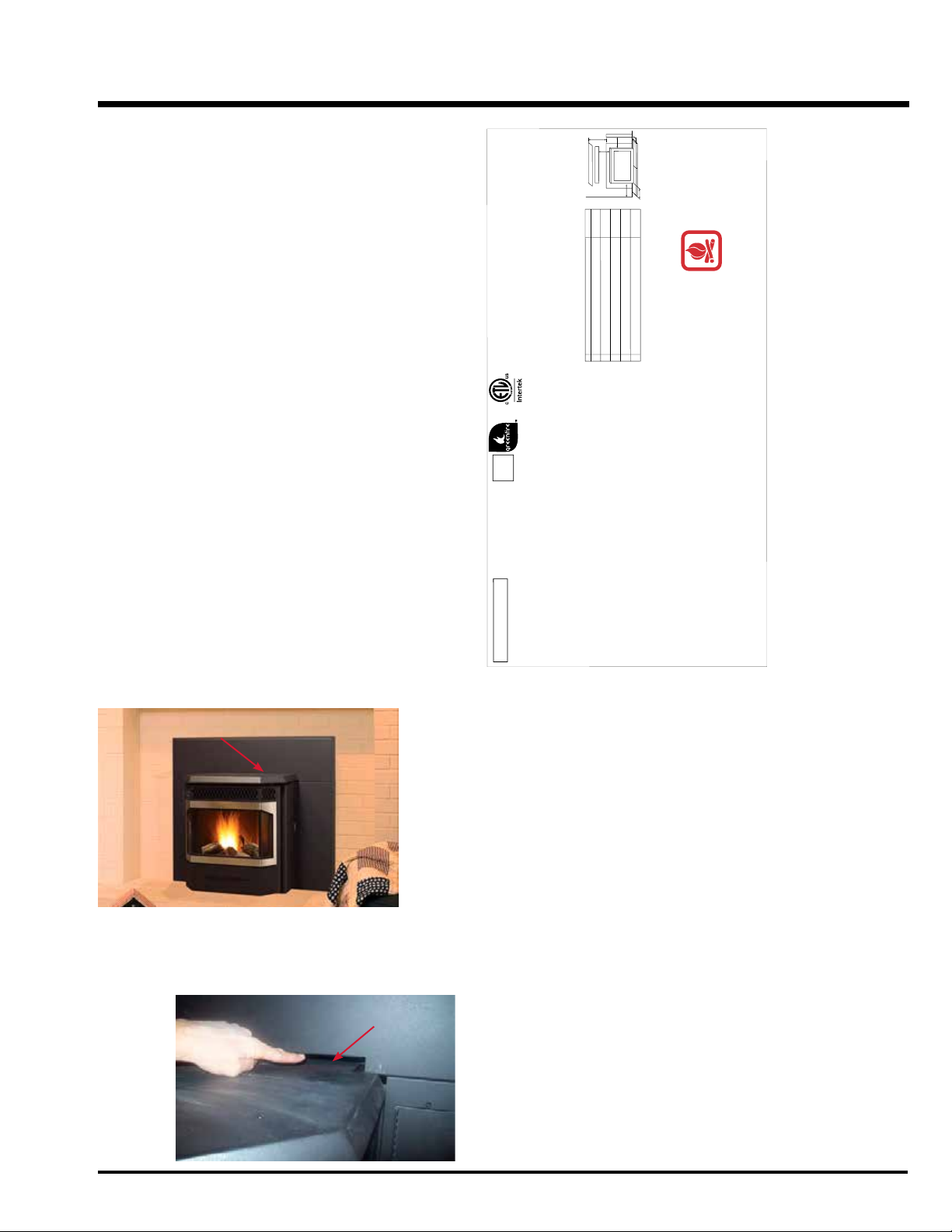

faceplate.

Certified for use in Canada & USA

Certifié pour installation au

Canada et aux Etats-Unis.

DATE OF MANUFACTURE /

DATE DE FABRICATION:

J F M A M J J A S O N D 2022 2023 2024 2025 2026

CAUTION:

Hot while in operation. DO

NOT touch, keep children,

clothing & furniture away.

Contact may cause skin

burns. See nameplate &

instructions

ATTENTION:

Chaud pendant le fonctionnement.

NE PAS toucher, garder les enfants,

les vêtements et les meubles à

distance. Tout contact peut

provoquer des brûlures de la peau.

Voir plaque signalétique et

instructions

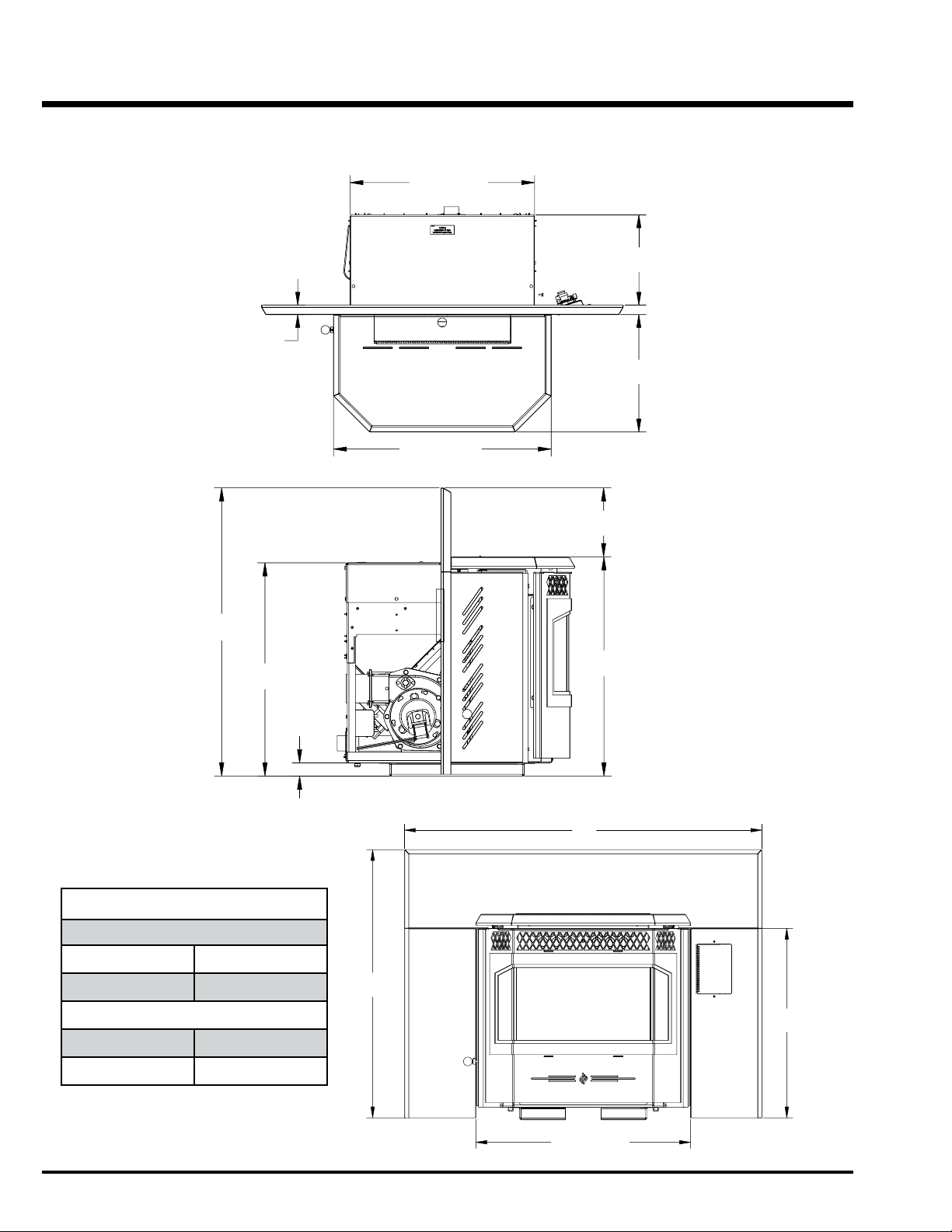

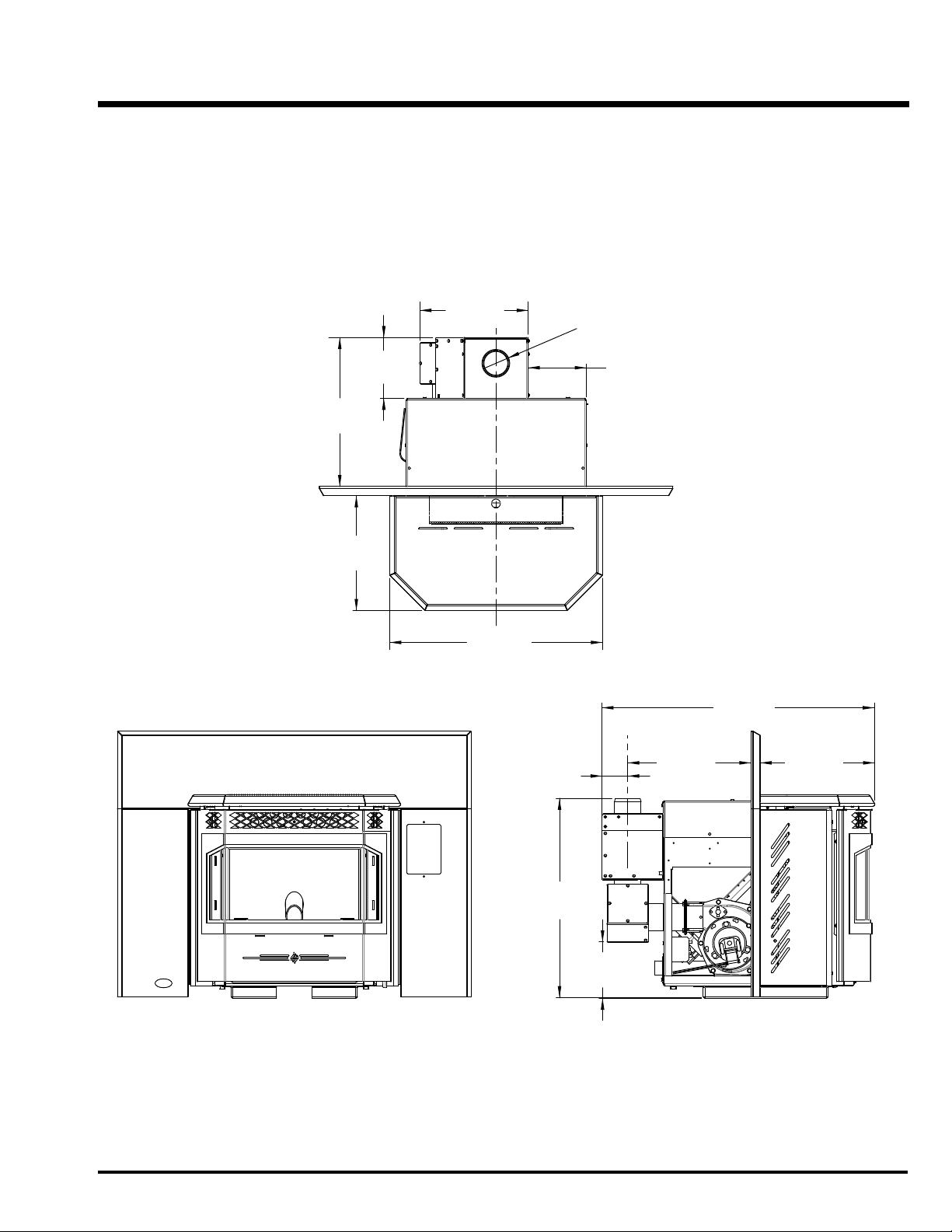

A Sidewall to Unit (Du mur latéral à l'appareil) 8” (203 mm)

B Top of unit to an unshielded 8” (203 mm) mantle

(Du sommet de l'appareil à un manteau de foyer non blindé) 8” (203 mm)

C Unit to top facing (protruding ¾” [19 mm])

(

De l'appareil au sommet du parement (dépassant de ¾ po [19 mm])

8” (203 mm)

D Unit to side facing (protruding ¾” [19 mm])

(

De l'appareil au côté du parement (dépassant de ¾ po [19 mm])

8” (203 mm)

E From door opening of unit to edge of floor protection

(De l'ouverture de la porte de l'appareil au rebord de la protection de plancher)

6” (152 mm)

F From side of unit to edge of floor protection

(Du côté de l'appareil au rebord de la protection de plancher) 6” (152 mm)

Combustible floors must be protected by a non-combustible material. - See Owners Manual. Le

plancher combustible doit être protégé par un matériel non combustible. - Consulterle manuel.

B

A

D

C

Adjacent wall / Mur adjacent

FE

FPI Model /

modèle

920-623

580

Serial No. / No. de série:

Greenfire Model / Modèle:

GFI55-2

(insert/encastrable)

Manufactured in Canada for /

Fabriqué au Canada pour:

FPI Fireplace Products

International Ltd.

Delta, BC, Canada

PFS TECO

REPORT

#21-695

Refer to Intertek’s Directory of Building Products for detailed information. / Reportez-vous à

l'annuaire Intertek des produits du bâtiment pour obtenir des informations détaillées.

Ouput Rating (puissance de sortie): 7,751 to 32,739 BTU/Hr (2.27 to 9.59 kWh)

Listed Room Heater, Pelletized Fuel Type (Appareil de chauffage à granules certifié)

Suitable For Mobile Home Installation (approuvé pour installation dans une maison mobile)

Certified to (agréé):

ULC-S628-93 (R 2016), ASTM E1509-22

This pellet appliance has been tested and listed for use in manufactured homes in accordance with Oregon Administration Rules 814-23-900 through 814-23-909.

Install and use only in accordance with the Manufacture’s installation and operating instructions. Contact local building or fire officials about restrictions and

installation inspection in your area. Do not connect this unit to a chimney flue serving another appliance. See local building codes and manufacturers instructions

for precautions required for passing a chimney through a combustible wall or ceiling. Electrical rating: 120 volts, 60 hz, 4.3 Amps. Route cord away from the

heater / Cet appareil a été testé et certifié pour être utilisédans des maisons mobiles en accord avec les règles administratives de l'Oregon 814-23-900 à

814-23-909. Installeret utilisercet appareil seulement selon les instructions d'installation et d'utilisation du fabricant. Contacterles autorités locales concernant les

restrictions et les inspections d'installation. Ne pas raccorder cet appareil à une cheminée desservant un autre appareil. Consulterles codes dubâtiment locaux et

les instructions du fabricant pour les précautions à prendre lorsqu'une cheminée doit être installée à travers un mur ou un plafond combustible. PUISSANCE

ÉLECTRIQUE : 120 Volts, 60 Hz, 4.1 Amps. Placerle câble électrique loin de la chaleur.

For Use With Only Pelletized Wood fuels. Keep viewing and ash removal doors tightly closed during operation. Only replace glass with ceramic glass.

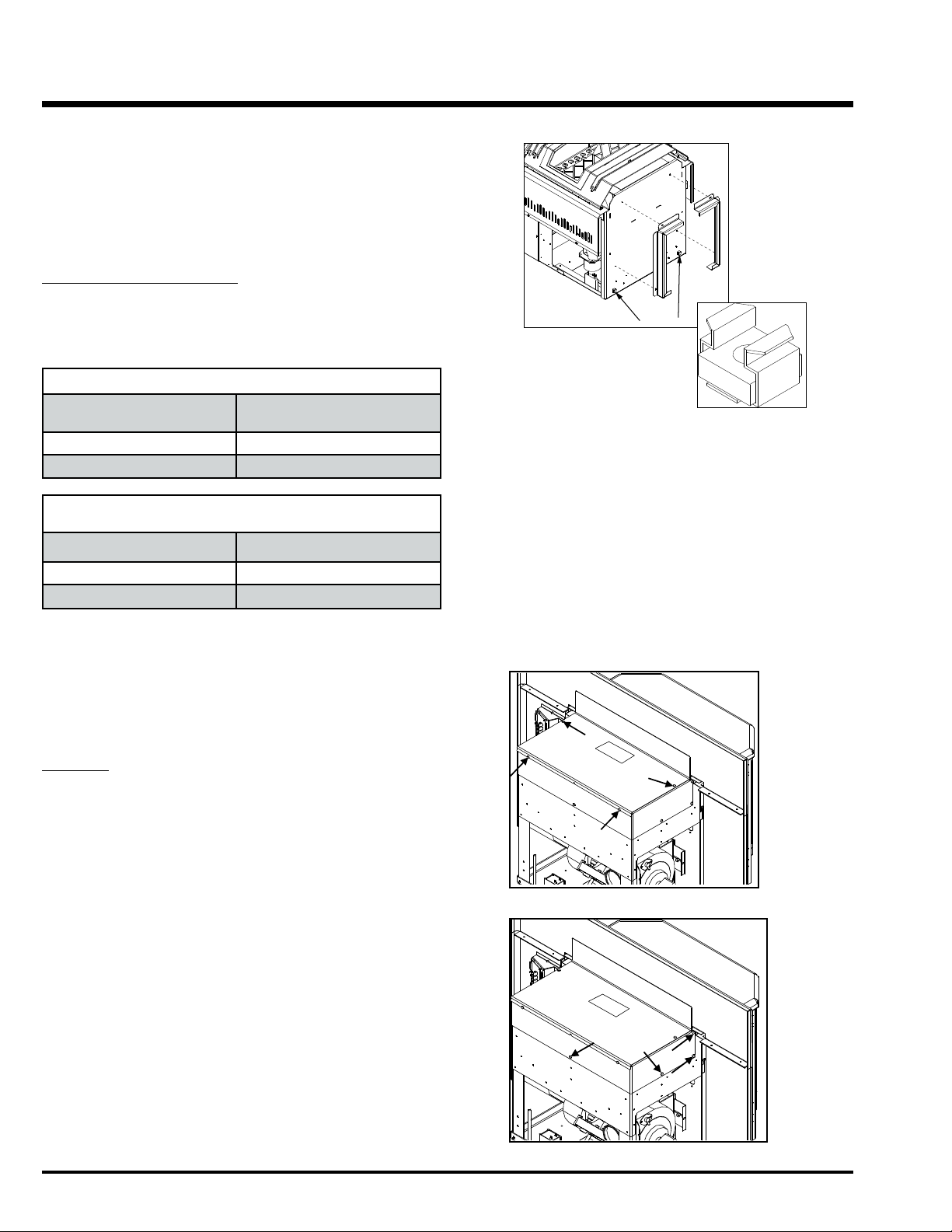

Components required for installation: a 3 inch (75 mm) or 4inch (100 mm) listed PL vent, complete with components. Insert and Hearth mount installations; a

listed single wall chimney liner may be used. Inspect and clean Exhaust Venting system frequently / À utiliser avec des combustibles sous forme de granules

uniquement. Utiliser seulement lorsque les portes avant et la porte du retrait descendressont fermées. Si une ou des vitres doivent être remplacées, utiliser

seulement de la vitrocéramique. Pièces requises pour l'installation :uneévacuation PL certifiéede 3 po / 75 mm ou de 4 po / 100m m avec ses composantes. Les

installations de l'encastrable et dumontage dufoyer :une doublure de cheminée à simple paroi peut être utilisée. Inspecter et nettoyer fréquemment le système

de ventilation et d'évacuation.

To Start Stove: Press the ON / OFF button. If the auger needs to be primed, press the Manual Auger Feed button until fuel starts to drop into the

Burn Pot.

To Operate Stove: MANUAL MODE: When a fire has been established the stove settings are adjustable. / HIGH/LOW MODE: (Requires a thermostat)

When the thermostat calls for heat the stove settings are adjustable. When the thermostat contacts open, the HEAT LEVEL and Fans will drop down to

the LOW setting until the thermostat contacts close again. / AUTO/OFF MODE: (Requires a thermostat) When the thermostat contacts close, the unit will

light automatically. Once up to temperature the stove settings are adjustable. When the thermostat contacts open, the stove will drop down to the LOW

settings for 30 minutes. If within the 30 min the thermostat contacts close, the HEAT LEVEL will return to previous MANUAL setting or if the thermostat

contacts remain open the stove begin its shutdown routine. To Turn Off Stove: MANUAL and HI / LOW mode: Press the ON / OFF button; AUTO / OFF

mode: Turn the thermostat down or off.

Pour démarrer le poêle : Appuyer sur le bouton “ON/OFF”. Si la vis sans fin doit être amorcée, appuyer sur le bouton manuel d’alimentation de la vis

jusqu'à ce que les granules se déversent dans le pot de combustion.

Pour faire fonctionner le poêle : MODE MANUEL: Lorsque le feu est bien établi, les réglages peuvent être ajustés. / MODE “HIGH/LOW”: (Nécessite un

thermostat) Lorsque le thermostat requiert de la chaleur, les réglages peuvent être ajustés. Lorsque les contacts du thermostat s’ouvrent, le réglage du

niveau de chaleur et les ventilateurs s’ajusteront au réglage “bas” jusqu'à ce que les contacts du termostat se referment. / MODE “AUTO/OFF”: (Nécessite

un thermostat) Lorsque les contacts du thermostat ferment, le poêle s’allumera automatiquement. Lorsque la température adéquate est atteinte, les

réglages peuvent être ajustés. Lorsque les contacts du thermostat s’ouvrent, le poêle s’ajustera aux réglages bas pendent 30 minutes. Si les contacts du

thermostat se ferment au cours de ces 30 minutes, le réglage de niveau de chaleur retournera en réglage MANUEL ou si les contactsdu thermostat

restent ouverts, le poêle entamera le processus d'arrêt.

Pour éteindre le poêle: MODE MANUEL ET “HIGH/LOW”: Appuyer sur le bouton “ON/OFF”. MODE

“AUTO/OFF”: Baisser le thermostat ou l’éteindre.

DO NOT REMOVE THIS LABEL /

NE PAS RETIRERCETTE ÉTIQUETTE

This wood heater needs periodic inspection and repair for proper operation. Consult the owner’s manual for further

information. It is against federal regulations to operate this wood heater in a manner inconsistent with the operating

instructions in the owner’s manual. U.S. ENVIRONMENTAL PROTECTION AGENCY Certified to comply with 2020

particulate emission standards. Under specific test conditions. this heater has been shown to have a particulate

emission level of 1.8 g/hr. Ce poêle à granules nécessite une inspection et une réparation périodiques pour un

fonctionnement correct. Consulter le manuel du propriétaire pour plus d’informations. Il est contraire aux règlements

fédéraux d'utiliser ce poêle à bois d'une manière non conforme aux instructions d'utilisation du manuel du

propriétaire. Certifié U.S. ENVIRONMENTAL PROTECTION AGENCY pour être conforme aux normes d'émission

de particules de 2020. Dans des conditions de test spécifiques, il a été démontré que ce poêle a un niveau

d'émission de particules de 1,8 g/hr.

INSTALLED AS A FIREPLACE INSERT STOVE MODEL / INSTALLÉCOMME

MODÈLE DE POÊLE AUTOPORTANT

Minimum clearances to combustible materials / Dégagements minimaux par rapport aux matériels combustibles :

removed. Once the Surround has been removed the rating plate will be