Frigidaire Gas & Electric Dryer User manual

Other Frigidaire Dryer manuals

Frigidaire

Frigidaire CAQE7011LW User manual

Frigidaire

Frigidaire FRG5711KW User manual

Frigidaire

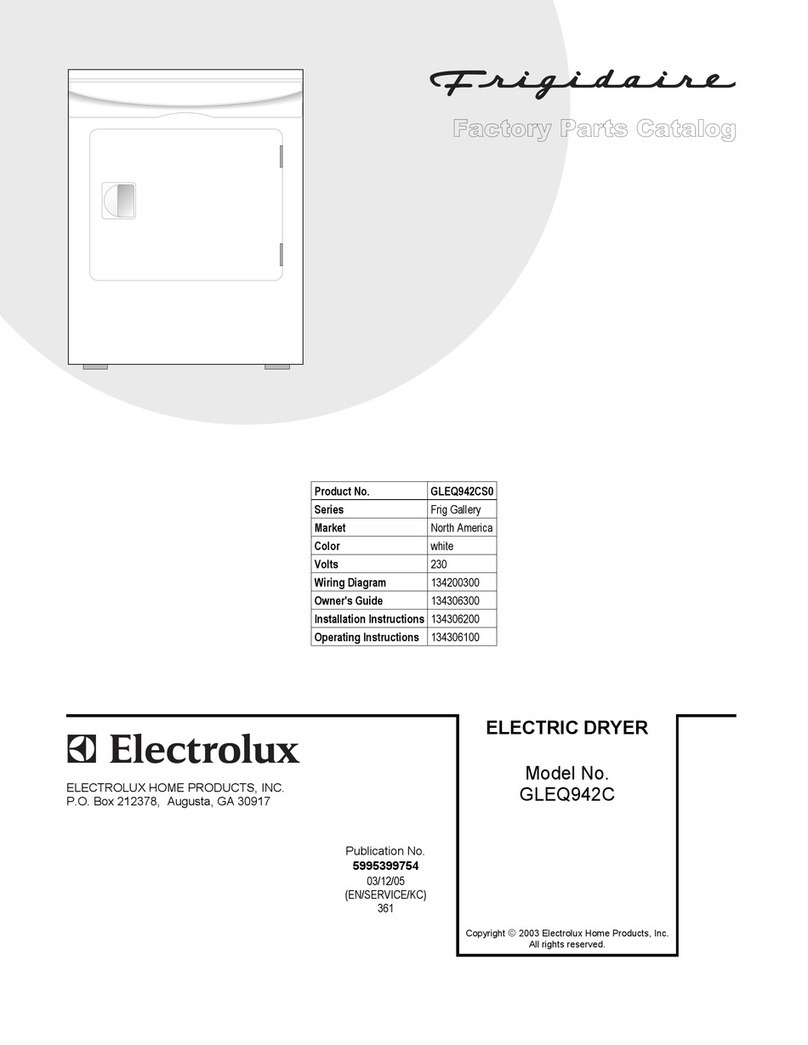

Frigidaire GLEQ942C User manual

Frigidaire

Frigidaire FEQ332 User manual

Frigidaire

Frigidaire LCGQ2152FE0 User manual

Frigidaire

Frigidaire FARE1011MW Installation instructions

Frigidaire

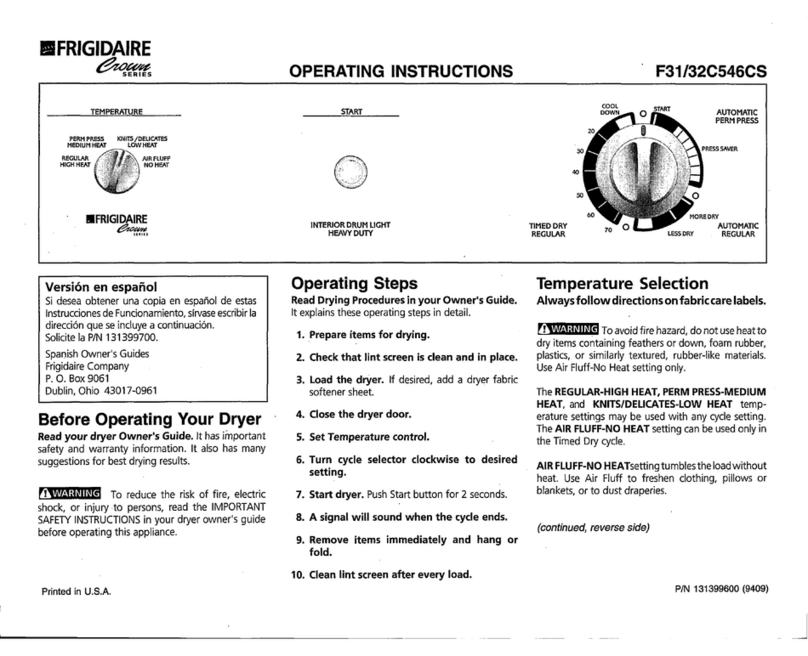

Frigidaire F31C546CS User manual

Frigidaire

Frigidaire FRE5711KW User manual

Frigidaire

Frigidaire GLER1042F User manual

Frigidaire

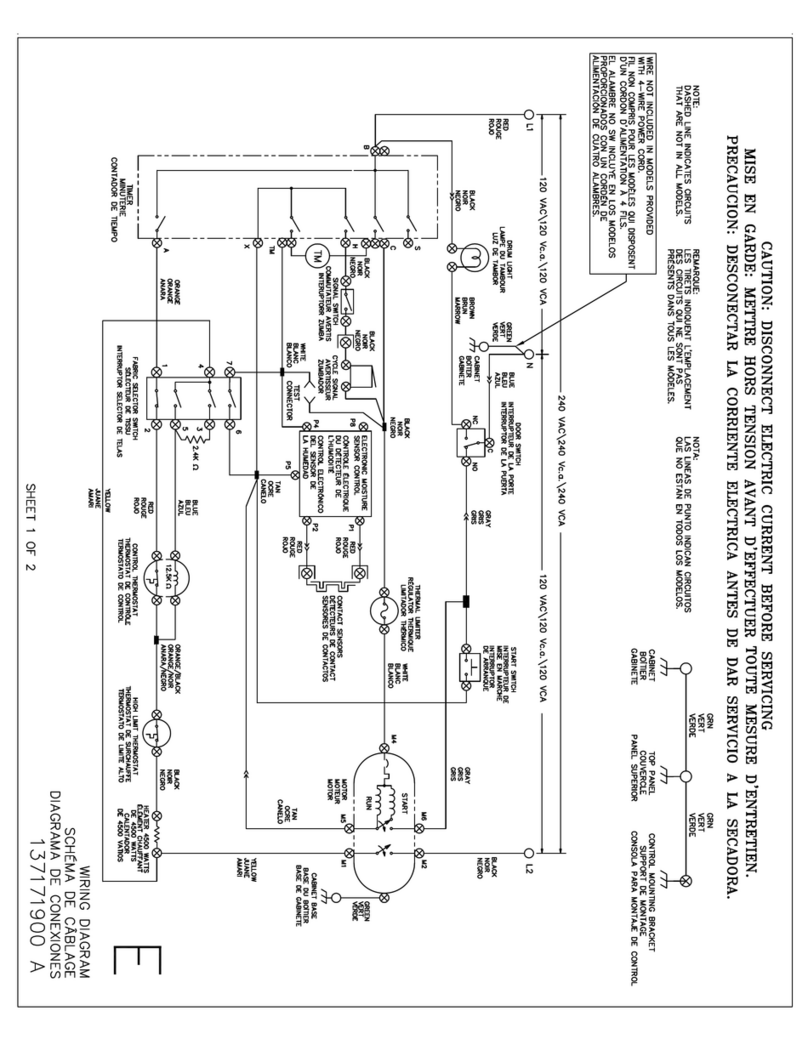

Frigidaire GLER341CDC0 User manual

Frigidaire

Frigidaire FEQ1442CES0 User manual

Frigidaire

Frigidaire AEQ6700FS - 27" Electric Dryer User manual

Frigidaire

Frigidaire FRE5711KW Quick start guide

Frigidaire

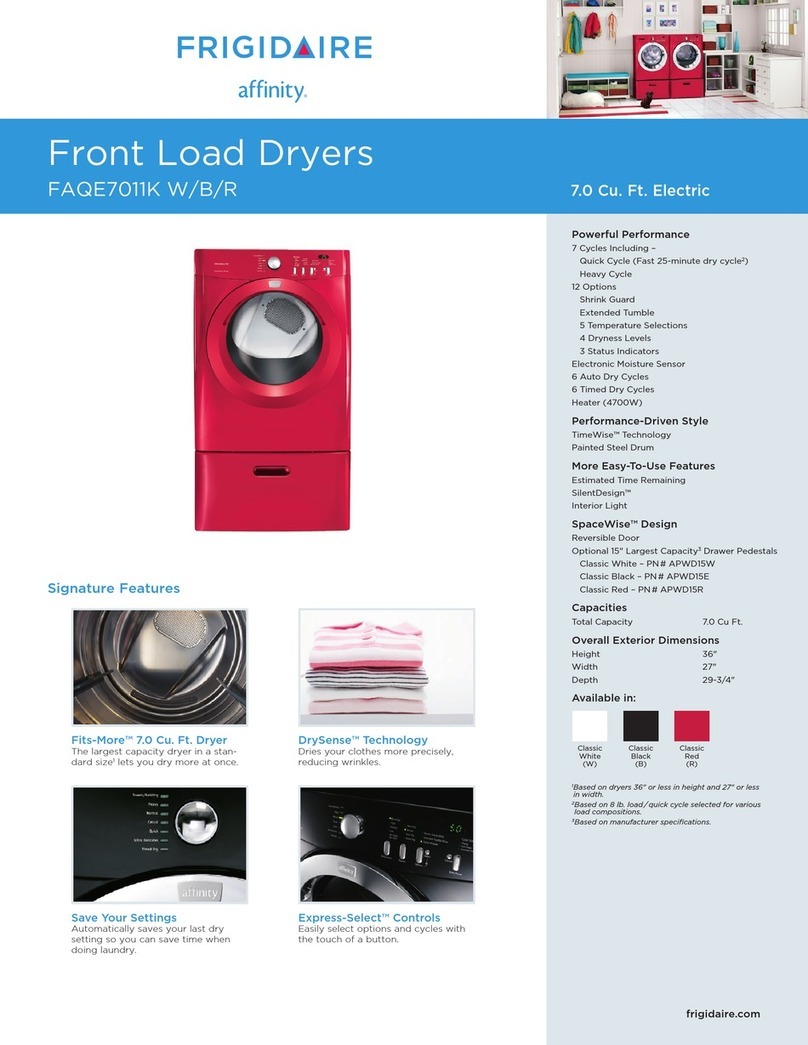

Frigidaire FAQE7011KW - 7 cu. Ft. Cycle Electric Dryer... Installation instructions

Frigidaire

Frigidaire CAQE7072LA0 Owner's manual

Frigidaire

Frigidaire GLEQ2152EE - 27" Front-Load Electric Dryer User manual

Frigidaire

Frigidaire FRQE7000LW0 Owner's manual

Frigidaire

Frigidaire FARE1011MW Owner's manual

Frigidaire

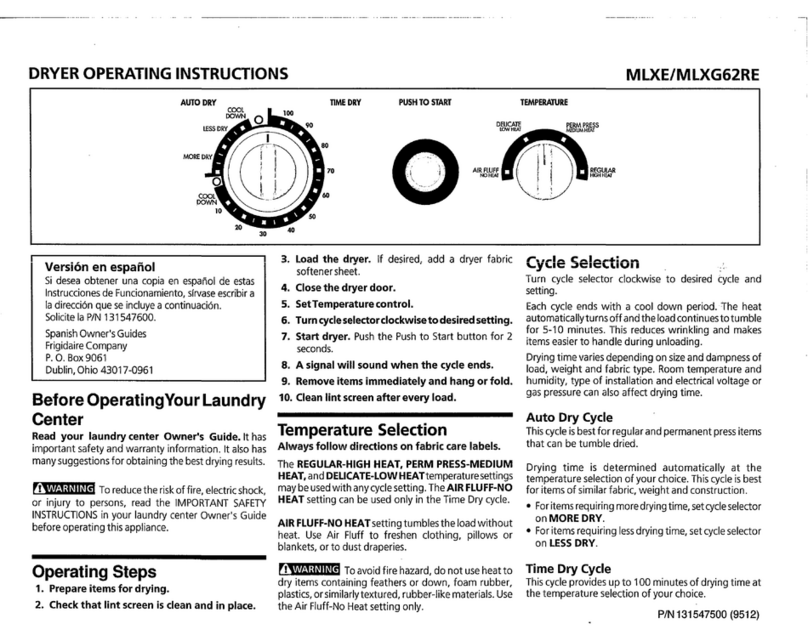

Frigidaire MLXE62RE User manual

Frigidaire

Frigidaire GLGR331AS0 User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual

Samsung

Samsung DV431AEPXAC user manual