Text: D. Vanderheyden

First Edition: 2023-04-10

Latest Revision: 2023-04-10

Copyright © 2019, 2022 Norwood Industries Inc. All rights

reserved. No part of this publication may be reproduced in any

form or by any means without permission in writing from the

publisher, Norwood Industries Inc.

The color orange as it relates to sawmills, edgers, skidders & related equipment,

the “chevron” graphic, the LumberJack®mascot, and the trade-names Norwood®,

LumberMax®, LumberPro®, LumberMate®, LumberMan®, LumberLite®, LM Pro®,

PortaMill®, SkidMate®, BladeMate®, SabreTooth®, SabreBar®, SabreChain®,

HD38®, HD36®, LM30®, MN27®, LM29®, MN26®, Trekker®, Duradeck®, Sawyer-

Assist®, Sawmill TV®, Omega®, Intelliset®, ProSetter™, Frontier®, OS®, OS18®,

OS23®, OS27®, OS31®, OS35®, Make Your Mark™, “Forest. Fun. Freedom.™”

& MultiMate®are registered trademarks owned by Norwood Industries Inc. in

multiple jurisdictions. Functional and design elements of Norwood sawmills and

log handling equipment are protected by registered patents and pending patents

in multiple jurisdictions.

U.S. Patent Nos. 6,932,555, 9,102,074, 7,784,387, 8,215,216, 8,261,645,

8,261,647, 8,276,493, 8,820,727, 9,676,116, 10,843,370, D816742, D818013,

D834623, D831711, D639,319, D654,101, D638,040 & 8,479,628 — Canada

Patent Nos. 2,432,863, 2,488,216, 132823, 2,541,734, 2,687,619, 2,687,622,

2,687,623, 2,688,407, 2,696,974, 2,782,909, 2,806,456, 2,800,791, 2,969,794,

3,037,006, 3,097,733, 3,092,814, 3,101,140, 3,124,208, 3,109,307, 3,127,409,

3,128,969, 3,141,581, 134185, 133049, 169785, 169786, 169787, 196297, 198385

& 169788 — EU Patent Nos. EP 2,746,009 B1, EP 2,332,706 B1, EP 2,332,683

B1, EP 2,684,631, EP 2,332,704, EP 2,759,384, 1117196-0001; 001212393-

0001; 001217277-0001, 001214662-0001, 003736255-0001, 003736255-0002,

003736255-0003, 003736255-0004, 008465066-0001 — UK Patent Nos.

6124839, 6138704, 6151320 — Brazil Patent Nos. BR30 2012 003601-1, BR10

2013 025882-2, BR10 2013 025883-0, PI 1004044-7, PI 1010352-0, DI 7001877-4,

DI 7001876-6 & PI 1009180-7 — Australia Patent Nos. 202111414, 201710613,

201710614, 201710616, 201710615, 202016960, 2021257893 — China Patent

Nos. 4192870, ZL202130153443.5, ZL201810569852.0. Other patents pending in

multiple jurisdictions.

Norwood Industries Inc. is constantly developing its equipment.

Wereserve the right to make changes to the design, construction and

finish of our equipment without notice.

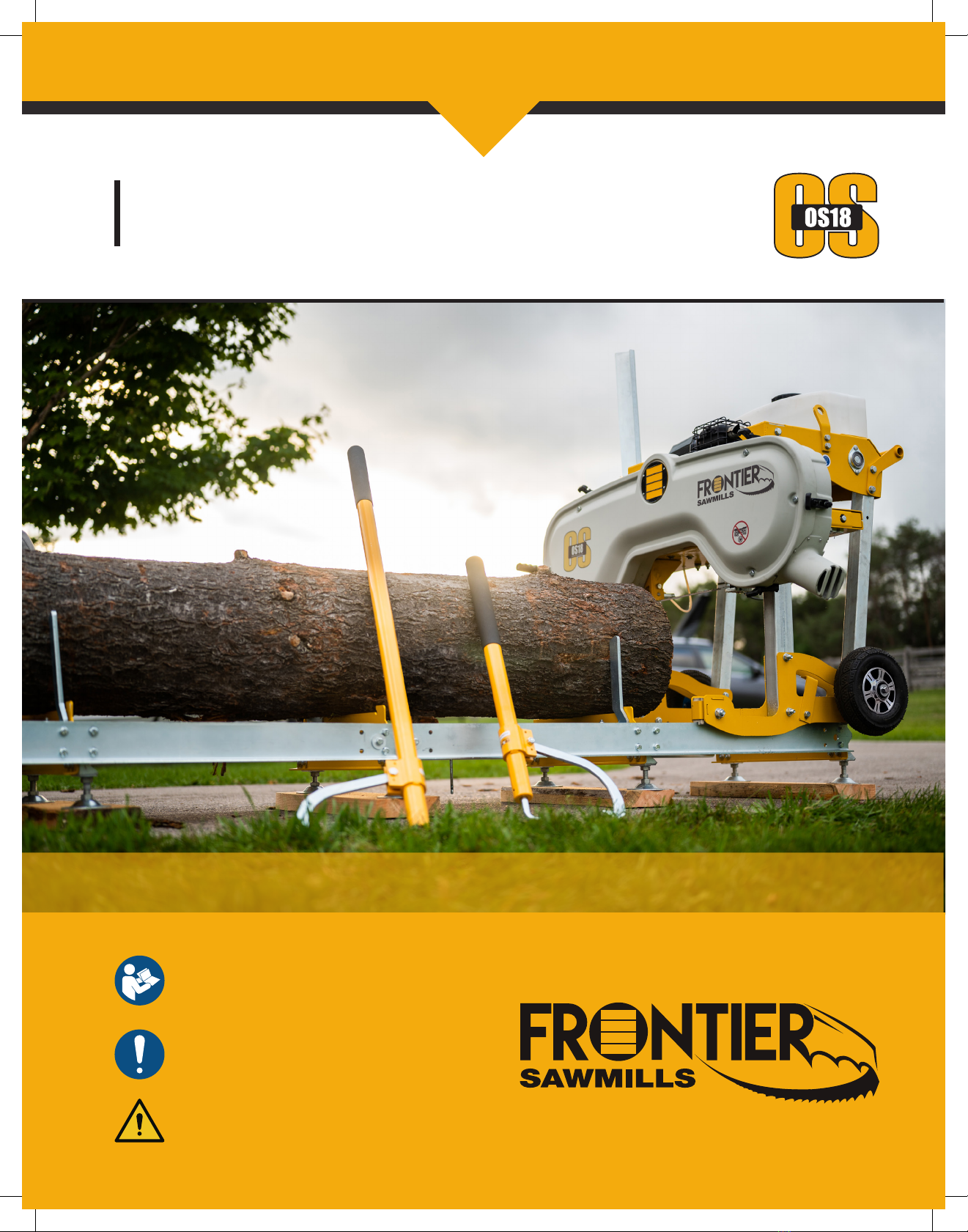

Photographs and illustrations in this manual may show optional

attachments or previous models and parts.

Toll-Free: 1-800-408-9995 (U.S. & Canada)

Telephone: +1-705-325-0030 (International)

E-mail: info@FrontierSawmills.com

Website: www.FrontierSawmills.com

Frontier Sawmills are designed, manufactured and

distributed by:

Norwood Enterprise

2267 15/16 Side Road East

Oro-Medonte ON L0L 1T0

Canada

Norwood Sawmills U.S.A. Inc.

730 Young Street, Suite 900

Tonawanda NY 14150

United States of America

®