3

EN

DEAR FRONIUS CUSTOMER

This brochure is intended to familiarise you with how to operate and

maintain your VR 4040 unreeling device. Es liegt in Ihrem Interesse, die

Bedienungsanleitung aufmerksam zu lesen und die hier angegebenen

Weisungen gewissenhaft zu befolgen. Sie vermeiden dadurch Störun-

gen durch Bedienungsfehler. Your machine will repay you by giving you

constant operational readiness and absolute reliability for many years to

come.

FRONIUS INTERNATIONAL GMBH

Warning! The VR 4040 unreeling device may only be operated

by trained personnel, and only in accordance with the technical

directions. When using the machine, you must follow the instruc-

tions given in the "Safety rules".

COPYRIGHT

Copyright to this instruction manual remains the property of Fronius

International GmbH.

Text and illustrations are all technically correct at the time of going to

print. The right to effect modifications is reserved. The contents of the

instruction manual shall not provide the basis for any claims whatever on

the part of the purchaser. If you have any suggestions for improvement,

or can point out to us any mistakes which you may have found in the

manual, we should be most grateful for your comments.

CONTENTS

Dear Fronius Customer ............................................................................ 3

Fronius International GmbH ................................................................ 3

Copyright ............................................................................................... 3

Safety rules................................................................................................ 4

General remarks ................................................................................... 4

Obligations of owner/operator ............................................................. 4

Obligations of personnel ...................................................................... 4

Utilisation for intended purpose only .................................................. 4

Informal safety precautions ................................................................. 4

Safety precautions at the installation location .................................. 4

Safety precautions in normal operation, and for the operator ......... 4

Spares / wearing parts and accessories ............................................ 4

Safety measures for maintenance, inspection and troubleshooting 5

Modifications to the VR 4040 unreeling device ................................. 5

Particular danger spots ........................................................................ 5

Protective features ............................................................................... 5

Transport ............................................................................................... 5

Personal protective equipment ........................................................... 5

Hazards from noxious gases and vapours ........................................ 5

Hazards from flying sparks, radiation and heat ................................ 5

Keep all solvent vapours well away from the arc radiation. ............ 5

Hazards from welding current ............................................................. 5

General remarks ....................................................................................... 6

Machine concept ................................................................................... 6

Areas of application, and features ...................................................... 6

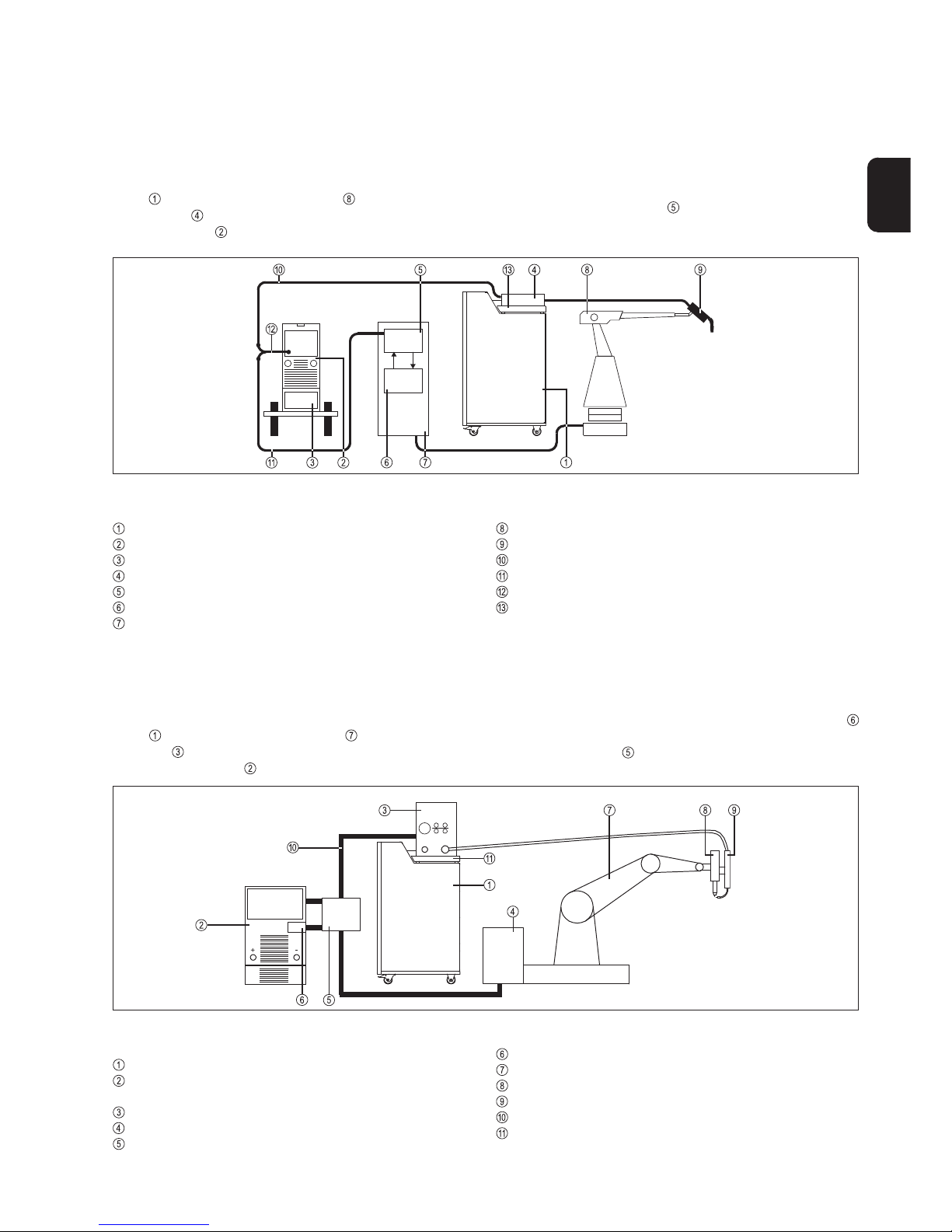

Practical examples ................................................................................... 7

Configuration 1: MIG/MAG welding .................................................... 7

Configuration 2: TIG cold-wire welding .............................................. 7

Start-up ...................................................................................................... 8

Accessories ........................................................................................... 8

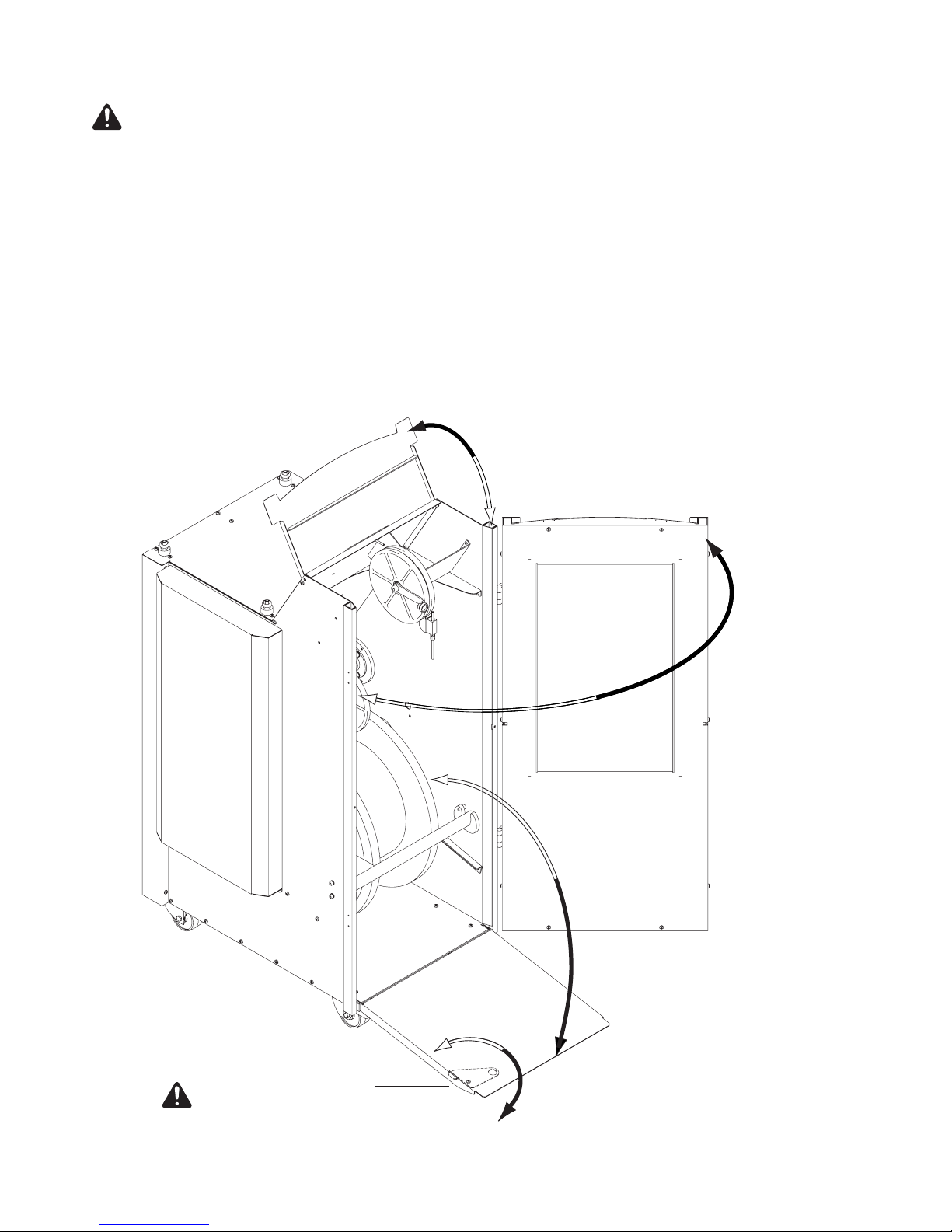

Opening and closing the VR 4040 unreeling device ........................ 8

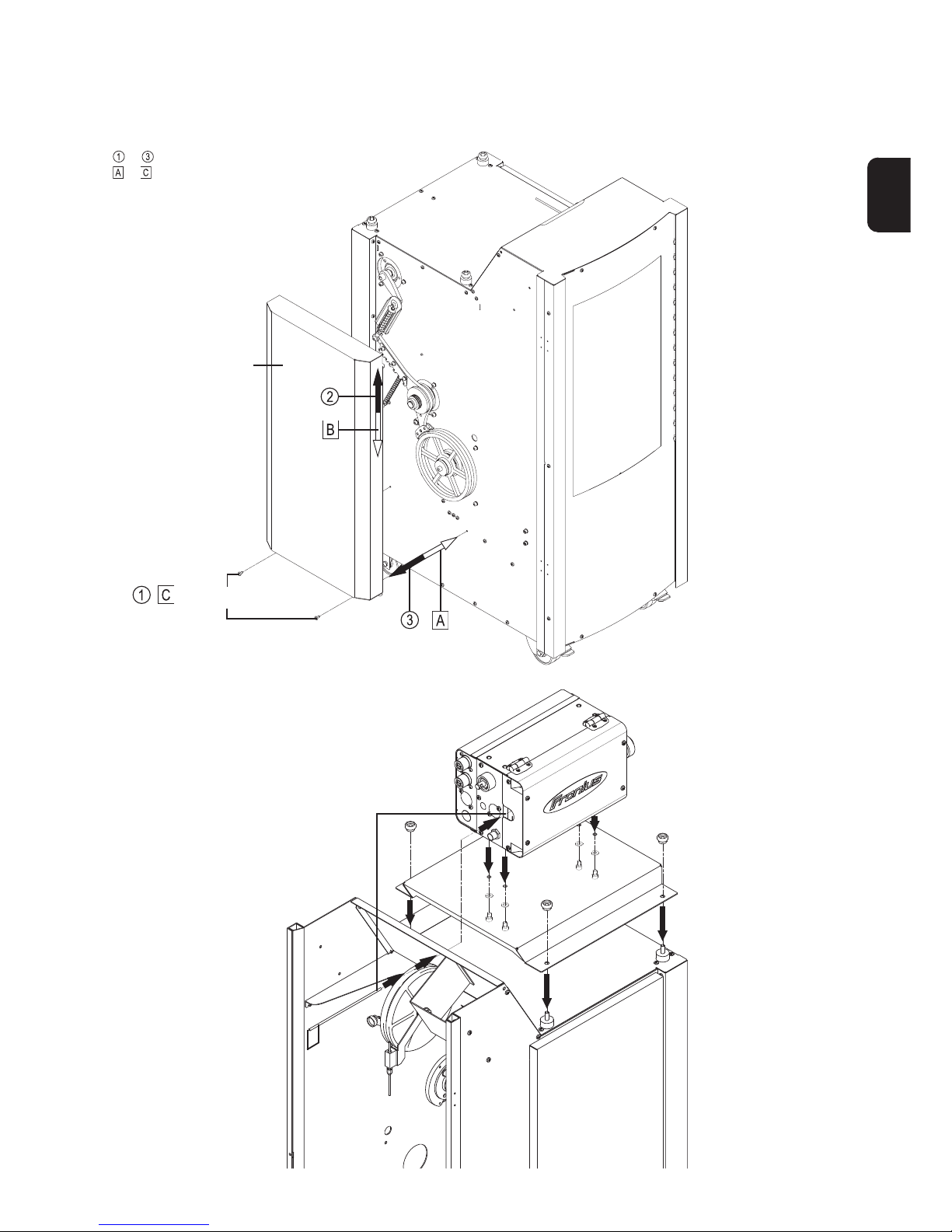

Dismounting and re-mounting the side guard panel......................... 9

Mounting the wirefeeder ...................................................................... 9

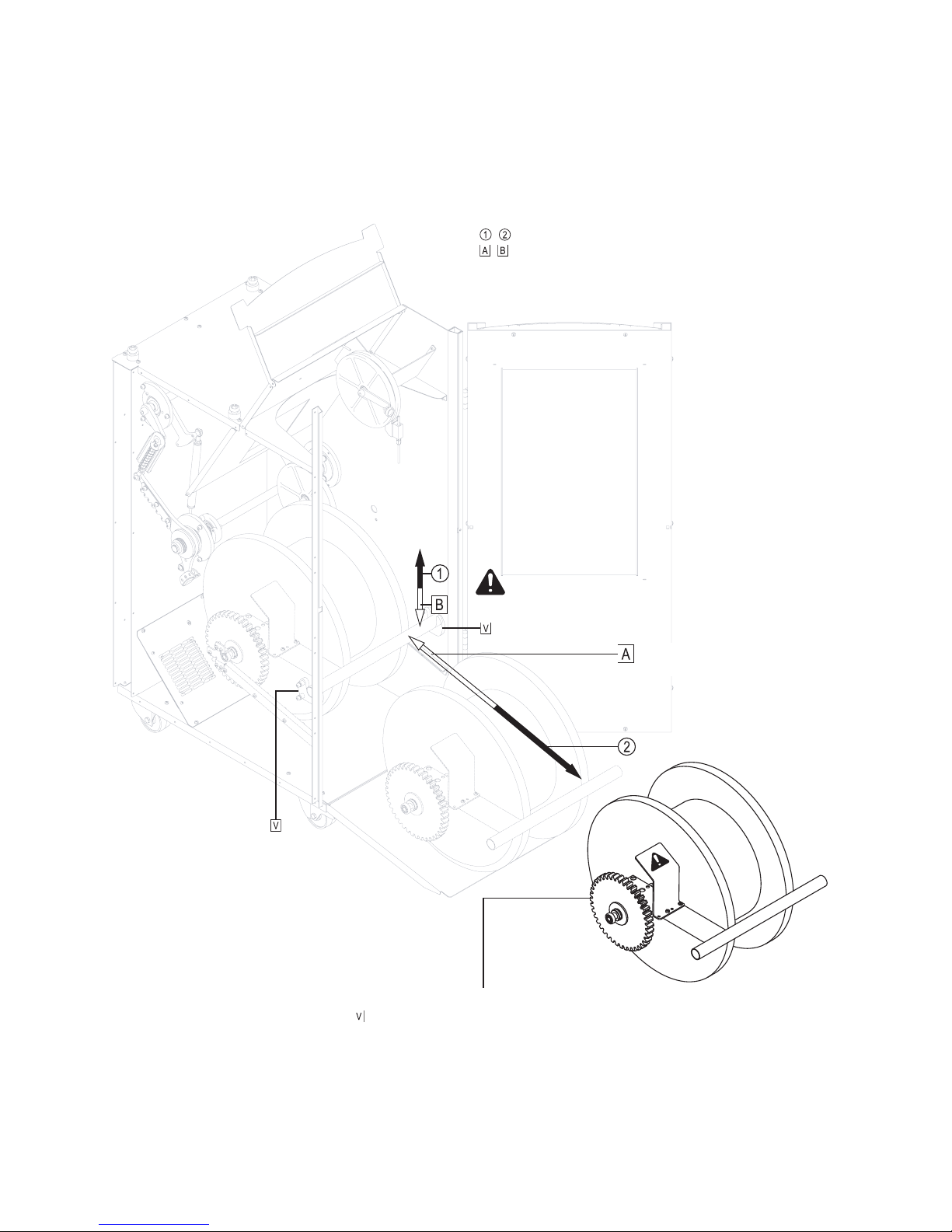

Removing and inserting the wire-spool carrier................................ 10

Mounting and dismounting the wire-spool driver ............................ 11

Fastening the wire-spool carrier to the Spool and detaching

it from the Spool ................................................................................. 11

Inserting the welding wire .................................................................. 12

230 V interior heating system, unregulated ..................................... 13

Mounting the interior heating system ............................................... 13

24 V interior heating system, regulated ........................................... 14

Mounting the interior heating system ............................................... 14

End-of-wire watchdog ........................................................................ 16

Mounting the end-of-wire watchdog ................................................. 17

Functional principle ................................................................................ 19

Idling..................................................................................................... 19

Accelerating......................................................................................... 19

Equilibrium, and working position ..................................................... 20

Decelerating ........................................................................................ 20

Adjusting the braking system ................................................................ 21

Adjusting the braking force ................................................................ 21

Adjusting the braking system response ........................................... 21

Adjusting the working position .......................................................... 22

Measuring the value for the wire tensile-force limitation ............... 22

Setting the wire tensile-force limitation ............................................ 23

Troubleshooting guide ............................................................................ 24

Care, maintenance and inspection ....................................................... 25

General remarks on the wearing parts ............................................. 25

Function test ........................................................................................ 25

Damper ................................................................................................ 26

Brake block .......................................................................................... 27

Brake clearance .................................................................................. 27

Overload coupling ............................................................................... 28

Wire-guide tubes................................................................................. 30

Drawback pulleys................................................................................ 31

Shoe for end-of-wire watchdog ......................................................... 32

Disposal of used parts and materials ................................................... 33

Technical Data ......................................................................................... 33

EC-Declaration of Conformity

Spare parts list

Circuit Diagram