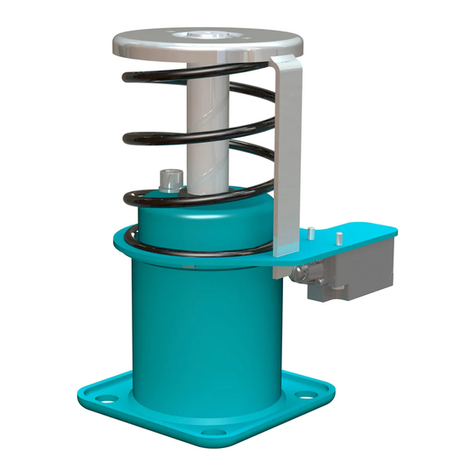

Figure 5

8

7OIL FILLING PROCEDURE

NOTICE

WARNING

The buer must be vertical and fully extended before filling with oil.

CAUTION

Take care when handling the oils. Observe the oil manufacturers recommendations.

DO NOT overfill past the maximum dipstick mark.

If this occurs, then oil must be removed from the buer.

1Unscrew the airscrew, remove from the buer and

keep safe. (GREEN in Figure 5).

2Unscrew the dipstick, remove from the buer and

keep safe. (GREY in Figure 5).

3 Gradually fill the buer with oil until the oil level is

visible between the minimum and maximum

levels on the dipstick (indicated on Figure 4).

4 Allow the buer to stand for a minimum of

30 minutes.

5 Re-insert the dipstick DO NOT screw down.

6 Remove dipstick and inspect level. The oil level

needs to be between the minimum and maximum

marks indicated on the dipstick as shown in Figure 4.

7 Once oil level is correct replace airscrew and

securely fasten.

8 Once oil level is correct replace dipstick and

securely fasten.

The oil must be within the correct operating range for the buer to perform

correctly. If further oil is required after checking repeat steps 1-8.