5CS2006OM (rev 00 07/2020)4

READ THIS MANUAL carefully to learn how

to operate and service your machine correctly.

Failure to do so could result in personal injury

or equipment damage. This manual and safety

signs on your machine may also be available in

other languages. (See your Frontier dealer to

order.)

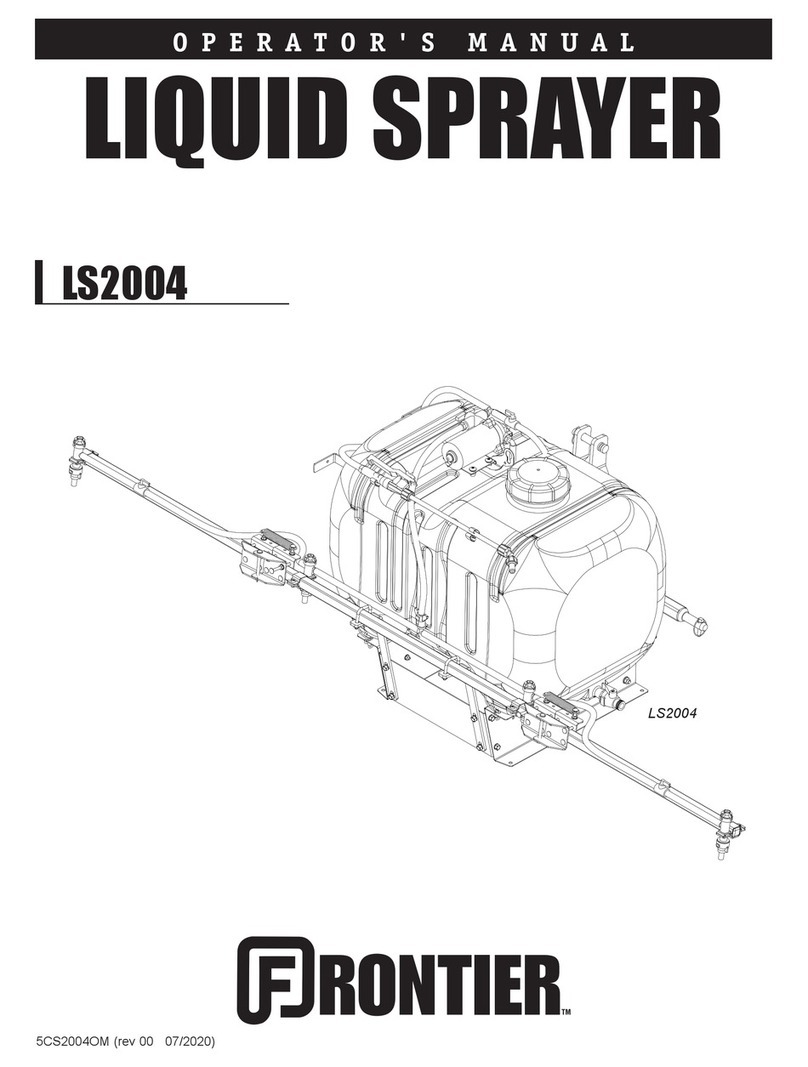

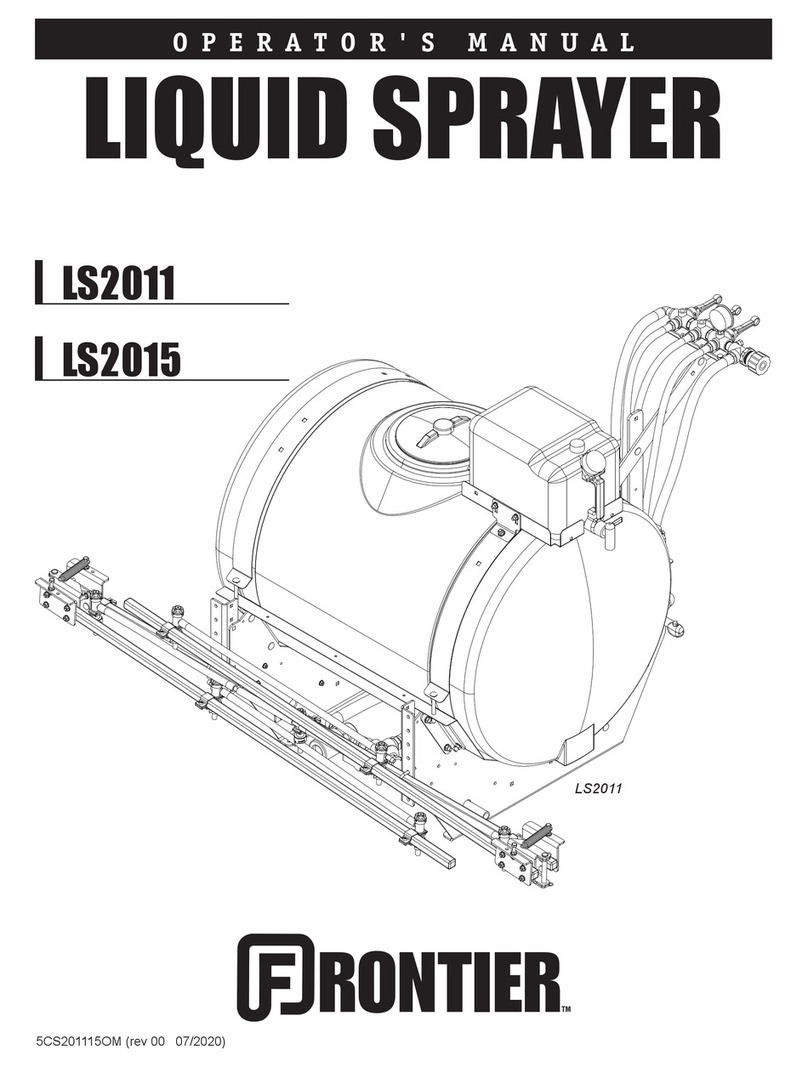

The illustrations and data used in this manual

were current at the time of printing but, due to

possible in-line production changes, your

machine may vary slightly in detail. We reserve

the right to redesign and change the machines

as may be necessary without notication.

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your machine and should

remain with the machine when you sell it.

MEASUREMENTS in this manual are given in

both metric and customary U.S. unit

equivalents. Use only correct replacement parts

and fasteners. Metric and inch fasteners may

require a specic metric or inch wrench.

RIGHT-HAND AND LEFT-HAND sides are

determined by facing in the direction of forward

travel.

WARRANTY is provided as part of Frontier’s

support program for customers who operate

and maintain their equipment as described in

this manual. The warranty is explained on the

warranty certicate or statement which you

should have received from your dealer.

This warranty provides you the assurance that

Frontier will back its products where defects

appear within the warranty period. In some

circumstances, Frontier also provides eld

improvements, often without charge to the

customer, even if the product is out of warranty.

Should the equipment be abused, or modied to

change its performance beyond the original

factory specications, the warranty will become

void and eld improvements may be denied.

Setting fuel delivery above specications

or otherwise overpowering machines will result

in such action.

If you are not the original owner of this

machine, it is in your interest to contact your

local Frontier dealer to inform them of this unit's

serial number. This will help Frontier notify you

of any issues or product improvements.

Safety

Read Safety in Machine Operator’s Manual

Read the general safety operating precautions

in your machine operator’s manual for addition-

al safety information.

Operate Safely

• Read the machine and attachment

operator’s manual carefully. Be thoroughly

familiar with the controls and the proper

use of the equipment. Know how to stop

the machine and disengage the controls

quickly.

• Do not let children or an untrained person

operate machine.

• Make any necessary adjustments before

you operate. Never attempt to make any

adjustments while the engine is running,

unless if recommended in adjustment

procedure.

• Take all possible precautions when

leaving the machine unattended. Shut

off the engine before making any repairs,

adjustments, or inspections. Lower the

attachment, lock the parking brake, stop

the engine, and remove the key.

• Look behind machine before you back up.

Back up carefully.

GENERAL INFORMATION

Introduction