INDEX

INDEX ......................................................................................................................................2

1 - INTRODUCTION.................................................................................................................3

1.1 General safety instructions .............................................................................................3

1.2 Warnings for the correct disposal of the product (EU) ....................................................3

1.3 Conventions used in this manual....................................................................................4

1.4 Keeping and updating the instruction manual................................................................. 4

1.5 Target audience..............................................................................................................4

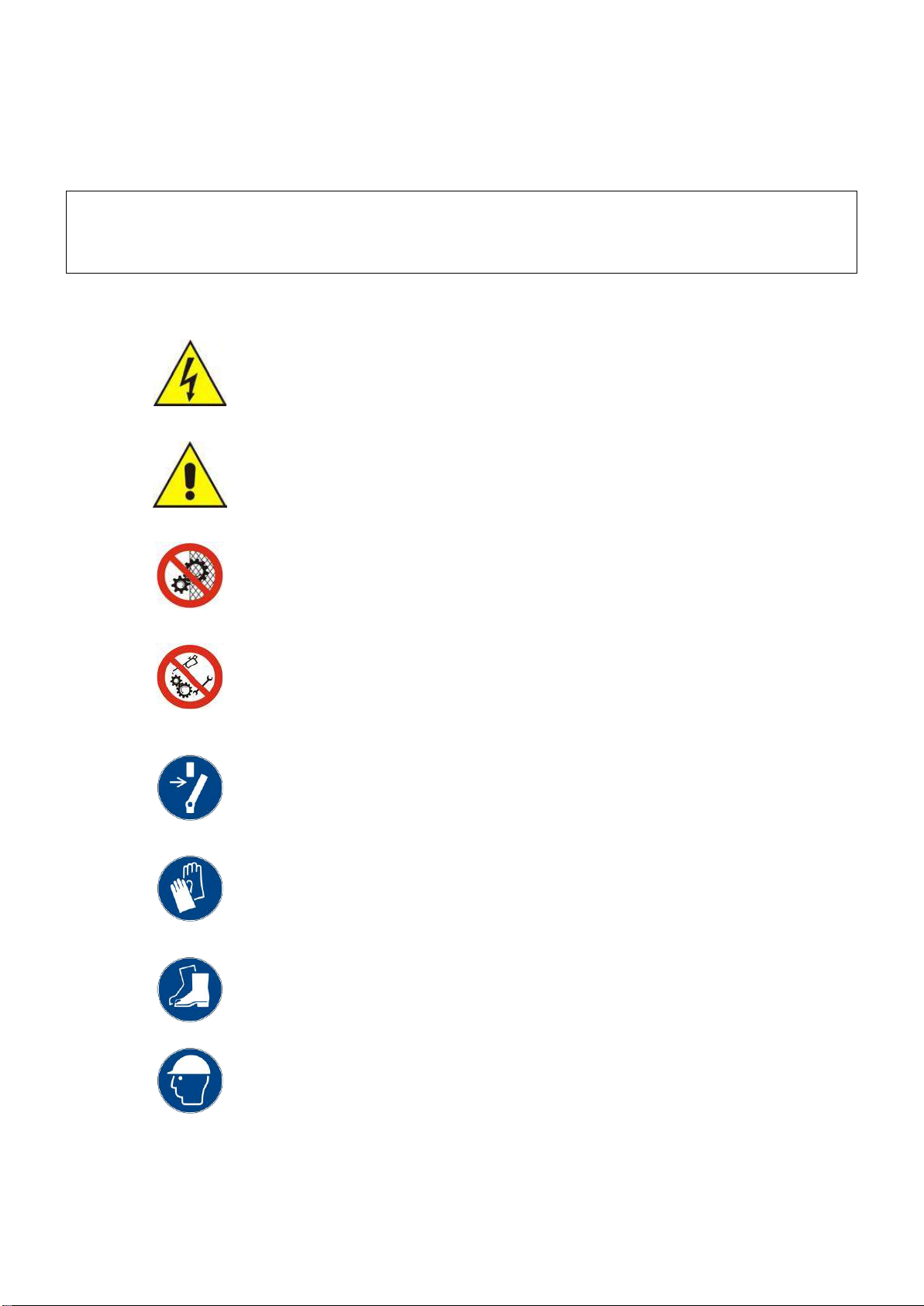

1.6 Pictograms...................................................................................................................... 5

1.7 Applications ....................................................................................................................7

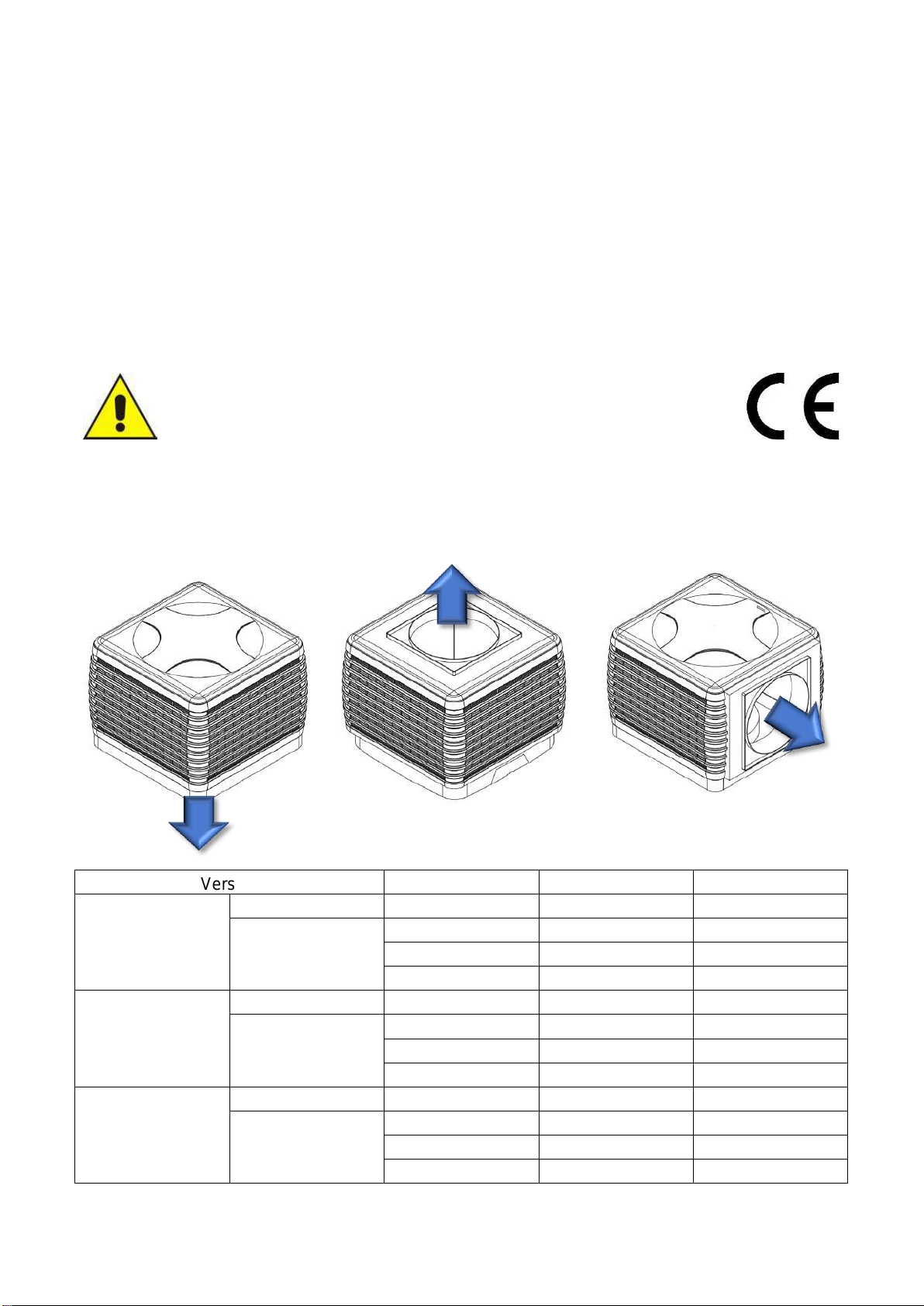

1.8 Versions..........................................................................................................................7

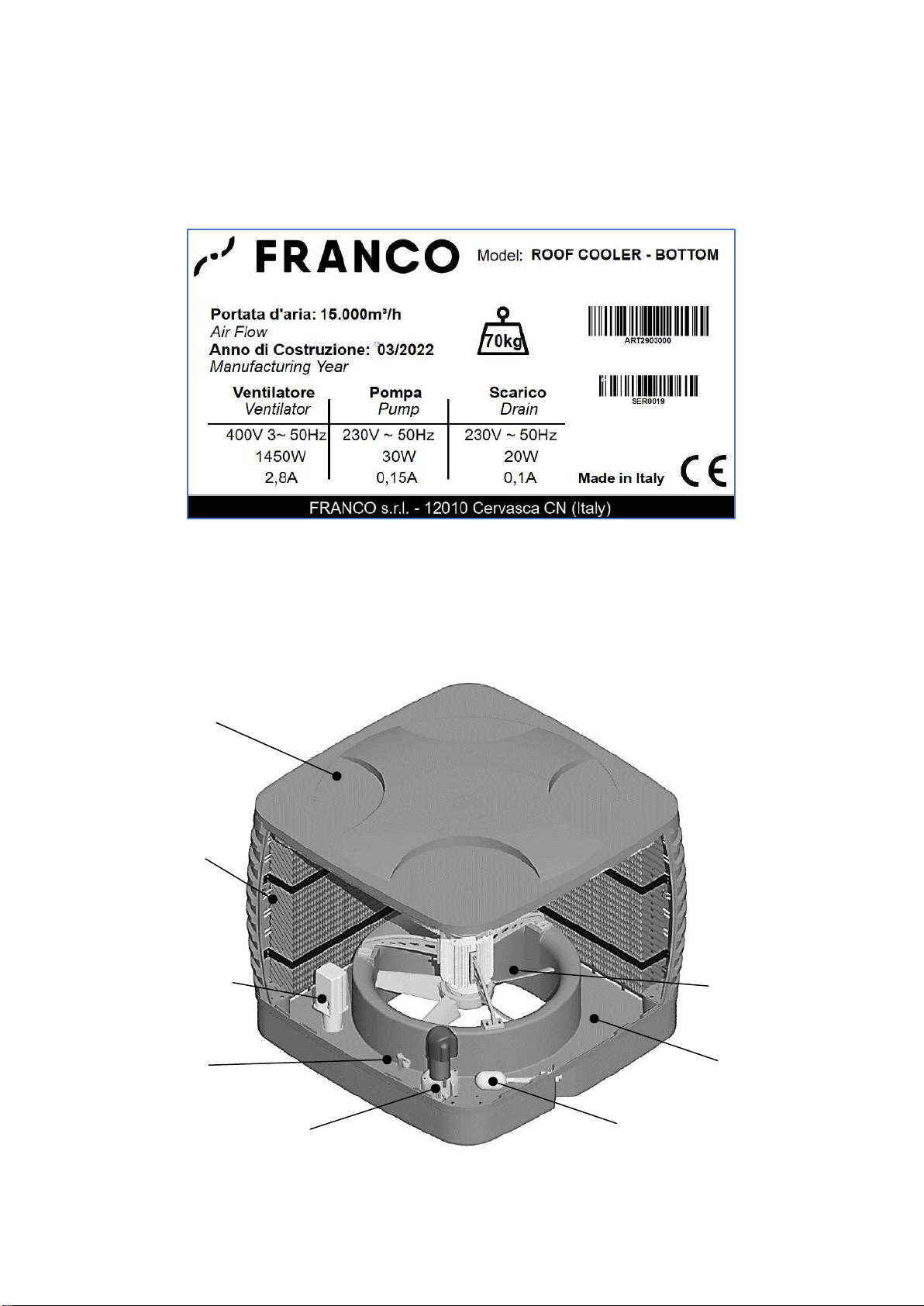

1.9 Machine identification data and plates............................................................................8

1.10 Description of equipment..............................................................................................8

1.11 Transport and handling.................................................................................................9

1.12 Warranty.......................................................................................................................9

1.13 Manufacturer's identification data .................................................................................9

1.14 Declarations..................................................................................................................9

1.15 Declaration of conformity............................................................................................10

1.16 Declaration of incorporation........................................................................................ 11

2 - INSTALLATION................................................................................................................ 12

2.1 Getting started..............................................................................................................12

2.2 Positioning....................................................................................................................12

2.3 Electrical connections...................................................................................................14

2.4 Hydraulic connections...................................................................................................14

3 - OPERATION..................................................................................................................... 15

3.1 Preliminary operations..................................................................................................15

3.2 First start-up.................................................................................................................. 15

3.3 Starting up ....................................................................................................................16

3.4 Optimum conditions of use ...........................................................................................16

3.5 Water discharge (bleed-off) ..........................................................................................16

4 - CLEANING AND MAINTENANCE ................................................................................... 17

4.1 Cleaning and maintenance programme........................................................................17

4.2 Cleaning and maintenance operations .........................................................................17

5 - TECHNICAL CHARACTERISTICS .................................................................................. 20

5.1 Overall dimensions ....................................................................................................... 20

5.2 Technical data ..............................................................................................................20

5.3 Electrical connections...................................................................................................21

5.4 Spare parts list.............................................................................................................. 23

6 - PROBLEM-SOLVING GUIDE........................................................................................... 26