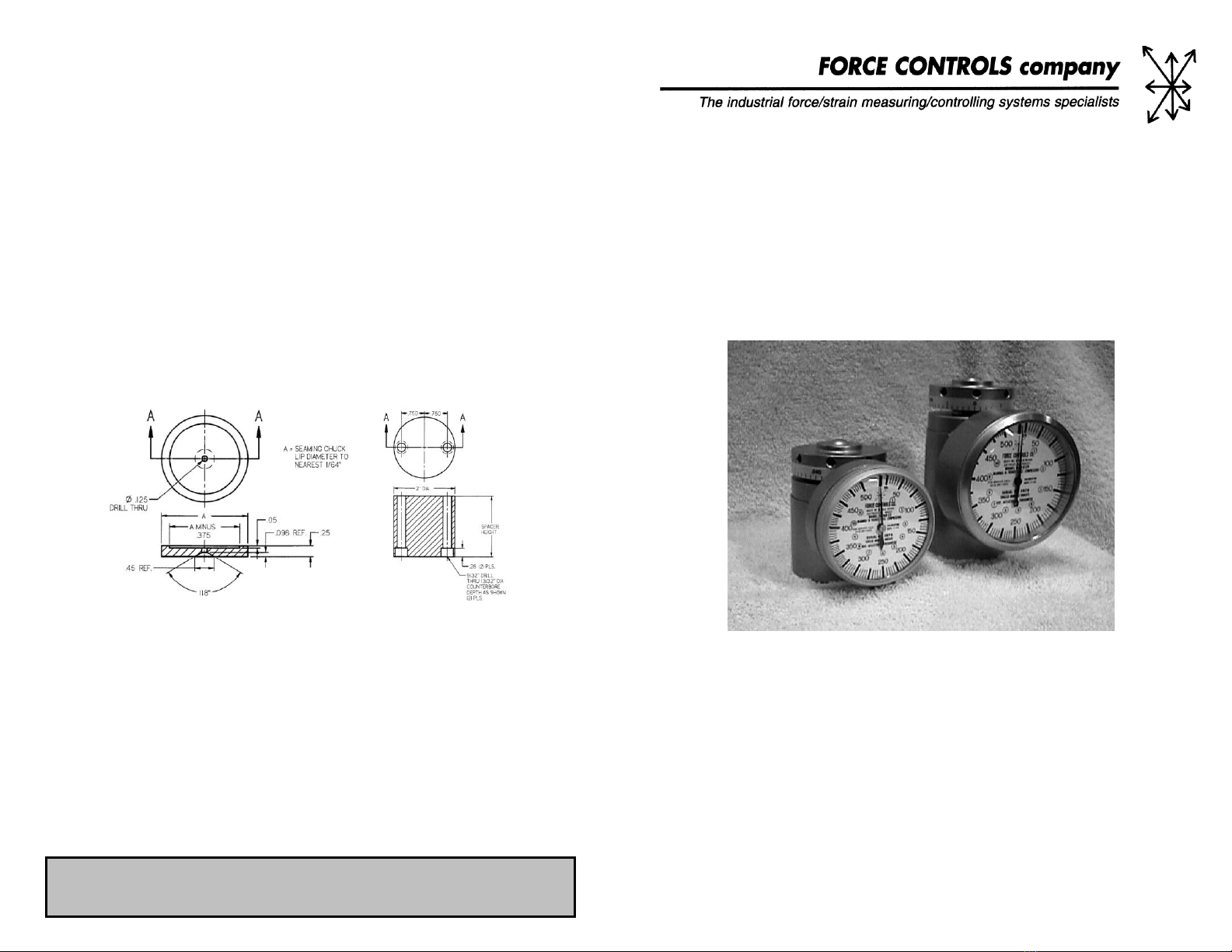

SPACERS AND SEAMING CHUCK ADAPTORS

The gage is supplied complete with case and loading wrench. However the

seaming chuck adapter and spacer need to be ordered separately. The seaming

chuck adapter and spacer allows the force gauge to fit in the seamer in such a

way that the three together simulates a can of the same height that is being

closed on the seamer. Determining the length of the spacer to order is easy.

Just take the height of the can size that you are using and subtract three inches

for the models1060CS and1050CS. Subtract 4.25 inches for the 8060CS. The

remainder is the height of the spacer to order. Determining the “A” dimension

that is needed to order a seaming chuck adapter is just as easy. The “A”

dimension is the same as the diameter of the can being used. Cans are

normally referred to as a 401X504 or a 603X510, etc. This means that in the first

example, the diameter is 4 1/16” and the diameter is 5 ¼”. The first number (4)

is inches. The second (01) is the number of 1/6ths. Hence 4 1/16”. This is a

standard in the caning industry, and will assist you in determining the “A”

dimension without having to measure the can that you are planning to use with

the gage.

RECOMMENDED SEAMING RECOMMENDED SPACER

CHUCK ADAPTER

New Cell Warranty: Any repairs needed on new cells within 120 days of invoice

will, be performed at no charge.

Recalibration and repairs.......................................$450.00

Certified calibration certificate ................................$50.00

Replacement pin wrench............................................$5.00

Plastic carrying case ................................................$30.00

Spacer .......................................................................$25.00

Spacer 3” or greater..................................................$50.00

Seaming chuck adaptor ...........................................$50.00

WARNING

Cells are not covered by warranty if external indicator adjustment screws

have been unplugged and or tampered with.

Mechanical Force Gauges for Can Closing Equipment

Instruction Manual for Models

1050CS, 1060CS

8050CS, 8060CS

For service: Send force gage in its protective case to:

Force Controls Company

4574 Elizabeth Lake Road

Waterford, MI 48328

(248) 738-7133

FAX 738-7134

www.forcecontrols.com

Please include contact information with the force gage