TRAILER T 14 4 WD

© 2005 FORS MW Ltd www.forsmw.com Page 7

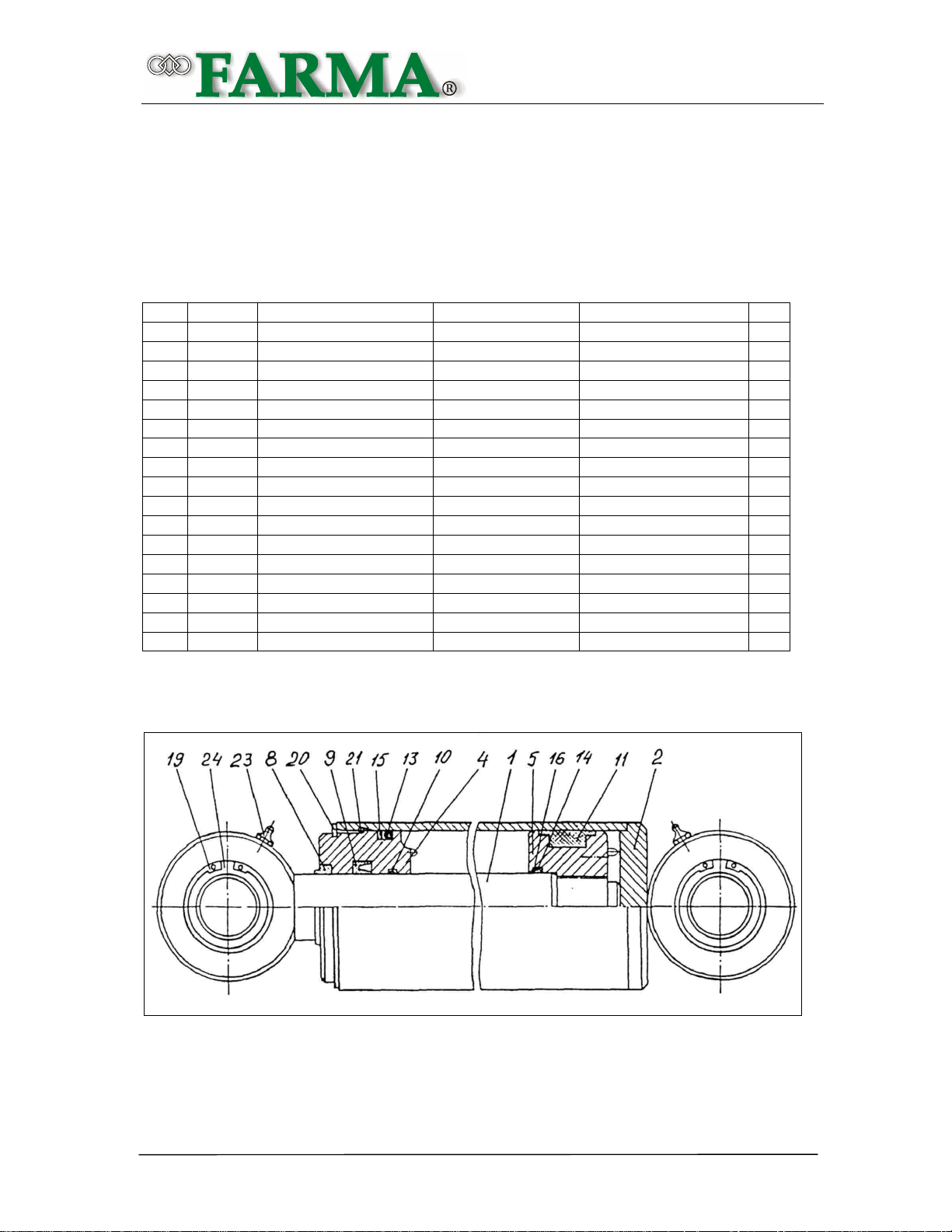

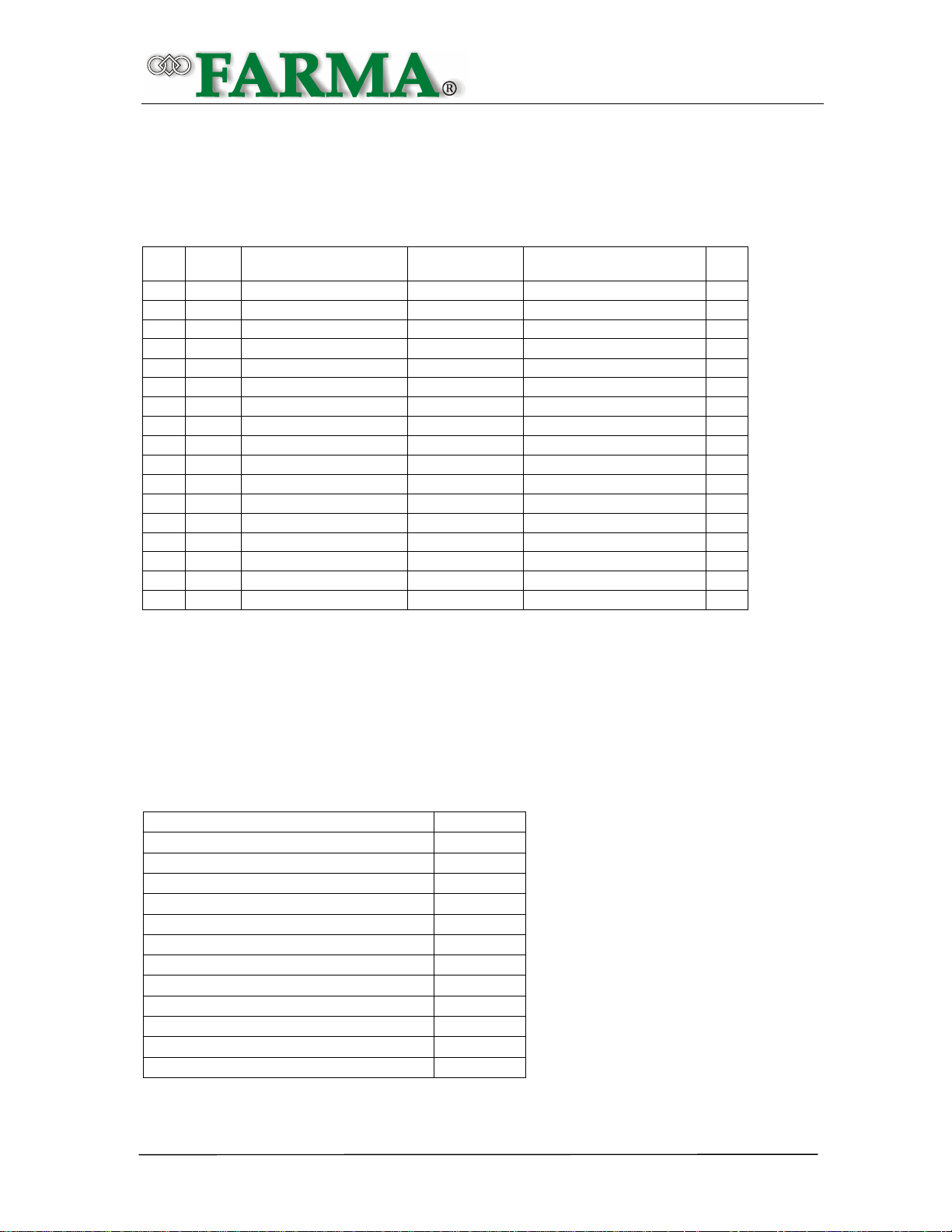

Sparepartlist for Hydraulic-cylinder 90/40-300

Stabilizer cyl for Trailer T14 4WD

Production no F10-100400.000

Pos

Art no Number Sparepart Dimension Pcs

1 56401 F13-100410.000 Piston road 1

2 56402 F10-100220.000 Tube 1

4 56403 M13-100100.001 Front bush 1

5 56404 M13-100100.002 Piston 1

8 56405 Scrape-ring AS40-50-7-10 1

9 56406 Sealing NI 300 40-55-10 1

10 56407 Buch DFI 40-45-5,5 1

11 56408 Sealing Simco 5×2 90-70-33,8 1

13 56409 0-ring 79,2×5,7 1

14 56410 0-ring 40,2×3,0 1

15 56411 Sealing SRA 90-5,1-1,5 1

16 56412 Sealing SRI 40-2,6-1,5 2

19 56413 Lock-ring SGH 55 2

20 56414 Lock-ring SGA 87 1

21 56415 Lock-ring N°72290 1

23 56416 Grease-nipple 1/8" 2

24 56417 Joint bearing GE35ES 2

Sparepart list hydraulic cyl 63/32-500

Moving wheel support for Trailer T14 4WD

Production no F10-100100.000

Pos

Art no Number Sparepart Dimension Pcs

1 55701 F10-100120.00 Piston rod 1

2 55702 F10-100110.00 Tube 1

4 55702 M13-100300.001 Front bush 1

5 55703 M13-100300.002 Piston 1

8 55703 Scraper AS 32-45-7-10 1

9 55704 Sealing NI300 32-47-10 1

10 55704 Bush DFI 32-35,1-4,0 1

11 55705 Sealing SIMKO 5×2 63-47-29,8 1

13 55705 O-ring 52,2×5,7 1

14 55706 O-ring 32,2-3,0 1

15 55706 Sealing SRA 63-5,1-1,5 1

16 55707 Sealing SRI 32-2,6-1,0 1

19 55707 Lock ring SGH 42 2

20 55708 Lock ring SGA 60 2

21 55708 Lock ring No 72240 1

23 55709 Grease nipple 1/8" 1

24 55709 Joint bearing GE25ES 2