Content

2 BA/Transsonic TI-H_GB_0306 © Elma GmbH & Co KG

1General................................................................................3

2Important safety warnings ...................................................3

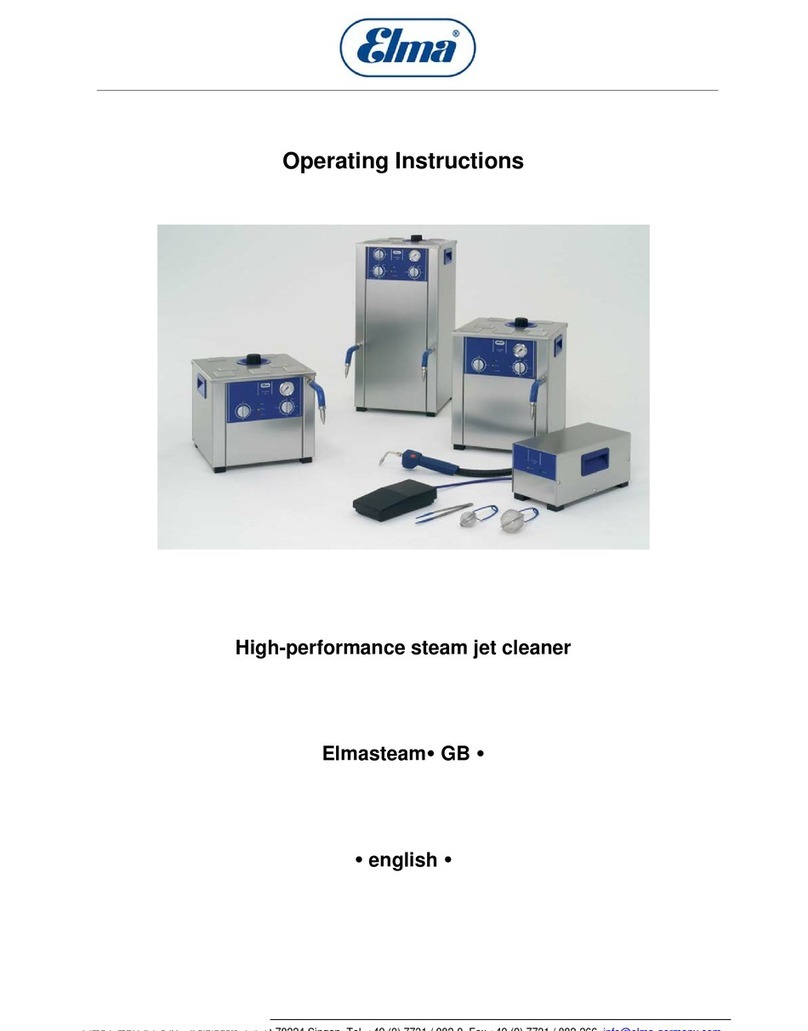

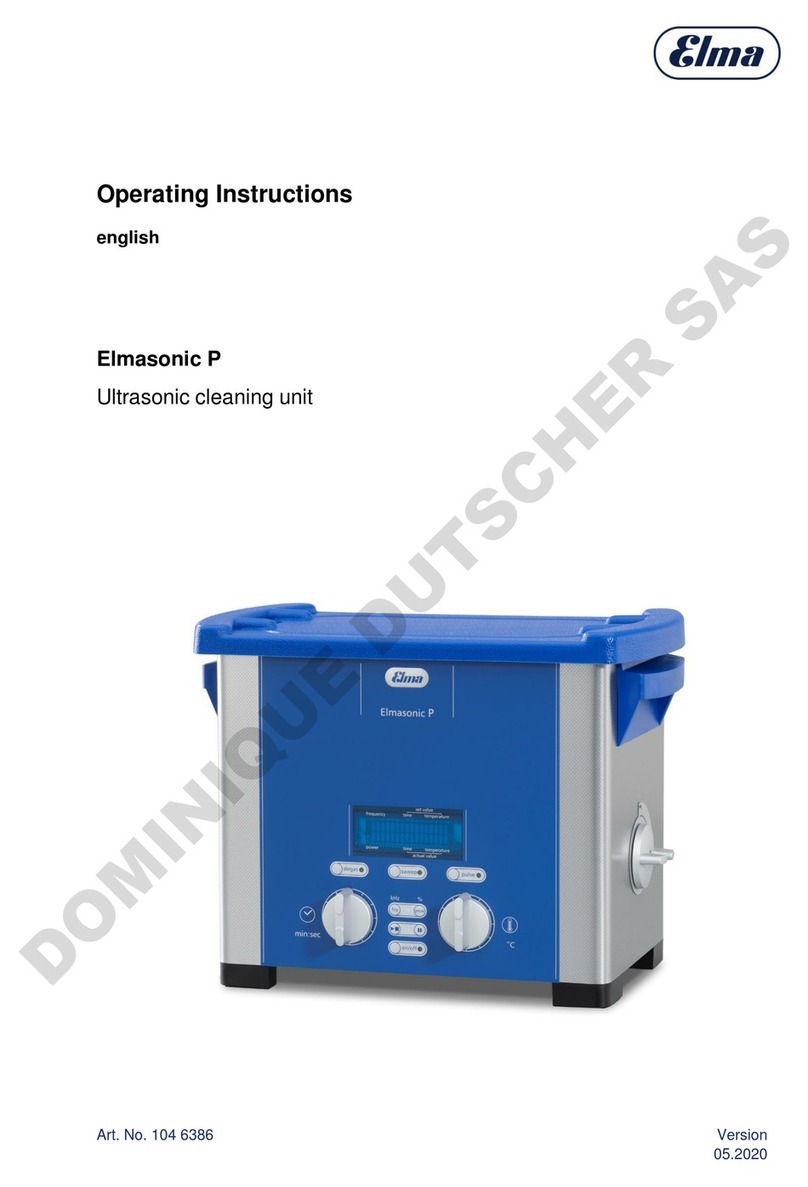

3Functioning..........................................................................4

4Product description..............................................................5

4.1 Product features ..........................................................5

4.2 CE conformity ..........................................................6

4.3 RFI declaration (European Union) ................................6

4.4 Delivered equipment .....................................................6

4.5 Additional accessories ..................................................6

4.6 Technical details ..........................................................7

4.7 Description of unit features – front view........................8

4.8 Description transducer tank ..........................................9

4.9 Description of unit features – back side ......................10

4.10 Description operating elements ...............................12

4.11 Safety devices ........................................................13

5Before initial operation.......................................................14

5.1 Unpacking and placement ..........................................14

5.2 Connect the unit to the mains .....................................14

6Putting into operation ........................................................15

6.1 Filling of the unit with cleaning liquid...........................15

6.2 Setting of the required cleaning liquid temperature ....16

6.3 Degassing of cleaning media

(multi-frequency units only).........................................17

6.4 Placement of cleaning items .......................................18

7Ultrasonic cleaning process ..............................................19

7.1 Setting of ultrasonic cleaning process ........................20

7.2 Setting of ultrasonic intensity ......................................20

7.3 Setting of ultrasonic frequency

(only on multi-frequency units)....................................20

7.4 Setting ultrasonic mode

(on multi-frequency units only)....................................21

7.5 After the cleaning ........................................................22

8Cleaning media .................................................................23

8.1 Limitations concerning solvent-containing cleaners....23

8.2 Limitations concerning aqueous cleaners...................24

9Maintenance......................................................................25

9.1 Maintenance / Care.....................................................25

9.2 Check the safety switch-off (on TI-H 25 and bigger)...26

9.3 Service life of the transducer tank...............................26

9.4 Repair ........................................................27

10 Putting out of action and waste disposal........................27

11 Manufacturer’s contact address .....................................27