INDEX

Page 4

TABLE OF CONTENTS

Service Manual Turbo Deli RotisseriePKII form 9120929 rev. 04/2021

Index .......................................................................................................................................................... 4

General technical data.............................................................................................................................. 6

Technical Data ....................................................................................................................................... 6

Programming instructions TDR p............................................................................................................. 7

Connecting mains power ...................................................................................................................... 7

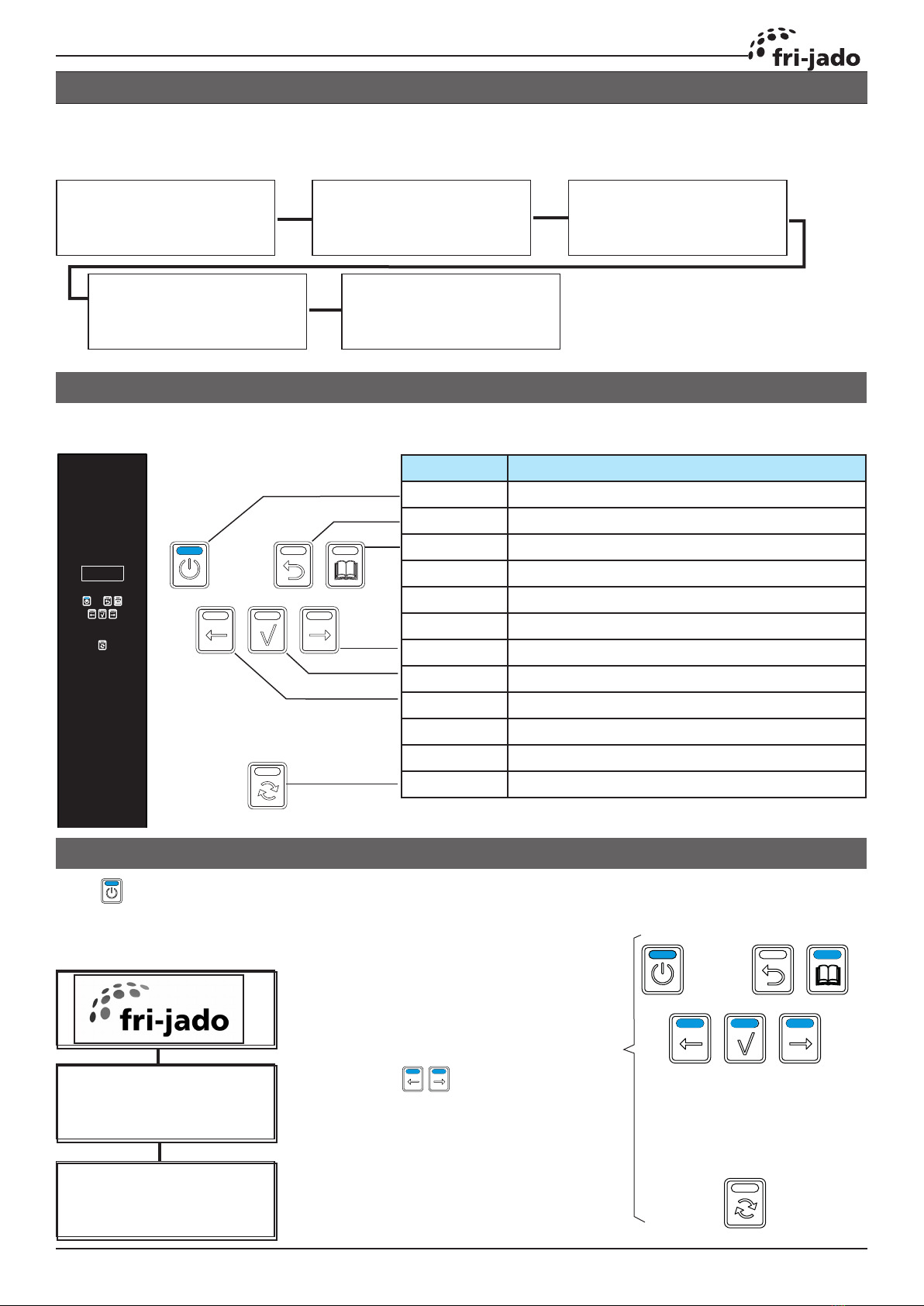

Overview of control panel .................................................................................................................... 7

Switching on .......................................................................................................................................... 7

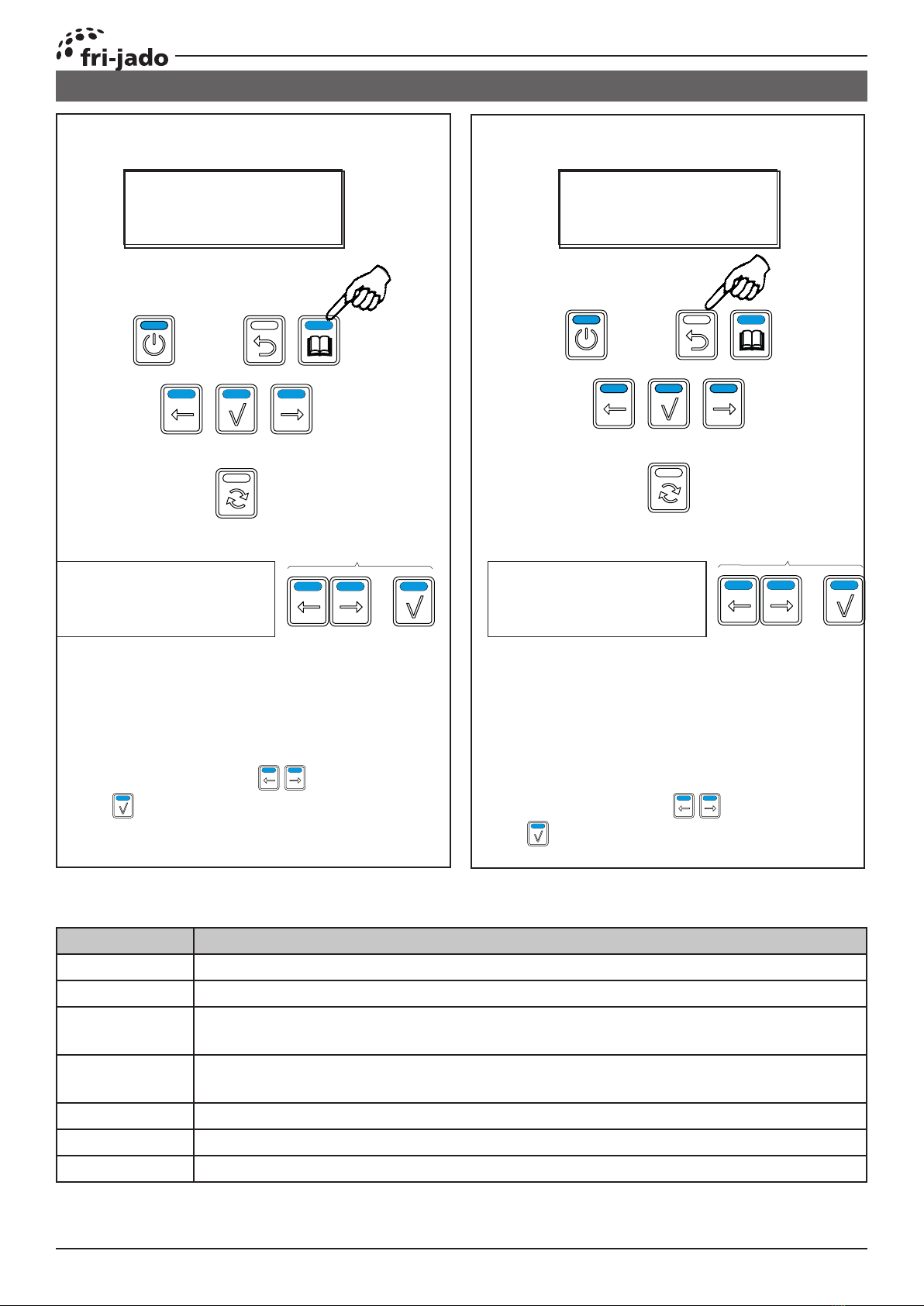

Entering the Manager or Service menu ............................................................................................... 8

The USB option read and store (cook books or parameters).......................................................... 10

The USB option transfer (error log and parameter settings)........................................................... 10

Files on the USB drive (strict rules) ..................................................................................................... 11

Updating software TDRp.................................................................................................................... 11

Manager and Service parameters ....................................................................................................... 13

Description of parameters................................................................................................................... 14

The automatic cook correction ........................................................................................................... 16

Default parameters EUR...................................................................................................................... 17

TDR i Programming instructions........................................................................................................... 19

MEnu settings TDRac ....................................................................................................................... 19

MEnu settings TDR-i ........................................................................................................................ 20

First Settings and Diagnostic Tools TDR-i ................................................................................... 21

I/O test TDR-i ....................................................................................................................................... 22

Updating software TDR-i.................................................................................................................... 23

Default parameters Version 6.01.27 TDR-i ........................................................................................ 24

Service procedures.................................................................................................................................. 26

Access to service parts TDR-p (2020)................................................................................................... 26

Access to service parts stacked units................................................................................................... 27

Operating panel (general) .................................................................................................................. 28

CPU board ............................................................................................................................................ 28

Broken buzzer...................................................................................................................................... 29

Keypad.................................................................................................................................................. 29

Door switch .......................................................................................................................................... 30

Rotor switch ......................................................................................................................................... 30

Replacing a lamp ................................................................................................................................. 31

lamp holder.......................................................................................................................................... 31

Blower motor....................................................................................................................................... 32

Heating element.................................................................................................................................. 33

Rotor drive motor................................................................................................................................ 34

High limit thermostat.......................................................................................................................... 36

PT 1000 sensor...................................................................................................................................... 36

Door inside........................................................................................................................................... 37

Door outside ........................................................................................................................................ 37

Electrical tests.......................................................................................................................................... 38

Measuring the heating elements....................................................................................................... 38

Measuring the Blowers....................................................................................................................... 38

Measuring the Rotor (drive) motor ................................................................................................... 40

Measuring the 500W lamp................................................................................................................. 40

Measuring the PT1000 sensor ............................................................................................................ 40

Trouble shooting ..................................................................................................................................... 41

Overview of error codes TDR-p........................................................................................................... 41

Error 55 explanation............................................................................................................................ 42

Trouble shooting by Symptom............................................................................................................ 43

Trouble shooting by part / function. .................................................................................................. 45