fos4X fos4Strain expert User manual

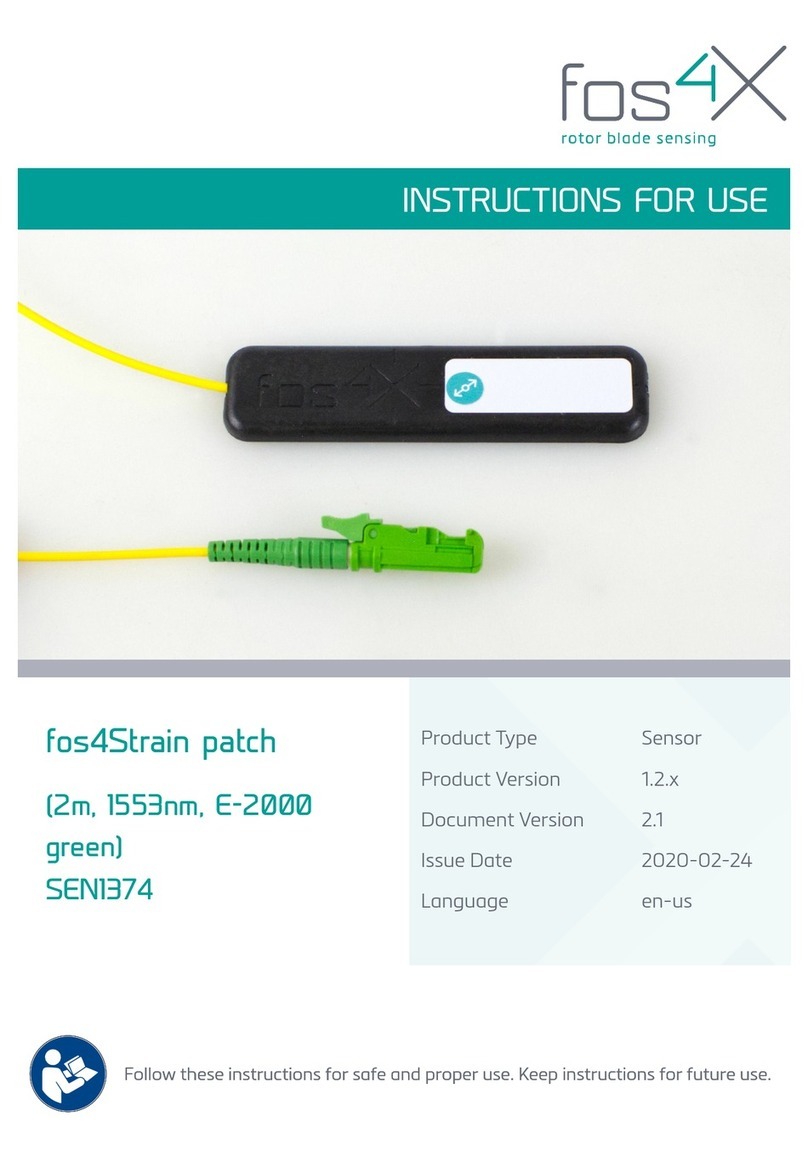

INSTRUCTIONS FOR USE

fos4Strain expert Product Type Sensor

Product Version 1.3.x

Document Version 4.0

Issue Date 2019-11-26

anguage en-us

INSTRUCTIONS FOR USE

fos4Strain expert Product Type Sensor

Product Version 1.3.x

Document Version 4.0

Issue Date 2019-11-26

anguage en-us

Imprint

Imprint

fos4X GmbH

Thalkirchner Str. 210

81371 Munich

Germany

Phone: +49 89 999542-00

Fax: +49 89 999542-01

www.fos4X.de

WEEE-Reg.-Nr. DE: 70390148

©2019 fos4X®

Distribution and reproduction of this document, exploitation and communication

of its contents are prohibited unless expressly permitted. Violations will result in the

liability for damages. All rights reserved in the event of patent, utility model or design

registration.

All rights reserved.

fos4X is a trademark of fos4X GmbH.

Brand names and protected trademarks are the property of their respective owners.

The naming of brand names and protected trademarks has only descriptive character.

Named trademarks are not part of any partnership or cooperation with fos4X.

2 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

Table of Contents

Table of Contents

1 About this Document......................................................................................... 6

1.1 Target Audience..................................................................................................... 6

1.2 Objective of these Operating Instructions.................................................... 6

1.3 Identification of Information............................................................................. 6

1.3.1 Safety-relevant Information................................................................. 6

1.3.2 Non-safety-related Information.......................................................... 7

1.4 Abbreviations...........................................................................................................7

2 Safety.................................................................................................................... 8

2.1 Changes to the Product......................................................................................8

2.2 Qualification of Personnel..................................................................................8

2.3 Intended Use........................................................................................................... 9

2.4 Residual Risks..........................................................................................................9

2.4.1 Explosion Protection................................................................................ 9

2.4.2 Working Environment Blade Manufacturing Facility....................9

2.4.3 Working Environment Wind Turbine...................................................9

2.4.4 Adhesives................................................................................................... 10

2.5 Personal Protective Equipment......................................................................10

3 Product Descri tion...........................................................................................12

3.1 Functional Description....................................................................................... 12

3.1.1 Function...................................................................................................... 12

3.1.2 Overview.....................................................................................................12

3.1.3 Operation....................................................................................................13

3.1.4 Calculation of strain............................................................................... 13

3.2 Technical Data...................................................................................................... 14

3.2.1 Measurement and Optical Data........................................................ 14

3.2.2 Cable Data................................................................................................. 14

3.2.3 Environmental Conditions....................................................................14

3.2.4 Mechanical Data..................................................................................... 15

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 3 / 42

Table of Contents

3.2.5 Dimensions................................................................................................ 16

3.3 Markings on the Product..................................................................................16

3.3.1 Type Plate.................................................................................................. 16

4 Packaging and Trans ort................................................................................. 17

4.1 Scope of Delivery................................................................................................. 17

4.2 Packaging................................................................................................................17

4.3 Unpacking...............................................................................................................18

4.4 Packing....................................................................................................................18

4.5 Transport................................................................................................................ 19

4.6 Storage.................................................................................................................... 19

5 Installation..........................................................................................................20

5.1 Important Safety Notes for Installation......................................................20

5.2 Preparing the Installation Position.................................................................21

5.3 Attaching the Sensor......................................................................................... 23

5.3.1 Attaching the Sensor with ergo 1665..............................................23

5.3.2 Attaching the Sensor with UHU P US B ACK............................... 27

5.4 Attaching the Cable............................................................................................32

5.5 Connecting a Sensor.......................................................................................... 33

6 Commissioning and O eration....................................................................... 35

7 Troubleshooting................................................................................................ 36

8 Maintenance.......................................................................................................37

8.1 Preventive Maintenance................................................................................... 37

8.2 Corrective Maintenance....................................................................................37

8.2.1 Cleaning E-2000/APC Connections................................................. 37

9 Taking out of Service and Dis osal............................................................... 39

9.1 Taking out of Service......................................................................................... 39

9.2 Disassembly..........................................................................................................40

4 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

Table of Contents

9.3 Disposal..................................................................................................................40

10 fos4X Su ort.................................................................................................... 41

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 5 / 42

1. About this Document

1 About this ocument

1.1 Target Audience

This documentation intended for technically trained personnel.

1.2 Objective of these Operating Instructions

These instructions for use describe all tasks for the intended use of the product.

1.3 Identification of Information

1.3.1 Safety-relevant Information

These o erating instructions contain the following safety information:

■Safety information in the Safety chapter applies to the entire use of the product.

See Safety, page 8.

■Safety notes at the beginning of a section apply to the entire section.

■Safety notes before a step apply to the entire following section.

Safety notes are shown in the operating instructions as follows:

DANGER Nature and cause of risk

Consequences

uMeasures to avoid the risk.

The safety notes with the signal words Caution and Notice have the following

meanings:

CAUTION Risk which, if not avoided, could result in minor injury.

NOTICE Risk which, if not avoided, will result in damage to property.

6 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

1. About this Document

1.3.2 Non-safety-related Information

TIP Advice on the optimal use of the product.

Symbols and Meaning

Table 1: Representation of the information in the operating instructions

Symbol Meaning

Task:

1. First step

2. Second step

Instruction with task and several steps

Task:

uStep Instruction with a single step

PResult Result of an instruction

List:

■Point 1

■Point 2

Enumeration with title

Identification of Information,

page Cross reference

Bold Text Highlighting of particularly important information

1.4 Abbreviations

CFRP Carbon Fiber Reinforced Polymer

GRP Glass-fibre reinforced plastic

GTIN Global Trade Item Number

IP International Protection

Max Maximum

Min Minimum

MTBF Mean Time Between Failures

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 7 / 42

2. Safety

2 Safety

2.1 Changes to the Product

Changes to the product may only be carried out by fos4X.

2.2 Qualification of Personnel

efinitions

■Instructed ersonnel: Personnel instructed in the tasks assigned to them.

■Trained ersonnel: Personnel trained in the operation and safe use of the

product.

■Qualified ersonnel: Personnel who, based on their specialist training, knowledge

and experience and knowledge of the relevant regulations, are able to assess the

work assigned to them and identify possible hazards.

Assignment of tasks

Tasks within the scope of use may only be carried out by the personnel defined below.

Table 2: Tasks

Task Personnel

Packaging and Transport Instructed personnel

Installation

Commissioning

Operation

Trained personnel

Troubleshooting Qualified personnel

Maintenance

Taking out of Service Trained personnel

Disassembly

Disposal

fos4X or specialized disposal

company

8 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

2. Safety

2.3 Intended Use

The sensor fos4Strain expert is optimized for use on GRP or CFRP in rotor blades.

For the use of the fos4Strain expert on other substrates, qualified personnel from

fos4X must be consulted.

Any other use or use going beyond this is considered improper use.

2.4 Residual Risks

2.4.1 Explosion Protection

The product is not suitable for use in potentially explosive environments.

2.4.2 Working Environment Blade Manufacturing Facility

The use of the product in blade manufacturing facilities requires special risk prevention

measures.

Risk revention measures in blade manufacturing facilities:

uObtain and observe safety and work regulations:

– Qualification and training of personnel

– Personal protective equipment

– Required permits

uEnsure that the use of the product is permitted on the wind turbine.

2.4.3 Working Environment Wind Turbine

The use of the product in wind turbines requires special risk prevention measures.

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 9 / 42

2. Safety

Measures for risk revention on wind turbines:

uObtain and observe safety and work regulations:

– Qualification and training of personnel

– Personal protective equipment

– Required permits

uEnsure that the use of the product is permitted on the wind turbine.

2.4.4 Adhesives

Adhesives can cause severe irritation and allergic skin reactions.

uAvoid skin contact.

uObserve the safety data sheet of the adhesive.

uUse personal protective equipment according to the safety data sheet of the

adhesive. See Personal Protective Equipment, page 10.

Fumes from adhesives can cause damage to health and allergic reactions.

uDo not inhale fumes.

uObserve the safety data sheet of the adhesive.

uUse adhesives only in sufficiently ventilated rooms.

Adhesives can cause severe environmental damage.

uObserve the safety data sheet of the adhesive.

uDispose of adhesives and adhesive packaging in accordance with applicable

environmental regulations.

2.5 Personal Protective Equipment

Protective Gloves

For all tasks where surfaces are heated:

uWear protective gloves with the following characteristics:

– General requirements according to DIN EN 420

– Protection against contact heat: Performance level 2 according

to DIN EN 407

10 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

2. Safety

For all tasks with adhesives:

uWear protective gloves according to EN ISO 374-1 (nitrile, min.

0.4 mm).

For all tasks with ergo. 1665:

uWear protective gloves according to EN ISO 374-1 (butyl, min.

0.5 mm).

Safety Goggles

For all tasks with adhesives:

uWear safety goggles with side protection according to DIN EN 166.

When grinding GRP:

uWear safety goggles with side protection according to DIN EN 166.

Protective Clothing

For all tasks:

uWear protective clothing (long-sleeved work clothing).

Respiratory Protection

When grinding GRP:

uWear respiratory protection with protection level A2 P2 according to

DIN EN 140.

For all tasks with ergo. 1665:

uIn case of insufficient ventilation: Wear respiratory protection with

protection level A P2 according to DIN EN 140.

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 11 / 42

3. Product Description

3 Product escription

3.1 Functional escription

3.1.1 Function

The fos4Strain expert is a fiber-optical strain sensor based on a fiber-Bragg grating.

The sensor was developed for the strain monitoring of composite structures and in

particular of rotor blades of wind turbines.

The sensor has passive temperature compensation adapted to the expansion

coefficient of the structure.

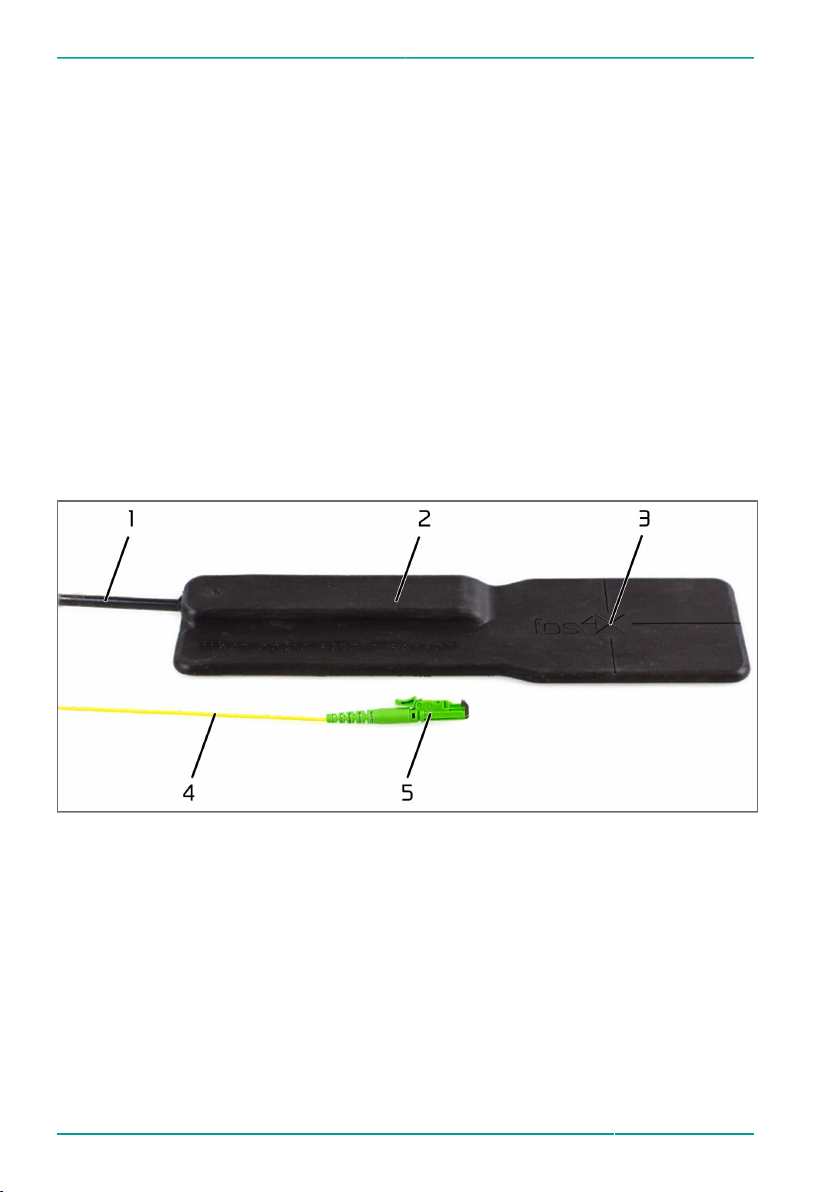

3.1.2 Overview

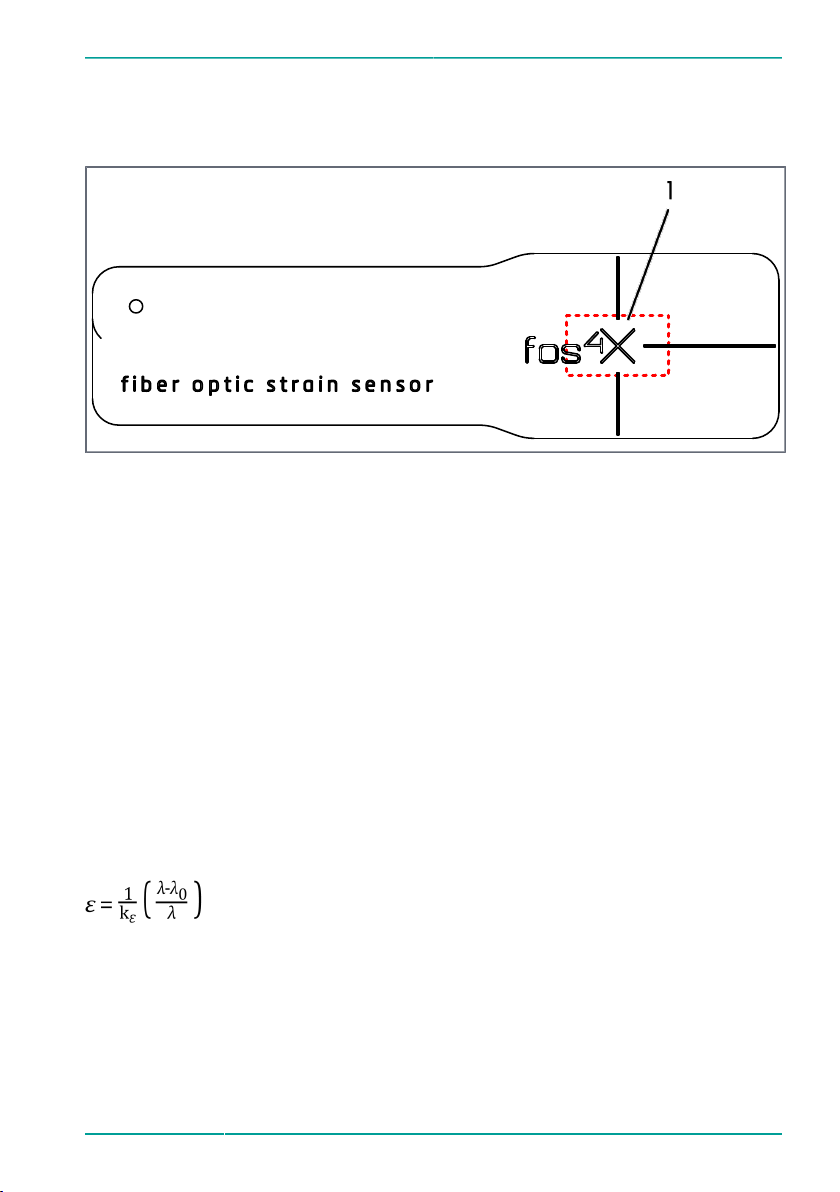

Figure 1: Overview

1Cable with step protection

2Sensor with step protection

3Centre of the measuring range

4Fan-out cable without step protection

5E-2000/APC connector

The fos4Strain ex ert consists of the following com onents:

■Sensor with GRP base plate and step protection.

■Cable with step protection and E-2000/APC connector.

12 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

3. Product Description

3.1.3 Operation

Figure 2: Centre of the measuring range

1Measuring range

The position of the sensor is selected so that the measuring range of the sensor

measures a defined strain of the structure. See Fig. 2: Centre of the measuring range,

page 13.

The surface of the structure is prepared so that the surface is flat, dust-free and dry.

The sensor is then glued to the structure with ergo. 1665 or UHU P US B ACK.

The sensor is connected to a compatible measuring device.

The wavelength of the sensor can then be used to determine the strain of the

structure. See Calculation of strain, page 13.

3.1.4 Calculation of strain

The strain is calculated on the basis of the measured wavelength difference as follows:

(ε: Strain; kε: k-factor; λ: current wavelength; λ0: rest wavelength)

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 13 / 42

3. Product Description

3.2 Technical ata

3.2.1 Measurement and Optical ata

For technical data on the measurement and optical properties, see the sensor data

sheet.

Data sheets available at www.fos4x.de/en/downloads.

3.2.2 Cable ata

Table 3: Cable Data

Pro erty Value Unit

ength *See type plate -

Diameter (cable with step protection) 6 ± 0.5 mm

Min. Bending radius (cable with step

protection) 50 mm

Min. bending radius (fan-out cable) 15 mm

Cable exchangeable No -

Connector type E-2000/APC -

* ength from sensor end to connector end.

3.2.3 Environmental Conditions

Table 4: Environmental Conditions

Pro erty Value Unit

IP protection class*IP67 -

Maximum operating altitude 3000 m

Permitted temperature

(Transport and storage) -40 … +80 °C

Permitted relative humidity

(Transport and storage) 0 … 95 %

Permitted temperature

(Operation) -40 … +55 °C

14 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

3. Product Description

Pro erty Value Unit

Permitted relative humidity

(Operation) 0 … 95 %

* The specified protection class only applies if the cable connections have the same or a higher

protection class.

3.2.3.1 Load cycles and MTBF

Table 5: oad cycles and MTBF

Pro erty Value Unit

oad cycles at ±1000 µm/m 108-

MTBF >400 Years

3.2.4 Mechanical ata

Table 6: Mechanical Data

Pro erty Value Unit

ength 260 mm

Height 12 mm

Width 70 mm

Total weight*0.2 kg

* fos4Strain expert without cable and packaging

Installation

Table 7: Installation

Pro erty Value Unit

Installation method Glued -

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 15 / 42

3. Product Description

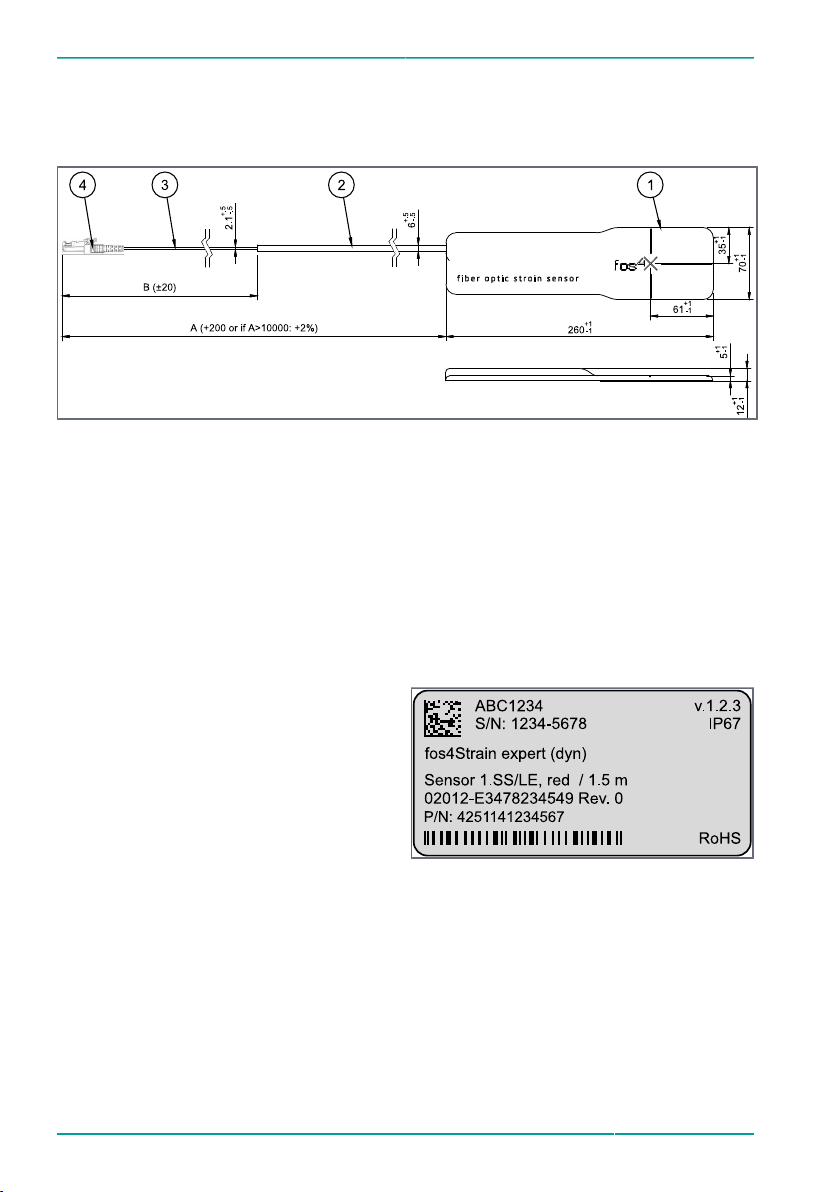

3.2.5 imensions

Figure 3: Dimensions

1fos4Strain expert

2Cable with step protection

3Fan-out cable without step protection

4E-2000/APC connector

ACable length total

BCable length fan-out

3.3 Markings on the Product

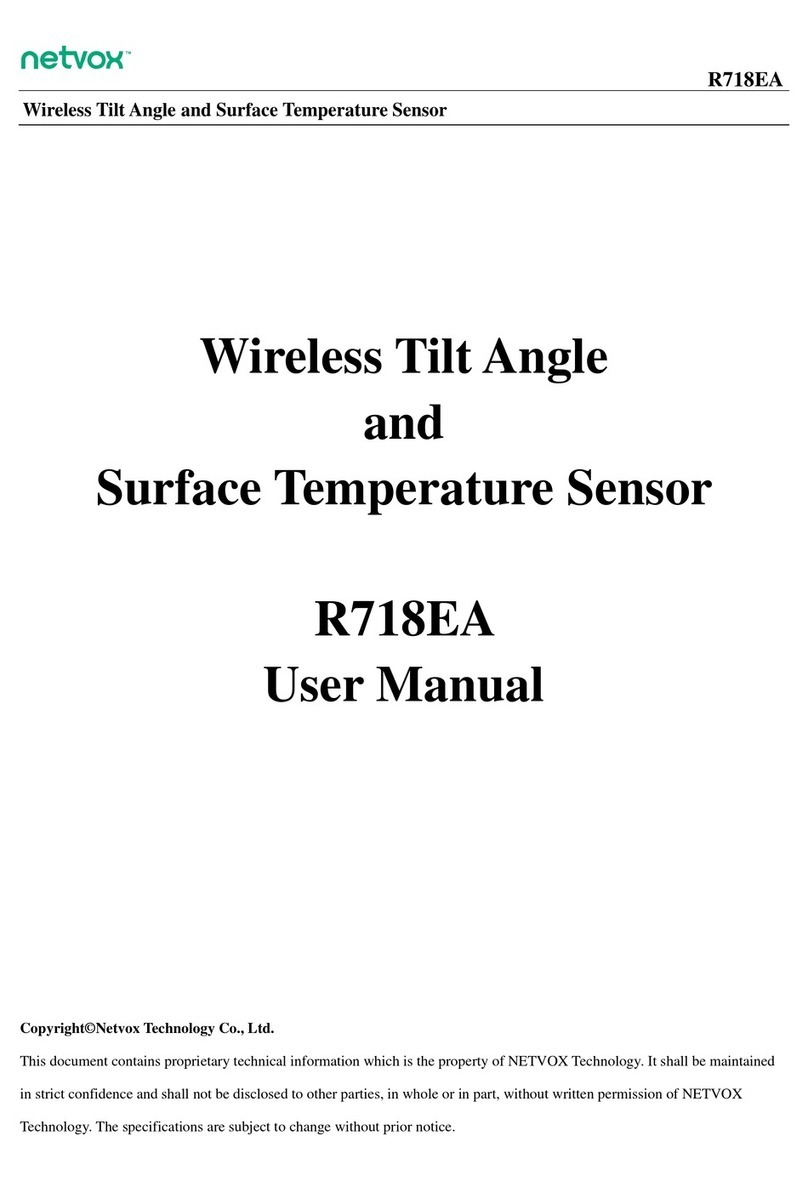

3.3.1 Type Plate

Contents of the ty e late (exam le data

from gra hic):

■QR-code of the serial number

■Product category and number:

ABC1234

■Product version: v1.2.3

■Serial number: S/N: 1234-5678

■IP protection class: IP67

■Product name: fos4Strain expert

(dyn)

■Other product data: Color marking,

cable length.

■GTIN: P/N: 4251141234567

Figure 4: Type Plate

16 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

4. Packaging and Transport

4 Packaging and Transport

4.1 Scope of elivery

The fos4Strain ex ert is delivered with the following sco e of delivery:

■1x fos4Strain expert

■1x Test certificate outgoing goods

4.2 Packaging

TIP uKeep the transport packaging.

In the original packaging, the product is best protected for

transport.

The fos4Strain expert is packed in a box.

One box contains up to

6 fos4Strain expert.

The box has the dimensions

180 x 390 x 410 mm (length x width x

height).

Figure 5: Packaging

The box has the following transport and storage conditions:

Table 8: Transport and storage conditions of the packaging

Pro erty Value Unit

Permitted temperature

(Transport and storage) -40 ... +80 °C

Permitted relative humidity

(Transport and storage) 0 ... 50 %

Max. Storage duration 5 Years

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 17 / 42

4. Packaging and Transport

4.3 Unpacking

Un acking the fos4Strain ex ert:

1. Open the box.

2. Remove the fos4Strain expert from the box.

3. Check the scope of delivery. See Scope of Delivery, page 17.

4. If parts of the scope of delivery are missing: Contact fos4X Support. See fos4X

Support, page 41.

4.4 Packing

NOTICE Damage to the fiber-optical cables.

Too small bending radii and kinks can irreparably damage the

fibers in fiber-optical cables.

uObserve the min. bending radii of the cable. See

Technical Data, page 14.

uDo not kink fiber optical cables.

Packing the fos4Strain ex ert in the original ackaging:

1. Wind up the fos4Strain expert and cable. Min. bending radius of the cable 50 mm.

2. Open the box.

3. Put the fos4Strain expert in a compartment of the box.

4. Close the box.

Pfos4Strain expert ready for transport or shipping.

Alternative: Packing the fos4Strain ex ert in a different ackaging:

1. Wind up the fos4Strain expert and cable. Min. bending radius of the cable 50 mm.

2. Select a box so that the fos4Strain expert with padding material fits into the box.

3. Open the box.

18 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

4. Packaging and Transport

4. Pack the fos4Strain expert in the box with padding material. Make sure the

fos4Strain expert is protected against shocks from all sides.

5. Close the box.

Pfos4Strain expert ready for transport or shipping.

4.5 Transport

Trans orting the fos4Strain ex ert:

uHandle the fos4Strain expert with care during transport.

uObserve the transport conditions. See Environmental Conditions, page 14.

uPack the fos4Strain expert in a transport packaging. See Packing, page 18.

4.6 Storage

Storing the fos4Strain ex ert:

uStore the fos4Strain expert in a dry and clean place.

uStore the fos4Strain expert in a transport packaging. See Packing, page 18.

uObserve the environmental conditions. See Environmental Conditions, page 14.

© fos4X 2019 4-10_1.3.x_4.0_fos4Strain expert-en-us 19 / 42

5. Installation

5 Installation

uObserve the safety instructions. See Safety, page 8.

5.1 Important Safety Notes for Installation

For all tasks:

NOTICE Damage to the fiber-optical cables.

Too small bending radii and kinks can irreparably damage the

fibers in fiber-optical cables.

uObserve the min. bending radii of the cable. See

Technical Data, page 14.

uDo not kink fiber optical cables.

When working with ergo 6305 or Sikaflex-512UV:

CAUTION Severe irritations and allergic reactions caused by contact

with adhesive.

uWear protective gloves according to EN ISO 374-1 (nitrile,

min. 0.4 mm).

uWear safety goggles with side protection according to

DIN EN 166.

uObserve the safety data sheet of the adhesive.

CAUTION Health damage and allergic reactions caused by inhalation of

adhesive fumes.

uDo not inhale fumes.

uEnsure adequate ventilation.

uObserve the safety data sheet of the adhesive.

20 / 42 4-10_1.3.x_4.0_fos4Strain expert-en-us © fos4X 2019

Table of contents

Other fos4X Accessories manuals

Popular Accessories manuals by other brands

Gaggenau

Gaggenau CA 060 600 instruction manual

LU-VE

LU-VE F31HC Series Installation, Operation, Service and Maintenance Instructions

HoMedics

HoMedics COMFORT PRO TRANSFORM HCM-T210GYQVC-GB instruction manual

Emos

Emos P5712 manual

netvox

netvox R718EA user manual

Rice Lake

Rice Lake MSI-8000HD Technical manual