2. Installation instructions

2.1. Warning to the user

All the local and national

regulations, and in particular

those relating to national and

European standards, must be

observed when installing the

appliance.

An incorrectly installed

heating appliance can cause

serious accidents (chimney

fires, burning of plastic

insulation materials, in partition

walls, etc.).

The insulation of both the

appliance and the exhaust gas

pipe has to be reinforced and

done according to the Standards

and the Building Regulations for

safety reasons. The installation

must be carried out according to

the Standards and the Building Regulations.

Failure to respect the mounting instructions leads to

engage the responsibility of the one doing the

installation.

The manufacturer’s responsibility shall be limited to the

supply of the appliance.

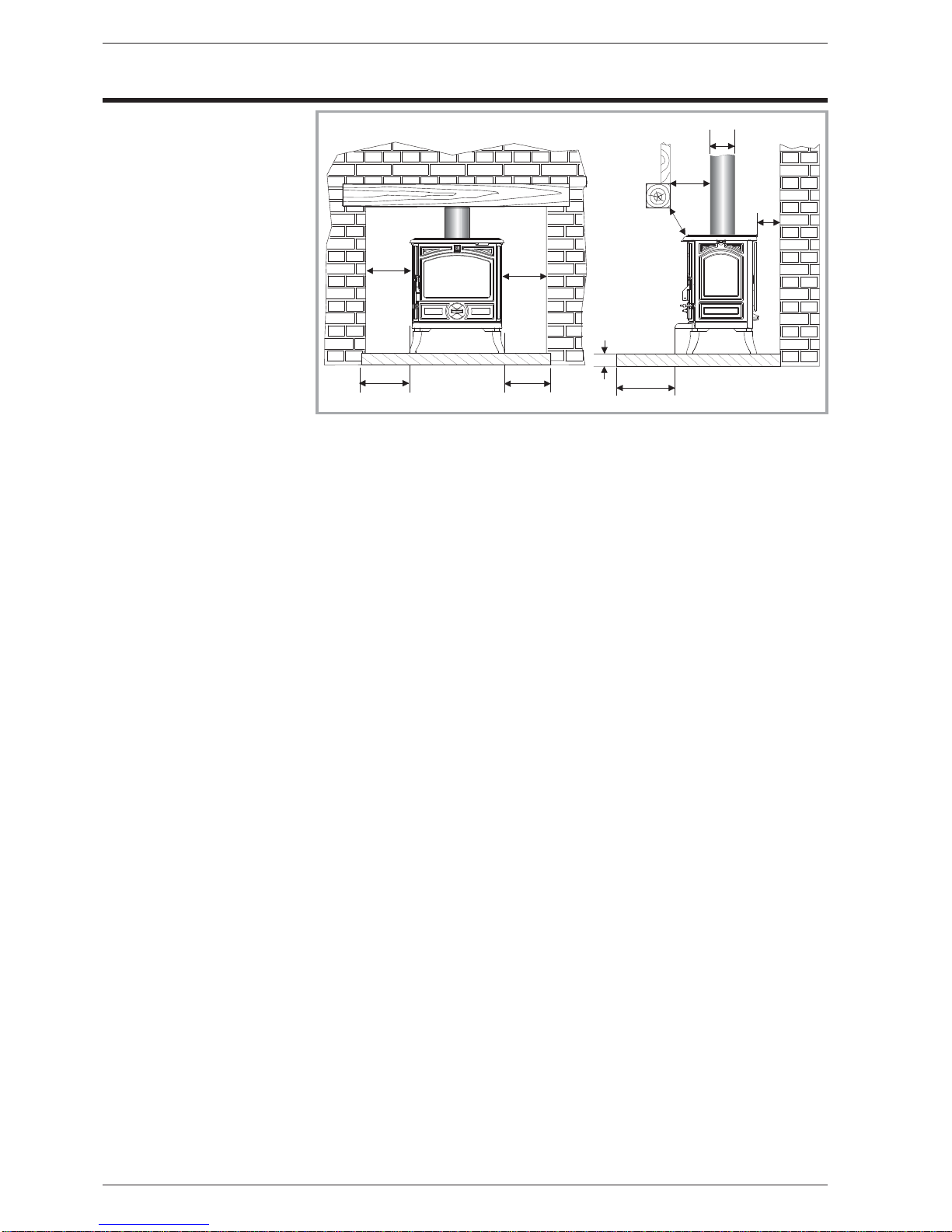

2.2. Location of the unit

Ventilation :

For satisfactory appliance operation with a natural

draught, check that sufficient air for combustion is

available in the room.

in houses equipped with one VMC (controlled

mechanical ventilation), this one aspire and renew the

ambient air ; In this case, the residence is under slight

low pressure and a non-sealable external air intake

must be installed in addition to the chimney itself, at

least 50cm² in section.

Position of the unit :

For new installations, select a central position within the

house, to provide a good heat distribution around the

building.

The heat distribution towards the other rooms will be

made through the communicating doors.

These rooms must be in negative pressure or must

include ventilation gratings.

Floor and walls :

Make sure that the floor can support the weight of the

appliance, its surroundings and the hood. In the

contrary the floor needs to be reinforced with a concrete

screed to distribute this load.

Make sure they are not combustible or covered with

combustible material (as per the Building regulations).

Otherwise it must necessary to install a

non-combustible protection.

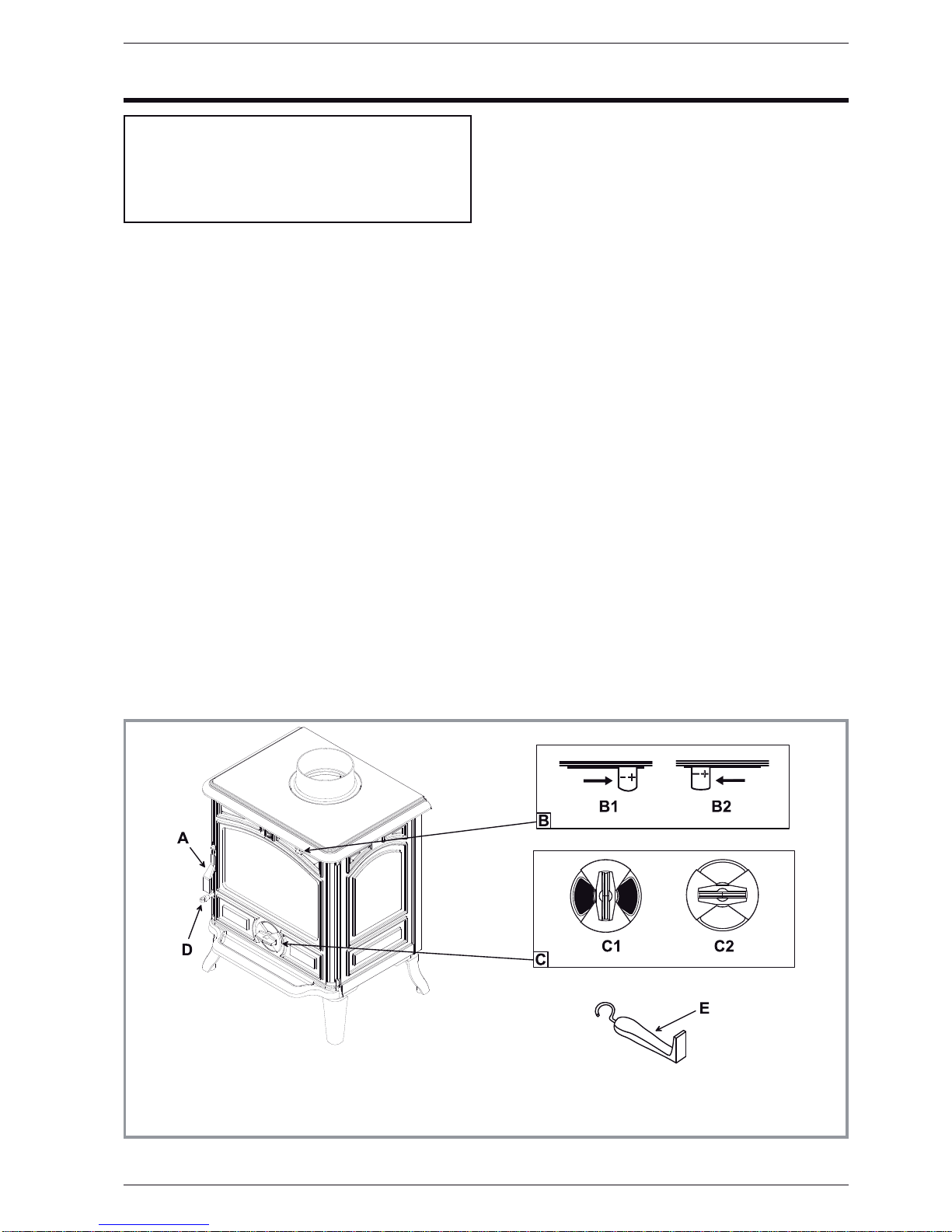

There must be a clearance of at least 150 mm at each

side of the appliance and at the back of the appliance

from a non-combustible wall.

This measurement may be reduced to a minimum gap

of 50 mm when the non-combustible wall is at least

200 mm thick.

This distance must be extended to a minimum

clearance of 425 mm from any combustible materials.

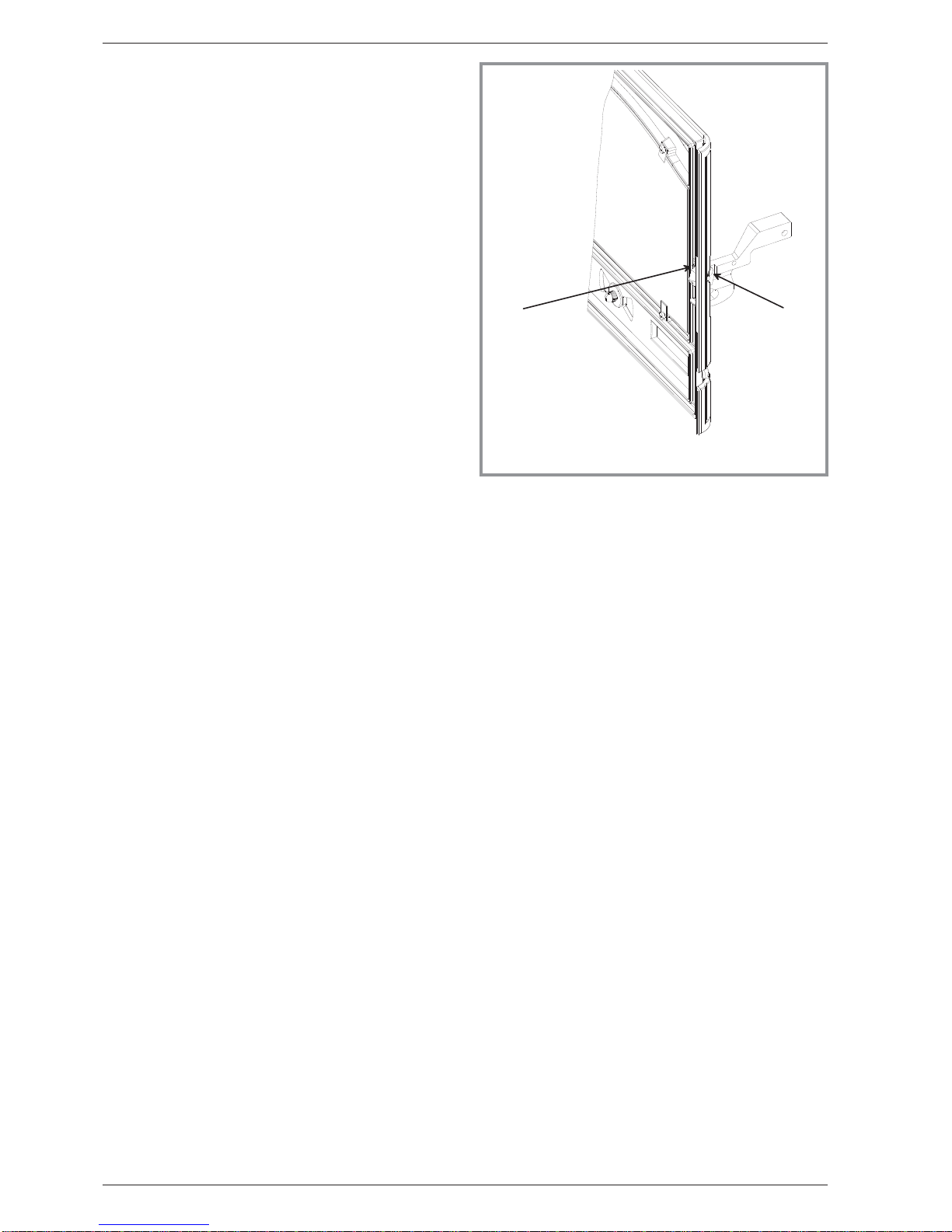

When using a single wall flue pipe, there must be a

clearance (A) of at least three times its diameter (B)

from any combustible materials.

If the appliance has to be located in an opening, this

distance must be extended to a minimum clearance (A)

of 375 mm from the pipe or the stove body to any

combustible materials.

Hearth :

The appliance must stand on a fireproof hearth.

It is possible to provide a hearth made of non

combusible board/sheet material or tiles at least 12 mm

thick (C).

Constructional hearths should be constructed of solid

non combustible material at least 125 mm thick

(including the thickness of any non combustible floor

under the hearth).

The hearth must protrude at least 225 mm in front of the

stove and 150 mm each side.

If the hearth is constructed on timber, there must be a

clearance of at least 250 mm from the timber to the top

surface of the hearth. See section J of the Building

regulations.

2.3. Flue

Existing flue :The chimney must comply with Current

Building Regulations. If in doubt, consult your Dealer or

local Building Inspector.

-The flue must be in good condition and must provide

sufficient draught.

-The flue must be suitable for the installation of solid

fuel burning appliances and comply with Current

Building Regulations.

-The flue must be clean. It should be swept to remove

soot and dislodge tar deposits.

-The flue must be well insulated. If the flue inner wall

surfaces are cold, a good thermal draw is impossible

causing condensation problems (tar formation etc) to

occur.

-The flue must not be shared with other appliances.

4Technical manual “1171”

“MONTFORT” - ref. 134 05 01 Installation instructions

1 5 0

1 5 0 1 5 0 3 0 0

1 5 0

B

A

A

C

1 5 0

Figure 2 - Clearances