5CS201115OM (rev 00 07/2020) 5

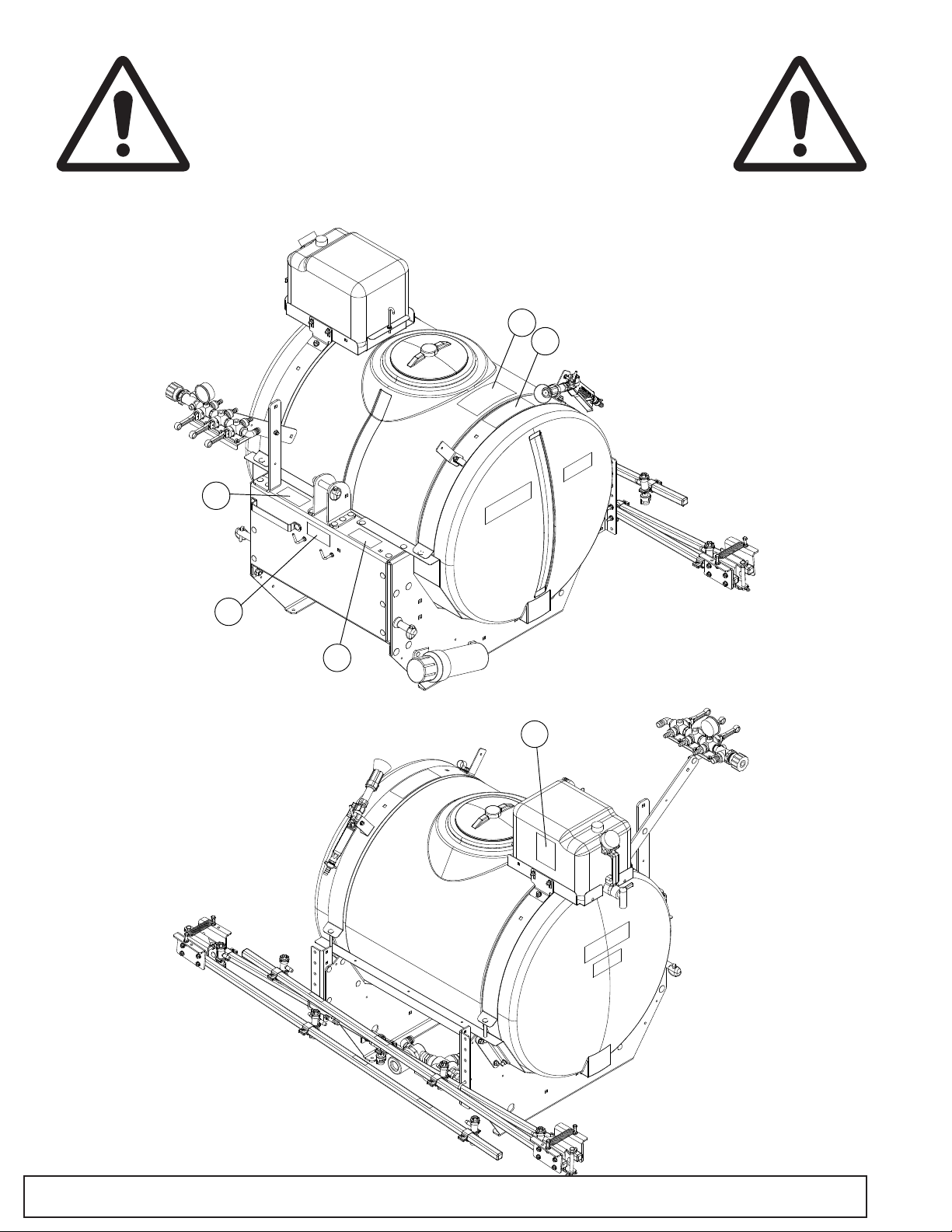

Read Safety in Machine Operator’s Manual

Read the general safety operating precautions

in your machine operator’s manual for

additional safety information.

Operate Safely

• Read the machine and attachment

operator’s manual carefully. Be thoroughly

familiar with the controls and the proper use

of the equipment. Know how to stop the

machine and disengage the controls quickly.

• Do not let children or an untrained person

operate machine.

• Make any necessary adjustments before

you operate. Never attempt to make any

adjustments while the engine is running,

unless if recommended in adjustment

procedure.

• Take all possible precautions when leaving

the machine unattended. Shut off the engine

before making any repairs, adjustments, or

inspections. Lower the attachment, lock the

parking brake, stop the engine, and remove

the key.

• Look behind machine before you back up.

Back up carefully.

• Do not let anyone, especially children,

ride on machine or attachment. Riders are

subject to injury such as being struck by

foreign objects and being thrown off. Riders

may also obstruct the operator’s view,

resulting in the machine being operated in

an unsafe manner.

• Use only attachments and accessories

approved by the manufacturer of this

product.

• If the machine vibrates abnormally, stop

the engine and check immediately for the

cause. Vibration is generally a warning of

trouble.

• Always refer to the Storage section of the

operator’s manual for important details if

storing this product for a long period of time.

• Keep people and pets out of the work area.

Stop machine if anyone enters the area.

• If you hit an object, stop the machine and

inspect it. Make repairs before you operate.

Keep machine properly maintained and in

good working order. Keep all shields and

guards in place.

• Always inspect the sprayer completely

before and after each use. Before

pressurizing the system, check to be sure

all ttings and hoses are tightly installed.

Be sure guards and shields are in good

condition and fastened in place. Make any

necessary adjustments before you operate.

• Never use the sprayer during windy

conditions.

• Always release pressure in the system

before lling, cleaning or servicing the

sprayer.

• Do not put nozzle tip or other sprayer parts

to your lips to blow out dirt. Use compressed

air.

• Install the recommended light kit when this

equipment obscures the tractor’s tail lamps

or stop lamps when transported on the road.

Contact your Frontier dealer to obtain the

recommended light kit.

Parking Safely

1. Stop vehicle on a level surface, not on a

slope.

2. Lock park brake.

3. Lower 3pt attachment to the ground.

4. Stop engine.

5. Remove key.

6. Before you leave the operator’s seat, wait

for engine and all moving parts to stop.

Mix and Handle Chemicals Safely

• Wear full cover clothing and wear protective

goggles and rubber gloves to protect

yourself while handling chemicals

Safety

SAFETY