P a g e | 1

Table of Contents

Introduction...........................................................................................................................3

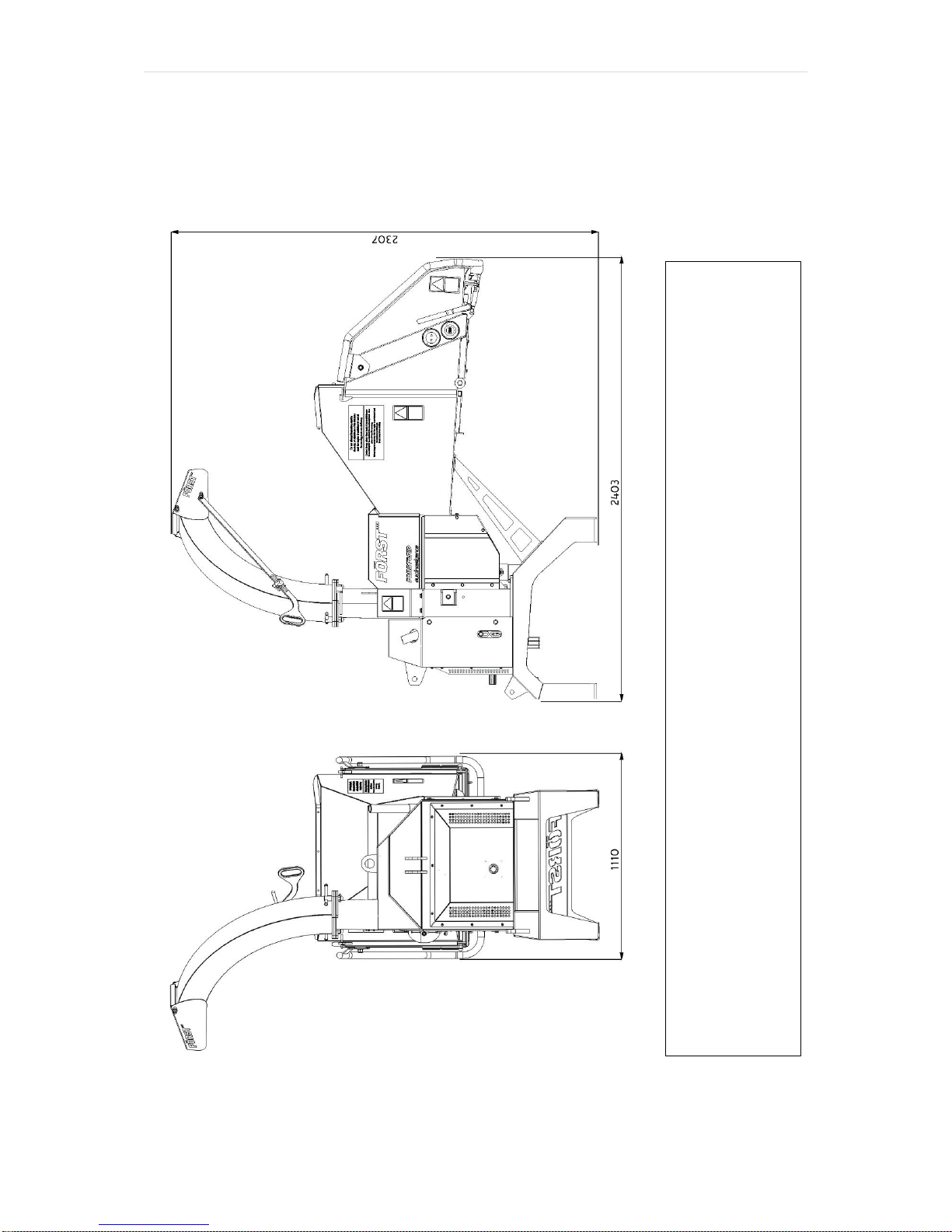

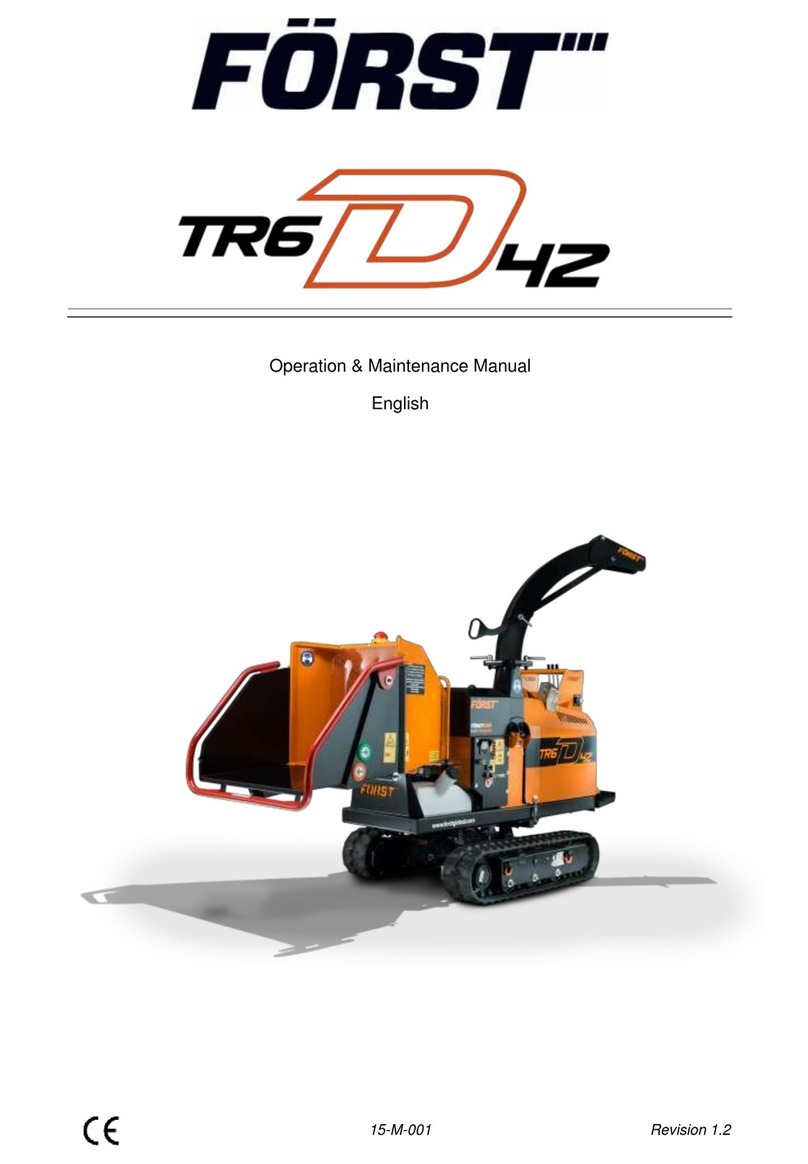

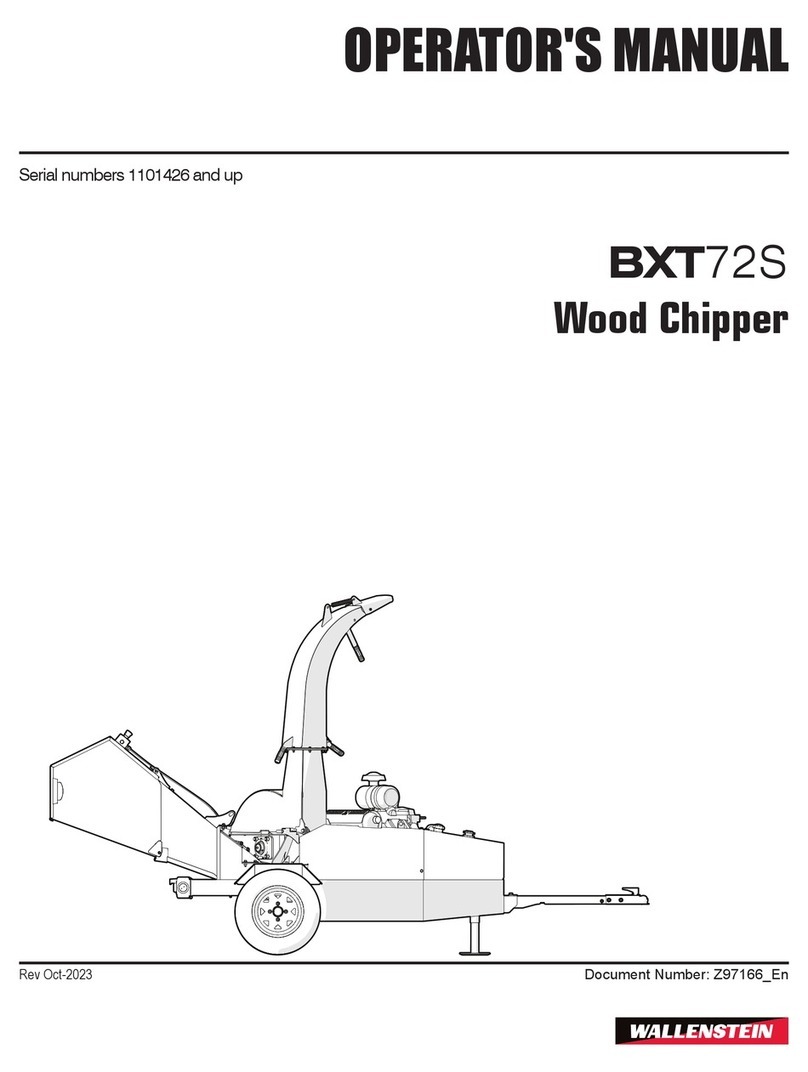

Purpose of machine..............................................................................................................4

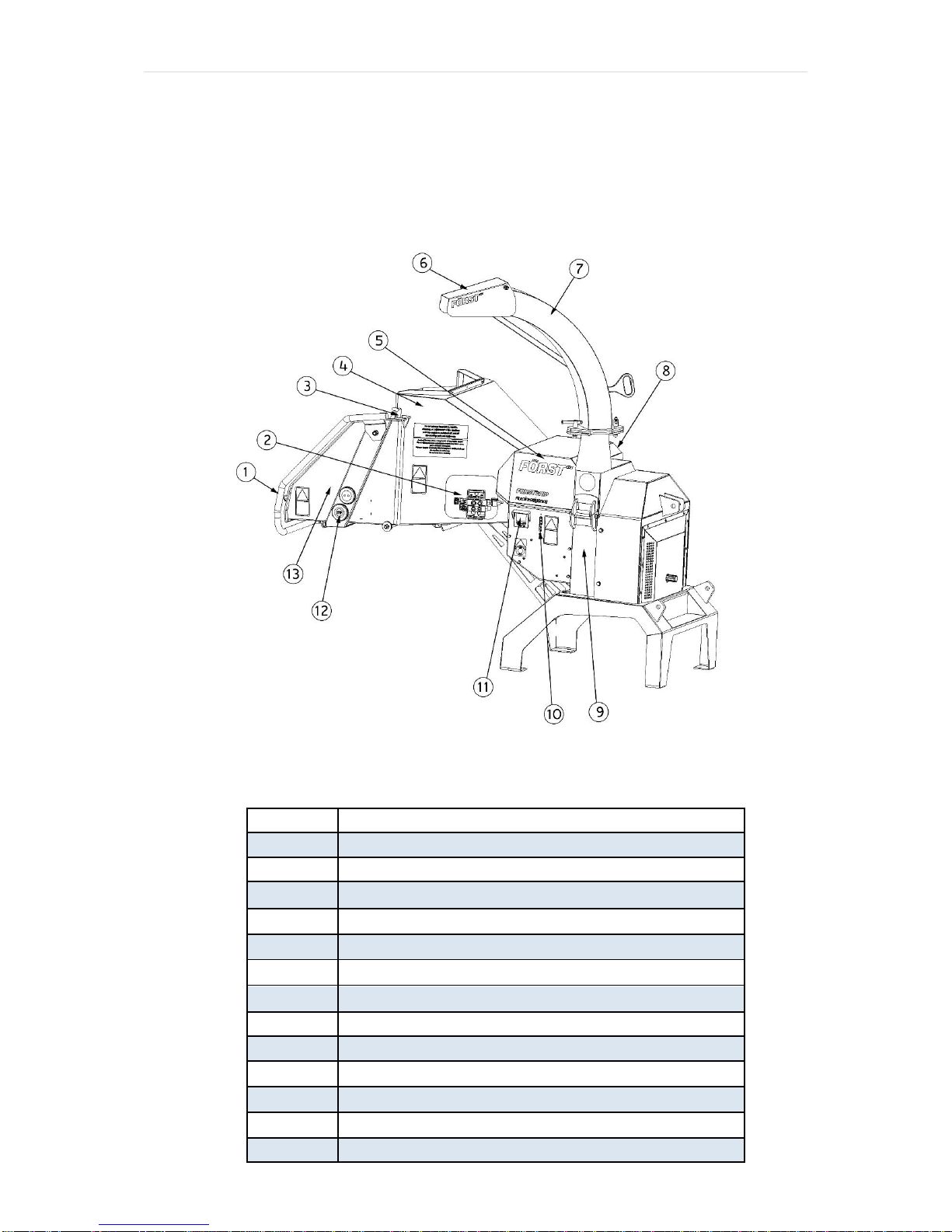

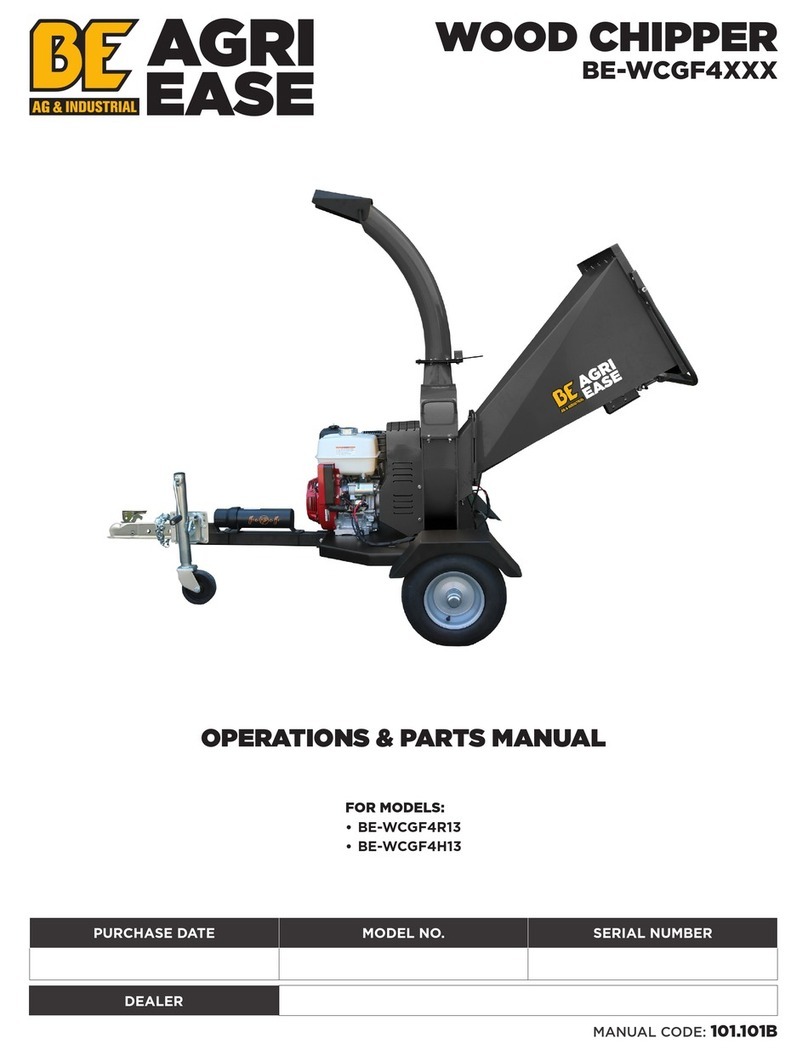

Exterior component identification ..........................................................................................5

Safe working .....................................................................................................................................6

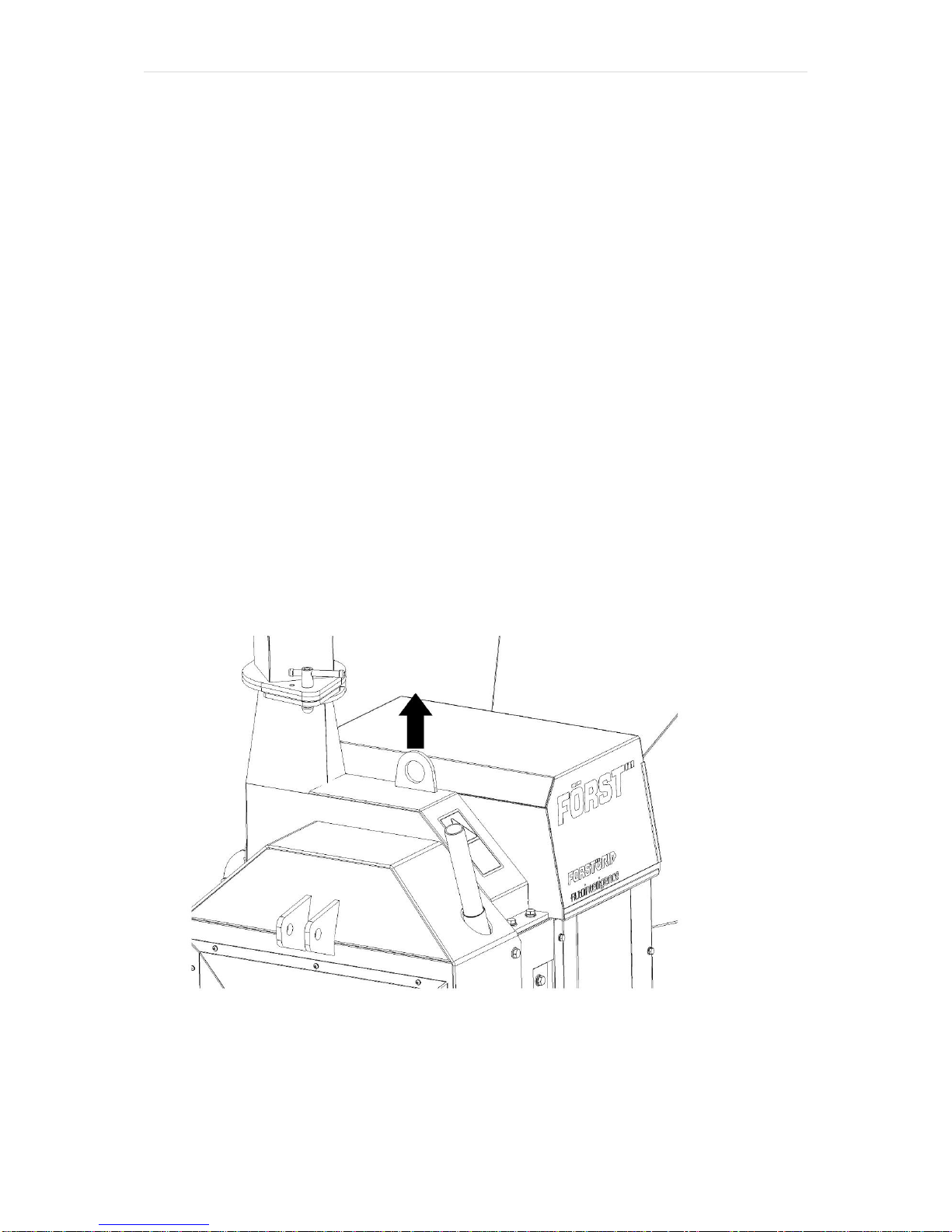

Machine lifting...................................................................................................................................7

DOs and DON’Ts .............................................................................................................................8

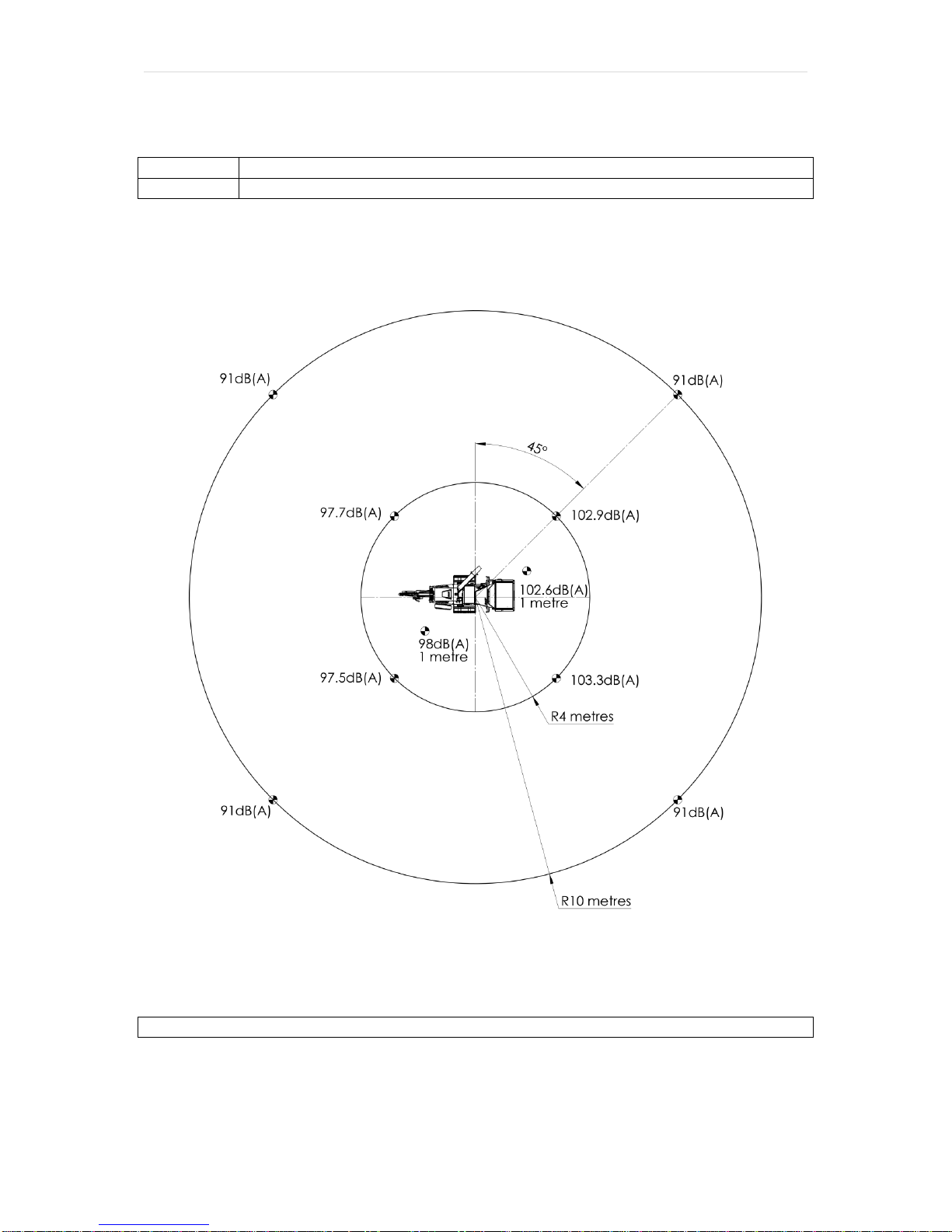

Noise test information ...........................................................................................................9

Machine operation ..............................................................................................................10

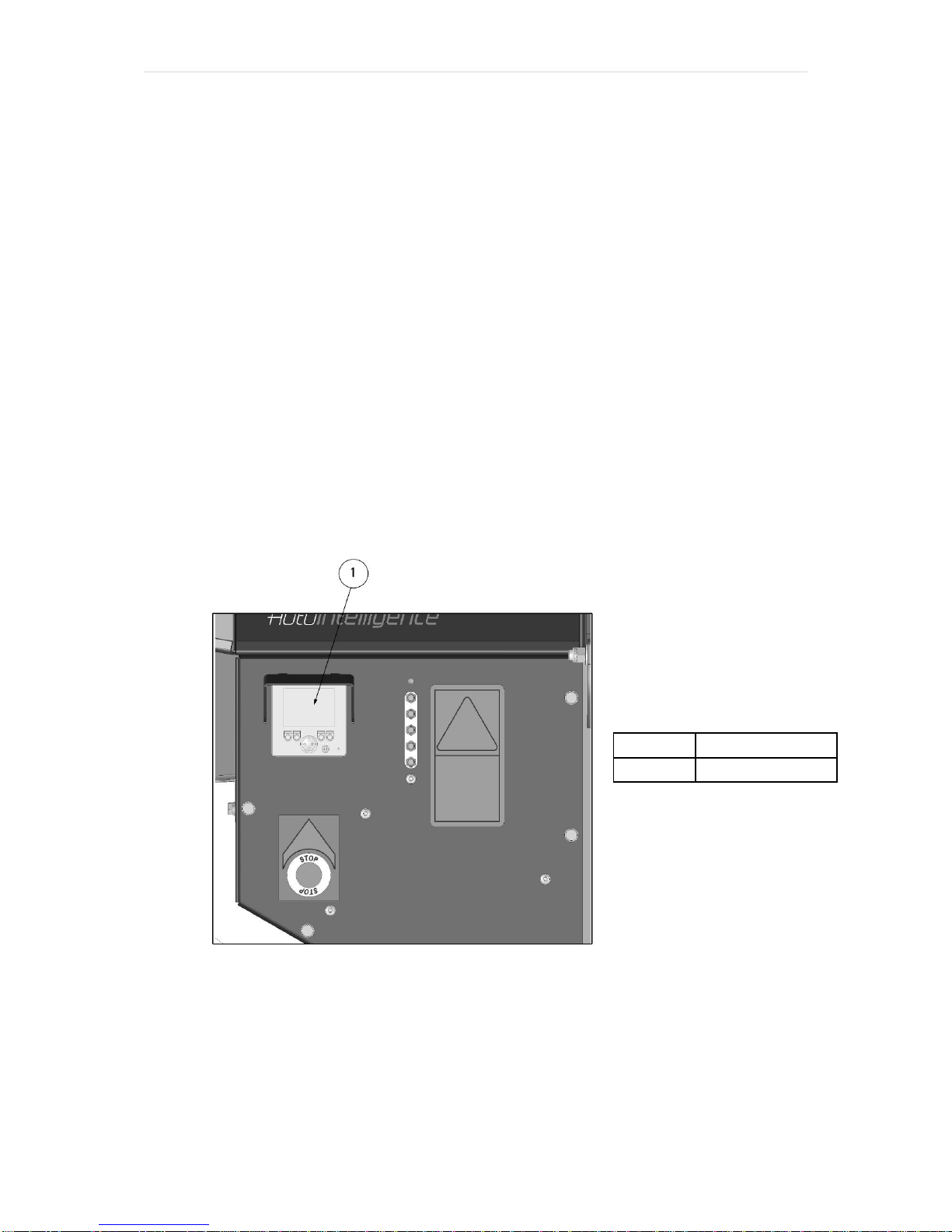

Machine control panel, start/stop & operating settings ............................................................11

Feed speed adjustment.................................................................................................................13

Feed jam & blockages.........................................................................................................13

Attaching to the Tractor.................................................................................................................15

Transportation.....................................................................................................................15

Stopping the Chipper.....................................................................................................................15

Disconnecting from the Tractor...........................................................................................16

Routine maintenance..........................................................................................................16

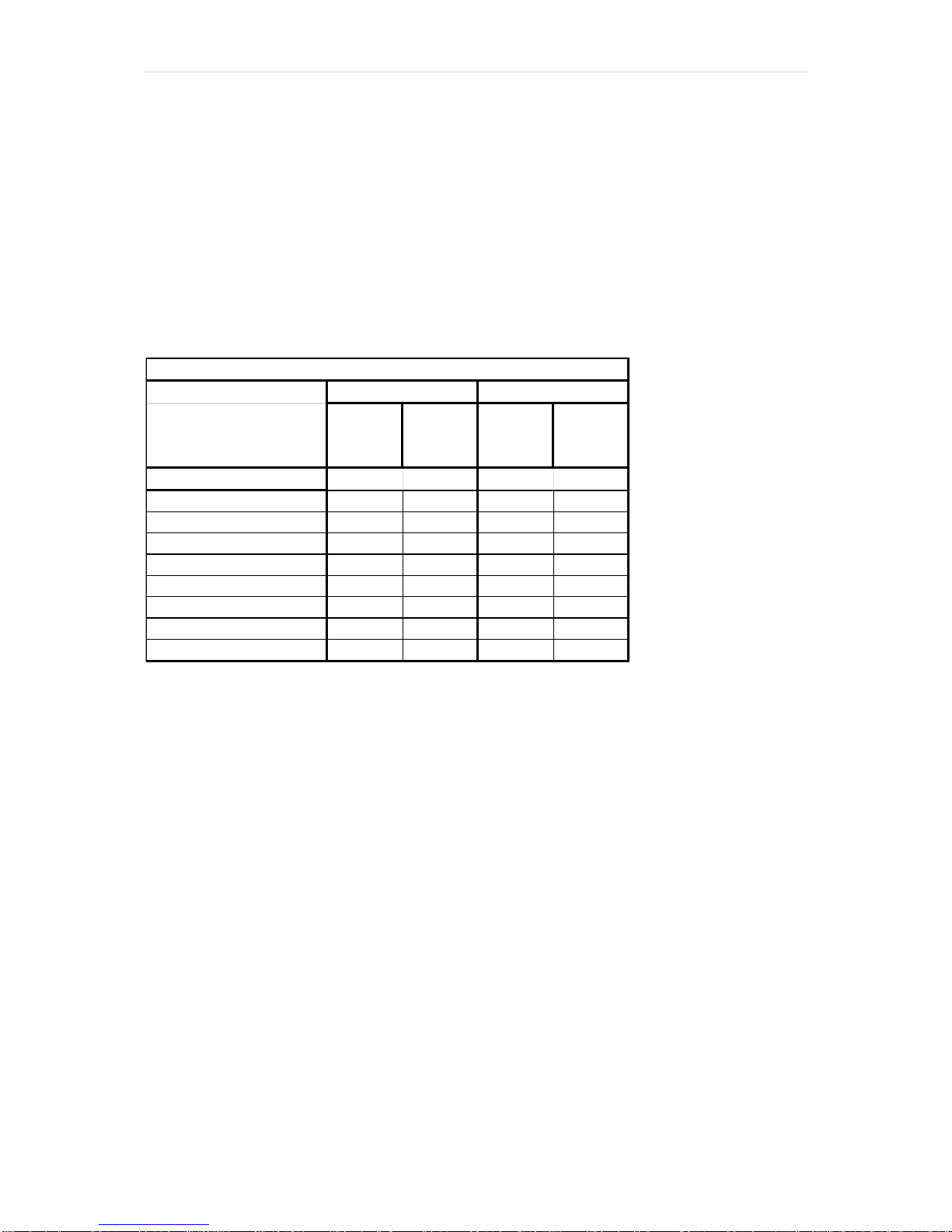

Fastener tightening torques..........................................................................................................17

Blade sharpening ...........................................................................................................................19

Hydraulic oil filter............................................................................................................................20

Drive belt tension............................................................................................................................22

Hopper tray touch sensor..........................................................................................................23

Chipping chamber assembly........................................................................................................24

Chipping chamber assembly - Bottom feed..............................................................................24

Chipping chamber assembly - Bottom feed & anvil.................................................................26

Chipping chamber assembly - Drive..........................................................................................27

Chipping chamber assembly - Flywheel drive..........................................................................28

Chipping chamber assembly - Bottom feed roller cover.........................................................29

Chute assembly............................................................................................................................30

Top feed roller assembly...............................................................................................................31

Flywheel assembly.........................................................................................................................32

Flywheel belt tensioner assembly...........................................................................................33

Hydraulic pump assembly.........................................................................................................34

PTO Assembly Parts………………………………………………………………..………………35

Hydraulics circuit diagram...................................................................................................36

Electrical circuit diagram –PTO touch sensor hopper.........................................................37