Greenfire GF45 BioEnergy Stove 5

INSTALLATION

IMPORTANT: SAVE THESE INSTRUCTIONS

The GF45 Stove must be installed in accordance with these instructions.

Carefully read all the instructions in this manual first. Consult the building

authority having jurisdiction to determine the need for a permit prior to

starting the installation.

NOTE: Failure to follow the instructions could cause a malfunction of the

heater which could result in death, serious bodily injury, and/or property

damage. Failure to follow these instructions may also void your fire

insurance and/or warranty.

BEFORE YOU START

It is very important to ensure that the stove is installed in a safe manner.

Be aware of fire prevention rules and laws in your area. All applicable

National and Local codes must be met and complied with.

We recommend that your pellet stove be installed by an authorized

dealer / installer.

The stove’s electrical connection is to a standard grounded wall socket.

Special care should be taken so the connection cable is not damaged

in any way.

It is strongly recommended that you install a smoke detector as well as

an ABC type extinguisher near the stove. A power surge bar is also highly

recommended to protect the electrical components.

If the stove is installed by an uncertified installer, FPI will not be held

responsible for any faulty operation including poor performance of the

stove.

IMPORTANT SAFETY INFORMATION

Only use approved fuels in multi-fuel burning appliances. Failure to comply

with this may create a hazardous situation and will void all warranties.

Never attempt to re-start your stove until it has fully cooled down. Starting

your stove using a gel is only recommended during automatic ignition

failure.

Never use or store flammable products close to the stove while it’s in use,

or at any other time.

The Prime button is only used to prime the auger when Hopper is empty.

Do not use the manual feeding procedures to start-up your stove as

these will create smoke in your house.

Ensure that the ash pan door is securely closed at all times when the stove

is in use. Air pressure could ignite the gas accumulated in the burn-pot

creating an overdraft condition in the combustion chamber altering the

performance of the burn-pot.

The GF45 model will not feed fuel if the front door or hopper lid are not

fully closed and the firebox in a negative pressure situation. These are

safety functions of the appliance.

INSTALLATION

UNIT LOCATION

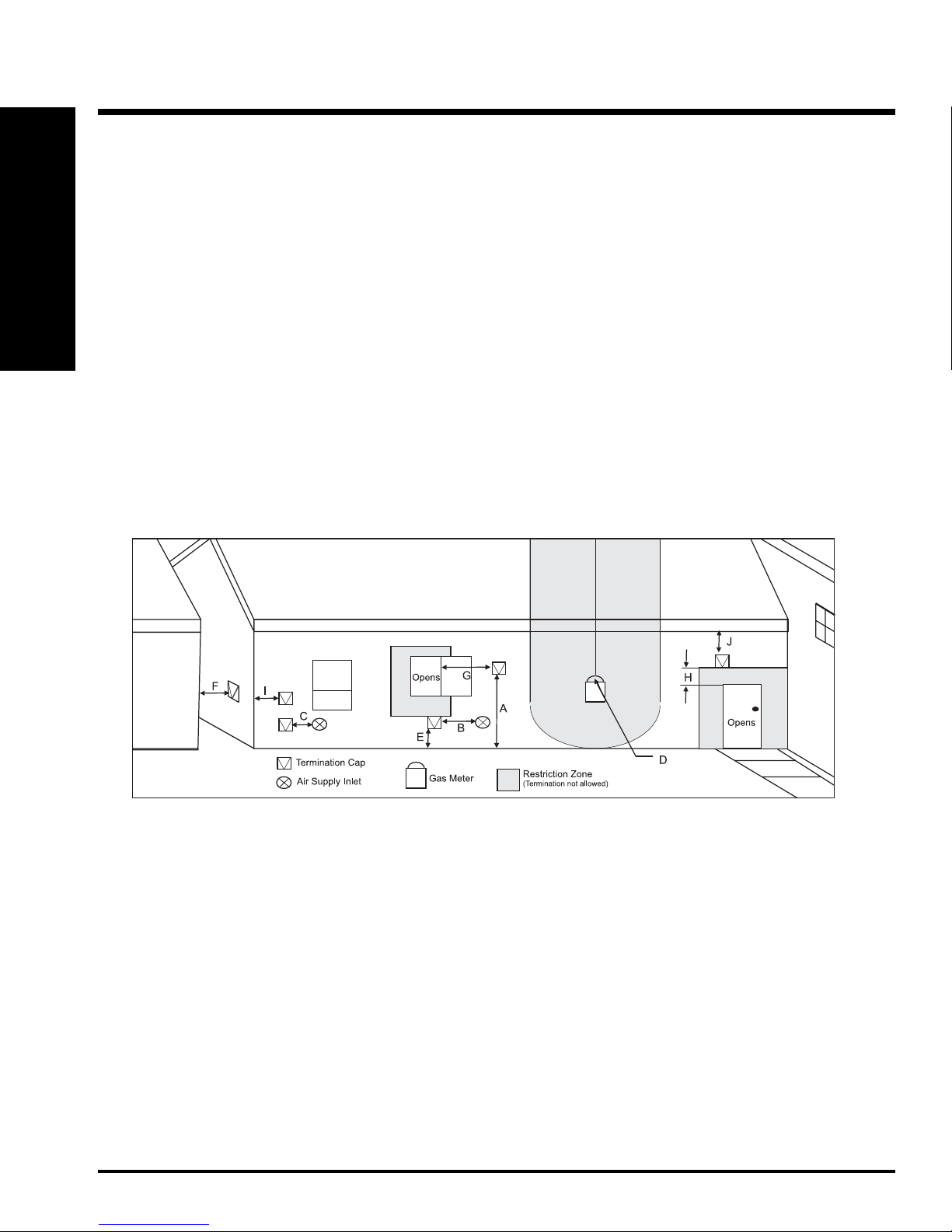

1. For optimum benefit from your appliance, speak to your professional

for help with your location.

2. The location you choose for your appliance can be a factor in how

it will perform. Choose an interior location where the vent will not

be affected by any external interference, i.e. trees, bushes, walls or

fencing (refer to "Vent Termination Requirements" section). Make

sure, at the time of the installation, that there is the least possible

interference with the existing components of the house. Install a non

flammable covering when necessary. Place the stove according to

recommendations made on "Clearances" section or according to the

safety label fixed on the stove.

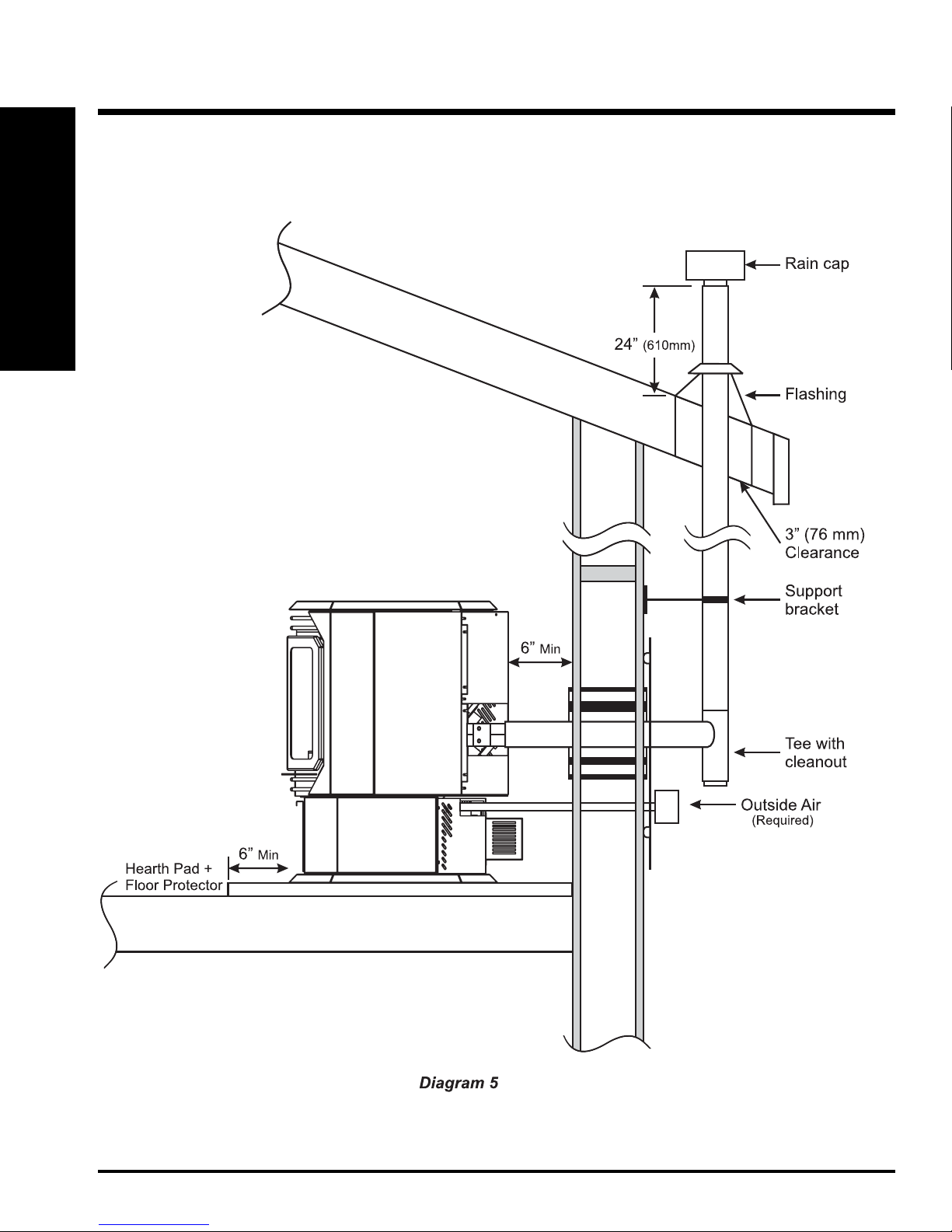

3. You can use the wall behind the stove to pass the chimney system

or simply join the stove to an existing chimney or a metal chimney,

with the use of an approved liner.

4. Ensure that all clearances to combustibles are met as per the safety

label and the diagrams on "Clearances" section.

5. This appliance requires outside air. Make sure that the outside

air supply does not come from a garage, an attic or any restricted

non-ventilated space. Air must come from the outside of the house

directly into the back of the stove.

6. This stove is not approved to be installed into a bedroom under any

circumstances.

7. The flooring under the stove must be made of a non-combustible

material, i.e. cement, ceramics, etc, and must extend at least 6"

(152mm) all around the stove. Refer to the diagrams on "Clearances"

section.

WHAT IS INCLUDED WITH THE GF45

Qty Description

1 pc User Manual

1 pc AC Power Inlet

1 pc Measuring Cup

1 pc Pipe Adapter Gasket

(for Pressure Reducer Plate)

1 pc Pressure Reducer Plate 1-1/4"

1 pc Pressure Reducer Plate 1-5/8"

1 pc Ash Poker

1 pc 7ft. 6in. Extension Cord

1 pc Outside Air Kit

IMPORTANT:

Stove must be cold before any attempt to clean the glass is made. Do

not use detergent containing abrasives to clean the windows or any

other parts of the stove. Use only recommended products found at

your local hearth shop for this type of cleaning.

IMPORTANT:

When cleaning the stove, always remove ashes into a steel container

and place outside the residence. Use gloves to handle or to empty

the ash pan.

IMPORTANT:

Before servicing the electrical panel, make sure that all electrical

sources is turned off to the stove and the power disconnected. Do

not forget to disconnect the battery, control board, fans and switches

as well.