Operating Manual BKS015

26.11.2018 2

Table of Contents

1 Safety Instructions ..................................................................................... 4

1.1 Description Conditions 4

1.2 List of Safety Instructions 4

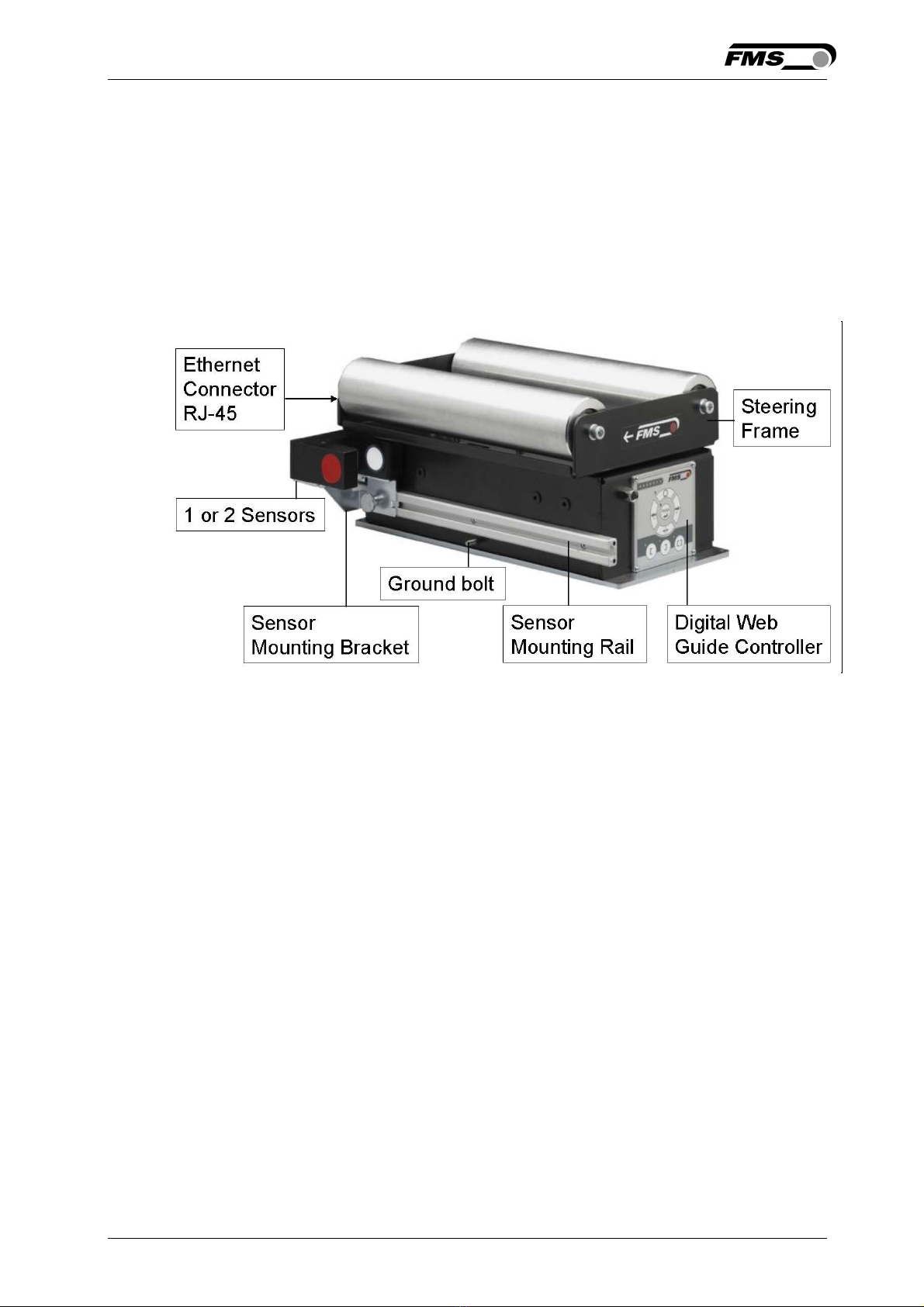

2 System Description .................................................................................... 5

2.1 Functional Description 5

2.2 Steering Frame 5

2.3 Web Guide Controller 5

2.4 Sensors 5

2.5 Cables 6

2.6 System Integration in an Ethernet Network 6

3 Quick Installation Guide ............................................................................. 6

3.1 Preparations for Set-up 6

3.2 Installation Procedure 7

4 Installation and Wiring ............................................................................... 8

4.1 Mounting the Steering Frame 8

4.2 Mounting the Sensors 8

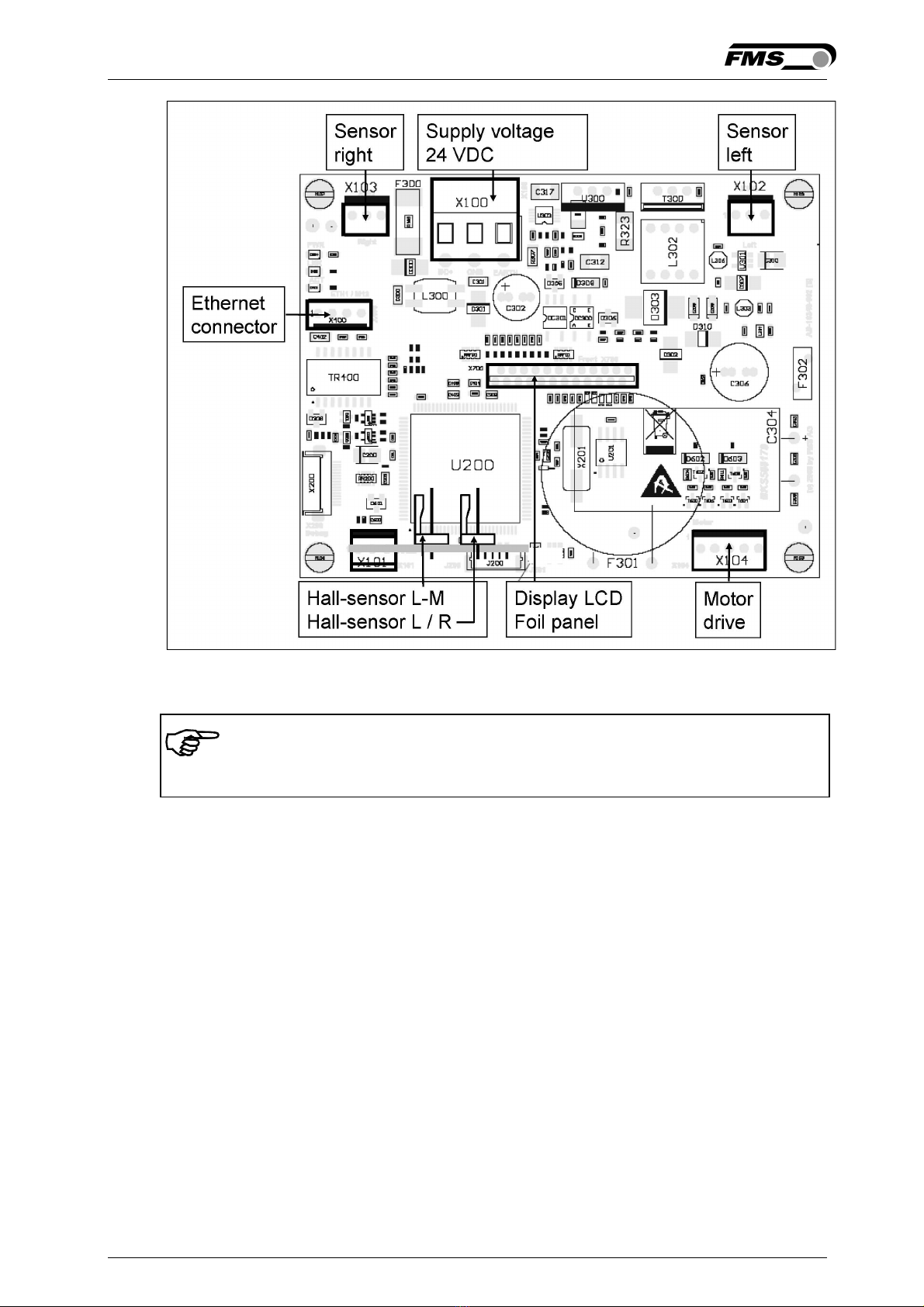

4.3 Connecting the BKS015.EIP 9

4.4 Connector and Screw Terminal Arrangement 9

5 Configuring the System ............................................................................ 11

5.1 Powering up the BKS015.EIP 11

5.2 Adjustment of the Sensors 11

6 Network Connection over EtherNet/IP ................................................... 12

6.1 EtherNet/IP Specification: 12

6.2 Controller Functionality over EtherNet/IP 12

6.3 Integration of BKS015.EIP in an Ethernet Network 12

6.4 Configuration of the Web Guide Controller over EtherNet/IP 12

7 Integration in an Allen-Bradley PLC ........................................................ 14

7.1 Hardware Environment 14

7.2 IP Configuration 14

7.3 Integration in a Project 14

7.4 Access to the Status Information 17

8 Operation .................................................................................................. 19

8.1 Operation Panel 19

8.2 Basic Instructions for Operation and Parameter Setting 19

8.3 Operating the Web Guiding System via the Front Panel 19

8.4 Operation in Automatic Mode 21

8.5 Operation in Manual Mode 22

8.6 Entering the Parameter Setting Mode 22

8.7 Description of the LED-row 23

8.8 Sensor Detection Range and Reference Position 24

9 Description Parameters ........................................................................... 25

9.1 Description Operation Parameters 25

9.2 Description of System Parameters 28

9.3 Reset to Default Parameter Set 30