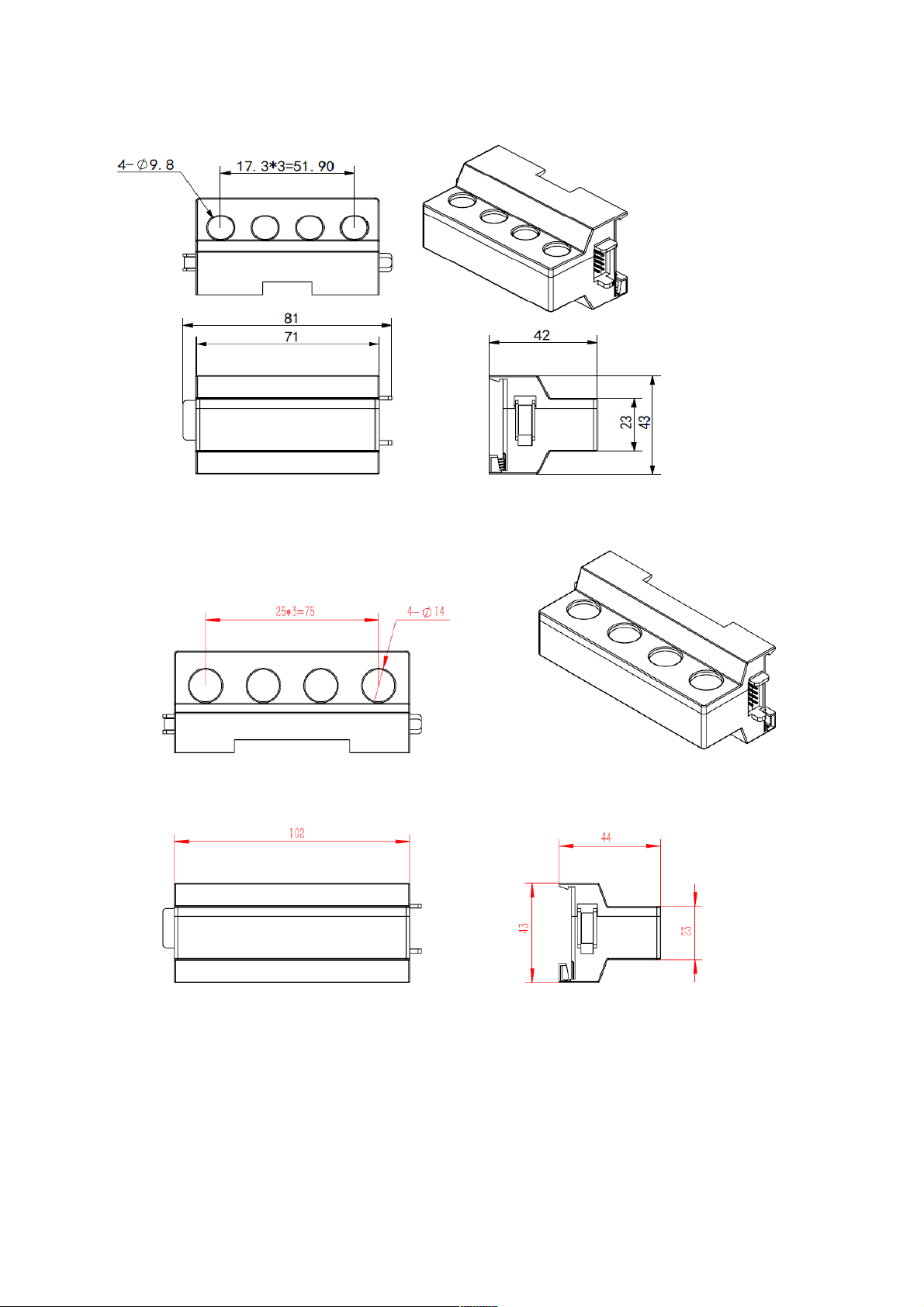

Mechanical Dimensions & Structure

FR-DCMG-MMPA /FR-DCMG-MMPB /FR-DCMG-MMPT Main Unit

5

FR-DCMG-HS4A /FR-DCMG-AS4A Hall Current Sensor

FR-DCMG-HS4T /FR-DCMG-AS4T Hall Current Sensor

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

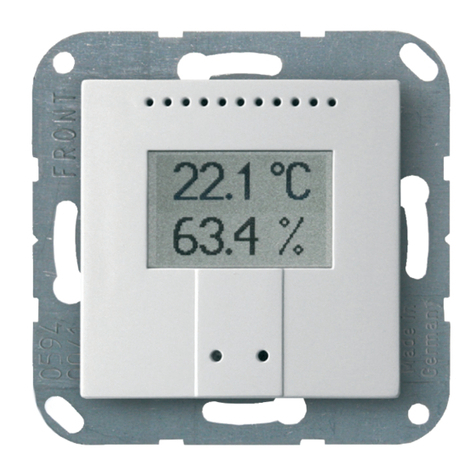

FR-PVMA-LHSA Leakage Current Sensor

FR-PVMG-SHTPA /FR-PVMG-SHTPT S unt Trip Power Unit

7

Ⅳ, Connection of Modules and Definition of the Terminals

Connection of the hall sensor module

FR-DCMG-HS4A, FR-DCMG-AS4A connect in the way of concatenation, support 4~24

channels current monitoring. Specific connection and instruction refer to the pictures

below(take 8 channels as example, the nearest FMB wire is channel 1):

FR-DCMG-MMPA /FR-DCMG-MMPB /FR-DCMG-MMPT Main Unit

FMB B s

Connector

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

Symbol Definition of the symbol

DC+、DC- PV DC bus power supply terminals

NC No connection

FG Field Ground terminal

TS External temperature sensor terminal

SG Temperature and digital input common terminal (Signal Ground)

DI1、DI2 Digital Input terminals

A、B Modbus communication terminals

RV、RG Power supply of the RTM bus

RA、RB Communication terminals of the RTM bus, for driver signal if need

shunt tripping coil

ANT SMA wireless antenna port/No connection

FMB bus Port of the FMB bus

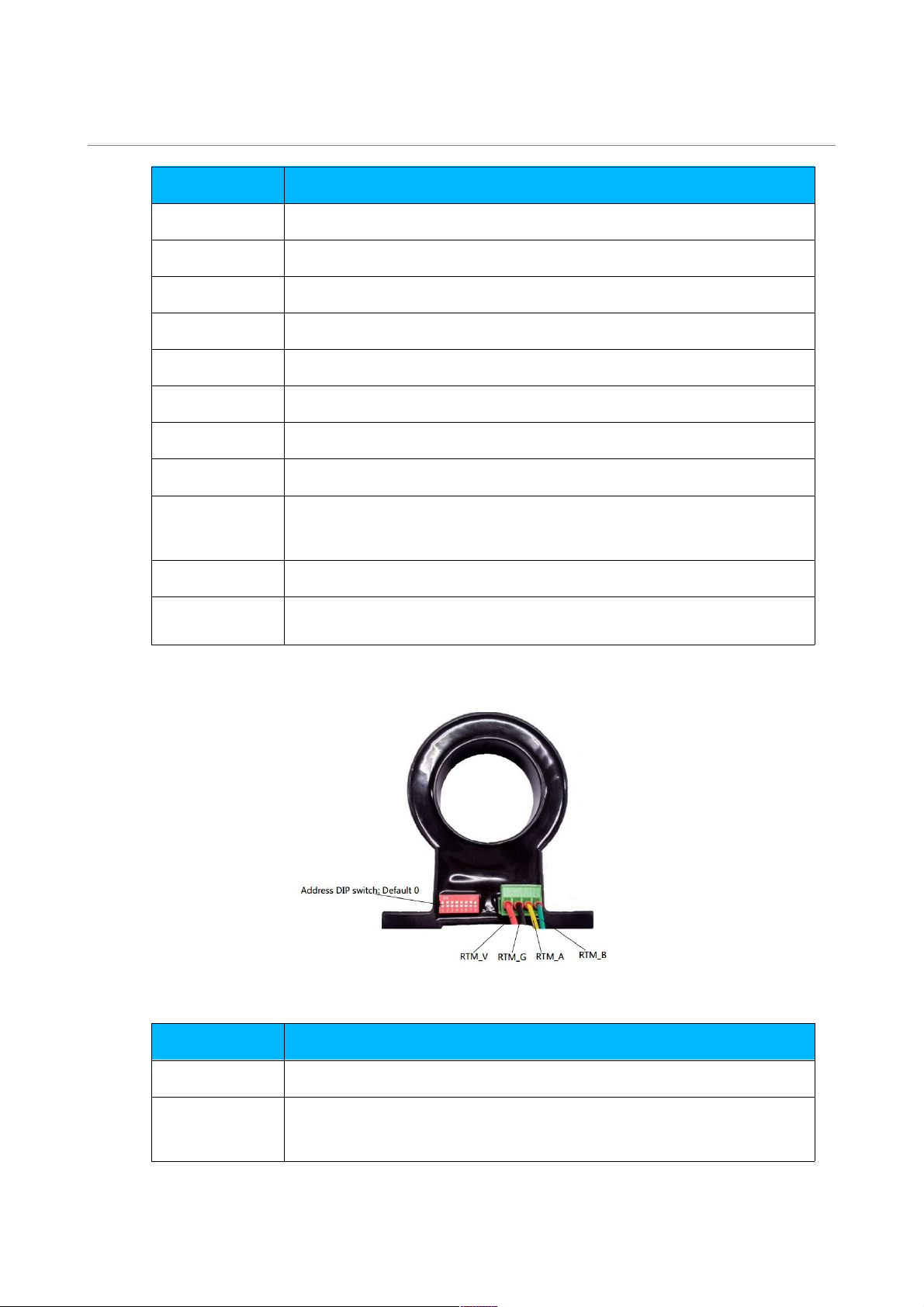

FR-PVMA-LHSA Leakage Current Sensor

Symbol Definition of the symbol

RTM_V, RTM_G Power supply from Main Unit, wire to RV, RG terminals in main unit

RTM_A, RTM_B Communication terminals of the RTM bus, wire to RA, RB terminals

in main unit

9

FR-PVMG-SHTPA /FR-PVMG-SHTPT S unt Trip Power Unit

Symbol Definition of the symbol

PV+、PV- PV DC bus power supply terminals

NC No connection

FG Field Ground terminal

RA、RB Drive terminal from main unit

+, - Drive Out terminal, wire to shunt trip coil, the level is 25VDC, max

power is 80W in 10ms

Earth connection

The FG terminal of the FR-DCMG main unit and power unit must be connected to the

field ground otherwise the communication will be disturbed, and the reliability of the

device will decrease. The FG terminal must connect to the nearby earth ground and the

wire that connects FG terminal to bottom board of the combiner box should not be longer

than 15cm, less than 10cm is great and the wire should be coarse enough. The bottom

board of the combiner must connect to the field ground.

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

Ⅴ, Local Operation

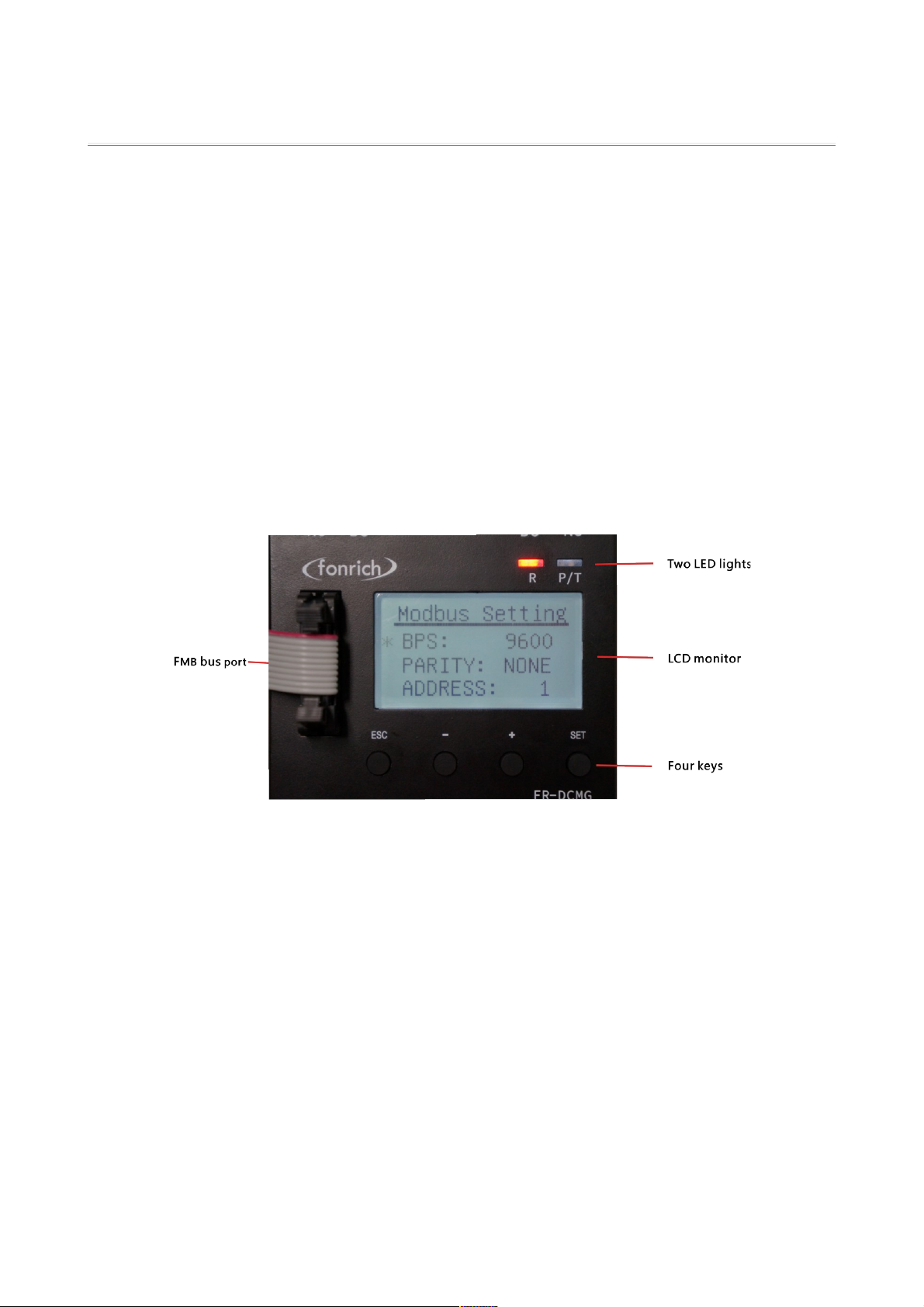

Instruction of buttons operation and display interface

FR-DCMG has four key buttons:“ESC”、“-”、“+”、“SET”. The key “ESC” is used

to return to the default interface or cancel the setting of parameters. The key “SET” is used to

enter the parameter setting interface, chose the parameter that to be configured, or confirm

the setting. The keys“+”and”-”is used to scroll the screen, or adjust the value of the

parameters. Press the keys “SET” and “ESC” at the same time will enter the mode select

interface. If no key is pressed in 15 seconds, the CD will jump to the default interface and the

brightness of backlight will decrease. If the key “ESC” is pressed, the interface will jump to the

default interface immediately.

FR-DCMG supports the histogram display of the detected current, digital display of the

detected current and generated energy, parameters' setting interface, the wireless node state

interface in the FWB GATEWAY mode. The plentiful interfaces make it convenient to operate the

device. Here is the description of every mode and the interface in the below.

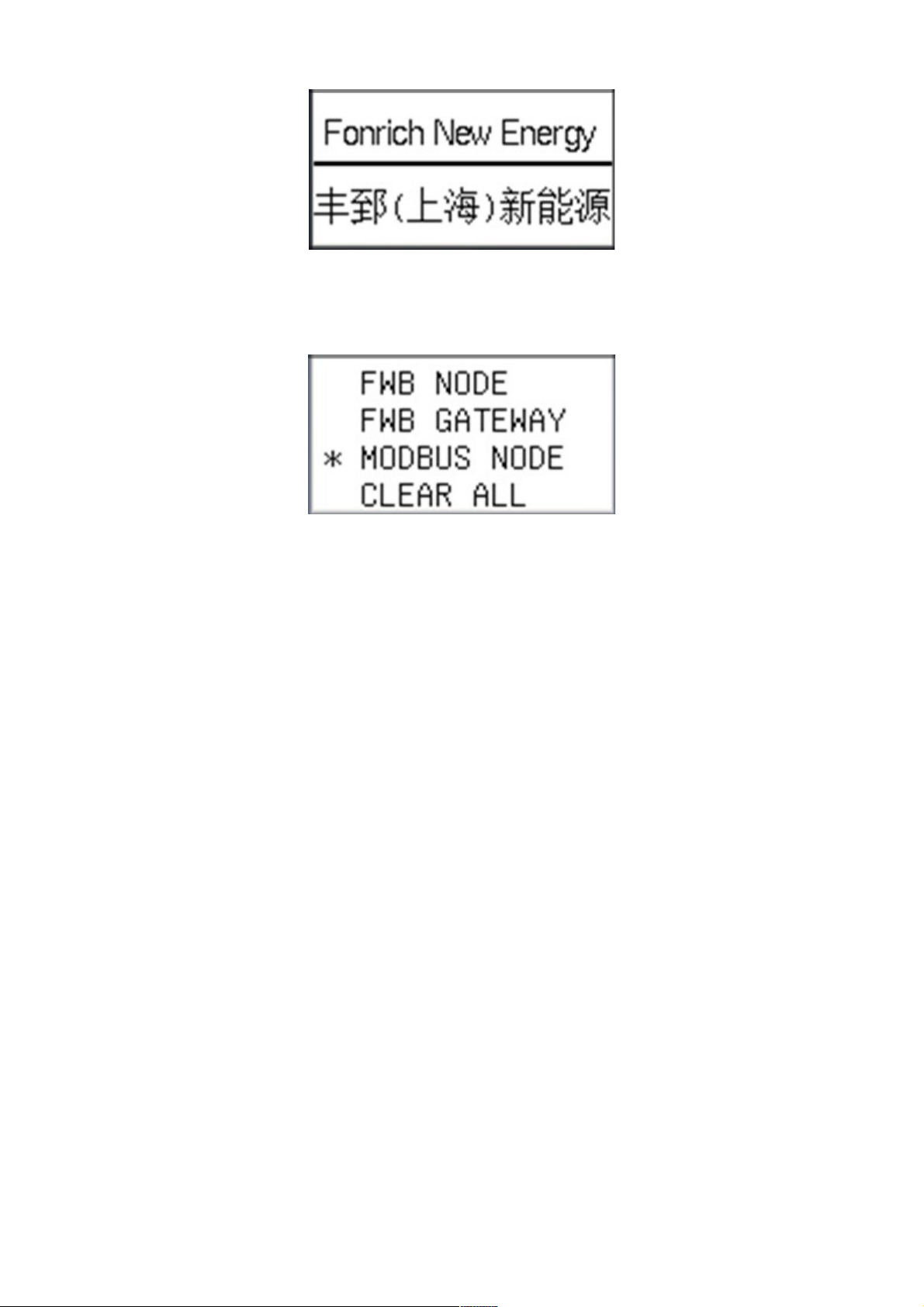

Mode setting

When FR-DCMG is powered up, the P/T light will be bright to show that the device is

working then the CD monitor will come up with the OGO picture for about 5 seconds.

11

When the OGO disappears FR-DCMG enters the relative mode, if keys “ESC”and “SET”

are pressed in the same time, FR-DCMG enters the mode selecting interface as below :

Among which

“*”: The selecting cursor that can be moved through pressing “+” and “-”keys.

FWB NODE:Actually, it is a wireless client mode. FWB means Field Wireless Bus, which

is robust filed wireless communication protocol designed by Fonrich. In this mode, the modbus

interface is also active.

FWB GATEWAY:In this mode the device is the wireless gateway of FWB network. In

this mode, the modbus interface is also active.

MODBUDS NODE:In this mode, only the modbus interface is active, and the wireless

is disabled.

C EAR A :Actually, it is not a work mode, which is just used to clear the generated

energy data that stored in the device in past.

When a different mode is selected and the key “SET” is pressed, the device will reboot to

enter the selected mode. If the previous mode is MODBUS mode then the parameters of the

modbus communication will be reserved for modbus communication.

MODBUS mode

The default mode of the device is MODBUS mode, when communicate with PC through

RS485, the ED lights R and P/T will twinkle to indicate that the communication is normal.

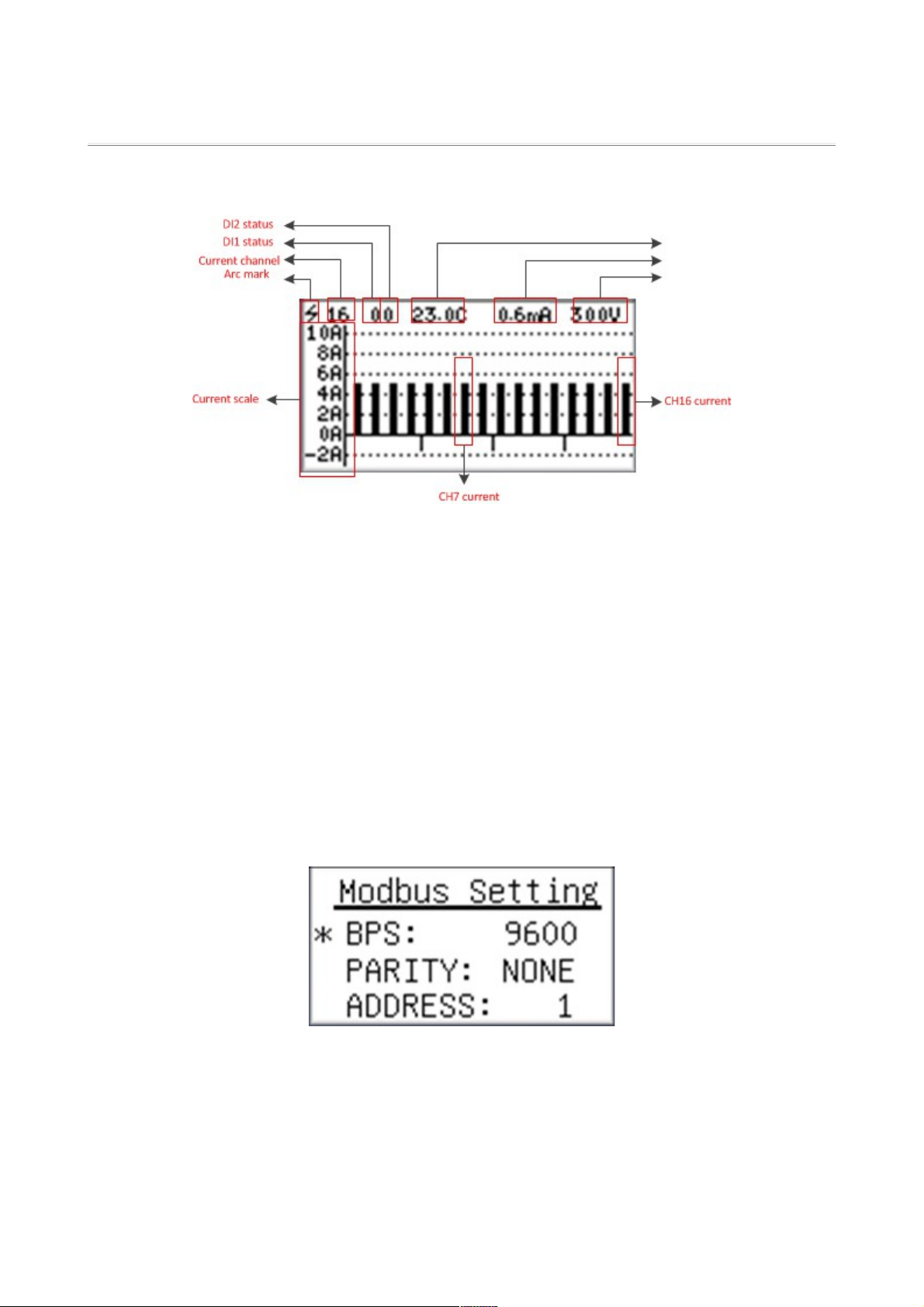

Histogram interface

The histogram interface will come up after the interface of OGO, histogram interface is the

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

default interface of MODBUS mode, it will be shown like below:

The histogram shows the current value of every channel, the current value ranges from -2A to

10A. For the hall sensors are four channel sensors, so in the histogram every four channels will

be indicated from another four channels which means that from left to right is channels 1-4,

channels 5-8, channels 9-12 and so on. If there is no button operations in 15 seconds, the

brightness of the CD will decrease.

If the 'Arc mark' is show, it means the current sensor is with Arc Fault Detect.

Parameters setting interface

When the key “SET” is pressed in the histogram interface the device will enter MODBUS

parameter setting interface, the device can communicate through RS485 in the other two mode

also but the modbus related parameter should be set in the MODBUS mode. MODBUS

parameter setting interface comes up as below:

Among which

BPS:MODBUS communication baud rate , the selectable rate are 2400、 4800、

9600(default rate), 19200、38400.

13

PARITY: The parity of MODBUS communication, the selectable parity none

parity(NONE), odd parity(ODD), even parity(EVEN)(default none parity).

ADDRESS: The address of the MODBUS slave device, ranges from 1 to 247(default 1).

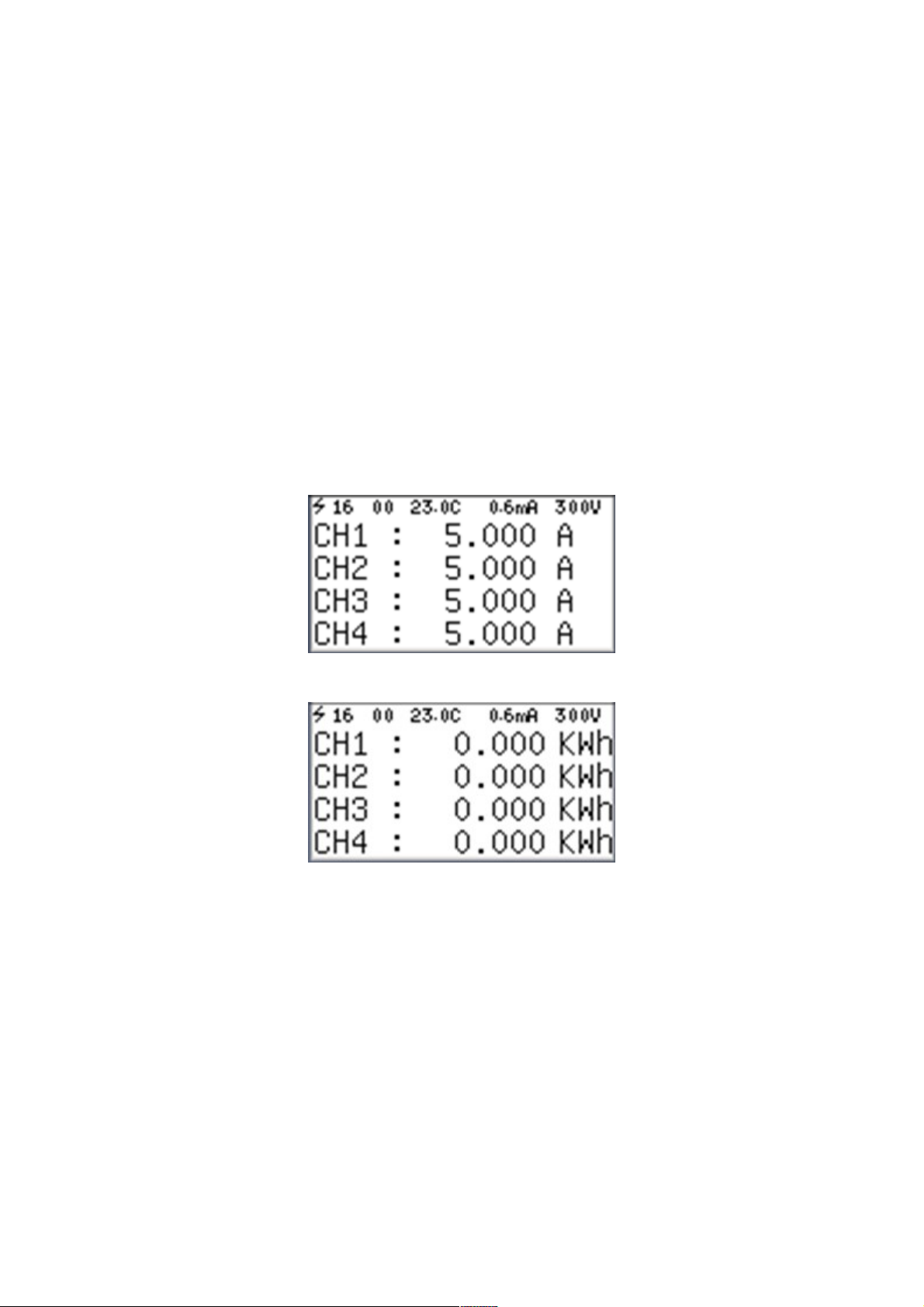

Digital displaying interface

When the key “+” or “-” is pressed in the histogram interface, the digital display

interface will come up to show the current values and generated energy values. When firstly

press key “+” then firstly shows the current value of the first four channels, when firstly press

key “-” then firstly shows the generated energy of the last four channels. Then go on pressing

the “+” or “-” key will scroll the screen to show current or generated energy value of other

channels. The generated energy value will come up at the end of current value, the current

value will come up after generated energy value on the reverse direction. Note that the top line

is the same with histogram interface.

Interface of the digital current:

Interface of the digital generated energy:

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

FWB NODE mode

Select FWB NODE mode in the mode selecting interface, if the previous mode is not FWB

NODE mode, the device will reboot after pressing the key “SET”, and the device will enter

FWB NODE mode.

Histogram interface

The histogram interface will come up after the interface of OGO, histogram interface is

also the default interface of FWB NODE mode, it will be shown the same as the MODBUS mode.

Parameters setting interface

When the key “SET” is pressed in the histogram interface the device will enter FWB NODE

parameter setting interface. FWB NODE parameter setting interface comes up as below:

Among which:

ADDRESS:the address of the wireless node, every device in FWB NODE mode will

get an unique address in the frequency indicated by FREQ, the address ranges

from 1 to 216.

FREQ:the frequency that the device used to communicate with other device, ranges

from 900MHz to 928MHz, step by 200KHz.

Digital displaying interface

When the key “+” or “-” is pressed in the histogram interface, the digital playing

interface will come up, which is the same as digital playing interface in MODBUS mode.

FWB GATEWAY mode

Select FWB GATEAY mode in the mode selecting interface, if the previous mode is not FWB

GATEWAY mode the device will reboot after the pressing of the key “SET”, and the device

enter FWB ATEWAY mode. When communicate with PC through RS485, the ED lights R and

15

P/T will twinkle to indicate that the communication is normal.

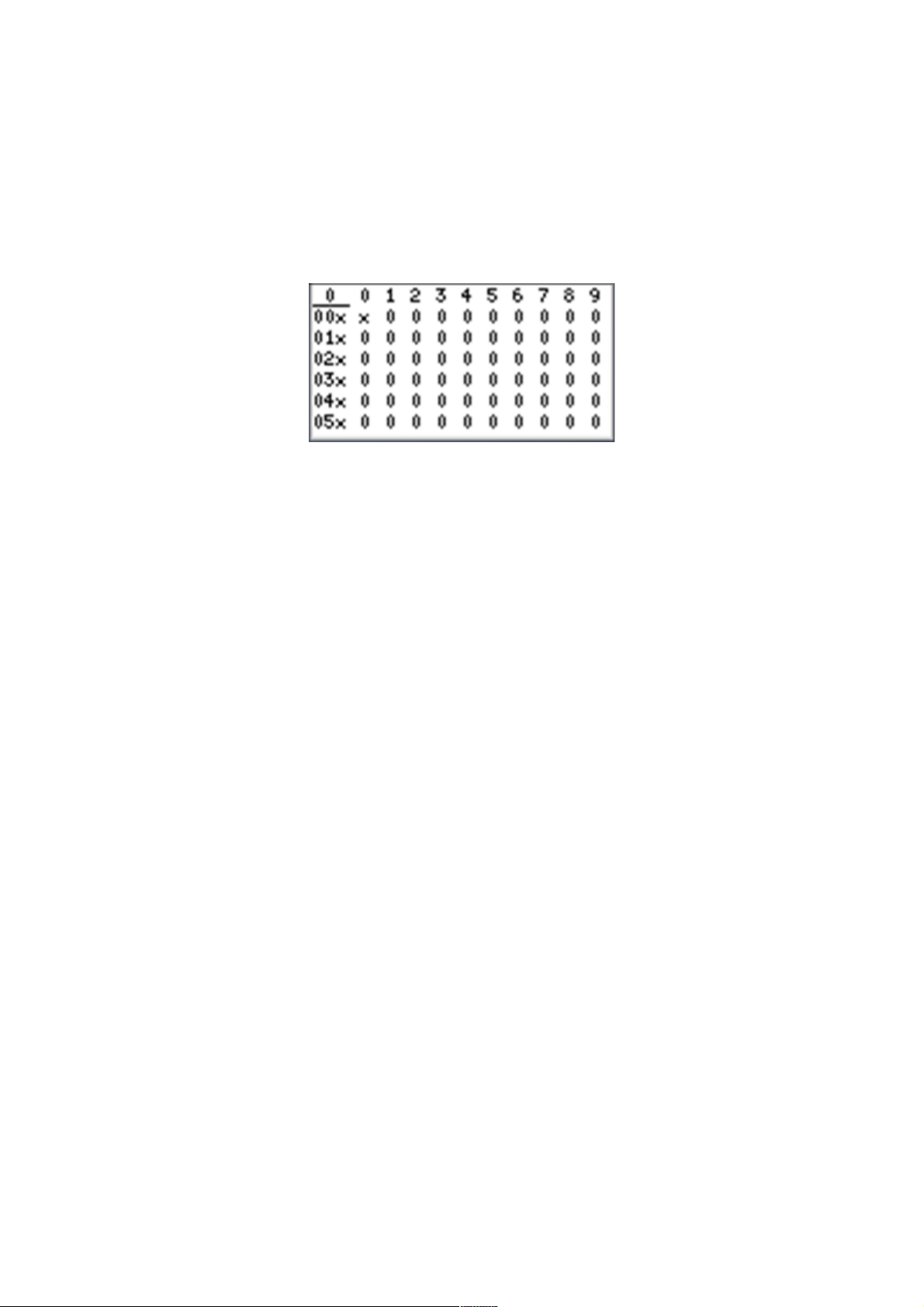

Wireless node connecting status interface

The wireless node connecting status interface will come up after the interface of OGO,

wireless node connecting status interface is the default interface of FWB GATEWAY mode, it will

be shown as below:

The number 1 on the left side of the top line means the online number of wireless node,

the address is composed by the numbers in the left column except the top “1” and the top

row also except the left “1”, calculate like :

address = xx(xx*) * 10 + x (x in the top row beside “1”)

take the upper picture as example, the supported number of wireless node is 30 for the

position whose address that bigger than 30 shows nothing but blank, there are one node

online, whose address is 01(01*) * 10 + 0 = 10 the position of the address shows the state of

the wireless node, 1 means the node is online and the distance to gateway is 1, 0 means that

the node is offline. Note that the distance dose not means the real distance, it just indicate that

weather the node need route transfer to communicate with gateway. Note that if the

supported number of wireless node is bigger than 60, you need scroll the screen to check the

state of the last node.

Histogram interface

The histogram interface will come up when press the key “+” till the end of wireless node

connecting state interface, if the supported number of the wireless node is less than 60 the

histogram interface will come up as soon as the key “+”is pressed. The histogram interface

will be shown the same as the MODBUS mode.

Digital displaying interface

When the key “+” or “-” is pressed in the histogram interface, the digital playing

interface will come up, which is the same as digital playing interface in MODBUS mode.

Parameters setting interface

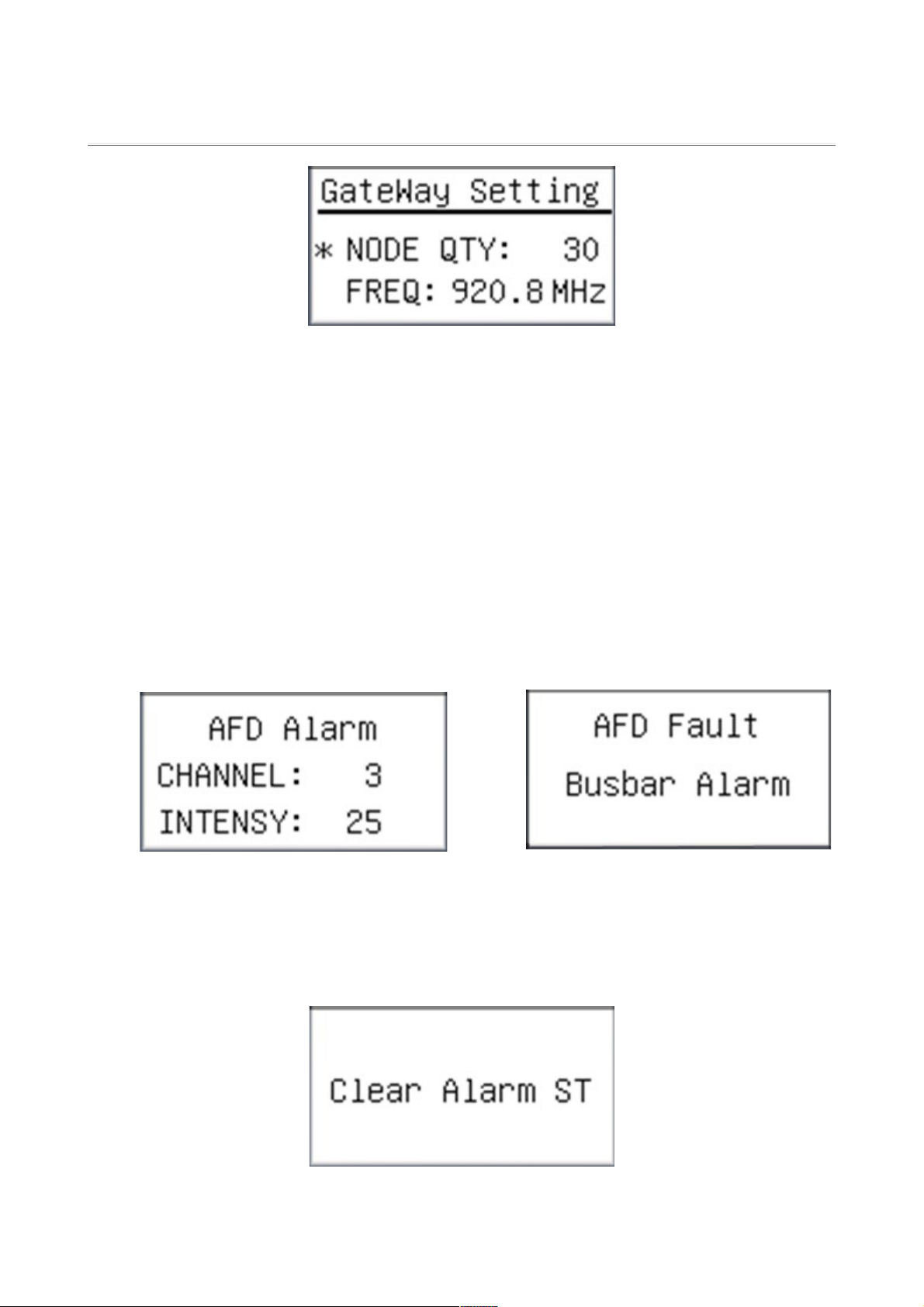

Press the key “SET” in wireless node connecting state interface will enter FWB GATEWAY

setting interface which will be shown as below:

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

Among which:

NODE QTY:the supported number of the wireless node by this gateway, default 30

ranges from 1 to 216. Generally, please keep this number as less as possible, because the

communication cycle will become longer as this number growing.

FREQ: the frequency that the device used to communicate with other devices

ranges from 315MHz to 928MHz, step by 200KHz.

Arc Fault Detect Alarm Function

Arc Fault Detect Alar picture

When the arc fault detected, the picture will change to alarm picture, which will shows as

below:

Channel Arc Fa lt B s-bar Arc Fa lt

It shows that: The CH3 has arc fault, the arc intensity is 25.

The arc intensity is a value means arc dangerous level. The default threshold value is 40.

If arc fault has excluded, it is necessary to reset the alarm picture. Press “ESC”key and

keep it abort 5 seconds.

17

Then the picture will change to histogram picture.

Shunt Tripping Setup Interface

At default picture, press key “ESC” and “+”in same time, will change to “Shunt

Tripping” set interface, shows as below:

Among which:

“TIME”: Set the shunt trip drive hold time, the shunt trip drive signal will be enable

when alarm event occurs, and hold on set time, then disable shunt trip drive signal.

“SE FCHECK”: If will start self check arc fault function. Check the arc sensor status

and check shunt tripping coil.

FR-DCMG DC System Monitor User Manual Fonrich New Energy Technology Co., td.

Ⅵ, Definition of the Modbus Protocol

Configuration of the modbus

Modbus communication mode:RTU mode

Address of the slave device:range from 1 to 247 (default 1)

Baud rate:(bps) 2400、4800、9600(default)、19200、38400

Parity of the byte:odd parity、even parity、none parity(default)

Description of the modbus frame

The byte in the communication frame composed by 1 start bit, 8 bits data bit, 1 parity bit, 1

stop bit like the below table(Refer to standard modbus RTU protocol):

Address code Function code Data field CRC field

1 byte 1 byte N*1byte 2 bytes

The address code is the slave device address. The function code tell the slave device how to

respond, and what request of the slave device response. N in data field can not be bigger than

252, the CRC field used to check the frame by using cyclic redundancy check.

Description of the function codes

FR-DCMG supports almost all function codes, includes 01, 02, 03, 04, 05, 06, 15 and 16. These

modbus function codes are separated to two kinds of operation: bit operation and word

operation. In FR-DCMG modbus implementation, all bit operations with different function

codes share same bit register address mapping, and all word operations with different function

codes share same word register address mapping.

Read and write operations of the registers in bit

•Function code 01 used to read the content of bit-type registers

•Function code 02 used to read the content of bit-type registers

19

•Function code 05 used to write single bit-type registers

•Function code 15 used to write multiple bit-type registers

the content of the bit-type register could be switches alarm information etc.

Read and write operations of the registers in word

•Function code 03、04 are used to read multiple word-type registers

•Function code 06 is used to write single word-type registers.

•Function code 16 is used to multiple word-type registers。

The content of the word-type registers can be voltage, current, generated energy, etc.

Description of the registers

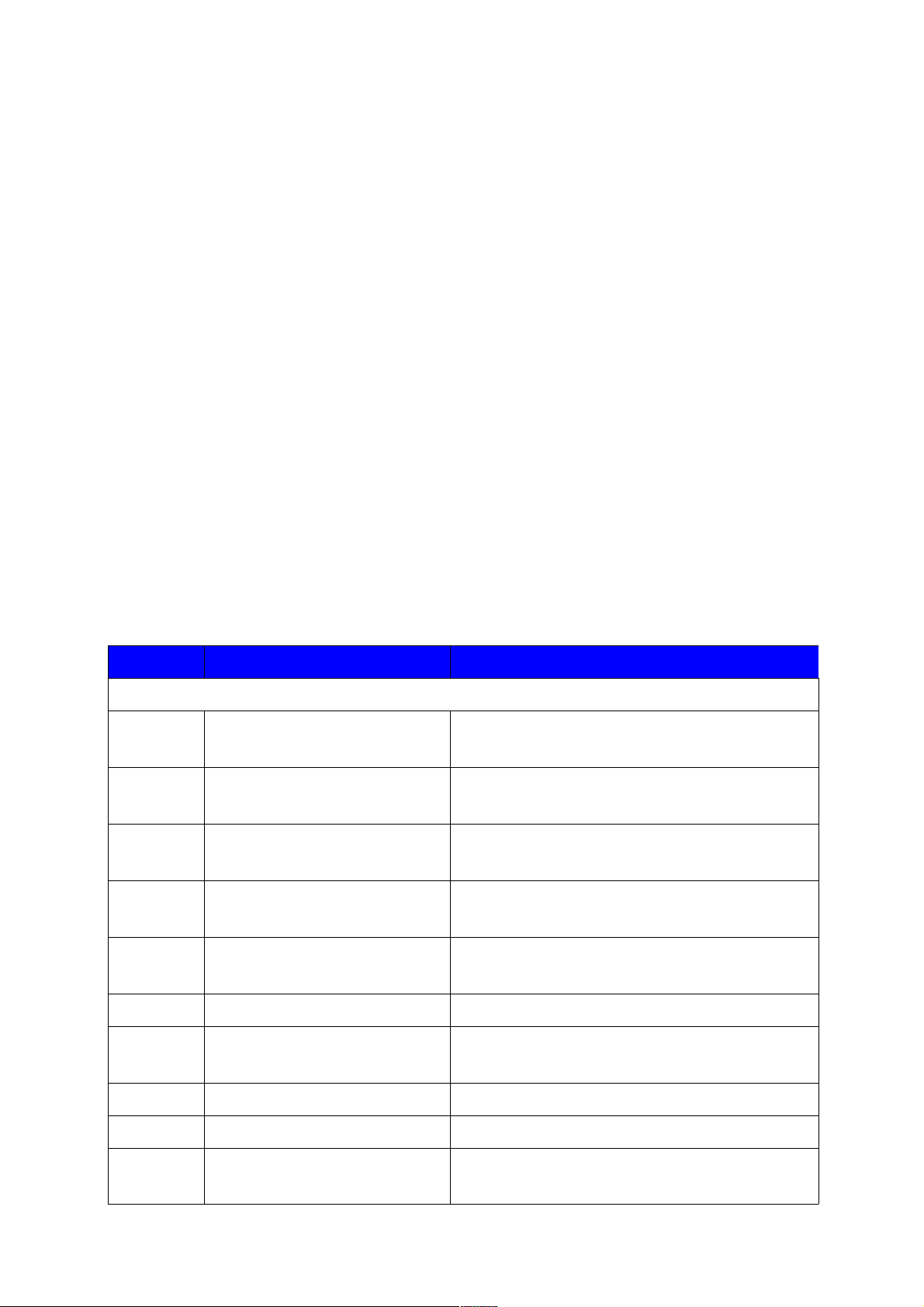

Description of the registers in bit

Bit address Functional description remark

Input switches and alarm signal(only Available to function code 02 )

0x0000 Digital input 1 status, DI1 The input switch DI1 of the device(0:break,1:

close)

0x0001 Digital input 2 status, DI2 The input switch DI2 of the device(0:break,1:

close)

0x0011 External temperature high alarm When the external temperature is higher than the set

value, set to 1

0x0020 Voltage too high alarm When the detected voltage is bigger than the set

value, set to 1

0x0021 Voltage too low alarm When the detected voltage is smaller than the set

value, set to 1

0x0030 Channel 1 no current alarm When current value equal to 0, set 1

0x0031 Channel 1 current too low alarm When current value smaller than the set value but not

equal to 0, set 1

0x0032 Channel 1current too high alarm When current value bigger than the set value, set 1

0x0033 Channel 2 no current alarm When current value equal to 0, set 1

0x0034 Channel 2 current too low alarm When current value smaller than the set value but not

equal to 0, set 1

This manual suits for next models

3

Table of contents

Other Fonrich Measuring Instrument manuals