formlabs Form Wash Setup guide

Manual Form Wash

Installation and Usage Instructions

Form Wash

Desktop Stereolithography Print Cleaner

Original English instructions and translations

Please read this manual carefully and keep it for future reference.

November 2019

REV 01

© Formlabs

Table of Contents

1. Preface ..................................................................8

1.1 Read and Retain Instructions................................................8

1.2 Obtaining Documentation and Information ...................................8

2. Introduction .............................................................10

2.1 Intended Use ............................................................10

2.2 Product Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3 Technical Data ...........................................................12

2.4 Form Wash Controls ......................................................12

3. Safety Warnings .........................................................13

3.1 Component and Subsystem Safety .........................................13

3.2 Personal Protective Equipment (PPE) .......................................15

3.3 Specifications of Tools to be Used .........................................15

4. Preparation and Set Up...................................................16

4.1 Arranging the Workspace .................................................16

4.2 Unboxing the Form Wash .................................................16

4.3 Installing the Form Wash ..................................................16

4.4 Transporting the Form Wash ...............................................18

5. Using the Form Wash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Operational Environment.................................................20

5.2 Washing ................................................................20

5.3 Considerations for Specific Geometries.................................... 22

5.4 Device Management..................................................... 23

5.5 Emergency and Exceptional Situations..................................... 25

6. Maintenance ...........................................................26

6.1 Inspecting the Product ................................................... 26

6.2 Inspection Tasks Between Wash Cycles ................................... 26

6.3 Monthly Inspection and Maintenance Tasks .................................27

6.4 Periodic Inspection and Maintenance Tasks .................................27

6.5 Planned Maintenance Procedures..........................................27

7. Troubleshooting and Repair.............................................. 30

7.1 Restarting with a Power Cycle ............................................ 30

7.2 Troubleshooting......................................................... 30

7.3 Disassembly and Repair.................................................. 30

8. Disposal................................................................ 32

8.1 Guidance for Recycling and Disposal ...................................... 32

9. Index................................................................... 33

10. Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7

Read and understand this manual and its safety instructions before using the Form

Wash. Failure to do so can result in serious injury or death.

DISCLAIMER

Formlabs has made every eort to ensure these instructions are as clear, complete, and correct

as possible. The information provided in this documentation contains general descriptions

and/or technical characteristics of the performance of the products contained herein. This

documentation is not intended as a substitute for, and is not to be used for, determining

suitability or reliability of these products for specific user applications. It is the duty of any

such user or integrator to perform the appropriate and complete risk analysis, evaluation, and

testing of the products with respect to the relevant specific application or use thereof. Neither

Formlabs nor any of its aliates or subsidiaries shall be responsible or liable for misuse of

the information that is contained herein. If you have any suggestions for improvements or

amendments or have found errors in this publication, please notify us.

Copyright © 2019 by Formlabs. All rights reserved.

support.formlabs.com

TRADEMARKS

All product names, logos, and brands are property of their respective owners. All company,

product, and service names used in this manual are for identification purposes only. Use of

these names, logos, or brands does not imply endorsement.

DOCUMENT REVISIONS

Date Version Document Changes

Oct 2015 REV 00 Initial publication of Quick Start Guide and Safety pamphlet

Nov 2019 REV 01 Initial publication

WARNING

8

1. Preface

Congratulations on purchasing the Form Wash. On behalf of the employees who create and

support Formlabs technology, we thank you for your purchase.

The instructions in this manual provide information for skilled persons to understand safety, setup

and installation, operation, and maintenance of the Form Wash. These instructions are intended

for anyone who is installing, operating, maintaining, or otherwise interacting with the Form Wash.

Supervise young or inexperienced users to ensure an enjoyable and safe operation.

1.1 Read and Retain Instructions

Read and understand this manual and its safety instructions before using the Form Wash.

Failure to do so can result in serious injury or death. Keep all safety information and instructions

for future reference and provide them to subsequent users of the product.

Follow all the instructions. This will avoid fire, explosions, electric shocks, or other hazards that

may result in damage to property and/or severe or fatal injuries.

The Form Wash shall only be used by persons who have fully read and understood the

contents of this usage manual. Ensure that each person who uses the Form Wash has read

these warnings and instructions and follows them. Formlabs is not liable for cases of material

damage or personal injury caused by incorrect handling or non-compliance with the safety

instructions. In such cases, the warranty will be voided.

1.2 Obtaining Documentation and Information

Visit support.formlabs.com to:

• Access the latest version of all Formlabs product documentation.

•

Contact Formlabs to request documentation, usage instructions, and technical information.

• Submit any comments or feedback regarding what is good and what can be improved.

• Request additional training.

1.2.1 Support and service

Retain a record of the original purchase to request warranty services. Service options depend

on the status of the specific product’s warranty. Include the serial name of the product when

contacting Formlabs for product support.

Instead of a serial number, all Formlabs machines have a serial name, which is a unique identifier to

track the history of manufacturing, sales, and repair, as well as to distinguish usage when connected

to a network. The serial name is on the back panel of the machine in this format: “AdjectiveAnimal.”

Service providers of Formlabs products also provide support and service. To the extent that

Formlabs or a certified service provider oers other or extended warranties, the terms of the

separate oer may apply. For products purchased from certified service providers, contact

the original service provider for assistance before contacting Formlabs.

For any support or service requests, including product information, technical assistance, or

assistance with instructions, contact Formlabs Services or a certified service provider:

support.formlabs.com USA

Formlabs, Inc.

35 Medford St.

Somerville, MA, USA, 02143

Germany

Formlabs GmbH

Nalepastrasse 18-50

12459 Berlin, Germany

Preface | 9

1.2.2 Returns

Formlabs accepts returns for unopened, unused, and undamaged products within 30 days

of the shipment date. Returns must be authorized by Formlabs. Visit Formlabs.com for more

detailed information about returning your purchase.

1.2.3 Warranty

This product is protected under warranty. Formlabs oers a warranty for all Formlabs-branded

hardware. Unless otherwise expressly stated, the Terms of Service, including the Warranty,

constitute the entire agreement between you and Formlabs with respect to the Service and

any product you purchase from Formlabs and supersedes all prior or contemporaneous

communications, proposals and agreements, whether electronic, oral or written, between you

and Formlabs. Read the warranty for more details on the Formlabs warranty for your region:

US formlabs.com/support/terms-of-service/#Warranty

EU (EN) formlabs.com/support/terms-of-service/eu/

EU (DE) formlabs.com/de/support/terms-of-service/eu/

EU (FR) formlabs.com/fr/support/terms-of-service/eu/

10

2. Introduction

2.1 Intended Use

The Form Wash automatically cleans uncured liquid resin from 3D printed parts’ surfaces. The

final performance characteristics of cured photopolymer resin may vary according to your

compliance with the instructions for use, application, operating conditions, material combined

with, end use, or other factors.

In some cases, the additive manufacturing process may inherently result in variable

performance characteristics between manufacturing runs or within a specific part.

Such variances may not be apparent and may result in unexpected defects in

additively fabricated parts.

You must independently verify the suitability of additive manufacturing, stereolitho-

graphy, Form Wash, and any specific designs or materials employed for the

application and intended purpose before use. In no event shall Formlabs be liable for

any loss, death, or bodily injury that you suer, or that you cause to any third party, in

connection with your use of Formlabs products. To the fullest extent legally permitted

Formlabs EXPRESSLY DISCLAIMS ANY IMPLIED OR EXPLICIT WARRANTY OF

FITNESS for a particular usage, the particular nature and circumstances of said usage

being unforeseen and unforeseeable to Formlabs.

Formlabs is not a manufacturer of medical devices. Formlabs provides tools and

materials that may be used in many applications, but makes no claims as to the safety

or eectiveness of any specific devices made using Formlabs products. Certain

Formlabs products, such as those commonly known in the industry as “biocompatible”

resins, have been engineered to comply with relevant industry standards. The specific

standards and most relevant technical specifications may be identified within the

technical data sheets and have been tested according to relevant testing protocols

for those standards and specifications. Biocompatible resins are a speciality product,

developed for use by medical professionals, and should be used in accordance with

their instructions for use.

Do not modify. The Form Wash is intended for use as-is. Modifying the unit without

explicit approval and directions from Formlabs will invalidate your warranty, and could

potentially ruin the machine and cause you bodily harm.

Never remove the bottom panel of the unit.

NOTICE

WARNING

WARNING

WARNING

Introduction | 11

2.2 Product Elements

Platform Mount Holds the

build platform when washing

parts on the platform.

Basket Removable container

holds parts to wash without the

build platform.

Basket Mount A single hook

secures the basket to raise

and lower.

Outer Lid Limits solvent

evaporation. Keep the lid closed

when not in use.

Inner Lid A hinged, secondary

lid opens and closes to contain

solvent while allowing parts to be

lowered or raised from the bucket.

Wash Bucket Removable container holds a maximum of 8.6 L of solvent. A rotating impeller

at the bottom circulates the solvent.

Display Shows status, time, and options for configuring the Form Wash.

Knob Turn or press to adjust time and to start, pause, or end a wash cycle.

Tool Storage Each side has designated locations for storing each tool.

Power Supply Provides power to the Form Wash. Specifications: 24 V, 2 A.

Solvent Not included. Dissolves liquid resin from printed parts’ surfaces.

The Form Wash includes storage space for commonly used tools during the print cleaning process.

Flush CuttersUse to carefully remove support tips from printed parts.

Removal ToolApply pressure under the base generated by PreForm to release the base

of your parts from the build platform.

Hydrometer If using isopropyl alcohol (IPA) as a solvent (or another solvent with an

equivalent specific gravity), float in IPA to measure the IPA’s resin concentration (based on

previous calibration in fresh IPA). Other solvents may require a dierent hydrometer for a

dierent specific gravity range.

ScraperCan be used to remove parts from the build platform, as well as to carefully clean

and inspect the resin tank for cured material.

TweezersUse to handle small parts or to manipulate supports after printing.

Siphon PumpTransfer solvent between the wash bucket and a solvent storage container.

See 10 Glossary for full product terminology.

1

2

3

4

5

6

7

8

9

10

1 1

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

10

11

A

B C E

F

D

12

2.3 Technical Data

Shipping Weight 9.0 kg (20 lb)

Product Weight 6.7 kg (14.5 lb)

Shipping Dimensions 33.0 × 35.4 × 45.6 cm (14 × 14 × 18 in)

Product Dimensions 26.2 × 29.3 × 34.0 cm (10.3 × 11.5 × 13.4 in)

Height when open: 64 cm (25.2 in)

Minimum Space Requirement 38.9 × 41.9 × 64.0 cm (15.3 × 16.5 × 25.4 in)

Power Requirements 100–240 V

2.0 A 50/60 Hz

50 W

Electrical Safety Standard 60950-1:2005+A1:2009+A2:2013 (and applicable

national deviations)

Sound Emission Does not exceed 70 dB(A).

Bucket Volume 8.6 L

Maximum Part Size 14.5 × 14.5 × 17.5 cm(5.7 × 5.7 × 6.9 in)

Operating Temperature Suggested 18—28 °C(64—82 °F)

Agitation Method Magnetically coupled impeller

2.4 Form Wash Controls

When connected to power, use the knob to program and operate the Form Wash:

• Rotate the knob counterclockwise or clockwise to move between items in the menu.

• Press the knob to select an option on the display.

The following options are available from the main menu on the Form Wash display:

• Start: Lowers the mount and basket and initiates the washing process.

• Open: Raises the mount and basket.

• Sleep: Lowers the mount and basket. The wash cycle does not start until Start is selected.

•

Time: Press the knob to select and adjust the time, indicated in minutes.Check each

material’s recommended wash time before beginning a cycle.

After beginning a wash cycle, the display shows the remaining time and additional menu options:

•

Pause: Stop the agitation and lift the platform and basket mount, while maintaining the

remaining time in the wash cycle.

• End: Cancel the remaining time in the wash cycle while also stopping the agitation and

lifting the platform and basket mount.

Safety Warnings | 13

3. Safety Warnings

Read and understand this manual and its safety instructions before using the Form 3.

Failure to do so can result in serious injury or death.

Supervise young or inexperienced users to ensure enjoyable and safe operation.

The instructions contain warnings and safety information, as explained below:

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death

or serious injury.

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in

death or serious injury.

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor

or moderate injury.

Notice indicates information considered important, but not hazard-related.

DANGER: Isopropyl alcohol is a flammable chemical.

3.1 Component and Subsystem Safety

3.1.1 Electronic Components

The Form Wash is a professional appliance that includes electronic components. As with any

such appliance:

• Do not operate the Form Wash with a damaged cord or plug.

• Always disconnect power before cleaning.

• Only use well-maintained equipment.

• Operate on a clear and level surface.

3.1.2 Sharp Tools

The accessories include sharp tools such as: a part removal tool, flush cutters, a scraper,

and tweezers.

Cutting hazard. Using these tools on slippery surfaces (such as a resin-coated build

platform) can result in sudden movement. Orient sharp tools away from yourself,

especially when cutting or scraping.

WARNING

DANGER

WARNING

CAUTION

NOTICE

WARNING

CAUTION

14

3.1.3 Resin

Respect Formlabs resin like any household chemical. Follow standard chemical safety

procedures andFormlabs resin handling instructions.

Wear gloves whenever handling liquid resin or solvents. If swallowed, immediately call

a poison center or medical professional.

In general, Formlabs resin is not approved for use with food, drink, or medical applications on

the human body. However, biocompatible resins, such as Dental SG, are biologically safe for

specific types and lengths of exposure to the human body. Refer to information about each

specific resin for more detail.

Never ingest resin in liquid or solid form.

Always consult theSDS (Safety Data Sheet)as the primary source of information to

understand safety and handling of Formlabs materials. Combinations of resin and

solvent should be handled according to the restrictions of both. For questions, consult

the appropriate SDS(s).

3.1.4 Radio Interference

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to CFR Title 47, Part 15 of FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at their own expense.

Changes or modifications to this product not authorized by Formlabs could void the

electromagnetic compatibility (EMC) and negate your authority to operate the product.

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

3.1.5 Solvents

Formlabs does not manufacture solvents. Always consult the safety data sheet

(SDS) from your solvent supplier as the primary source of information for storage

and handling.

Comply with local or organizational regulations, which may have specific requirements for:

storage, ventilation, personal protective equipment, and disposal of solvents.

WARNING

WARNING

NOTICE

CAUTION

NOTICE

Safety Warnings | 15

Some solvents, such as isopropyl alcohol (IPA) are flammable and should be stored away from

sources of ignition. Handle solvents with gloves in a well-ventilated area. Keep storage container

lid(s) closed whenever possible. More information is available atsupport.formlabs.com.Always

refer to the supplier’s SDS.

Use the included siphon pump to avoid overfilling or spilling solvent. Operate the Form Wash

on a clear and level surface. Always remove the wash bucket or empty alcohol from the wash

bucket before storing or transporting the Form Wash.

3.2 Personal Protective Equipment (PPE)

Resin and solvents may cause skin irritation or an allergic skin reaction. Wear gloves

when handling liquid resin, liquid solvent, or resin-coated surfaces. Wash skin with

plenty of soap and water.

Some methods of support removal may cause small pieces of supports to break away.

Beware of flying debris. Wear eye protection and gloves to protect the skin and eyes.

3.3 Specifications of Tools to be Used

The Form Wash shall only be used with supplied accessories and additional tools recommended

by Formlabs. Third-party accessories and materials may cause damage.

Purchase additional supplies:

• Paper towels. Keep paper towels in stock to ensure a clean work environment for printing

and finishing.

• Solvent. Multiple solvents are suitable for washing SLA printed parts. Choose the solvent

that best meets your needs and fits your workflow. For more information about solvents

and a complete list of compatible solvents, visit support.formlabs.com.

•

Personal Protective Equipment. Powder-free, chemical-resistant, disposable gloves (nitrile

or neoprene)

WARNING

CAUTION

16

4. Preparation and Set Up

Consider the weight and dimension of the product for installation.

For the fastest unboxing and setup experience, purchase 10 liters of your selected solvent in

advance andreview the Form Wash system overviewbefore starting.

4.1 Arranging the Workspace

For best results:

1. Choose a stable, level workspace to install and operate the Form Wash.

2. Reserve the following minimum dimensions for the most convenient access:

° Width: 38.9 cm (15.3 in)

° Depth: 41.9 cm (16.5 in)

° Height: 64 cm (25.2 in)

3. Allow additional space for accessories, such as the Formlabs SLA printer, Finish Kit, and

Form Cure.

4. Ensure either the wall outlet or power supply for the Form Wash is easily accessible. To

disconnect the equipment from mains electricity and power o the unit, unplug the power

cable from the wall outlet, or the power supply.

4.2 Unboxing the Form Wash

The Form Wash ships in a cardboard carton, protected by foam inserts above and below the

machine. The upper foam insert also contains the accessories. During unboxing, inspect the

Form Wash for any damage or missing items. In the case of damage or missing items, contact

Formlabs or the certified service provider.

To unbox the Form Wash:

1. Open the box from the top.

2. Lift and remove the foam insert containing the accessories.

3. Use the provided handles on each side of the unit to lift the Form Wash out of the box.

4. Remove internal packaging.

5. Raise the mount to access and remove any twist ties that secure the bottom of the basket

to the basket mount.

6. Remove the siphon pump from the wash bucket.

Remove all packaging material before connecting power. Retain all packaging and

inserts for warranty service.

4.3 Installing the Form Wash

To prepare to use the Form Wash, follow the steps below to fill the wash bucket with solvent.

If you are using isopropyl alcohol, calibrate the included hydrometer. The hydrometer can

only be calibrated in fresh IPA (or another solvent with an equivalent specific gravity) with a

concentration of 90% or higher.

NOTICE

NOTICE

Preparation and Set Up | 17

4.3.1 Assemble Siphon Pump

To assemble the siphon pump, screw the handle into the rigid tube of the siphon pump.

Use the siphon pump to avoid overfilling or spilling solvent. The siphon pump is designed

to transfer liquid without splashing. This includes transferring both used solvent into empty

containers as well as fresh solvent into the wash bucket.

4.3.2 Fill Wash Bucket with Solvent

To fill the Form Wash:

1. Open the outer lid.

2. Pour or siphon solvent into the wash bucket to fill to a level between the minimum (7.8L)

and maximum (8.6 L) fill lines. For more information about using the siphon pump, visit

support.formlabs.com.

4.3.3 Connect Power Supply

Connect the power cable and external supply to the Form Wash and a power source.

The Form Wash includes a USB port to allow forfirmware updates.

A B

NOTICE

A

B

18

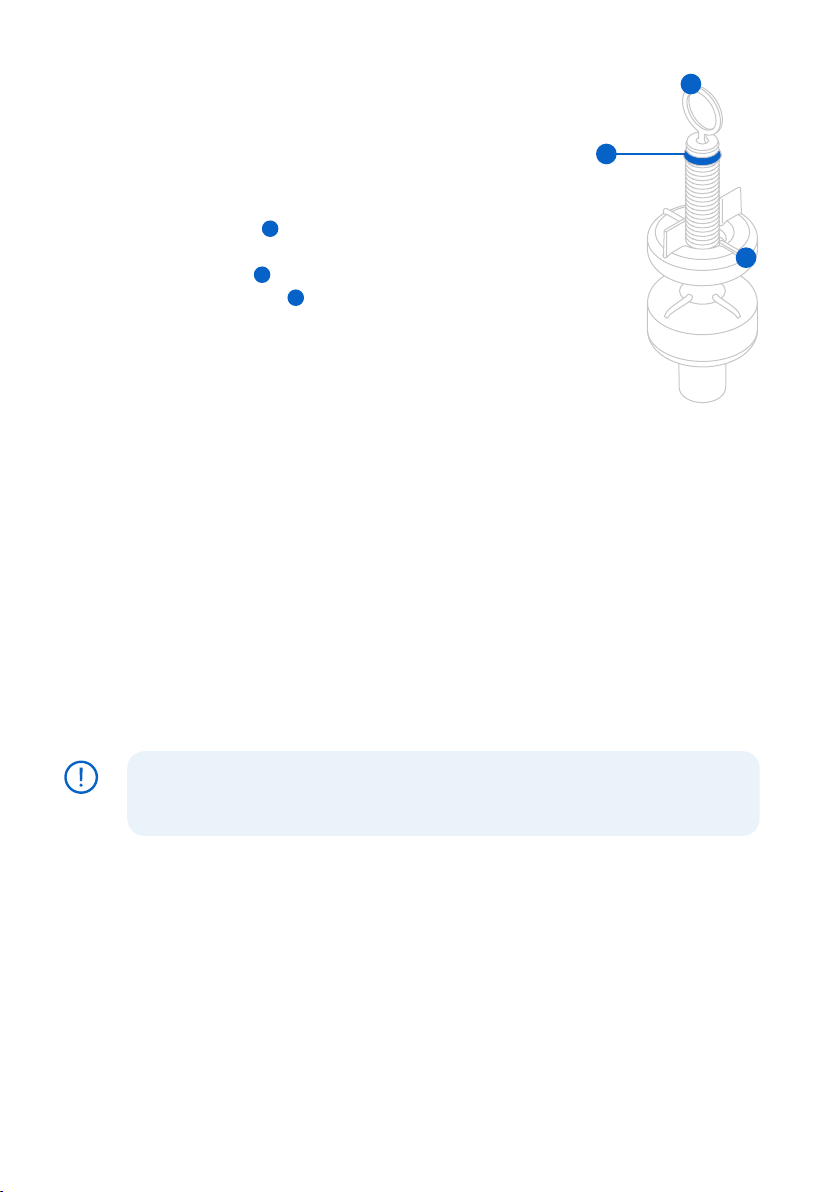

4.3.4 Calibrate the Hydrometer (IPA Only)

If you have filled your Form Wash with IPA (or another solvent with

an equivalent specific gravity), calibrate the included hydrometer.

Once calibrated, the hydrometer can be used to determine when

the solvent should be changed.

To calibrate the hydrometer:

1. Hold the handle and release the tool in the wash bucket’s

fresh IPA.

2.

Slide the O-ring along the ribbed stem until the O-ring aligns

with the short wings at the top of the float.

3. Leave the O-ring in this position. The alignment of the wings

and O-ring is used to check the resin concentration of IPA

between washes.

4. Store the hydrometer in the tool storage area at the back

of the unit.

The Form Wash is ready for use once the wash bucket has

been filled between the minimum and maximum fill lines and the

hydrometer is calibrated. Choose whether to wash the part on

the build platform or in the basket.

4.4 Transporting the Form Wash

Refer to 2.2 Technical Specifications for product weight and dimensions. Keep the packaging

for transportation or shipping.

The Form Wash complete packaging kit consists of:

• 1 outer cardboard carton

• 1 foam bottom insert

• 1 foam upper insert, which holds the small accessory boxes

• 1 protective plastic bag

• Plastic wrap

Original packaging may be required for warranty service. Do not ship with solvent

inside the bucket. Solvent left inside the Form Wash can damage the unit in transit,

which may lead to additional fees or void the warranty.

To prepare to transport the Form Wash:

1. Remove solvent.

2. Wipe residual solvent from the wash bucket and inner lid.

3. Remove tools from tool storage.

4. Insert the wash bucket.

5. Insert the wash basket.

6. Lower the basket mount.

7. Close the outer lid.

8. Wrap the unit with plastic wrap to secure the tool storage and lids.

A

B

C

NOTICE

A

C

B

Preparation and Set Up | 19

9. Reassemble the box.

10. Place the bottom foam insert in the box.

11. Place the Form Wash on top of the bottom foam insert.

12. Place the upper foam insert on top of the Form Wash.

13. Seal the box with tape.

When shipping a machine to Formlabs for service, do not ship the accessory tools

or the power supply. Accessories will not be returned after service. The product’s

original packaging is required for warranty service. Contact other authorized resellers

for unique guidance on shipping requirements.

NOTICE

20

5. Using the Form Wash

5.1 Operational Environment

Operate the Form Wash in a well-ventilated room with a temperature of 18–28 °C (64–82 °F).

For optimal performance, do not exceed this range.

5.2 Washing

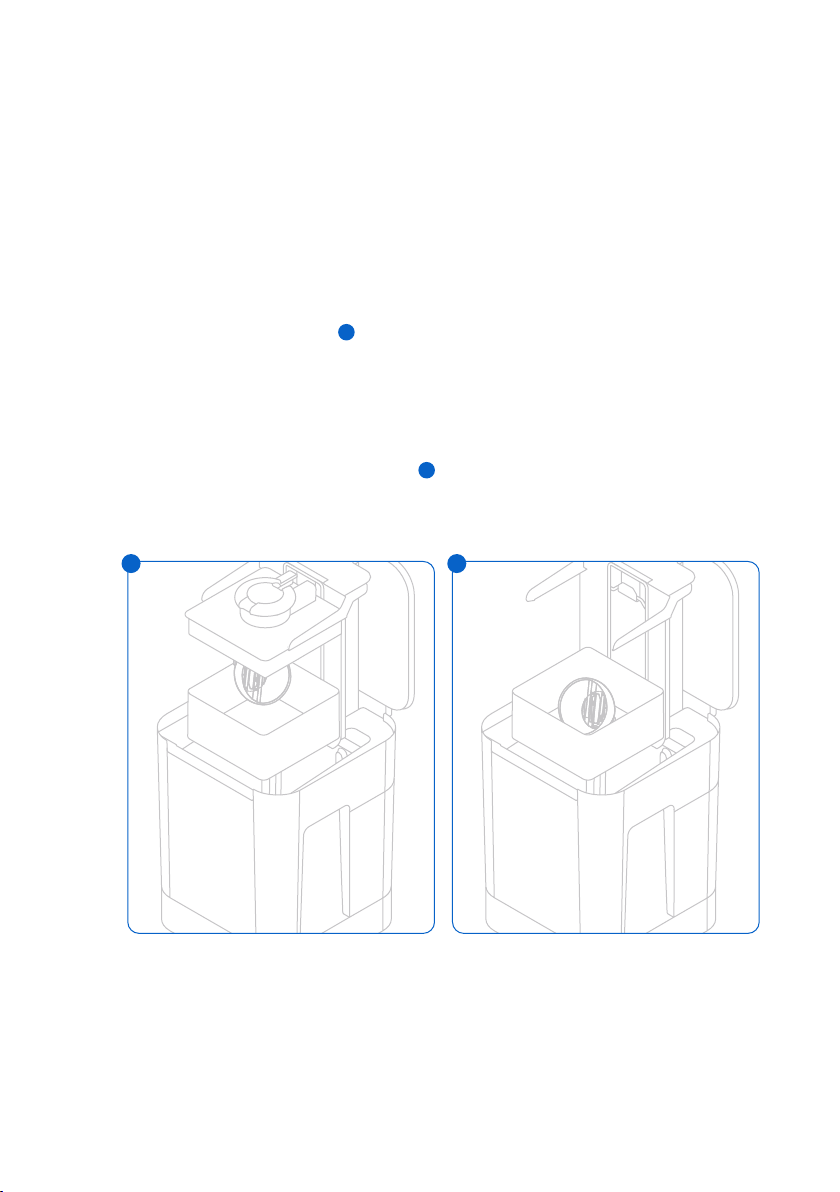

5.2.1 Insert Print

To wash a printed part:

1. Use the display and knob to raise the platform and basket mounts.

2. For convenience, install the build platform with printed parts directly in the Form Wash to

clean parts before removal . Align the top lip of the build platform with the arms of the

Form Wash platform mount, and fully insert to touch the back.

Parts must be washed on the build platform or in the basket. Ensure parts are fully secured

to the build platform when washing parts without the basket installed. Washing loose parts

directly in the wash bucket—whether intentionally or accidentally—may damage printed parts,

create noise, and interfere with solvent agitation.

Parts can also be washed in the basket , either as an alternative or in addition to the

platform mount. Place parts directly in the basket after removing them from the build

platform using the removal tool, scraper, or flush cutters. The basket comes installed in

the Form Wash.

To remove the basket from the Form Wash:

1. Remove the build platform from the platform mount.

2. Lift the basket vertically out of the basket mount.

1

2

1 2

Using the Form Wash | 21

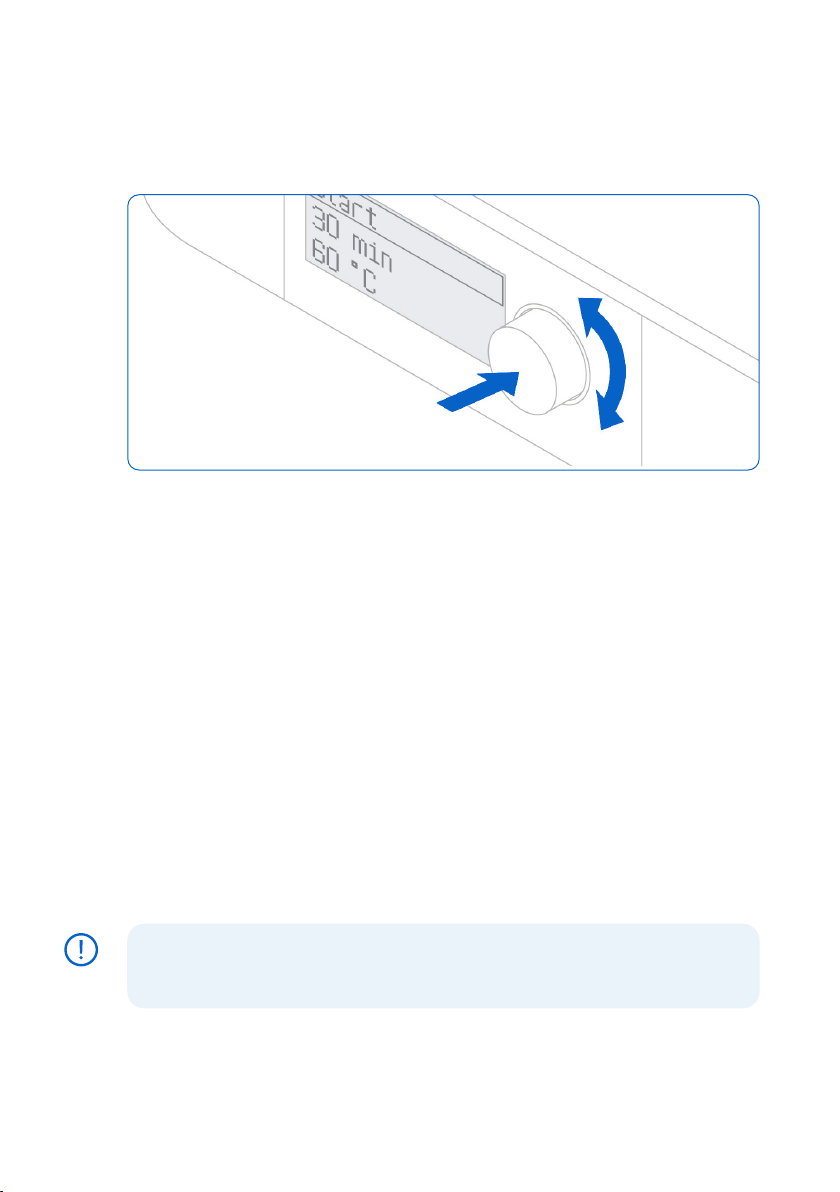

5.2.2 Set Wash Time

To wash parts for a specific amount of time:

1. Turn the knob to navigate the display menu and adjust the wash time.

2. Press the knob to select or confirm.

3. Once the wash cycle begins, select Pause to raise the platform and basket.

Part washing time depends on the resin and solvent used. Check support.formlabs.com for

specific wash time recommendations. Wash for additional time when using partially resin-

concentrated solvent. The wash cycle begins when the platform and basket lower. Ensure

that the outer lid closes and is not obstructed.

To adjust the wash cycle time:

1. Press the knob to access the display menu.

2. Select Pause to raise the platform and basket.

5.2.3 Drain and Dry Prints

The platform mount and basket raise automatically at the end of the wash cycle. Solvent drains into

the wash bucket as parts dry and drips onto the inner lid. Thoroughly drain solvent from printed

parts; carefully check and drain concave or hollow geometries that may hold additional solvent.

Allow parts that have been washed in any solvent that evaporates readily to air dry for at least 30

minutes after washing and draining. Solvents that do not evaporate readily, such as tripropylene

monomethyl ether (TPM), should be washed o the parts with a secondary water rinse. Consult

support.formlabs.com for additional information about working with specific solvents.

Ensure appropriate ventilation while the solvent evaporates. Observe necessary safety

precautions, according to the solvent supplier’s SDS. Options for drying include air drying

or forced air. Forced air, such as a fan or clean compressed air, may dry parts more quickly.

Check inside cavities and channels for uncured resin or liquid solvent. Remove

residual liquid before drying to avoid fully or partially cured resin in unwanted areas.

Compressed air may be helpful to empty internal channels before drying.

To begin the next wash immediately, dry the parts outside of the Form Wash. Take extra care

with sharp objects and slippery surfaces when removing wet parts from the build platform.

NOTICE

22

5.2.4 Collect Prints

Remove the build platform or parts from basket, depending on the wash method used in 5.2.1

Insert Print.

5.2.5 Finish Your Print

After washing parts on the build platform, remove parts from the build platform with the removal

tool, scraper, or flush cutters.

Once each part is washed and dried, check the specific material’spost-curing settings on

support.formlabs.com. Post-curing is optional for Standard Resins and required for many other

materials to achieve their optimal properties.

After post-curing (if necessary), use the flush cutters that come in your Finish Kit to carefully

cut the supports attached to the part(s). Supports can also be removed before post-curing, but

parts may warp under exposure to light and heat without structural support.

Wear safety glasses to protect eyes from dislodged fragments of supports.

You can sand support marks and polish your parts for a smooth finish.

5.3 Considerations for Specific Geometries

Consider the specific geometry of each part when choosing a method to wash the part and the

sequence of steps. Take special care when washing parts that are large, hollow, concave or cup

shaped, or have internal chambers or channels that hold solvent, air, or uncured resin inside.

5.3.1 Hollow Geometries

Design hollow parts with drainage holes for successful printing. During the washing process,

the drainage hole allows the solvent to flow inside and clean the internal surfaces. Take care

when removing hollow parts from the alcohol bath. Check to ensure that all solvent drains out

of the chamber before transferring the part to another surface.

5.3.2 Internal Channels

Thin channels, such as those used in micro-fluidic designs, may not drain entirely on their

own. Use a syringe filled with clean solvent to flush out internal channels. After cleaning, use

compressed air to fully drain and dry the channel.

5.3.3 Large Parts

Parts move around the basket with the circulation of alcohol in the wash bucket. Check the

path of the basket and inner lid to ensure that all parts can safely raise out of the bucket when

the wash cycle completes and the basket raises. Parts that hang outside the basket perimeter

may dislodge the inner lid when the wash cycle completes.

Whether using the build platform or basket as a wash method, the maximum single part size

that can be washed in the Form Wash is 14.5 × 14.5 × 17.5 cm (5.7 × 5.7 × 6.9 in).

5.3.4 Concave Surfaces, Printed and Washed on the Build Platform

Hollowed parts—such as hollowed dental models—printed directly on the build platform can

trap resin inside during the wash cycle, when they are washed still attached to the build

platform. Consider washing these parts in the Form Wash basket or adding a second wash

cycle after removing them from the build platform to remove uncured resin that is not removed

when washing on the build platform alone.

CAUTION

Other manuals for Form Wash

1

Table of contents

Popular Ultrasonic Jewelry Cleaner manuals by other brands

Graymills

Graymills HANDI-KLEEN PL364 Operation and maintenance instructions

TYROLIT Hydrostress

TYROLIT Hydrostress VCE2500D Series operating instructions

Makita

Makita DCL284F instruction manual

Nilfisk-Euroclean

Nilfisk-Euroclean Compact Patio operating instructions

Ultrawave

Ultrawave Q Series quick guide

Kärcher

Kärcher WV 1 Plus Operator's manual