Tab e of Contents

Table of Contents

1 About this Document......................................................................................... 5

1.1 Target Audience..................................................................................................... 5

1.2 Objective of these Operating Instructions.................................................... 5

1.3 Identification of Information............................................................................. 5

1.3.1 Safety-re evant Information................................................................. 5

1.3.2 Non-safety-re ated Information..........................................................6

1.4 Abbreviations.......................................................................................................... 6

2 Safety.....................................................................................................................7

2.1 Changes to the Product...................................................................................... 7

2.2 Qua ification of Personne .................................................................................. 7

2.3 Intended Use........................................................................................................... 8

2.4 Residua Risks......................................................................................................... 8

2.4.1 Exp osion Protection................................................................................8

2.4.2 Working Environment B ade Manufacturing Faci ity....................8

2.4.3 Working Environment Wind Turbine...................................................8

2.4.4 Adhesives..................................................................................................... 9

2.5 Persona Protective Equipment........................................................................ 9

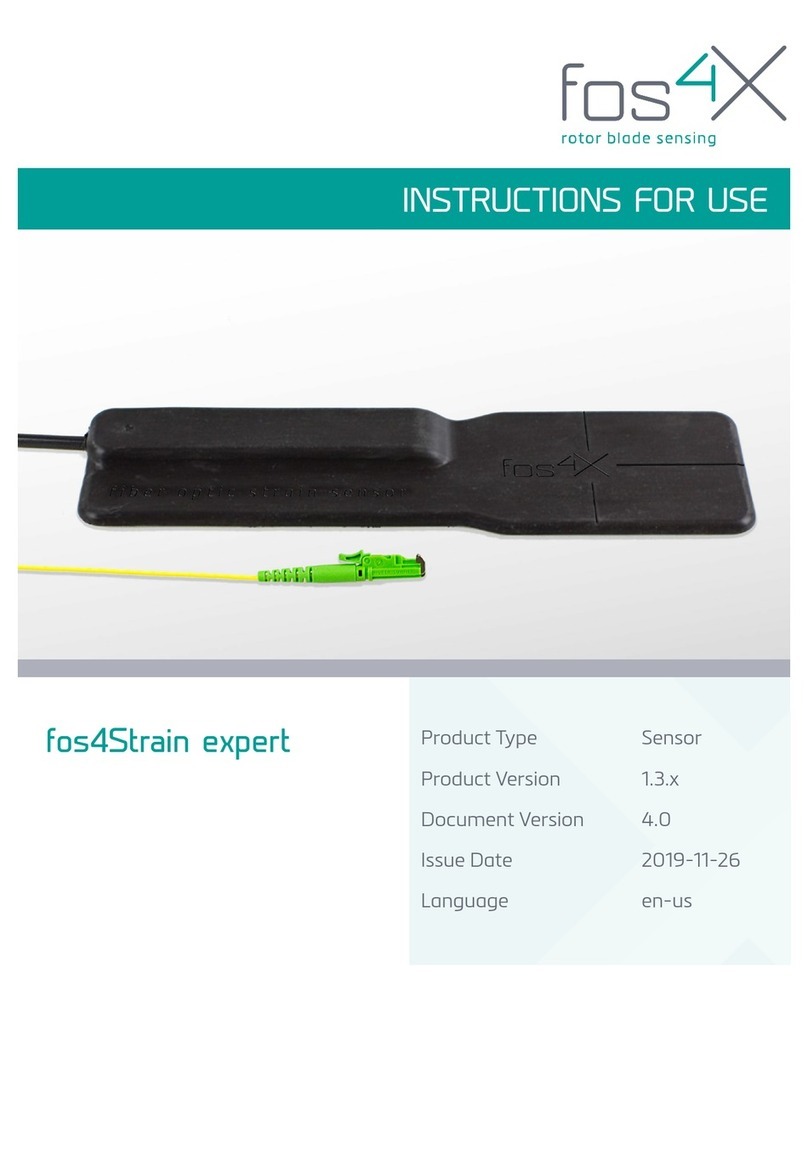

3 Product Descri tion........................................................................................... 11

3.1 Functiona Description........................................................................................ 11

3.1.1 Function.......................................................................................................11

3.1.2 Overview......................................................................................................11

3.1.3 Operation....................................................................................................12

3.1.4 Ca cu ation of strain............................................................................... 13

3.2 Technica Data.......................................................................................................13

3.2.1 Sensor Data...............................................................................................13

3.2.2 Optica Data..............................................................................................14

3.2.3 Cab e Data................................................................................................. 14

3.2.4 Mechanica Data..................................................................................... 14

© fos4X 2020 SEN1374_4-10_1.2.x_2.1_fos4Strain

patch_(2m, 1553nm, E-2000 green)-en-us 3 / 35