Essemtec Fox User manual

Fehler! Unbekannter

Name für Dokument-

Eigenschaft.

Fox

Maintenance Manual

ObjectNo.

0000074/05

Release Date

March 31, 2017

Copyright

© Essemtec AG, Switzerland, 2017

All rights reserved. No partof this publication may be reproduced, stored, in a retrieval system, or

transmitted, inany means, electronic, mechanical, photocopying, recordingor otherwise, without the prior

written permission of the publisher.

The Fox works as is. Screenshots and description cover the actualbehavior as far as possible. The contentof

this manualdoes notgive any claim to software performance orimplemented software features.

Essemtec AG Customer Support

Headquarter

Essemtec AG

Mosenstrasse 20

CH-6287 Aesch/LU

Schweiz

Phone:

+41 41 919 60 60

Fax:

+41 41 919 60 50

Poland

Essemtec Poland

Wrzeciono 16/24

01-961 Warszawa

Germany

Essemtec Deutschland AG+Co.KG

Söckingerstrasse 12

82319 Starnberg

Tel:

+48 / 661 922 962

Phone:

+49 / 8151 2685501

Fax:

+49 / 8151 2685503

Mail: sales-poland@essemtec.com

North America & Mexico

Essemtec USA

816N. Delsea Drive #308

08028-1499 Glasboro, NJ

Phone:

+1 / 856 218 1131

Fax:

+1 / 856 218 1134

Mail: sales@essemtec-usa.com

Imprint

Fox Maintenance Manual

Concept: ArminMueller

Authoring: ArminMueller

Checked: Stefan Baumann

Approved: Fernando Marcos

OriginalLanguage: English

ManualFeedback: a[email protected]m

Essemtec Information: www.essemtec.com

Fox Maintenance © Essemtec AG iii

0000074/05 / March 31, 2017

Contents

1Materialsand Tool-Kits 1-1

1.1 MaterialsandTool-Kits Overview..............................................................................................................................1-1

2Configuration of the Machine 2-1

2.1 Configurationof Machine and Modules.................................................................................................................2-1

2.1.1 Introduction......................................................................................................................................................................2-1

2.1.2 ToolsandMaterial...........................................................................................................................................................2-1

2.1.3 Configuration Tasks........................................................................................................................................................2-2

3Calibration of the Machine 3-1

3.1 Introduction......................................................................................................................................................................3-1

3.2 Preparation/ Terminationfor XY Mapping............................................................................................................3-4

3.2.1 Machine with PCB Table(no conveyor)...................................................................................................................3-4

3.2.2 Machine with Conveyor................................................................................................................................................3-9

3.3 MechanicalAdjustmentPossibilities.....................................................................................................................3-11

3.3.1 PCB Handling.................................................................................................................................................................3-11

3.3.2 Cameras...........................................................................................................................................................................3-14

4Preventive Maintenance 4-1

4.1 Introduction......................................................................................................................................................................4-1

4.2 Preventive Maintenance Schedule...........................................................................................................................4-3

4.3 Daily Maintenance a.......................................................................................................................................................4-5

4.3.1 Tools, Material and Scheduling..................................................................................................................................4-5

4.3.2 Prerequisites......................................................................................................................................................................4-5

4.3.3 Used Tape cutting andremoving..............................................................................................................................4-6

4.3.4 RejectBin Emptying.......................................................................................................................................................4-7

4.3.5 ContaminatedAreas Cleaning(Dispensing).........................................................................................................4-7

4.3.6 Dispensing Valve Cleaning..........................................................................................................................................4-9

4.4 Weekly Maintenance a...............................................................................................................................................4-10

4.4.1 Tools, Material and Scheduling...............................................................................................................................4-10

4.4.2 Prerequisites...................................................................................................................................................................4-11

4.4.3 Safety Check...................................................................................................................................................................4-12

Contents

iv © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

4.4.4 Bottom Vision GlassCleaning...................................................................................................................................4-14

4.4.5 Cover and Monitor Cleaning.....................................................................................................................................4-14

4.4.6 NozzleCleaning.............................................................................................................................................................4-15

4.4.7 Conveyor BeltChecking and Cleaning..................................................................................................................4-18

4.5 Weekly Maintenance b................................................................................................................................................4-19

4.5.1 Tools, Material and Scheduling................................................................................................................................4-19

4.5.2 Prerequisites...................................................................................................................................................................4-20

4.5.3 Feeder and Rack Cleaning..........................................................................................................................................4-20

4.5.4 Trailing Cable Checkingand Cleaning ..................................................................................................................4-21

4.5.5 Production AreaCleaning..........................................................................................................................................4-22

4.5.6 Linear Motor MagnetsChecking and Cleaning..................................................................................................4-23

4.6 MonthlyMaintenancea..............................................................................................................................................4-25

4.6.1 Tools, Material and Scheduling................................................................................................................................4-25

4.6.2 Prerequisites...................................................................................................................................................................4-26

4.6.3 Height Laser Cleaning.................................................................................................................................................4-27

4.6.4 Air Maintenance Unit Checking...............................................................................................................................4-27

4.6.5 Optical Measuring System Checking possibly Cleaning.................................................................................4-28

4.6.6 P&PHeadChecking......................................................................................................................................................4-29

4.6.7 Dispense Axes Cleaning/ Lubricating...................................................................................................................4-36

4.6.8 ConveyorClamping Checking/ Lubricating.......................................................................................................4-39

4.7 Yearly Maintenance c...................................................................................................................................................4-41

4.7.1 Tools, Material and Scheduling................................................................................................................................4-41

4.7.2 Prerequisites...................................................................................................................................................................4-45

4.7.3 Linear Slider / Rails Cleaningand Lubricating....................................................................................................4-46

4.7.4 Electronic Cabinets Checking and Cleaning.......................................................................................................4-48

4.7.5 Head Maintaining..........................................................................................................................................................4-50

4.7.6 Dispense Axes Linear Guide Cleaning / Lubricating........................................................................................4-58

4.8 Yearly Maintenance a..................................................................................................................................................4-59

4.8.1 Tools, Material and Scheduling................................................................................................................................4-59

4.8.2 Prerequisites...................................................................................................................................................................4-60

4.8.3 Machine Calibration.....................................................................................................................................................4-61

4.9 Stepsto gain Prerequisitsfor Maintenance.........................................................................................................4-62

4.9.1 GainingPrerequisitsa..................................................................................................................................................4-62

4.9.2 GainingPrerequisitsb.................................................................................................................................................4-63

Contents

Fox Maintenance © Essemtec AG v

0000074/05 / March 31, 2017

4.9.3 GainingPrerequisitsc.................................................................................................................................................4-66

5Corrective Maintenance 5-1

5.1 Introduction......................................................................................................................................................................5-1

5.2 MalfunctionTable...........................................................................................................................................................5-3

5.3 Preparation........................................................................................................................................................................5-3

5.4 P&PHead............................................................................................................................................................................5-5

5.4.1 Head V5 Vacuum Feedthrough Cleaning / Lubricating....................................................................................5-5

5.4.2 Head Removal fromMachine...................................................................................................................................5-15

5.4.3 Head Mounting ontoMachine................................................................................................................................5-19

Fox Maintenance © Essemtec AG vii

0000074/05 / March 31, 2017

About this Manual

History

Index

Release

Changes

01

September 15,

2016

Firstrelease

02

January 06,

2017

Procedure to rinse the vacuum passage extendedin chapter 'Head

Maintaining' ofYearly Maintenance c (spindle tip cleaning by meansof

the conical brush).

03

February01,

2017

Procedure forConveyor Clamping Checking/ Lubricating addedto

chapter 'MonthlyMaintenance a'.

Corrective Maintenance, chapter 'P&P Head', description if head removalis

required or not, has been improved.

Sub-chapter 'Head Removal from Machine', moved to theend of chapter

'P&P Head' to avoid anymisunderstandings.

04

February10,

2017

Corrective Maintenance, chapter 'MalfunctionTable', has beenimproved.

05

March 31,

2017

Part numberof grease added at all positions whereP&P Head Greaseis

used.

Procedure to rinse vacuum passage reworked.

Loctite 7063 replaced by IPA Isopropyl alcohol.

Purpose

ThisMaintenanceManualcontainsessential information(whereapplicable)concerning:

•the safe andefficient performanceof preventive maintenance tasks on the Fox

•the safe andefficient performanceof corrective maintenance tasks on the Fox

•the safe andefficient configuration and calibration ofthe Fox

•the schematics (electrical,electronic and pneumatic) of theFox

•the tool kitsused for calibration etc.

The knowledgeof and adherence to the safetyregulations andthe compliancewith additional

warning instructions described inthis Maintenance Manualis a basic precondition for a safe and

error free work with orat the Fox.

This document (Maintenance Manual) and especially the safety regulations have to be observed by

all personswho work with or atthe Fox. Additionally,all local safetyand environmental regulations

have to be observed.

AboutthisManual

viii © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

How to Use

In general, this Maintenance Manualshould be usedin conjunction with allother relevant

documentation providedwith themachine. To findspecific informationquickly, alluser

informationcontain followingfeatures:

•Tableofcontents

•Cross-referenceswithin text

•Margin notes, pictograms, symbols etc.

•Glossary, givinga helpful list of themost frequentlyused terms ofSMT technology

Manual used as Reference Book

This MaintenanceManual can be used as reference book forworking with theequipment. All

equipment users can follow the task description stepseasy and fast. suggests to acquire

application knowledgein training courses.

Manual used as Training Information

This MaintenanceManual is structured according to the method of Performance Based Equipment

Training (PBET).Therefore it can be usedas training informationto pursue tasks stepby step. It will

be used in training courses.

AboutthisManual

Fox Maintenance © Essemtec AG ix

0000074/05 / March 31, 2017

Personnel Requirements

The maintenancetasks on the Fox, its modules or options may only be performed by authorized

maintenance personnel whofulfill the followingrequirements.

Function

Responsible for regularchecks of themachine, for cleaning and lubrication, forregular adjustments

as well as forremoval and replacementof faulty assemblies.

Duties and Responsibilities

•Handles materialand chemicals in a correct and safemanner.

•Knows how tointerpret material safety data sheets (MSDS).

•Interprets the maintenance information correctly.

•Interpretshints and errors and takes correctaction.

•Follows approved technical methods for maintainingthe Fox, modulesor optionsof it.

•Participates inregular trainings to maintain therequired levelof knowledge related to

maintain and service the equipment and trains subordinate personnel as required.

•Wears and uses protectiveequipment (goggles, protective gloves, etc.)when working with

aggressive substances.

CompulsoryReading

The Startup& Safety Manual is an integral partof the MaintenanceManual. Read the

Safety Chapter of the Startup & Safety Manual before working withor at the Fox.

Essemtec AG declines all responsibility for personal injuries or materialdamages

occurring as aresult of non-observance of the safety chapter's instructions an warnings.

AboutthisManual

x© Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

Signal Words and their Meanings

Throughout thisdocument, attention is drawn to safetyissues using thefollowing signal words:

Danger

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Thissignal word is limited to the mostextreme situations.

Warning

Indicates a potentially hazardous situation which, if notavoided, could result in death or

serious injury.

Caution

Indicates asituation which, if notavoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Notice

Indicates a situation which, if notavoided, may result in equipment or material damage.

Safety Alert Symbol

Refers to a safety relevant text in the Startup & SafetyManual.

AboutthisManual

Fox Maintenance © Essemtec AG xi

0000074/05 / March 31, 2017

Pictograms and their Meanings

Pictograms areused in thisManual in order to supportthe understanding ofthe text and to

increase the efficiency ofthe practical work. Inline with textno pictograms areused.

Menu

-menu is written

next to the pictogram ina hierarchical form.

Example:

System

Calibration

XY gantry

Soft Key

Meaning of pictogram: "click the soft key ...". The corresponding soft keyis written next to the

pictogram in bold italic font.

Example:

Calibrateall

Tool

Meaning of pictogram: a tool is required to carry out a step in a procedure. Thepictogram is placed

next to the correspondinginstruction.

Example:

Tighten the fixation screw.

Check

Meaning of pictogram: aselection has to be done (check boxes). The pictogram is placed next to

the correspondinginstruction.

Example:

Setupcheck

Hint / Notification

Meaning of pictogram: apop up window giving a hint or awarning. The textof the pop upwindow

is written next to the pictogram in a non proportional font.

Example:

Make sure that all boards are removed before continuing calibration

AboutthisManual

xii © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

Text Box

Meaning of pictogram: avalue (alphanumeric)has to be enteredby means of the on-screen

keyboard, after clicking the text box (usually a parameter). The pictogram is placed next to the

correspondingparametername.

Example:

Barcode, enter thebarcode of thefeeder.

Drop Down List

Meaning of pictogram:one of the presented itemson the drop downlist has to be selected, after

clicking the box (usually aparameter). The pictogram is placed next to thecorresponding

parameter name.

Example:

No of pick retries,select the desired numberof pick retries.

AboutthisManual

Fox Maintenance © Essemtec AG xiii

0000074/05 / March 31, 2017

Text Conventions and their Meanings

Various text styles are used in this Maintenance Manual in order to support the readabilityof the

text or to emphasizethe meaningof text segments.

Meaning

Description / Text Style

Example

Parameters and

actual Values

Machine parameters and actual values are

visualized by bold characters and in the same

spelling as inthe menu. Also the state of the

parameter iswritten in thesame way.

Set the parameter

Optimizationmode to

Maximum performance

Pickup 5 [ms]

Soft Key

Context sensitivefunction keys are written in

italic and bold. Normallythey are shown

together with the respective pictogram.

Press New to create a new

lightprofile

MenuKey

(Screen)

Startsa submenu. Same style asthe Soft Keys.

ProductionSettings

Check Boxes

Are located anywhere on ascreen. They have

same style as Soft Keys.

SelectSetupcheck

MenuTree

In a text flow thehierarchy of a menu is visu-

alized by using hyphensand bold characters.

Setup - Optimization -

Recipe Splitting

Screen

Screens are written in bold usingcapital and

smallletters.

... on Produce screen

Cross

Reference

Written in blue italic.

seeonpage...

Notification

Error

Warning

Appearing in a pop up window providing tips,

instructions and messages. They are writtenin a

non proportional font.

The following warning

appears:

No components found

to be produced

Note

If a certain subject must be emphasizedit is

written as anote.

Note:

Adjust the guide pins

symmetrically

AboutthisManual

xiv © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

Information Concept

The User Documentation of theFox consistsof the following manuals andonline help:

•UnpackingInstruction

•InstallationManual

•Startup & Safety Manual

•Maintenance Manual

•ElectronicSparepartCatalogue

•OnlineHelp:

–Context Info with QuickHelp and How to information

–InfoPage

Fox Maintenance © Essemtec AG 1-1

0000074/05 / March 31, 2017

1 Materials andTool-Kits

1.1 Materials and Tool-Kits Overview

The materials and tool-kits describedin this chapter are necessary for:

•Configuration

•Calibration

•Preventive Maintenance

•CorrectiveMaintenance

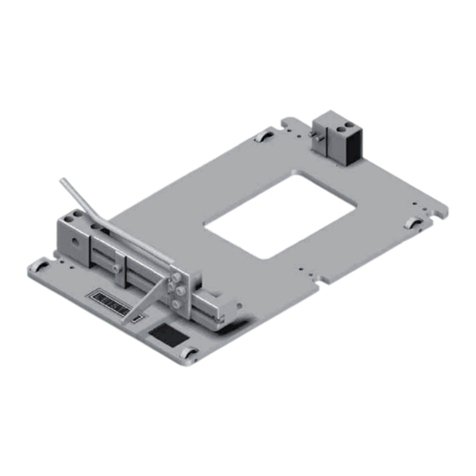

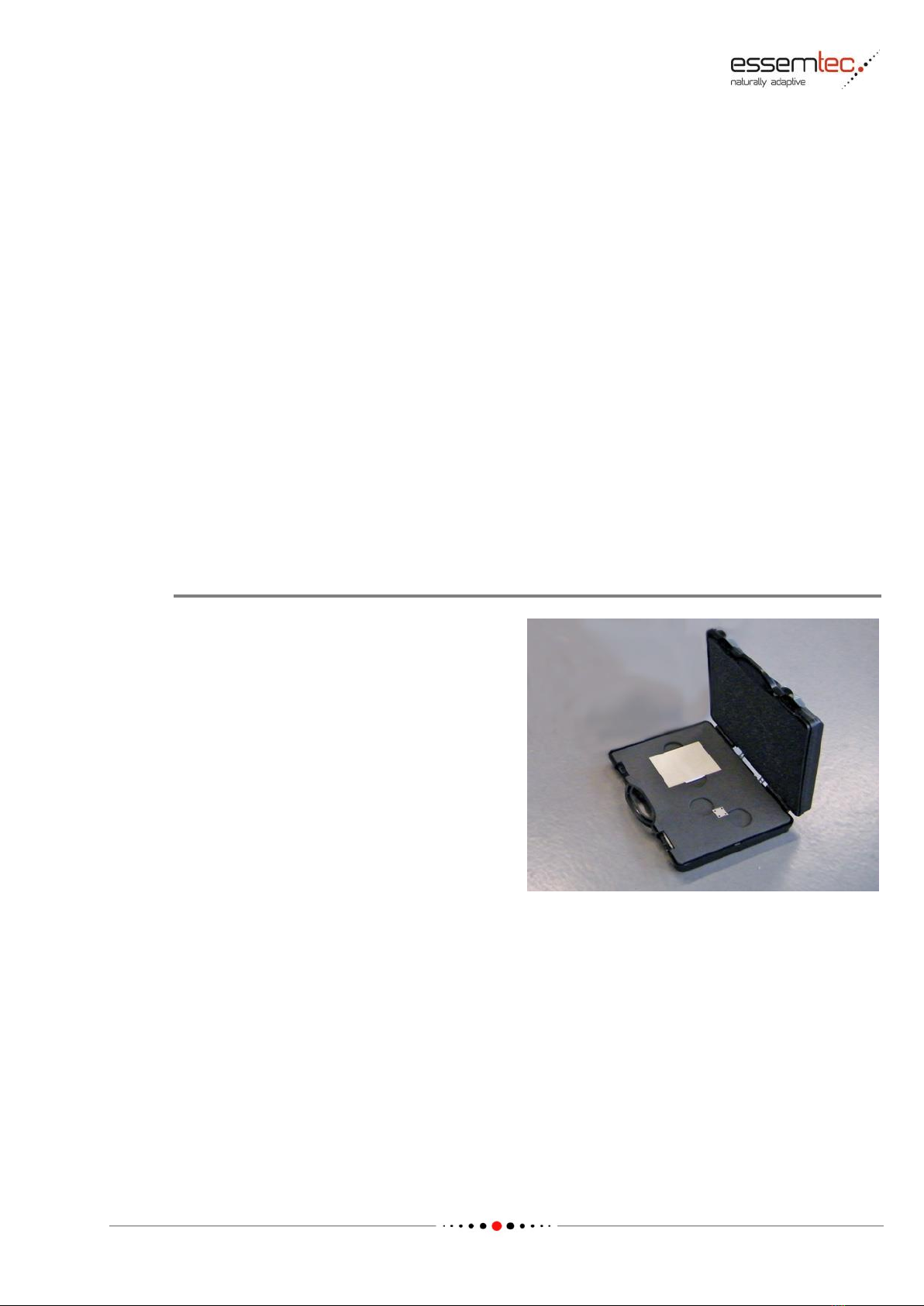

CAL-SET12 Tool-Kit for P&P Head Maintenance

Partnumber:CAL-SET12

The purposeof this set is to recalibrate the Pick

& Place Head.The kit consistsof:

•Glass plate 65 x 50 mm

•Aluminum calibration plate 15 x 15mm

MaterialsandTool-Kits

1-2 © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

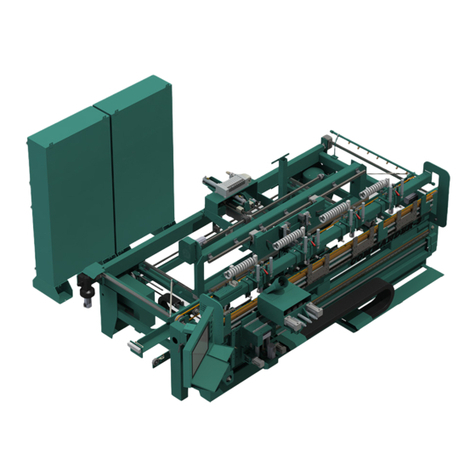

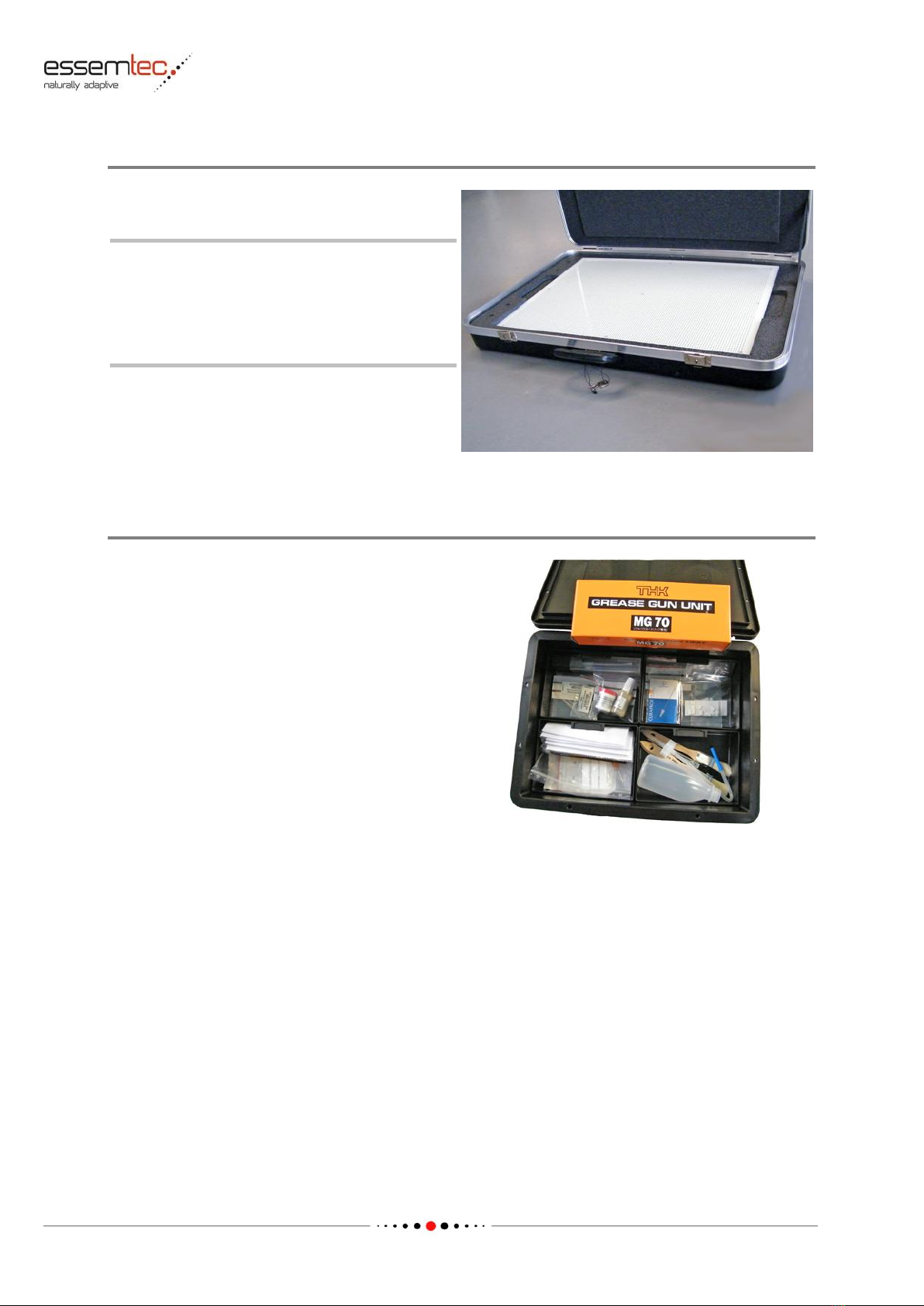

CAL-SET13 Tool-Kit for XY Mapping / Head Rotation

Partnumber:CAL-SET13

Note:

The CAL-SET13 Tool-Kit is not scopeof

the machine delivery.

The arrangement of thetools in the

delivered tool-kit may vary fromthe

illustration.

The purposeof this set is to calibrate the XY

mapping and head rotation. The kitconsists of:

•1x glass plate 300 x 610 mm

•4x supportpins PC-SUP-C00

SP26/MAIN05 Tool-Kit for P&P Maintenance Tasks

Partnumber:SP26/MAIN05

The purposeof this set is to provide thecorrect

toolsandmaterialsformachine maintenance.

The kit consists of:

•grease gun with greasefittings

•grease for linear carriages

•contact pins forPC feeder

•variousbrushesfor cleaning

•2x head assembly tool fordownholding the

ZT elements

•leaf springs for pulling back the nozzle on

the ZT element shaft

•microfibre eyeglass cloth for cleaning the

opticalmeasuringsystem

•squeeze bottle for rinsing the vacuum

passage

•various filters for valves

•vacuum silicon tubesfor head

•grease for head lubricating

MaterialsandTool-Kits

Fox Maintenance © Essemtec AG 1-3

0000074/05 / March 31, 2017

SP26/HG10 Grease Gun Kit

Partnumber:SP26/HG10

Note:

The Grease Gun Kit is not scope of the

machinedelivery.

The purposeof this kit isto provide thecorrect

grease gun for machinemaintenance either if

the original maintenance kit does not contain a

gun or to replacean old gun whichis worn out.

The kit consists of:

•1x gun complete

•1x grease cartridge

•1x grease gun adapter (bended spout)

•3x coupler for the different lubricating

nipples

Circlip Pliers

Partnumber:SP/TOOL-26

Note:

The circlip pliersis not scope of the

machinedelivery.

The delivered circlip pliers may vary from

the illustration.

The purposeof this tool isto maintain the P&P

head (vacuumfeedthrough cleaning and

lubricating)

MaterialsandTool-Kits

1-4 © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

Pusher Needles

Partnumber:SP26/BN01-Tool

Note:

The pusherneedle kit is not scope of the

machinedelivery.

The arrangement of theneedles in the

delivered kitmay vary from the

illustration.

The purposeof this setis to pushout the

nozzles. The kit consists of:

•5 pusher needlesfor nozzle 1

Fox Maintenance © Essemtec AG 2-1

0000074/05 / March 31, 2017

2 Configurationof the Machine

For better visibility of subjacent functions, covershave been removed or opened before

taking pictures. In standard operating mode all covers have to be in place at any time.

2.1 Configuration of Machine and Modules

Since the configuration includes also adjustments, the safety regulations written in the

Startup & Safety manual must be read before starting the tasks.

2.1.1 Introduction

The machine Fox itselfis a very flexible andmultipurpose equipment. Therefore it is necessary to

configure it fora specific task or function. The configuration includes also some necessary

adjustments.

2.1.2 Tools and Material

For an effective and efficient machineconfiguration,the following toolsand material haveto be

provided:

Required Tools / Material

Tools:

USB mouse and USB keyboard

1 metal ruler

1 vacuum meter

Screwdrivers and Allenkeys in different sizes

Nozzles:

4xNozzle4

1xNozzle6

1xNozzle3

Configurationof the Machine

2-2 © Essemtec AG Fox Maintenance

0000074/05 / March 31, 2017

2.1.3 Configuration Tasks

The configuration is doneonline at the machine. Thereby the order of the tasksdoes not matter.

Most of thetime the tasks aresoftware guided.

System

Configuration

to see details of purpose,parameters, softkeysetc. in the online help.

Table of contents

Other Essemtec Industrial Equipment manuals