List of Figures

Figure 3-1 GR716-BOARD Development Board ...............................................................5

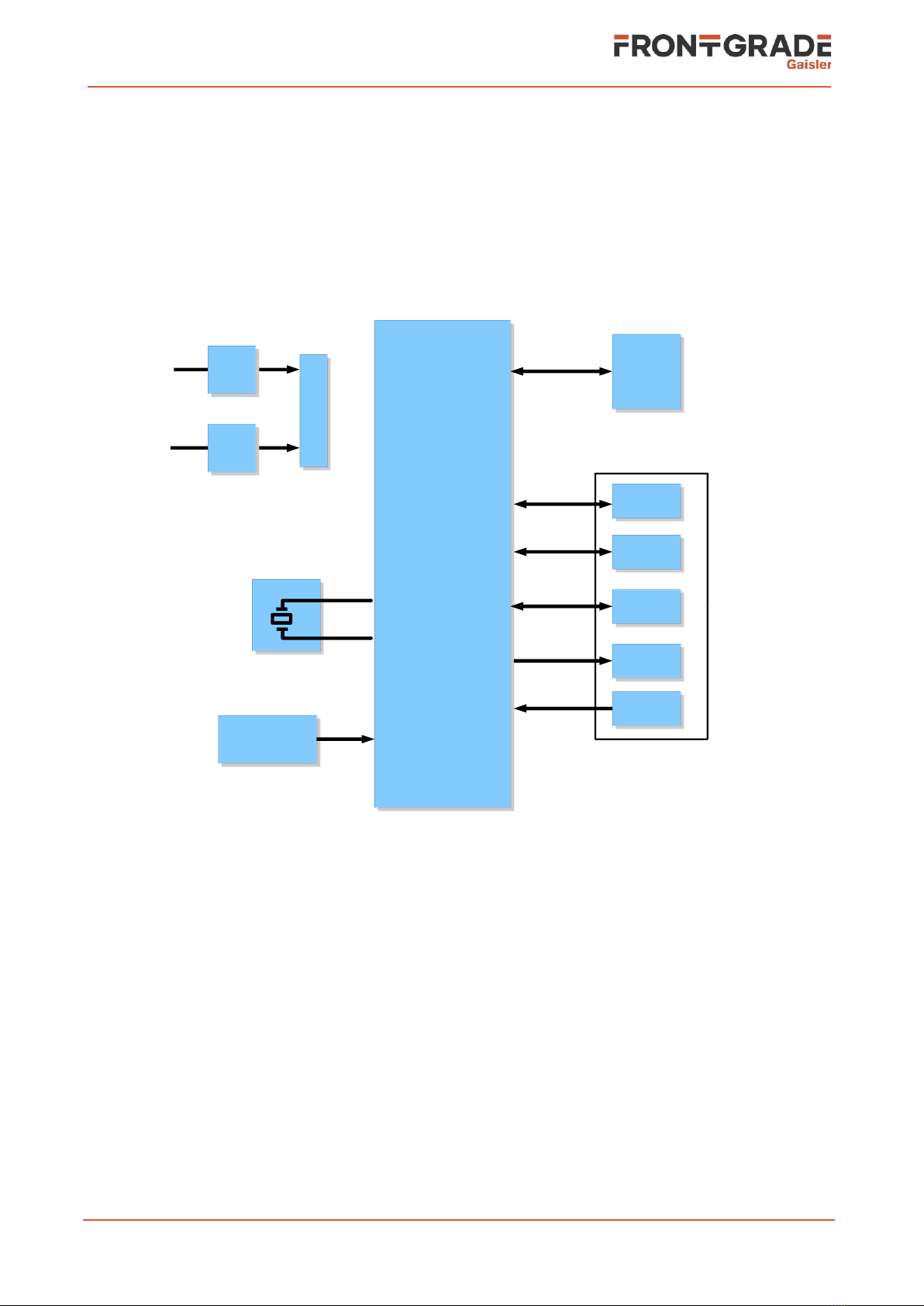

Figure 4-1 GR716-BOARD Board Block Diagram .............................................................7

Figure 4-2 GR616-BOARD Board Dimensions..................................................................8

Figure 4-3 GR716-BOARD mounted on a GR716-CPCI-DEV Carrier board ....................9

Figure 4-4 GR716-TEST-MEMORY BOARD...................................................................10

Figure 4-5 GR716-TEST-ADCDAC BOARD....................................................................10

Figure 4-6 GR716 Microcontroller Block Diagram ...........................................................11

Figure 4-7 GR716 Package.............................................................................................11

Figure 4-8 SPI Boot Memory Connectons.......................................................................12

Figure 4-9 Debug Support Unit connections....................................................................15

Figure 4-10 GR716-DSU-USB Adapter..........................................................................15

Figure 4-11 Board level Clock Distribution Scheme .......................................................16

Figure 4-12 Power Regulation Scheme .........................................................................18

Figure 4-13 Power Supply Configuration Jumpers.........................................................19

Figure 6-1 PCB Top View ................................................................................................24

Figure 6-2 PCB Bottom View...........................................................................................25

Figure 6-3 PCB Top View (Photo)....................................................................................26

Figure 6-4 PCB Bottom View (Photo) ..............................................................................27

List of Tables

Table 1: Bootstrap Resistor Settings..................................................................................14

Table 2: List of Connectors ................................................................................................21

Table 3: J1 Screw Terminal Connector for Input Voltages..................................................21

Table 4: J2 POWER-External Power Connector ................................................................21

Table 5: Expansion connector P1 Pin-out .........................................................................22

Table 6: Expansion connector P2 pin-out ..........................................................................22

Table 7: List and definition of Oscillators and Crystals.......................................................23

Table 8: List and definition of PCB mounted LED's............................................................23

Table 9: List and definition of Switches ..............................................................................23

Table 10: Definition of Switch S1 functions (refer to [RD1]) ...............................................23