Should it be necessary to examine

the lamp with the front bezel

removed, always use a protective

shield to ensure a safe working

environment;

Never attempt to clean the lamp

when in use;

Searchlights get hot. Never touch

the unit when lit and always allow

at least ten minutes for cooling

down after turning off;

Ensure the lamp has cooled

sufficiently before removal. During

the cooling down period avoid

mechanical or thermal shock to

the lamp as this may cause

shattering;

If undue force appears necessary

to remove the lamp, the

equipment should be inspected by

a competent person, or contact

the manufacturer;

When breaking a lamp for

disposal, care must be taken to

ensure that the fragments are

safely contained. Precautions

must be taken against flying glass

and other fragments. This

operation should be performed

outdoors or in a well ventilated

area. In ALL cases reference

should be made to the lamp

manufacturers instructions packed

with the lamp;

Due to the vast range of lamps

available, it may appear possible

that more powerful lamps can be

used in the equipment for which it

was designed. Even when the unit

will physically accept a higher

wattage lamp, this substitution is

not recommended as it could be

dangerous.

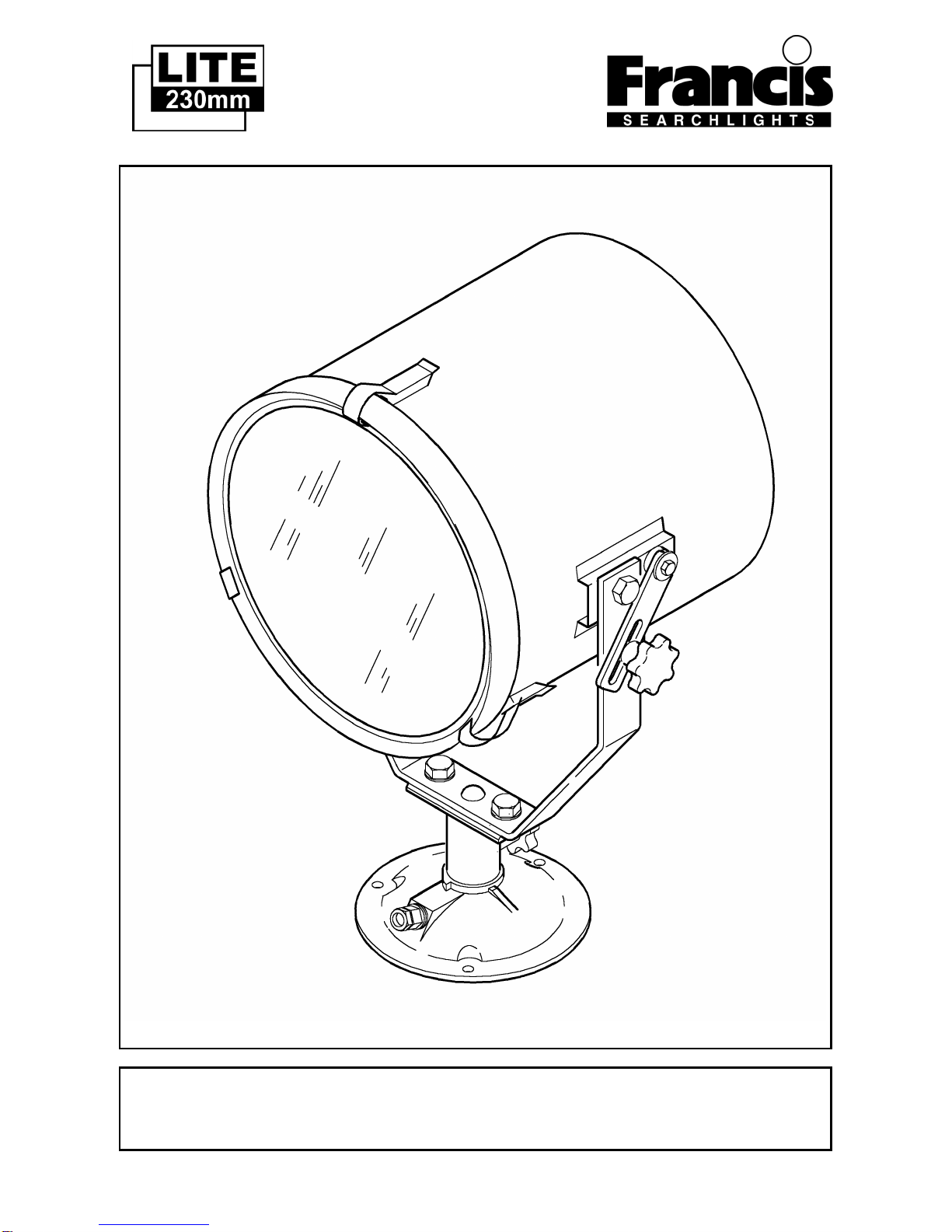

Unpacking Instructions

Care should be taken when

unpacking the searchlight, so as not

to cause damage to the equipment or

cause personal injury. A visual

inspection of the equipment should be

conducted to check for damage

during transit or damaged lamps.

Enclosed in the packing is the flange

sealing gasket. This should be

retained for installation purposes.

For Cabin, Deck Pedestal and Cabin

Pedestal models, conversion kits are

supplied and should be retained for

installation purposes.

Installation Instructions

The following instructions should be

read and fully understood prior to

installing the equipment to ensure

correct procedures are followed and

all safety precautions are observed.

Note: If the equipment has

been in storage for a

considerable time, it is

advisable to conduct a

routine maintenance

check on all parts before

installation.

Safety Precautions

This equipment should not be

connected to an electrical supply

before being installed. Installation

procedures should be adhered to in

order to ensure a safe working

environment and reduce the risk of

damage or injury.