Table of Contents

ii M0741021_en | Installation and operating instructions Spring blade agitator FBR

1 General ......................................................................................................................................................... 4

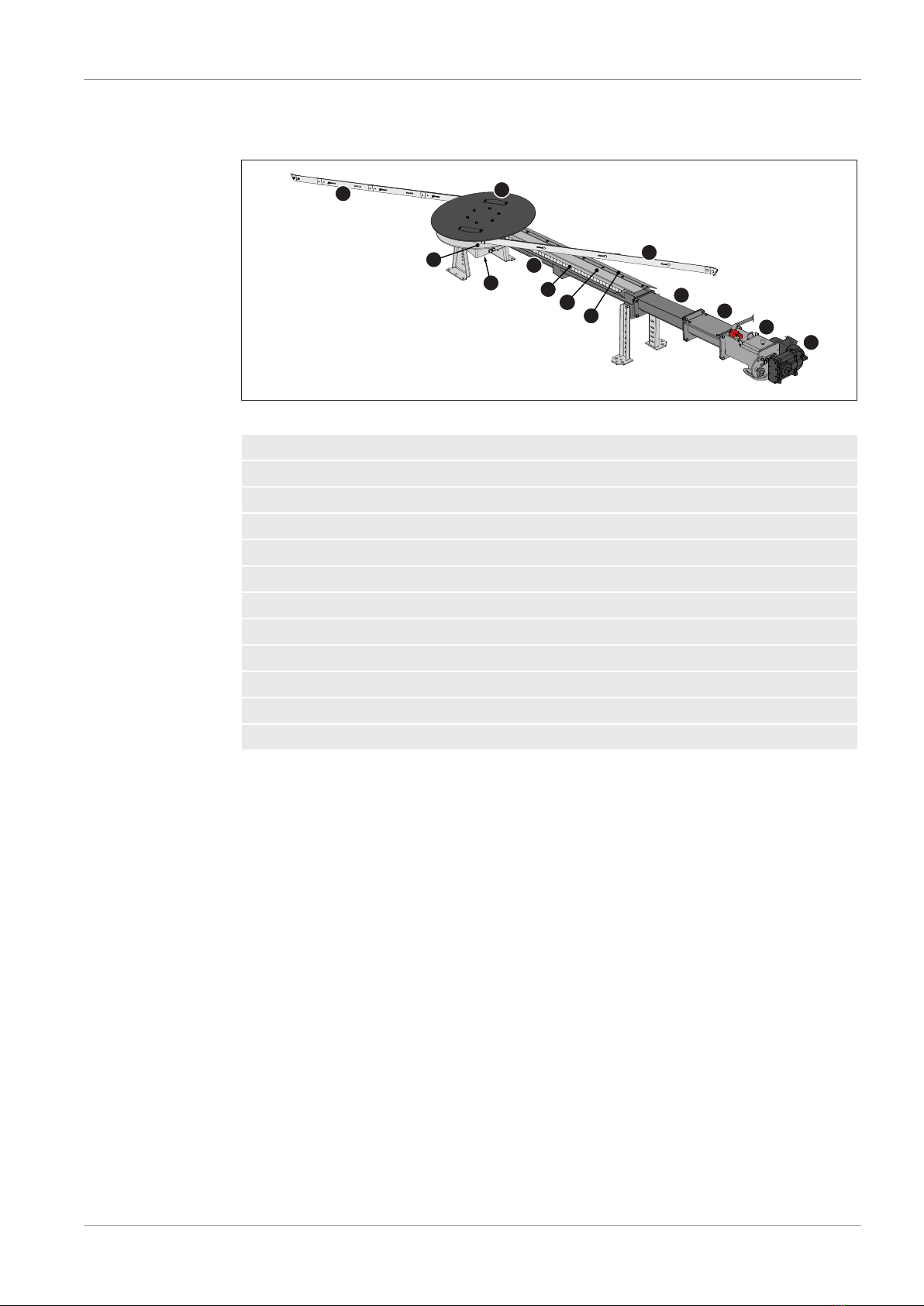

1.1 Functional description........................................................................................................................... 5

2 Safety............................................................................................................................................................ 6

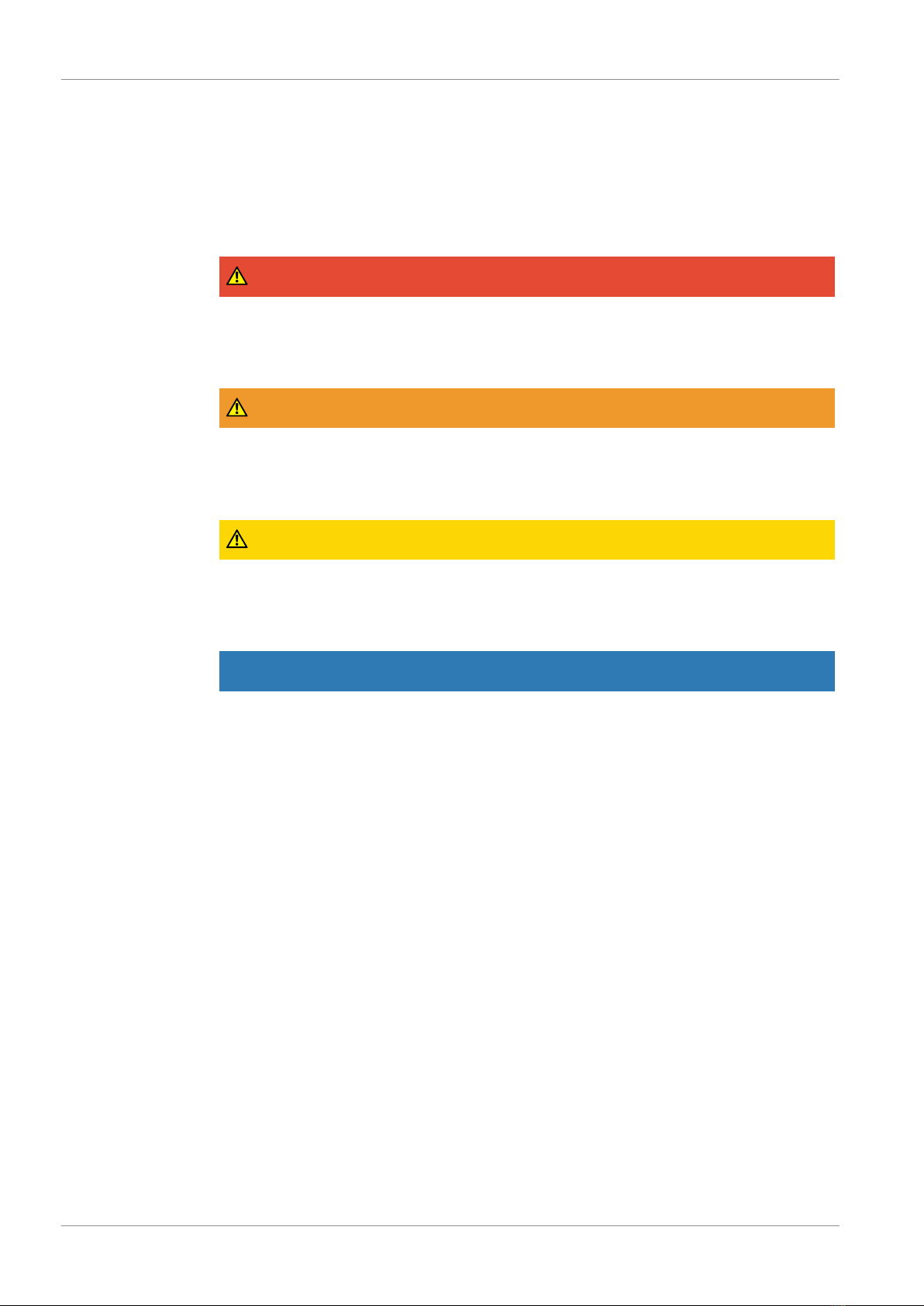

2.1 Hazard levels of warnings..................................................................................................................... 6

2.2 Permitted uses...................................................................................................................................... 7

2.2.1 Permitted fuels........................................................................................................................... 8

2.3 Qualification of staff .............................................................................................................................. 9

2.3.1 Qualification of assembly staff ................................................................................................... 9

2.3.2 Personal protective equipment for assembly staff ..................................................................... 9

2.3.3 Qualification of operating staff ................................................................................................... 9

2.3.4 Protective equipment for operating staff .................................................................................... 10

2.4 Design information................................................................................................................................ 10

2.4.1 Standards................................................................................................................................... 10

2.4.2 Requirements at the installation site.......................................................................................... 11

2.5 Safety devices ...................................................................................................................................... 12

2.6 Residual risks ....................................................................................................................................... 13

3 Technology .................................................................................................................................................. 15

3.1 Dimensions ........................................................................................................................................... 15

3.2 Store sizes ............................................................................................................................................ 16

3.3 Technical specifications........................................................................................................................ 17

4 Installation.................................................................................................................................................... 18

4.1 Transport and handling......................................................................................................................... 18

4.1.1 Temporary storage..................................................................................................................... 18

4.2 Installation site ...................................................................................................................................... 18

4.2.1 Wall penetration......................................................................................................................... 19

4.3 Installing the spring blade agitator ........................................................................................................ 20

4.3.1 Materials supplied ...................................................................................................................... 20

4.3.2 Assembling the gears and feeder trough................................................................................... 21

4.3.3 Fitting the rotary agitator head................................................................................................... 24

4.3.4 Mounting the fibre shredder (optional)....................................................................................... 25

4.3.5 Fitting the upper part of gravity shaft and drive unit................................................................... 26

4.3.6 Fitting attachments..................................................................................................................... 29

4.3.7 Fitting the spring blades............................................................................................................. 30

4.3.8 Fitting adjustable feet in boiler room (optional).......................................................................... 31

4.3.9 Closing the wall penetration....................................................................................................... 31

4.3.10 Temperature monitoring device in the fuel store (TMD): ........................................................... 32

4.4 Connecting the system ......................................................................................................................... 33

4.4.1 Electrical connection.................................................................................................................. 33

4.4.2 Connecting the sprinkler system................................................................................................ 33

5 Operating the system.................................................................................................................................. 34

5.1 General information .............................................................................................................................. 34

5.2 Initial startup ......................................................................................................................................... 34

5.3 Filling/refilling the store with fuel........................................................................................................... 35

5.3.1 Loading of fuel for a partially emptied store with rotary agitator ................................................ 35

5.3.2 Loading fuel into an empty fuel store with a rotary agitator ....................................................... 36

5.3.3 Blowing in fuel for a partially emptied store with rotary agitator................................................. 36

5.3.4 Blowing in fuel for an empty store with rotary agitator ............................................................... 37

5.3.5 Drainage of fuel store................................................................................................................. 38

5.4 During operation ................................................................................................................................... 38

5.5 Decommissioning ................................................................................................................................. 39

5.5.1 Disassembly............................................................................................................................... 39