8640-0450 - 1

CONTENTS

english

Contents:

GENERAL NOTES.................................................................................................................................................................................................................................... 3

Symbols ......................................................................................................................................................................................................................................................

4

Safety notes.............................................................................................................................................................................................................................................

4

Scope of delivery ...........................................................................................................................................................................................................................

5

Warranty conditions ..................................................................................................................................................................................................................

5

TECHNICAL DATA ................................................................................................................................................................................................................................... 7

Valve construction........................................................................................................................................................................................................................ 8

Method of functioning of valves Type 0450 .............................................................................................................................................

8

Media ...............................................................................................................................................................................................................................................................

8

Electrical connection ...............................................................................................................................................................................................................

9

ASSEMBLY AND COMMISSIONING ...................................................................................................................................................................... 11

Measures to be taken before commissioning.................................................................................................................................. 12

Assembly and commissioning .............................................................................................................................................................................. 12

Construction of block assemblies with aluminium baseplate MP 05 .............................................................. 13

Assembly of valve Type 04540 on the aluminium baseplate ...................................................................................... 14

Disassembly of valve Type 04540 from the aluminium baseplate ........................................................................ 14

Fixing the valve block to a standard rail.................................................................................................................................................. 14

Fixing the valve block to the wall ......................................................................................................................................................................... 14

MAINTENANCE AND TROUBLE SHOOTING............................................................................................................................................ 15

Maintenance...................................................................................................................................................................................................................................... 16

Trouble shooting ........................................................................................................................................................................................................................ 16

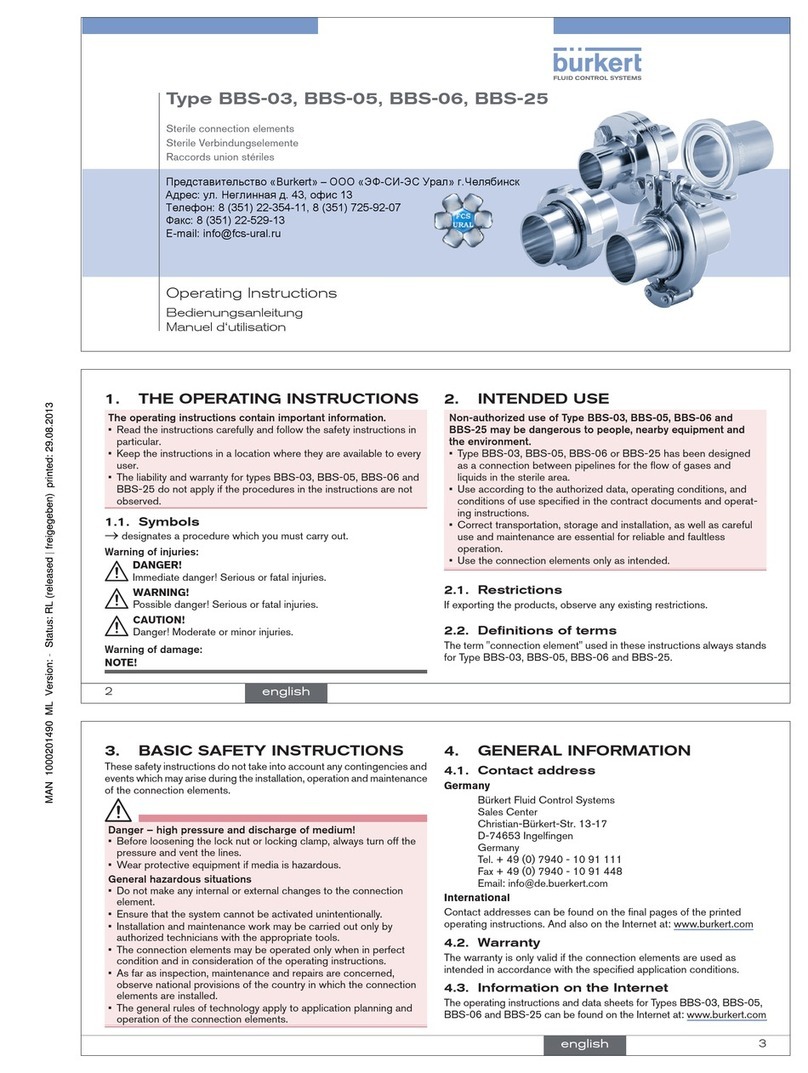

Block assembly Type 0450

Aluminium baseplate Type MP05