Equip ent and Accessories

In addition to the kit contents you will need some accessories, R/C, and small hardware items to

complete your ‘Komet’. Below are our recommendations, from experience with the prototypes.

Motor: The Komet has been designed primarily for electric flight, for a Speed-400 sized

motor of 400 - 700 watts. We used a Mega-motor 16/15/3 (400 watt) in the first prototype, which

gave more than adequate performance and ran very cool. Currently we are using a 700 watt Ty-

phoon 2W-20 from Overlander Technologies, which gives amazing performance and easy hand-

launches, even in zero-wind conditions. With both motors we’ve been using APC thin & raupner

CAM electric propellers, both 4.75 x 4.75” size, and can recommend these. Larger props provide

too much load, and can lead to overheating of system components.

Speed-Controller (ESC): You will need a suitable speed-controller (with BEC circuit) that matches

your chosen electric motor and battery packs. Please follow the recommendations of the motor

supplier for the rating. For the 700 watt motor we have been using a ‘Castle Creations’ Phoenix

60 amp unit, which has been working very well indeed on both 3S1P and 4S1P Lipo packs.

The power package for this plane was developed in conjuction with Overlander Technologies in

the UK (www.overlander.co.uk). It is very important to have a well matched combination of motor,

ESC and batteries for good performance, without overheating any of the system components.

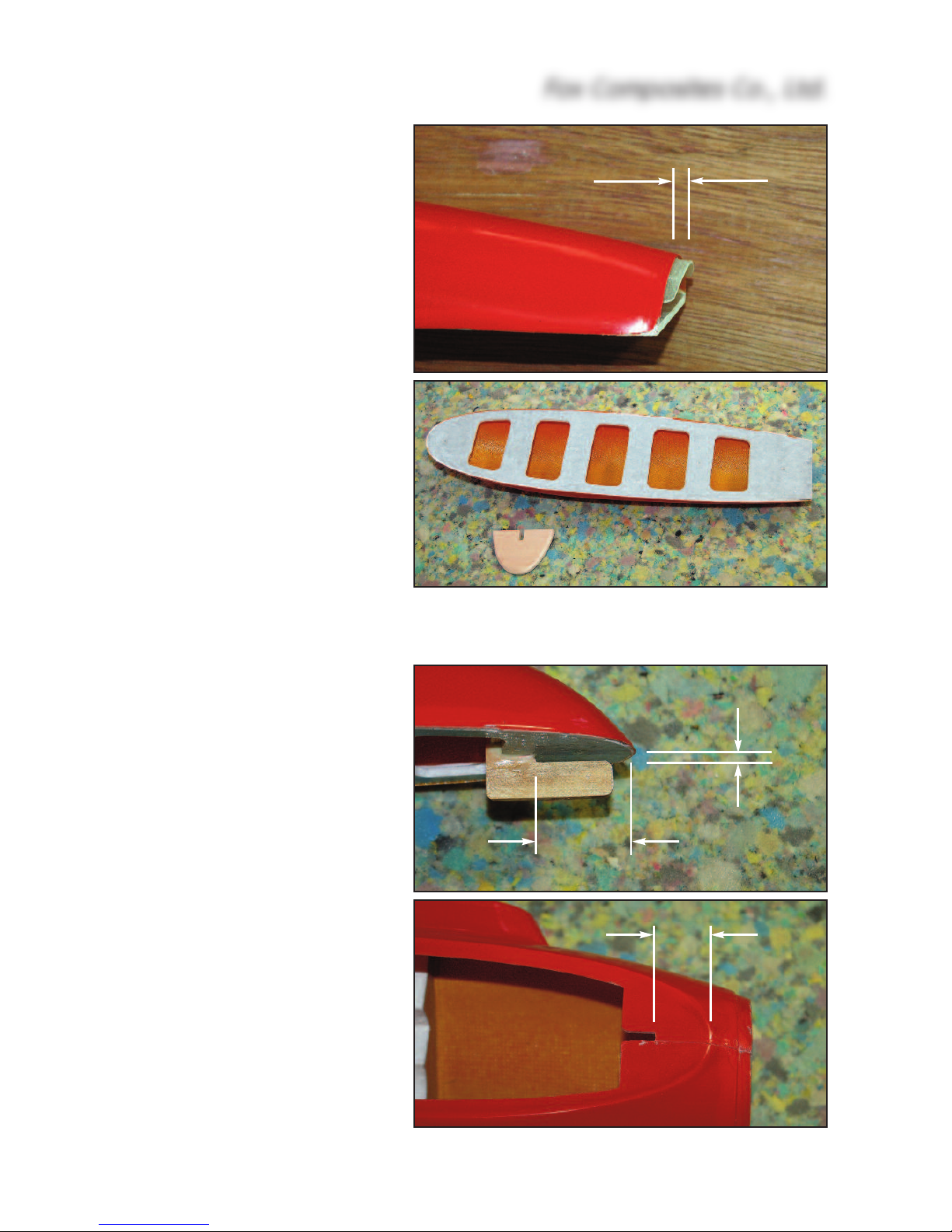

Flight batteries: Any good quality 3S1P or 4S1P Lipo pack of at least 2200mAH will be fine. Ex-

pect about 3.5 - 4.5 minute flights with a battery of this capacity. We are currently using Kokam

2200 (3S) and 3200 (4S) packs.

Ser os: You will need 2 ‘thin’ digital wing servos for the elevons, of minimum 3.5kg torque,

such as the JR DS161 or Hitec HS-5125 M , and the servo mounts are milled to suit these. If you

fit the optional rudder, then any mini servo of min. 2.5kg torque should be sufficient.

About the Me-163 ‘Ko et’

The Fox Composites ‘Komet’ was designed as a semi-scale electric ‘fun-fly’ model. Normally the

model is hand-launched, but you could also use a very short bungee system if you fly on your

own. Performance is sparkling with a 700 watt motor, with shallow dive speeds of over 130 mph

(200 kph), and you have to be careful to keep it within eyesight range. It is fully aerobatic and will

perform all the usual manoeuvres that a tail-less plane is capable of, and it has great gliding char-

acteristics. If you chose to fit the (optional) rudder you will be surprised at the excellent knife-edge

flight, which has no roll-coupling at all. Landing is also easy as it is very docile at slow speeds.

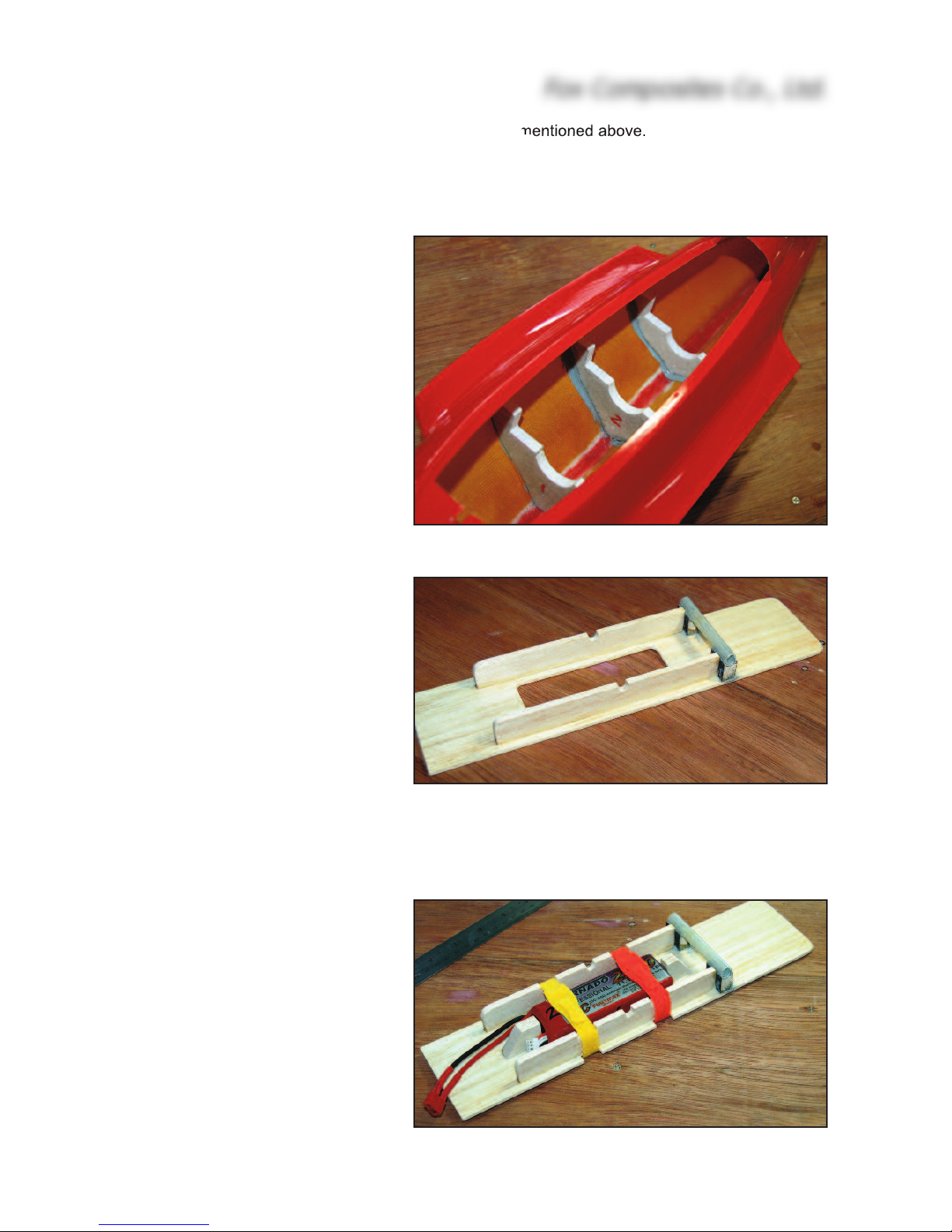

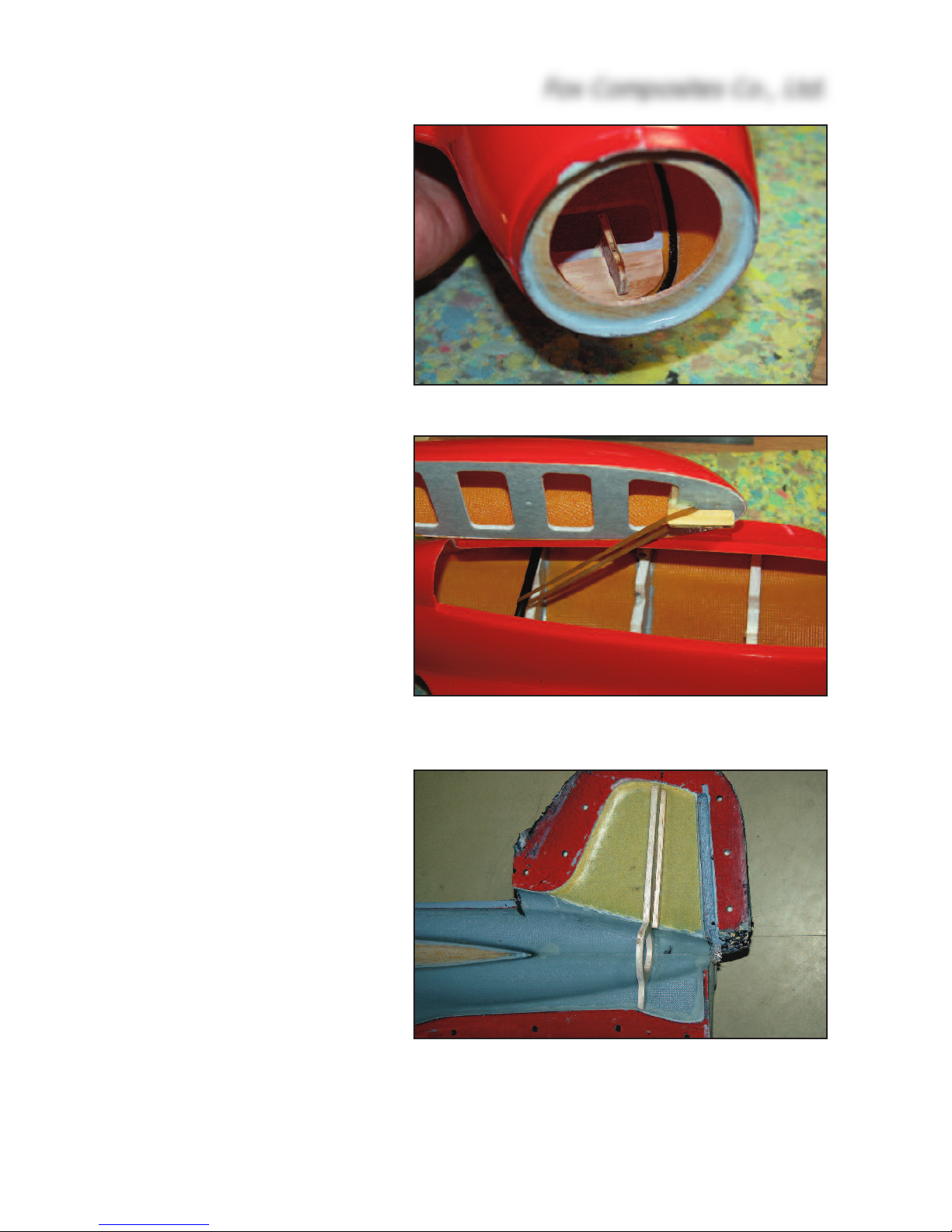

During testing of the 3 prototype models we ex-

perimented with the fitting of a small .15 glow

motor (Thunder Tigre .15), but the results were

rather disappointing ! It was much more work to

build, slightly heavier, noisy, dirty ... and did not

have the performance and ‘fun-factor’ of the elec-

tric versions. However we have included a couple

of photos of the glow motor installation, and a fi-

breglass fairing for the muffler is available as an

option, for anyone that wants to fit a small 2-

stroke motor.

Fox Composites Co., Ltd.

5