Hose Products Division

Parker Hannifin Corporation

Wickliffe, Ohio

www.parkerhose.com

2

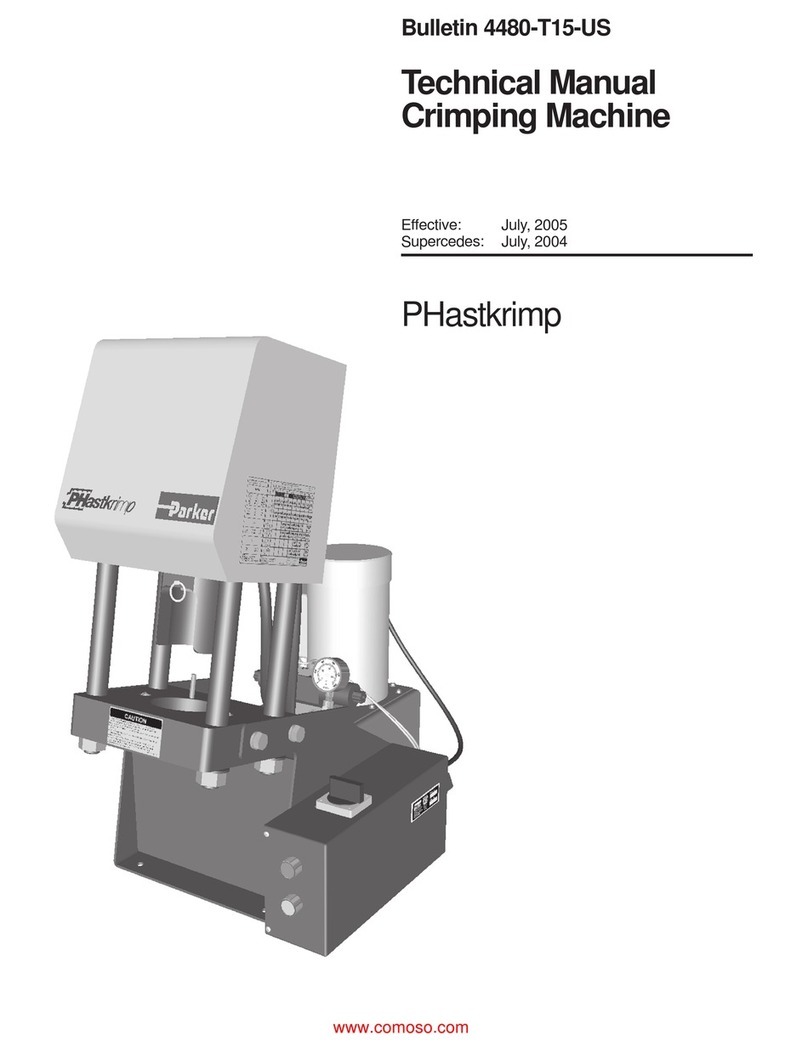

Crimping Machine

TH8-D206

Bulletin 4480-T22-US

WARNING - When using this machine, always exercise basic safety precautions, Including the following:

• Use the power unit only for its intended purpose: to hydraulically operate Parker crimpers

• This machine must be properly installed and located in accordance with the installation instructions before it is operated.

To Minimize the possibility of personal injury:

• The power unit must be connected to a grounded properly rated, protected and sized power-supply circuit to prevent electrical

shock and electrical overload

• DO NOT OPERATE OVER MAXIMUM RATED WORKING PRESSURE

• CHECK FOR SAFETY SYSTEM SETUPS

Make sure that the valve, connecting hoses and other components are protected from any external source of damage such as

excessive heat, flame, moving machine parts, sharp edges, falling objects, corrosive chemicals, etc.

∆

!

Table of Contents

Overview ...............................................................................................................2

TH8-D206 Component Identification (pictures) .......................................................3

Quick Start Guider and Calibration Check...............................................................4

Parker Crimp Specifications ...................................................................................5

Crimping with Small Die Series ..............................................................................6

Crimping with Large Die Series ..............................................................................7

TH8-D206 Crimper Features..................................................................................7

Troubleshooting Guide........................................................................................... 8

TH8-D206 Component Identification (graphic) ...................................................9-10

Safety Guide (Parker Publication 4400-B.1)..................................................... 11-15

Offer of Sale ........................................................................................................16

∆

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are

governed by the provisions stated in the "Offer of Sale".

Offer of Sale

Parker Safety Guide for Selecting and Using Hose, Tubing, Fittings and Related Accessories

Parker Publication No. 4400-B.1

Revised: May, 2002

WARNING: Failure or improper selection or improper use of hose, tubing, fittings, assemblies or related accessories (“Products”) can cause death, personal injury and

property damage. Possible consequences of failure or improper selection or improper use of these Products include but are not limited to:

•Fittings thrown off at high speed.

•High velocity fluid discharge.

•Explosion or burning of the conveyed fluid.

•Electrocution from high voltage electric powerlines.

•Contact with suddenly moving or falling objects that are controlled by the conveyed fluid.

•Injections by high-pressure fluid discharge.

Before selecting or using any of these Products, it is important that you read and follow the instructions below. Only Hose from Parker’s Stratoflex Products Division is approved for in flight

aerospace applications, and no other Hose can be used for such in flight applications.

•Dangerously whipping Hose.

•Contact with conveyed fluids that may be hot, cold, toxic or otherwise injurious.

•Sparking or explosion caused by static electricity buildup or other sources of electricity.

•Sparking or explosion while spraying paint or flammable liquids.

•Injuries resulting from inhalation, ingestion or exposure to fluids.

!