Brano Z321 Installation guide

BRANO a.s, 747 41 Hradec nad Moravicí

Czech Republic

tel.:+420 / 553 632 303

http://www.brano-zz.cz; http://www.brano.eu;

SAFETY PRINCIPLES, OPERATION AND MAINTENANCE

MANUAL

FOR

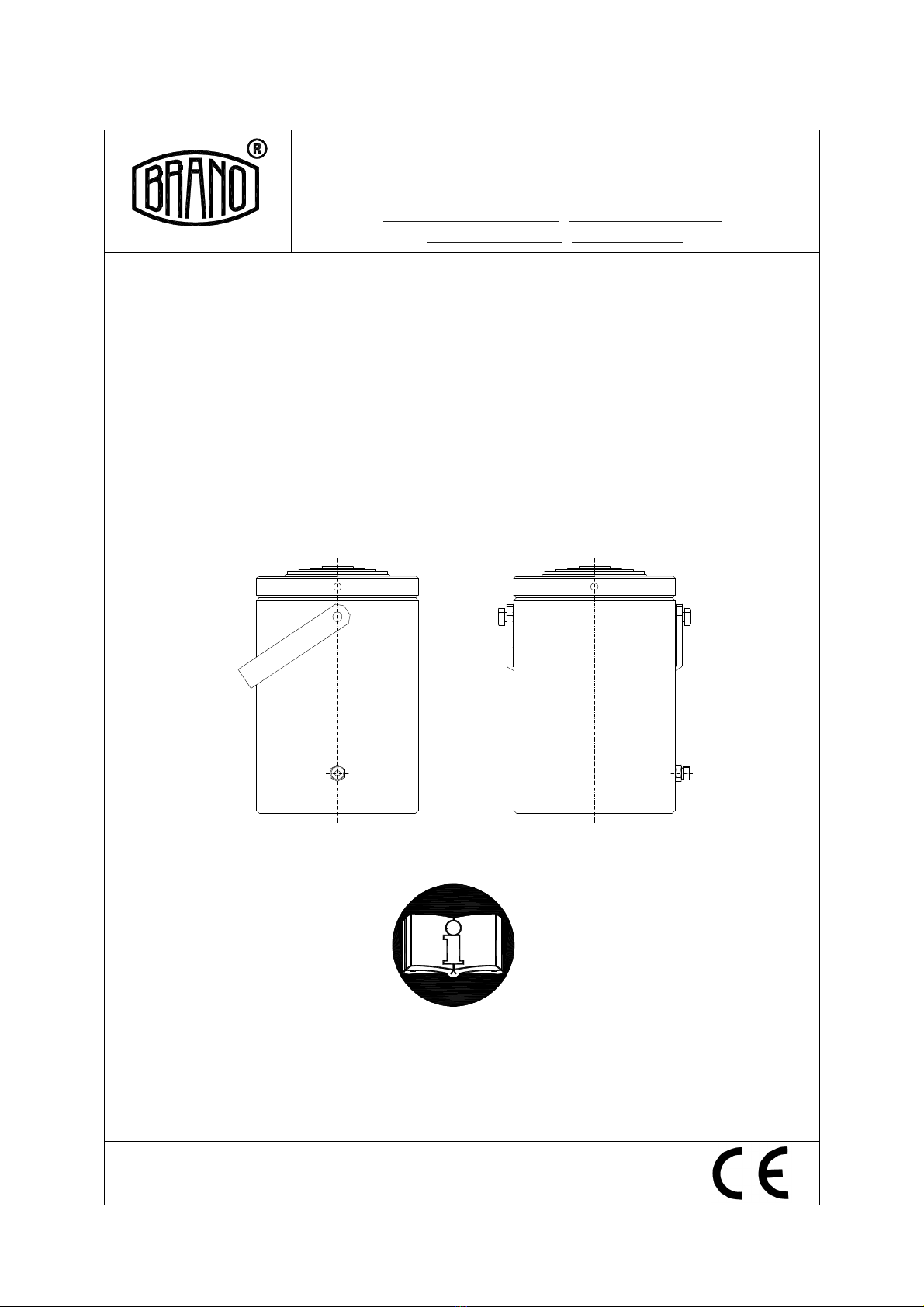

HYDRAULIC CYLINDER

type Z321

lifting capacity 25t; 50t; 100t and 200t

Read this manual carefully before using this product. The manual contains important

safety, installation, operation and maintenance instruction. Make this manual

available to all responsible persons.

Keep for further use!

Edition 3rd

MARCH

2017

Evidence number 1-52238-0-1

2

CONTENT

1

DEFINITION .......................................................................................................................... 3

2

INTENDED

PURPOSE........................................................................................................... 3

3

SAFETY

PRINCIPLES........................................................................................................... 4

3.1 SAFETY SUMMARY ....................................................................................................... 4

3.2. SAFETY PRINCIPLES .................................................................................................... 4

3.2.1 Before use........................................................................................................................ 4

3.2.2 While operation............................................................................................................... 5

3.2.3 After use .......................................................................................................................... 5

3.2.4 Risk analysis.................................................................................................................... 5

3.2.5 Maintenance .................................................................................................................... 5

4

PACKING,

STORAGE

AND

MANIPULATION .................................................................. 5

4.1 PACKING .......................................................................................................................... 5

4.2 STORAGE ......................................................................................................................... 6

4.3 MANIPULATION ............................................................................................................. 6

5

MAIN

TECHNICAL

PARAMETERS.................................................................................... 6

6

OPERATION

OF

CYLINDER ............................................................................................... 7

Cylinder is supplied without the oil charge.............................................................................. 7

6.1 KONTROLA PŘED INSTALACÍ..................................................................................... 7

6.1.1 Support face..................................................................................................................... 7

6.2 CONNECTION OF CYLINDER WITH PUMP ............................................................... 7

6.3 POSITION OF CYLINDER DURING LIFTING OR LOWERING ................................ 8

6.4 LIFTING A LOAD ............................................................................................................ 8

6.5 LOWERING A LOAD....................................................................................................... 8

6.6 TEST BEFORE THE USE................................................................................................. 8

7

OPERATION .......................................................................................................................... 9

7.1 USE OF THE CYLINDER ................................................................................................ 9

7.2 SAFETY WORKING ENVIRONMENT .......................................................................... 9

8

INSPECTION

OF

CYLINDER............................................................................................... 9

8.1 INSPECTION..................................................................................................................... 9

8.1.1 Inspection classifications................................................................................................. 9

8.1.2 Daily inspection............................................................................................................. 10

8.1.3 Regular inspection......................................................................................................... 10

8.1.4 Occasionally used hydraulic cylinder ........................................................................... 10

8.1.5 Inspection record........................................................................................................... 10

8.2 INSPECTION PROCEDURE.......................................................................................... 10

9

TROUBLSHOOTING........................................................................................................... 11

10

MAINTENANCE................................................................................................................ 11

10.1 SAFETY PRINCIPLES ................................................................................................. 11

10.2 GENERAL INSTRUCTION.......................................................................................... 12

10.3 EXCHANGE OF PISTON CUP (DISMANTLING OF PISTON) - fig. 10.3............... 12

10.4 CHECK .......................................................................................................................... 12

10.5 REPAIR.......................................................................................................................... 13

10.6 TEST .............................................................................................................................. 13

11

REMOVING

FROM

OPERATION

–

LIQUIDATION ...................................................... 13

12

RELATED

DOCUMENTATION....................................................................................... 13

13

FINAL

REQUIREMENTS

OF

THE

MANUFACTURER

TO

A

CUSTOMER................. 13

3

1 DEFINITION

! DANGER

Danger: indicates the presence of a hazard, which will cause

death or severe injury if the warning is ignored.

! WARNING

Warning: indicates the presence of a hazard, which can cause

death or severe injury if the warning is ignored.

! CAUTION

Caution: indicates the presence of a hazard, which can cause

minor injury if the warning is ignored. Caution can also indicate

dangerous practices.

Lifting capacity (Q): indicates maximum mass of load (working load limit) the cylinder

is designed to support in general service under conditions given by this manual.

2 INTENDED PURPOSE

2.1 Hydraulic cylinder type Z321, lifting capacity 25t; 50t; 100t and 200t (further only

cylinder) is designed solely for lifting and lowering free loads of big weight in vertical

direction by the help of manual pump at normal atmospheric condition on a workplace.

Weight of load during lifting must not exceed nominal lifting capacity.

2.2 Design of the cylinder meets requirements given by Directive of European

Parliament and Council 2006/42/EC as amended by the Czech technical regulation –

Government regulation no. 176/2008 Collection of law as amended and requirements

of harmonized Czech technical standards ČSN EN ISO 12100 and ČSN EN 1494+A1.

2.3

Výrobek svým provedením vyhovuje požadavkům stanoveným Směrnicí

Evropského parlamentu a Rady 2014/34/EU ve znění českého technického předpisu –

nařízení vlády č. 116/2016 Sb. v platném znění. Výrobek je proveden jako zařízení

IM2c dle ČSN EN 13463-1:2009 a ČSN EN 13463-5:2012. Splňuje podmínky pro

použití v důlním prostředí „nebezpečné atmosférické podmínky 2“

dle ČSN EN 1127-2.

2.4Výrobek svým provedením vyhovuje požadavkům stanoveným Směrnicí

Evropského parlamentu a Rady 2014/34/EU ve znění českého technického předpisu –

nařízení vlády č. 116/2016 Sb. v platném znění. Výrobek je proveden jako zařízení

II2GDcT85°C dle ČSN EN 13463-1:2009 a ČSN EN 13463-5:2012. Splňuje

podmínky pro použití v prostředí „zóna 1 a zóna 21“, “zóna 2 a zóna 22“

dle ČSN EN 1127-1.

Note: Articles 2.3 and 2.4 are valid for type of construction of hydraulic cylinder for

explosive environment.

4

3 SAFETY PRINCIPLES

3.1

SAFETY

SUMMARY

Danger exists particularly when the cylinder is not used properly or is poorly

maintained. Since an accident or serious injury could result, special safety precautions

apply to the operation with the hydraulic cylinder during its use, maintenance and

inspection.

! WARNING

NEVER work under lifted load or close to it.

NEVER lift more than lifting capacity shown on cylinder.

ALWAYS make sure the ground is firm enough to support safely fully loaded cylinder

and all lifting operation.

ALWAYS keep sufficient spacing from the load.

ALWAYS let people around to know when lift is about to begin.

ALWAYS read the operation manual and safety instructions.

Remember proper rigging and lifting techniques are the responsibility of the operator.

Ch

eck all applicable national directions, regulations and standards for further

information about the safe use of your hydraulic cylinder.

3.2.

SAFETY

PRINCIPLES

! WARNING

3.2.1 Before use

ALWAYS ensure physically strong, qualified and instructed persons elder 18 years of

age, knowing this manual and trained in safety conditions and way of work

operate the cylinder.

ALWAYS check the cylinder every day, prior starting the work according to the article

8.2.(1) „Daily inspection“.

ALWAYS make sure the lift is sufficient for intended operation.

ALWAYS ensure load against unwanted motion.

ALWAYS make sure the cylinder stands on firm ground.

ALWAYS make sure the cylinder stands vertically.

ALWAYS use recommended pumps and connection houses only.

NEVER use damaged or worn cylinder.

NEVER use cylinder without visible marking of the lifting capacity on it.

NEVER use a cylinder marked by the label „OUT OF SERVICE“.

ALWAYS consult use of the cylinder in non-standard or extreme conditions with

manufacturer or the authorised representative.

5

3.2.2 While operation

ALWAYS make sure the load is properly placed on a cylinder.

ALWAYS pay attention not to exceed maximum height of lift marked by the red

groove on a piston.

ALWAYS after lifting a load ensure the piston of the cylinder by the nut.

ALWAYS underlay load, if you intend to work on it.

ALWAYS pay a special attention to a cylinder, if piston is released to maximum

position

(marked by the red groove on a piston).

NEVER use cylinder for permanent underlying of loads.

NEVER allow the load, causes impacts or vibrations.

3.2.3 After use

NEVER leave lifted load without attendance and without ensuring the piston against

self downturn by the nut.

3.2.4 Risk analysis

The analysis of possible risk in turn of design, operation and environment of the

hydraulic cylinder application is mentioned in freestanding document “Risk analysis”.

This document can be required in service centres.

3.2.5 Maintenance

ALWAYS let qualified personnel inspect the cylinder regularly.

Only such interventions can be done when maintaining that are in compliance with

requirements of the manufacturer specified in the chapter 13 of this manual.

It is not allowed to provide repairs and maintenance in a different way then specified

by the manufacturer. It is especially prohibition of use of no original parts or providing

changes of product without the agreement of manufacturer.

4 PACKING, STORAGE AND MANIPULATION

4.1

PACKING

4.1.1 Cylinders are supplied assembled with hydraulic liquid, free loaded in transport

cases.

4.1.2 The following accompanying documentation is a part of the delivery:

a) Operation manual

b) EC Declaration of conformity

c) Certificates of Quality and Completeness and Guarantee Card

c1) Guarantee period is stated in the Guarantee Card.

c2) The guarantee does not apply to defects caused by infringement of the

instructions stated in this Operation Manual and defects occurred owing to

improper use and unskilled intervention.

c3) The guarantee does not apply also to any modifications on the product

without a written approval of the manufacturer.

c4) Claim of product defects is carried out according to applicable provisions

of commercial code eventually as amended.

Table of contents

Other Brano Industrial Equipment manuals