6-2

CARB Approved IOM 6 - Healy Breakaway Model 807 Swivel - Executive Orders VR-201 and VR-202

DRIVE-OFF BREAKAWAY RECONNECTION PROCEDURE

Use this procedure to either reconnect or disconnect (reverse order) the Healy 807 Swivel Breakaway

as part of Section 1.4 Procedure for Reconnecting Breakaway and Testing Fueling Point after Drive-

Off in the Healy Systems Scheduled Maintenance.

TOOLS NEEDED:

•Healy Breakaway Reconnection Clamp, Part No. 795

•8mm Hex Head Socket

•Torque wrench

•Safety glasses

1. Inspect each half of the separated breakaway for obvious damage to the outer-shell, plastic

insert or o-rings; including cracks, chips or tears that may effect reconnecting the two halves.

2. Check the shear pin bushing hole (see Figure 3) located in the half of the breakaway attached

to the hose for any part of the pin left behind at separation. A gentle tap on the opposite side

of the breakaway should eject the pin.

3. After completing inspection, lightly lubricate the main o-ring on the half of the breakaway that’s

attached to the hose and the two small o-rings inside the half of the breakaway attached to the

nozzle. Any weight motor oil is acceptable.

4. Remove the black handle cover from the nozzle (See Figure 1).

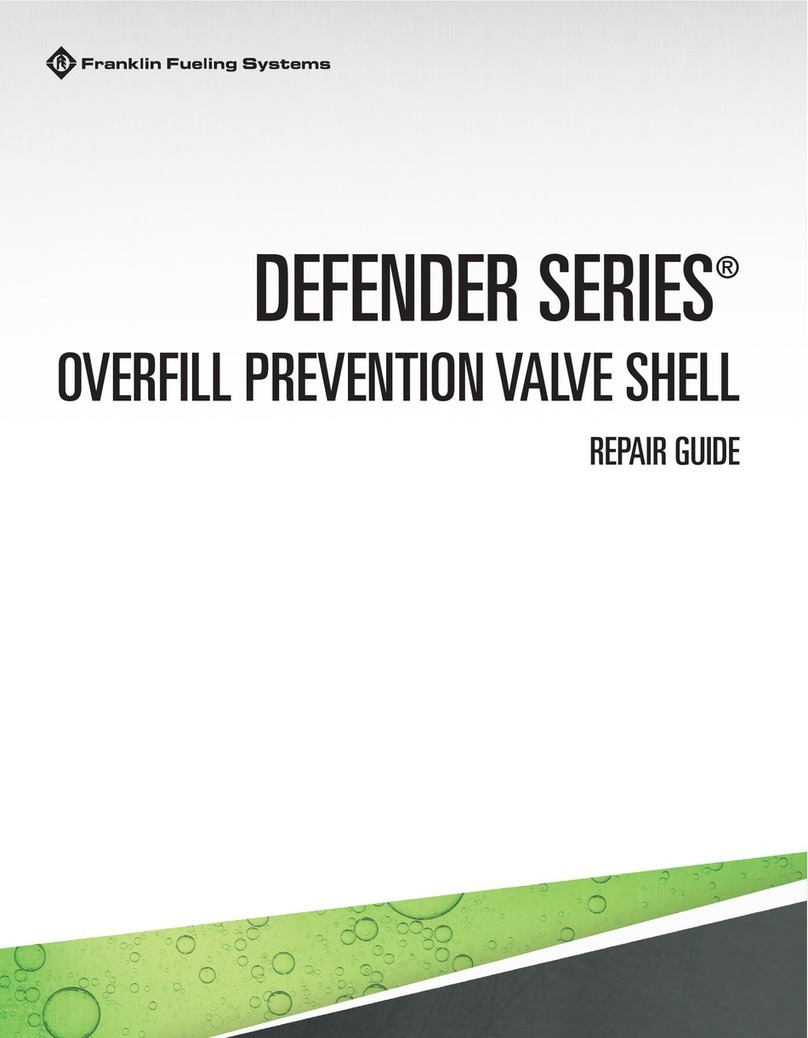

5. Slide the top clamp of the Breakaway Reconnection Clamp above the two at surfaces on the

nozzle (See Figure 2).

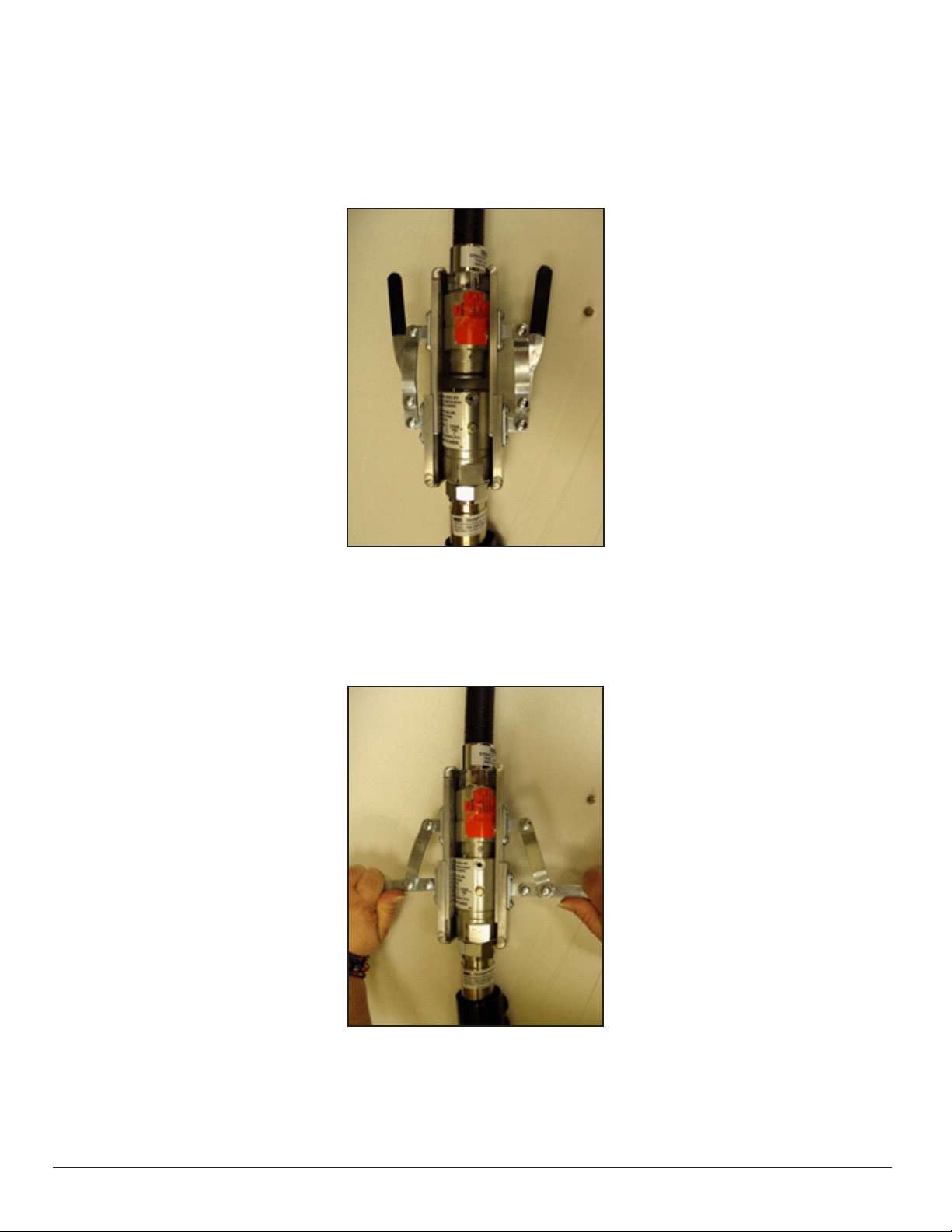

6. Slide the half of the breakaway that’s attached to the hose onto the bottom clamp of the

Breakaway Reconnection Clamp and begin squeezing the grip to slowly bring the two halves

together. Check the main o-ring for position as the top and bottom of the breakaway join

together (See Figure 2).

7. Align the dowel pin in the top half of the breakaway with the dowel pin guide located in the

bottom half of the breakaway (See Figure 3). When dowel pin and guide are aligned, continue

squeezing tool grip until the breakaway halves come together (See Figure 4).

Caution: Reconnection can cause a small amount of gasoline to leak out of the

breakaway. A towel wrapped loosely around the breakaway can help to

minimize fuel spills.