TRILETY MCK User manual

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

1

INSTRUCTION MANUAL

STREET CLEANER

MCK FOR MULTICAR FUMO/ M31

Specifications

Operating Instructions

Maintenance

List of Spare Parts

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

2

TABLE OF CONTENTS

1

SPECIFICATIONS ...............................................................................................4

1.1

TECHNICAL DATA ...............................................................................................................................4

1.2

Technical Description ..............................................................................................................................5

1.3

Construction And Function ....................................................................................................................5

1.4

Base Framework ......................................................................................................................................6

1.5

Hopper ......................................................................................................................................................6

1.6

Water Tank ..............................................................................................................................................6

1.7

Suction Fan Unit ......................................................................................................................................7

1.8

Sweeping and Suction Unit .....................................................................................................................7

1.9

Front Disk Brush (Optional Equipment) ...............................................................................................8

1.10

Hydraulic System ................................................................................................................................9

1.11

Electric System ....................................................................................................................................9

1.12

Spray Water System .........................................................................................................................10

1.13

Operation Principle...........................................................................................................................11

2

OPERATING INSTRUCTIONS ..........................................................................12

2.1

SAFETY TIPS........................................................................................................................................12

2.2

PREPARATION OF THE Multicar CHASSIS ..................................................................................14

2.3

MOUNTING AND DEMOUNTING THE SWEEPER ......................................................................14

2.3.1

Mounting the Sweeper Unit............................................................................................................14

2.3.2

Demounting the Sweeper Unit........................................................................................................16

2.4

Sweeping operation................................................................................................................................18

2.4.1

Filling the spray-water tank............................................................................................................18

2.4.2

Controls Multicar Vehicle ..............................................................................................................19

2.4.3

Control panel MCK sweeper..........................................................................................................21

2.4.4

Information for operating the vehicle:............................................................................................21

2.4.5

Starting the sweeping operation .....................................................................................................22

2.4.6

General information for sweeping ..................................................................................................23

2.4.7

Used Water Drainage .....................................................................................................................24

2.4.8

Concluding the sweeping operation................................................................................................25

2.4.9

Dumping.........................................................................................................................................26

2.4.10

Working with the Hand Suction Hose .......................................................................................29

2.4.11

Using the High Pressure Water Unit..........................................................................................32

2.4.12

Pressure Adjustment ..................................................................................................................34

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

3

3

MAINTENANCE .................................................................................................35

3.1

Chassis and engine .................................................................................................................................35

3.2

Hopper ....................................................................................................................................................35

3.2.1

Baffle Plate.....................................................................................................................................35

3.2.2

Filter Screens..................................................................................................................................35

3.2.3

Wastewater filter screen .................................................................................................................36

3.2.4

Air Ducts ........................................................................................................................................36

3.2.5

Safety Bar.......................................................................................................................................36

3.3

Spray water system................................................................................................................................37

3.3.1

Working in Freezing Temperatures................................................................................................37

3.3.2

Water Tank.....................................................................................................................................37

3.3.3

Water Pump....................................................................................................................................37

3.3.4

Water Filter ....................................................................................................................................38

3.4

Suction fan..............................................................................................................................................38

3.4.1

Cleaning .........................................................................................................................................38

3.4.2

Fan Impeller Bearing......................................................................................................................39

3.5

Sweeping and suction unit.....................................................................................................................40

3.5.1

Basic Settings .................................................................................................................................40

3.5.1.1

Suction Hood ........................................................................................................................40

3.5.1.2

Disk Brush ............................................................................................................................41

3.5.2

Adjustments....................................................................................................................................43

3.5.2.1

Suction Hood ........................................................................................................................43

3.5.2.2

Disk Brush ............................................................................................................................43

3.5.2.3

Front Brush* .........................................................................................................................45

3.6

Hydraulic system....................................................................................................................................46

3.6.1

Safety Tips .....................................................................................................................................46

3.6.2

General Information .......................................................................................................................46

3.6.3

Checking the Hydraulic Oil Level ..................................................................................................47

3.6.4

Checking the Hydraulic Oil Temperature.......................................................................................47

3.6.5

Checking the Hydraulic Filter ........................................................................................................47

3.6.6

Bleeding the Hydraulic System ......................................................................................................48

3.7

Troubleshooting .....................................................................................................................................49

3.7.1

Sweeping and Suction Gear............................................................................................................49

3.7.2

Hydraulic System ...........................................................................................................................51

3.8

Maintenance schedule............................................................................................................................52

4

LIST OF SPARE PARTS ...................................................................................56

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

4

1 SPECIFICATIONS

1.1 TECHNICAL DATA

Permitted total weight 4,800 kg

Hopper capacity 2,2 m

3

Water tank capacity** 370 l

Sweeping width with standard brush gear (2 brushes) max. 2,000 mm

Sweeping width with additional front brush max. 2,600 mm

Suction fan capacity max. 8,000 m

3

/h

Suction fan speed max. 3,000 rpm

Suction vacuum during sweeping approx. 550 mm WS

Maximum suction vacuum approx. 1,100 mm WS

Sweeping speed approx. 0...15 km/h

Vehicle length without front brush approx. 5,200 mm

Vehicle length with front brush approx. 6,300 mm

Vehicle width 1,600 mm

Vehicle height approx. 2,100 mm

Total weight without optional equipment approx. 3,180 kg

Payload approx.1,620 kg

Noise level at engine speed 1,800 rpm 78.5 dB(A) Mean value

Noise level at the driver’s position, window closed 76.8 dB(A)

Noise level at the driver’s position, window open 77.4 dB(A)

The sweeper unit should be only used to clean the street surface, park places,

underground garages and other solid surfaces and to suck out canal ducts.

The sweeper must not be used for picking up material that are explosive,

inflammable or which may constitute a health hazard!

Any alterations to the construction of the sweeper unit can only preformed after

they have been authorized by the manufacture.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

5

1.2 Technical Description

The sweeper MCK is designed as an exchangeable unit for Multicar chasses and is

partly constructed out of stainless steel (hopper, water tank). The sweeper may be used

for cleaning roads, car parks, large public and industrial areas, etc. All the important

working functions are controlled by the driver in the cab. In addition, a video system to

monitor the rear working area (optional equipment) can be fitted onto the rear of the

vehicle.

Large objects, such as stones, tins, bottles etc., can be picked up through an

automatically working, remote-controlled* bulky debris pick-up flap.

To meet a wide variety of requirements, the exchangeable sweeper unit may be fitted

with a number of optional features:

•Front mounted 3

rd

brush for an increased sweeping width and for sweeping out road

bays and sloping kerbs.

•Rear mounted hand suction hose to empty gully holes or sucking up leaves

•Hopper made entirely of aluminium (Weight saving approx. 300 kg)

•Spotlights for sweeping in the night

•Rotating flashing beacon on the hopper roof

•Rear view camera with monitor in the cab

1.3 Construction And Function

The entire sweeper unit consists out of the following:

Base Framework

Hopper

Fan Unit

Water Tank

Sweeping and Suction unit

Option Front Brush Unit

The entire sweeper unit can be fitted onto the ball joints of the Multicar M26 chassis

using a few easy steps.

The hopper is located at the rear of the sweeper unit.

The suction fan and the fan motor are located at the front of the sweeper unit.

The water tank is built under the suction fan into the frame.

The sweeping and suction unit is mounted onto a swivelling arm at the rear of the

sweeper unit.

A large storage basket is built into the frame under the hopper.

The sweeping and suction functions, including the hopper tipping control, are controlled

through the:

•Multicar hydraulic system

•Electrical system

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

6

1.4 Base Framework

The entire sweeper unit is construction onto a robust base framework fabricated out of

rectangular tubes. The base framework can be mounted onto the ball joints of the

vehicle chassis.

Extra holding tubes are fitted into the base framework, to strengthen the construction

and to allow that support legs can be inserted.

The front section of the sweeper unit contains the water tank and the machinery

compartment which is lined with sound absorbing material.

A storage basket is built into the middle part of the base framework.

1.5 Hopper

The hopper is made out of stainless steel (optional Aluminium) and is mounted onto the

base framework using robust bearing blocks.

The hopper capacity is approx. 2,2 m

3

.

Observation flaps has been set into each side of the hopper, so that the fill volume can

be controlled and to allow that bulky objects, which cannot be picked up by the suction

hood, can be manually thrown into the hopper.

A wear-resistant elastic spiral hose, 220 mm in diameter, connects the suction hood to

the hopper.

A rubber-lined baffle plate is installed above the suction air inlet of the hopper. The

sucked air then flows via the filter plates fitted on the upper right and left-hand sides of

the hopper through the air duct into the suction fan and then is dispersed over the

exhaust-air duct.

The contents of the hopper are emptied through a large flap that covers the entire rear

side of the hopper. The flap is closed by hand, the flap is opened kept in the opened

position using gas filled spring cylinders.

The locking mechanism for the closed flap is operated using an electric motor.

The hopper is tipped by using 2 hydraulic cylinders; through the high position of the

bearing blocks a tipping height of approx. 1,450 mm is obtained. The tipped hopper can

be secured using the supplied safety support bar.

1.6 Water Tank

The water tank is made of stainless steel and is mounted at the front end of the base

framework. The tank capacity is approx. 370 l (250 l with low-height models).

The tank is filling system is fitted with a Storz-C-coupling connection and contains an

anti backflow system. The water level can be seen on the water level gauge. A water-

level indicator in the cab* is available as an optional equipment.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

7

1.7 Suction Fan Unit

The suction fan unit is mounted, elastically supported, at the front end of the base

framework.

The suction fan unit is fitted with high-performance suction fan blade which has been

designed to obtain an optional suction efficiency for the sweepings.

The suction fan is driven by a hydraulic axial piston motor which is flange-mounted onto

the suction fan unit. The hydraulic motor is driven by the hydraulic oil supplied by the

hydraulic system of the Multicar chassis.

The exhaust air of the suction fan is so dispersed underneath the sweeper body, that

there is no annoyance from the air flow, even in the immediate vicinity of the sweeper.

1.8 Sweeping and Suction Unit

The sweeping and suction gear is mounted onto a swivelling frame on the rear side of

the base framework and consists of:

•Swivelling arm (allows sweeping and suction unit to be swivelled to the side of the

vehicle when the hopper is emptied)

•Lifting arm (lifts and lowers the sweeping and suction unit)

•Floating arm (automatically adjusts so the sweeping and suction units are parallel to

the road surface even when the road slopes)

•Suction hood with suction hose

•Bulky debris pick-up flap

•2 disk brush units

The suction hood with suction hose is mounted in the middle of the floating arm.

The bulky debris pick-up flap is located in front of the suction hood.

The disk brush units are mounted onto the right and left sides of the floating arm and

their height can be adjusted by hand; the brushes can also be swivelled outwards.

While sweeping, the floating arm is trailed behind the vehicle on two robust large

support wheels (∅250mm). The sweeping and suction unit on the floating arm are

raised from the road surface by a hydraulic cylinder on the lifting arm.

When the hopper is to be emptied, the complete sweeping and suction unit is swivelled

to the side of the vehicle using the swivelling arm.

To reduce the quantity of dust raised while sweeping, all sweeping and suction units are

fitted with a spray water nozzles.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

8

1.9 Front Disk Brush (Optional Equipment)

To increase the swept width and to facilitate sweeping along kerbstones and sloping

kerbs, the sweeper can be fitted with a front brush unit.

The front disk brush is mounted onto the vehicles front mounting plate and consists of

the following:

−Mounting plate

−Telescoping arm or swivelling arm (depending on the model)

−Disk brush unit

The swivelling and height-adjustable disk brush unit is mounted onto a telescoping or

swivelling arm. The brush unit is extended or swivelled by means of a hydraulic

cylinder. The front brush is lifted via the vehicles front mounting plate.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

9

1.10 Hydraulic System

Max. flow volume in the brush drive circuit 18 l (can be adjusted on the

solenoid valve block of the chassis. The volume is preset and should not be altered)

The hydraulic circuits are connected to the hydraulic system of the Multicar chassis

using quick release couplings and control the following functions:

•Suction fan drive

•Disk brush drive

•Tipping of the hopper

•Front brush* drive

•Extending of front brush*

These functions are controlled using the control elements of the Multicar chassis in the

cab or using the switches on the separate control panel for the sweeper unit.

1.11 Electric System

All electrical contacts, plug and sockets that are used for the connections

between the vehicle and the sweeper unit are to be weekly sprayed with a

commercial contact spray to prevent corrosion and the possibility of error

conditions.

The sweeper is fitted with a 12-volt electric system.

The power is supplied via the electric system of the Multicar M26 chassis and regulates

the following functions:

•Water pump drive

•Solenoid valves for the spray water

•Solenoid valves for the brush drive controls

•Rear flap locking device

•Remote control bulky debris pick-up flap*

•Spotlights for control of the brushes *

•Rotating flashing beacon on the hopper roof*

The controls for these functions are located on the separate control panel of the

sweeper unit.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

10

1.12 Spray Water System

The spray water system is fitted to reduce the quantity of dust raised during the

sweeping operation and helps to separate the dust from the sucked debris in the

hopper.

The standard delivered hand spray pistol and hose are used to clean the discharge flap

sealing and the interior of the hopper after dumping.

The water is separately supplied via solenoid valves, to the suction hood, disk brushes

and front brush*.

The spray water system consists of:

•Water tank, 370 l (250 l with low-height models)

•Water filling equipment

•Water drainage equipment

•Water filter

•Water pump, electrically powered

•Overpressure valve

•Solenoid valves, to actuate the spray nozzles

•Spray nozzles:

Disk brushes 2 nozzles each brush

Suction hood 5 nozzles

Front brush* 4 nozzles

•Water filling hose with C-coupling and hydrant key

•Water hose with spray pistol

The water tank is filled using a pressureless none return flow system, which conforms

to the requirements of the “protection of drinking water from contamination in water

supply systems“.

The water level in the water tank can be controlled using the water level gauge.

The electrical water pump (dry running safe) is designed so that it will not be damaged

when running without water. The pump delivers a volume of approx. 15 l/min. While

sweeping, the water pressure of the spray water system is adjusted to max. 2 bar. The

water hose and spray pistol can be connected to the sweeper unit using the quick

release coupling for the water to the suction hood.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

11

1.13 Operation Principle

As the vehicle drives, the disk brushes sweep the debris in front of the suction hood.

The swept width can be increased by actuating the front brush* (optional equipment).

The front brush also facilitates the sweeping of road bays and between parked cars.

To reduce the quantity of dust raised while sweeping, the debris is sprayed with water

by means of spray nozzles fitted onto the sweeping and suction units.

The suction fan generates a vacuum in the hopper, this vacuum then sucks the

sweeping through the suction hood and the flexible suction hose into the hopper.

Due to the much larger cross-section in the hopper, the speed of the sucked air is

considerably reduced and the debris then settles in the hopper. A rubber-lined baffle

plate, fitted above the suction connection piece in the hopper, protects the hopper roof

from damage.

The suction fan then sucks the air, free from the sweeping through the filter screens

and then blows it into the exhaust air duct. The filter screens prevent that bulky but light

debris (paper, leaves etc.) are not sucked into the suction fan.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

12

2 OPERATING INSTRUCTIONS

2.1 SAFETY TIPS

The sweeper may only be operated by trained personnel!

The safety support bar must be inserted under all circumstances when

working underneath the tipped hopper!

Before starting work inside the hopper, open the discharge flap as wide as

possible; remove the vehicle’s ignition key and keep it an a safe place,

inaccessible for other people!

While the hopper is being lowered ensure that no persons are within the

danger zone of the equipment!

The person activating the tipper control must ensure that the area is clear,

before and during the procedure for lowering the hopper!

The hopper should be only tipped when the discharge flap lock is open – even

if the hopper is partly filled!

Maintenance on the suction fan should only be performed after the fan impeller

has stopped . For safety reasons, the ignition key of the vehicle should be

removed and kept in a safe place that is inaccessible for other people.

Before driving the vehicle, ensure that the rear sweeping and suction unit is

correctly positioned and locked onto the vehicle also ensure that the brushes

are in the raised position and secured with the steel cable!

Before driving the vehicle, ensure that the front brush is completely retrieved

and the brush is raised and locked in the raised position with the locking pin!

Internal-combustion engines must not be kept running in closed or narrow

spaces – danger of exhaust gas poisoning!

The vehicle must not be overloaded!

The vehicle should not be driven with raised hopper!

The sweeper must not be used for picking up material that are explosive,

inflammable or which may constitute a health hazard!

The hand spray pistol must not be directed at people, or at objects that contain

electricity!

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

13

Special care is necessary when mounting / removing the sweeper unit onto /

from the vehicle chassis!

Note:

Additionally the safety tips specified in the following chapters must also be observed

under all circumstances!

Note:

In addition, the safety regulations for operating the vehicle must also be observed under

all circumstances (see separate manual!)!

The information left and right are always related to the direction of travel (forward drive)

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

14

2.2 PREPARATION OF THE MULTICAR CHASSIS

The Multicar chassis that is to serve as the carrier vehicle must be suitable for the

exchangeable sweeper body and must be specially adapted for the sweeper body with

the following equipment:

•07-4 power hydraulic

•Hydraulic connections for operating the sweeper unit

•Electric connections for the sweeper and controls in the cab

•Water pipes for front brush

2.3 MOUNTING AND DEMOUNTING THE SWEEPER

The exchangeable sweeper MCK is designed as a quick-swap body for Multicar

chasses and can be easily and quickly mounted onto a Multicar chassis that has been

pre-fitted with the appropriate equipment with a few easy steps:

To ensure easy connection, the supply lines and cables (hydraulics, electrics, water)

are fitted with quick release couplings.

! Caution !

Special care should be taken when changing the attachment – high risk of

accidents by incorrect performance!

2.3.1 Mounting the Sweeper Unit

1. Remove the tipping platform from the vehicle using the vehicle manufacturer

instructions.

! Caution !

To prevent damage to the sweeper unit, the vehicles tipping cylinder

disconnected from the vehicle hydraulics!

2. Raise the front mounting plate completely.

3. Insert the connection between the hydraulic pressure coupling and the

pressure transfer to the rear on the front (only applies if brush drive circuit

is not at the rear or without frontbrush = pressure forwarding)

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

15

4. Wind up the 4 sweeper unit support legs, so that the sweeper unit is in a

position that ensures that the vehicle can be driven underneath without

touching the sweeper unit.

5. Drive the vehicle underneath the sweeper unit and position the vehicle so

that the ball joints are underneath the ball joint receptacles.

6. Connect the sweeper unit hopper tipping hydraulic hose connections to the

quick release couplings for the vehicle tipping cylinder.

7. Evenly lower the sweeper body onto the vehicles ball joints by winding down

the 4 support legs. Ensure that all the ball joints are correctly inserted in the

receptacles. Insert the safety pins underneath the ball joints.

8. Remove the support legs from the holding tubes and store them.

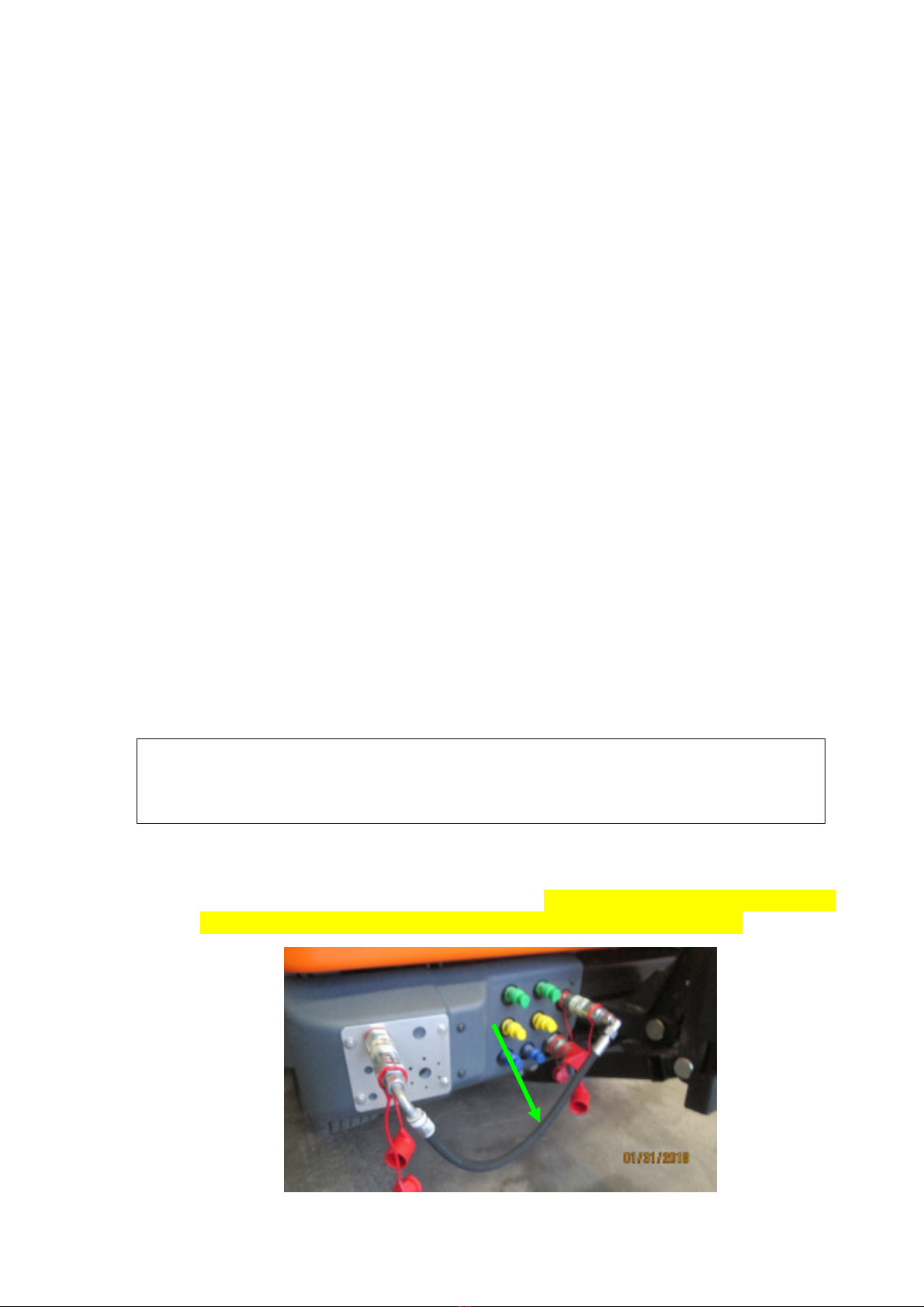

9. Connect the hydraulic hoses for the suction fan on to the connectors on the

right hand side behind the drivers cab.

10. Connect Leakoil.

11. At the rear of the vehicle, connect the hydraulic hose quick release

connections according to the numbering (or description)

12. Connect the 7-pin electrical plug for the additional Road Traffic Licensing

Regulations lighting onto the socket on the rear of the vehicle.

13. Connect the electrical plug for the connecting cable onto the socket at the

rear of the vehicle or place the control panel into the cab through the rear

window (depending on the model).

Connect here

hydraulic-tube for

suction unit lifting

(coupling for tipping

cylinder)

leakoil

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

16

Model with Front brush

14. Connect the water pipe to the connection at the rear of the vehicle.

15. Lower the front mounting plate and drive the vehicle to the mating plate of

the front brush.

16. Hook the mating plate of the front brush into the front mounting plate.

17. Raise the front mounting plate completely, ensure that location pins are the

inserted into the location holes at the top of the mating plate.

18. Swing in and tighten the retaining screws on the left and right hand side of

the mating plate.

19. Connect the hydraulic couplings and water pipe at the front of the vehicle.

2.3.2 Demounting the Sweeper Unit

Ensure that the removed sweeper unit will be stored on an even and stable

surface.

Before demounting the sweeper unit, completely empty the hopper and the water

tanks and thoroughly clean the brushes and the hopper.

1. Drive the Multicar vehicle with mounted sweeper to a parking area with firm,

level ground.

2. Before driving the vehicle, ensure that the rear sweeping and suction unit is

correctly positioned and locked onto the vehicle also ensure that the brushes

are in the raised position and secured with the steel cable.

3. Turn off the vehicle.

4. At the rear of the vehicle, disconnect the hydraulic quick release couplings,

place dust covers over the disconnected hydraulic couplings.

5. Disconnect the all the electrical plugs at the rear side (1 or 2 pcs., depending

on the model).

6. On the left and right hand side behind the drivers cab, disconnect the

hydraulic hoses for the suction fan and place dust covers over the

disconnected hydraulic couplings.

7. Insert the 4 support legs into the holding tubes. Remove the safety pins from

under the ball joints.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

17

8. Evenly wind up the support legs so that the sweeper unit is raised from the

vehicle. Lift the sweeper unit as high as necessary to ensure that the vehicle

can be driven away without touching the sweeper unit.

9. Disconnect the sweeper unit hopper tipping hydraulic hose connections to

the quick release couplings for the vehicle tipping cylinder.

10. Ensure that all connections to the vehicle are disconnected and that all the

hydraulic hoses, pipes and cables are so placed that they do not hinder the

vehicle's removal.

11. Start the vehicle.

12. Drive the vehicle away from underneath the sweeper unit that is supported

by the support legs.

13. Turn off the vehicle.

14. Reconnect the vehicle tipping cylinder to the vehicle hydraulic system.

15. Mount the tipping platform to the vehicle using the vehicle manufacturer

instructions.

Model with Front brush

16. Disconnect the hydraulic couplings and water pipe at the front of the vehicle.

17. Loosen and swing out the retaining screws on the left and right hand side of

the mating plate.

18. Lower the front mounting plate until the mating plate of the front brush is

completely disengaged from the mounting plate.

19. Drive the vehicle a short distance away from the front brush unit.

20. Raise the front mount plate completely and insert the fastening bolt for the

front mount plate to lock the plate.

20. Disconnect the water pipe to the connection at the rear of the vehicle.

Note:

When uncoupling the connections, check if any markings have become illegible

or have been lost; renew the markings, if necessary. To protect the disconnected

hydraulic couplings ensure that the dust covers are fitted.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

18

2.4 SWEEPING OPERATION

! CAUTION !

Vehicles and sweeper units which are not roadworthy and could malfunction

should not be put into operation!

The following items should be controlled each time before operating:

•The sweeper unit is correct mounted and fixed on the ball joints and that the front

brush is correctly mounted on the front mounting plate.

•Water level in the spray-water tank

•Adjustment of the sweeping and suction units

- brush load pressure

- height adjustment of the suction hood rubber strips

- wear of the brushes, suction hoses, rubber strips and rubber aprons

Before starting the sweeping operation, it is essential to observe the safety

instructions in accordance with point 2.1!

2.4.1 Filling the spray-water tank

1. Drive the sweeper to a hydrant with a C-coupling connection.

2. Open the locking system that locks the suction hose of the rear sweeping unit

on to the connection piece of the rear flap of the hopper.

3. Disconnect the suction hose from the hopper and hang it on the hook of the

sweeping unit.

4. Tip the hopper up a little, so that the items in the storage basket can be

reached. Caution for sweeping and suction unit.

5. Switch the vehicle off.

6. Remove the blank cover from the hydrant, open the hydrant for a short time

to wash any accumulated dirt away so that this dirt can not enter the water

tank.

7. Remove the blank cover from the water inlet port on the front right-hand side.

8. Place the water filter* on the hydrant connection and connect the water filling

hose to the water inlet port and water filter.

9. Open the hydrant valve.

Note: To limit the filling speed, the filling pipes have a reduced cross section.

10. Check the filling process on the water level gauge.

11. Fill in water until water exits out of the overflow of the water tank. Then

immediately close the hydrant.

12. Disconnect the water filling hose first from the water filter, then from the water

inlet port; roll up and store the hose in the storage basket.

13. Disconnect the water filter* from the hydrant, then reconnect the filter in the

reverse direction and rinse the filter for a short time by opening the hydrant.

14. Disconnect and store the water filter* in the storage basket.

15. Reattach all blank covers.

16. Switch the vehicle on.

17. Lower the hopper.

18. Reconnect the suction hose to the hopper.

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

19

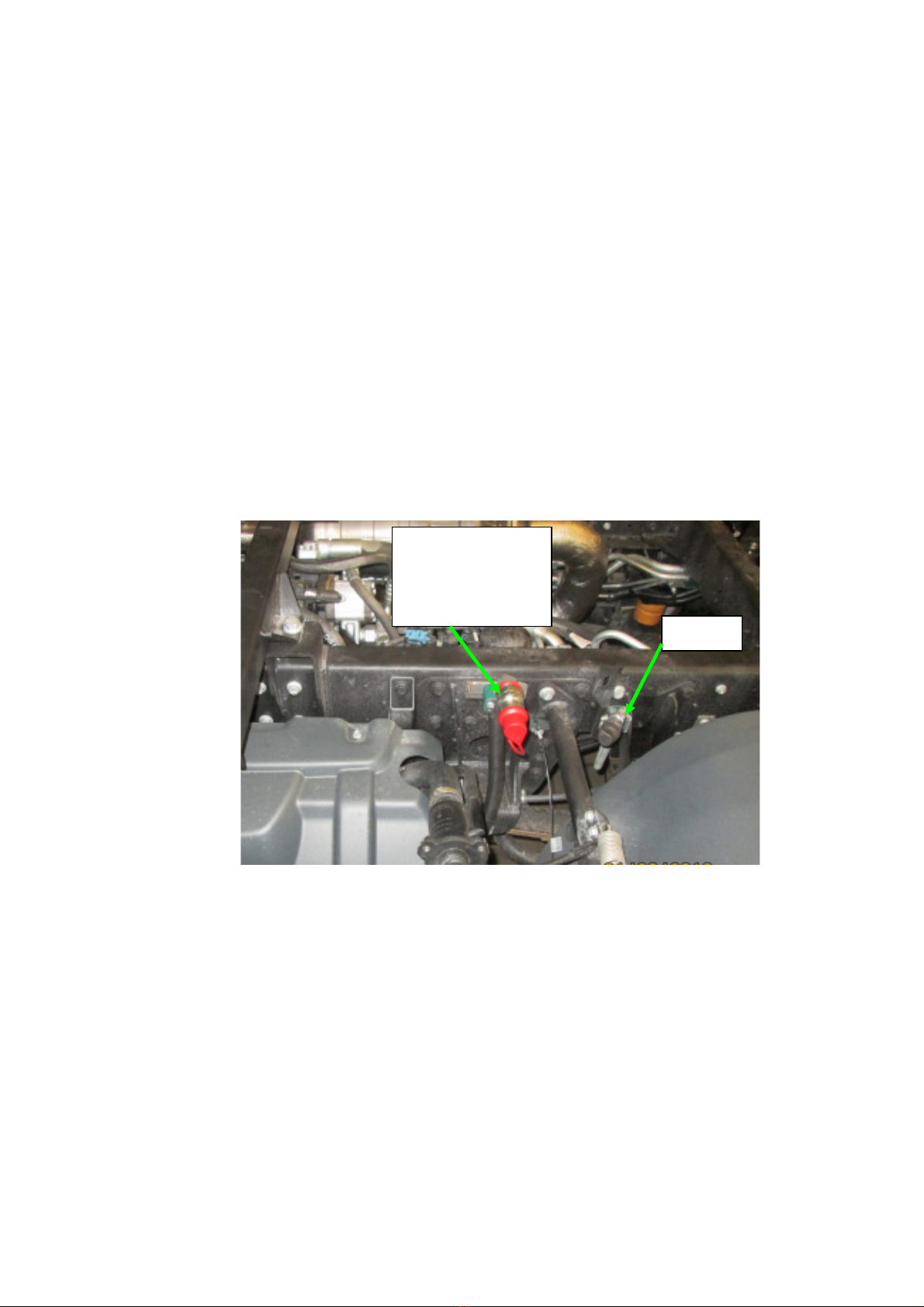

2.4.2 Controls Multicar Vehicle

The controls for the vehicle can vary according to options from Multicar carrier vehicle

(see original multicar manual) Adjust hydraulic flow with regulator in cabin or on

hydraulic block (right side behind drivers cab)

Hydraulic oil quantities: Suction fan appr.50 .... 55 l/min

Actuators and actuating functions 13 .... 15 l/min

For settings, see operating instructions Multicar chassis!

4.Brush drive

ON / OFF

3.Suction Fan

ON / OFF

2.Hydraulic system

ON / OFF

1. Hydraulik

drive on

Adjust vehicle

motorspeed

Gebrüder TRILETY Ges.m.b.H. MCK-M31 1.02 09/ 2018

* Optional equipment Page

20

Speedregulator brushes

adjust 12...15 l/min

Speedregulator suction

fan adjust 55 l/min

Frontbrush

raise/lower

Frontbrush

left-right and

slope

Adjust on

hydraulic valve

block on left side

beside battery

This manual suits for next models

1

Table of contents